Future Trends in Alkyl Technology and Applications

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Alkyl Tech Evolution

Alkyl technology has undergone significant evolution since its inception in the early 20th century. The journey began with simple alkylation processes used in petroleum refining, primarily for producing high-octane gasoline components. As the demand for cleaner and more efficient fuels grew, alkyl technology expanded its applications and sophistication.

In the 1940s and 1950s, the focus shifted towards developing more selective alkylation catalysts, leading to improved product quality and process efficiency. The introduction of solid acid catalysts in the 1960s marked a pivotal moment, offering advantages over traditional liquid acid catalysts in terms of safety and environmental impact.

The 1970s and 1980s saw a surge in research on zeolite-based catalysts, which revolutionized alkylation processes by providing higher selectivity and longer catalyst lifetimes. This period also witnessed the expansion of alkyl technology into the petrochemical industry, particularly in the production of linear alkylbenzenes for detergents.

The 1990s brought about a renewed interest in environmentally friendly processes, driving the development of ionic liquid catalysts and supercritical fluid technology for alkylation. These innovations aimed to reduce waste and improve the overall sustainability of alkylation processes.

The turn of the millennium saw the emergence of novel reactor designs, such as microreactors and membrane reactors, which offered enhanced control over reaction conditions and improved product yields. Concurrently, computational modeling and simulation tools became increasingly sophisticated, enabling more accurate prediction of reaction outcomes and optimization of process parameters.

In recent years, the focus has shifted towards bio-based alkylation processes, utilizing renewable feedstocks to produce sustainable alkyl compounds. This trend aligns with the growing emphasis on circular economy principles and the need to reduce dependence on fossil resources.

Looking ahead, the future of alkyl technology is likely to be shaped by advancements in catalyst design, process intensification, and the integration of artificial intelligence for real-time process optimization. The development of hybrid catalytic systems, combining homogeneous and heterogeneous catalysis, shows promise for achieving higher selectivity and efficiency in alkylation reactions.

Moreover, the application of alkyl technology is expected to expand beyond traditional sectors, finding new uses in areas such as advanced materials, pharmaceuticals, and energy storage. As global challenges related to sustainability and resource scarcity intensify, alkyl technology will play a crucial role in developing innovative solutions for a more sustainable future.

In the 1940s and 1950s, the focus shifted towards developing more selective alkylation catalysts, leading to improved product quality and process efficiency. The introduction of solid acid catalysts in the 1960s marked a pivotal moment, offering advantages over traditional liquid acid catalysts in terms of safety and environmental impact.

The 1970s and 1980s saw a surge in research on zeolite-based catalysts, which revolutionized alkylation processes by providing higher selectivity and longer catalyst lifetimes. This period also witnessed the expansion of alkyl technology into the petrochemical industry, particularly in the production of linear alkylbenzenes for detergents.

The 1990s brought about a renewed interest in environmentally friendly processes, driving the development of ionic liquid catalysts and supercritical fluid technology for alkylation. These innovations aimed to reduce waste and improve the overall sustainability of alkylation processes.

The turn of the millennium saw the emergence of novel reactor designs, such as microreactors and membrane reactors, which offered enhanced control over reaction conditions and improved product yields. Concurrently, computational modeling and simulation tools became increasingly sophisticated, enabling more accurate prediction of reaction outcomes and optimization of process parameters.

In recent years, the focus has shifted towards bio-based alkylation processes, utilizing renewable feedstocks to produce sustainable alkyl compounds. This trend aligns with the growing emphasis on circular economy principles and the need to reduce dependence on fossil resources.

Looking ahead, the future of alkyl technology is likely to be shaped by advancements in catalyst design, process intensification, and the integration of artificial intelligence for real-time process optimization. The development of hybrid catalytic systems, combining homogeneous and heterogeneous catalysis, shows promise for achieving higher selectivity and efficiency in alkylation reactions.

Moreover, the application of alkyl technology is expected to expand beyond traditional sectors, finding new uses in areas such as advanced materials, pharmaceuticals, and energy storage. As global challenges related to sustainability and resource scarcity intensify, alkyl technology will play a crucial role in developing innovative solutions for a more sustainable future.

Market Demand Analysis

The market demand for alkyl technology and its applications has been experiencing significant growth in recent years, driven by various factors across multiple industries. The automotive sector, in particular, has shown a strong interest in alkyl-based products, especially in the development of high-performance lubricants and fuel additives. These applications aim to improve engine efficiency, reduce emissions, and extend the lifespan of vehicle components, aligning with the industry's push towards more sustainable and environmentally friendly transportation solutions.

In the personal care and cosmetics industry, there is a growing demand for alkyl-based ingredients due to their versatility and effectiveness in formulations. Consumers are increasingly seeking products with natural and mild ingredients, leading to a rise in the use of alkyl-derived surfactants and emollients. This trend is expected to continue as manufacturers focus on developing eco-friendly and biodegradable alternatives to traditional petrochemical-based ingredients.

The pharmaceutical sector has also shown increased interest in alkyl technology, particularly in drug delivery systems and the synthesis of active pharmaceutical ingredients (APIs). Alkyl-based excipients and intermediates are being explored for their potential to enhance drug solubility, stability, and bioavailability, addressing key challenges in drug formulation and efficacy.

In the agriculture industry, alkyl-based pesticides and herbicides are gaining traction due to their improved efficacy and reduced environmental impact compared to conventional products. Farmers and agricultural companies are seeking more targeted and sustainable crop protection solutions, driving research and development in this area.

The electronics industry is another key market for alkyl technology, with applications in semiconductor manufacturing and advanced materials. Alkyl-based precursors and thin film deposition techniques are being utilized to create high-performance electronic components and improve device efficiency.

Market analysts project that the global alkyl technology market will continue to expand at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to the increasing adoption of alkyl-based products across various end-use industries and the ongoing development of novel applications.

Regionally, Asia-Pacific is expected to dominate the market growth, driven by rapid industrialization, urbanization, and increasing consumer awareness of sustainable products. North America and Europe are also significant markets, with a focus on research and development of advanced alkyl technologies for specialized applications.

As environmental regulations become more stringent worldwide, there is a growing emphasis on developing bio-based and renewable alkyl technologies. This shift presents both challenges and opportunities for market players, as they strive to balance performance, cost-effectiveness, and sustainability in their product offerings.

In the personal care and cosmetics industry, there is a growing demand for alkyl-based ingredients due to their versatility and effectiveness in formulations. Consumers are increasingly seeking products with natural and mild ingredients, leading to a rise in the use of alkyl-derived surfactants and emollients. This trend is expected to continue as manufacturers focus on developing eco-friendly and biodegradable alternatives to traditional petrochemical-based ingredients.

The pharmaceutical sector has also shown increased interest in alkyl technology, particularly in drug delivery systems and the synthesis of active pharmaceutical ingredients (APIs). Alkyl-based excipients and intermediates are being explored for their potential to enhance drug solubility, stability, and bioavailability, addressing key challenges in drug formulation and efficacy.

In the agriculture industry, alkyl-based pesticides and herbicides are gaining traction due to their improved efficacy and reduced environmental impact compared to conventional products. Farmers and agricultural companies are seeking more targeted and sustainable crop protection solutions, driving research and development in this area.

The electronics industry is another key market for alkyl technology, with applications in semiconductor manufacturing and advanced materials. Alkyl-based precursors and thin film deposition techniques are being utilized to create high-performance electronic components and improve device efficiency.

Market analysts project that the global alkyl technology market will continue to expand at a compound annual growth rate (CAGR) of 5-7% over the next five years. This growth is attributed to the increasing adoption of alkyl-based products across various end-use industries and the ongoing development of novel applications.

Regionally, Asia-Pacific is expected to dominate the market growth, driven by rapid industrialization, urbanization, and increasing consumer awareness of sustainable products. North America and Europe are also significant markets, with a focus on research and development of advanced alkyl technologies for specialized applications.

As environmental regulations become more stringent worldwide, there is a growing emphasis on developing bio-based and renewable alkyl technologies. This shift presents both challenges and opportunities for market players, as they strive to balance performance, cost-effectiveness, and sustainability in their product offerings.

Current Challenges

Despite the widespread use and importance of alkyl technology in various industries, several significant challenges persist, hindering its full potential and future development. One of the primary obstacles is the environmental impact associated with traditional alkyl production methods. The current processes often involve the use of hazardous chemicals and generate substantial amounts of waste, raising concerns about sustainability and ecological footprint.

Another major challenge lies in the energy-intensive nature of alkyl synthesis. The high energy requirements not only contribute to increased production costs but also raise questions about the overall efficiency and carbon footprint of these processes. As global energy demands continue to rise and environmental regulations become more stringent, finding more energy-efficient methods for alkyl production becomes increasingly crucial.

The limited selectivity in alkyl reactions presents a significant technical hurdle. Achieving precise control over the formation of specific alkyl compounds, especially in complex reaction environments, remains a challenge. This lack of selectivity often results in unwanted by-products, reducing overall yield and necessitating additional purification steps, which in turn increases production costs and resource consumption.

Scalability is another critical issue facing the alkyl technology sector. While many innovative approaches show promise at the laboratory scale, translating these methods to industrial-scale production presents numerous engineering and economic challenges. The difficulty in scaling up novel processes often hinders the adoption of potentially game-changing technologies in commercial applications.

The volatility of raw material prices, particularly petroleum-based feedstocks, poses a significant economic challenge to the alkyl industry. Fluctuations in oil prices can dramatically impact production costs, making it difficult for companies to maintain consistent pricing and profitability. This volatility underscores the need for alternative, more stable feedstock sources and production methods.

Regulatory compliance and safety concerns continue to be major challenges in alkyl technology. Stringent regulations regarding the handling, storage, and transportation of alkyl compounds, coupled with the inherent reactivity of many alkyl species, necessitate substantial investments in safety measures and compliance protocols. These requirements can be particularly burdensome for smaller companies and startups, potentially stifling innovation in the field.

Lastly, the development of sustainable and bio-based alkyl technologies faces significant technical and economic barriers. While there is growing interest in green chemistry approaches, such as using renewable feedstocks or enzymatic processes, these methods often struggle to compete with traditional petrochemical routes in terms of efficiency and cost-effectiveness. Overcoming these challenges to create economically viable, environmentally friendly alkyl technologies remains a key focus for researchers and industry professionals alike.

Another major challenge lies in the energy-intensive nature of alkyl synthesis. The high energy requirements not only contribute to increased production costs but also raise questions about the overall efficiency and carbon footprint of these processes. As global energy demands continue to rise and environmental regulations become more stringent, finding more energy-efficient methods for alkyl production becomes increasingly crucial.

The limited selectivity in alkyl reactions presents a significant technical hurdle. Achieving precise control over the formation of specific alkyl compounds, especially in complex reaction environments, remains a challenge. This lack of selectivity often results in unwanted by-products, reducing overall yield and necessitating additional purification steps, which in turn increases production costs and resource consumption.

Scalability is another critical issue facing the alkyl technology sector. While many innovative approaches show promise at the laboratory scale, translating these methods to industrial-scale production presents numerous engineering and economic challenges. The difficulty in scaling up novel processes often hinders the adoption of potentially game-changing technologies in commercial applications.

The volatility of raw material prices, particularly petroleum-based feedstocks, poses a significant economic challenge to the alkyl industry. Fluctuations in oil prices can dramatically impact production costs, making it difficult for companies to maintain consistent pricing and profitability. This volatility underscores the need for alternative, more stable feedstock sources and production methods.

Regulatory compliance and safety concerns continue to be major challenges in alkyl technology. Stringent regulations regarding the handling, storage, and transportation of alkyl compounds, coupled with the inherent reactivity of many alkyl species, necessitate substantial investments in safety measures and compliance protocols. These requirements can be particularly burdensome for smaller companies and startups, potentially stifling innovation in the field.

Lastly, the development of sustainable and bio-based alkyl technologies faces significant technical and economic barriers. While there is growing interest in green chemistry approaches, such as using renewable feedstocks or enzymatic processes, these methods often struggle to compete with traditional petrochemical routes in terms of efficiency and cost-effectiveness. Overcoming these challenges to create economically viable, environmentally friendly alkyl technologies remains a key focus for researchers and industry professionals alike.

Existing Alkyl Solutions

01 Alkyl-based polymer synthesis

This technology focuses on the synthesis of alkyl-based polymers, including methods for polymerization, modification, and functionalization of alkyl chains. These polymers have various applications in industries such as coatings, adhesives, and plastics due to their unique properties.- Alkyl-based polymer synthesis: This technology focuses on the synthesis of alkyl-based polymers, including methods for polymerization, copolymerization, and modification of alkyl chains. These processes are used to create materials with specific properties for various applications in industries such as plastics, coatings, and adhesives.

- Alkyl-functionalized materials: This area involves the development of materials functionalized with alkyl groups to enhance their properties. These materials can include nanoparticles, surfaces, and composites, with applications in fields such as catalysis, electronics, and water treatment.

- Alkyl-based surfactants and emulsifiers: This technology focuses on the development and application of alkyl-based surfactants and emulsifiers. These compounds are used in various industries, including personal care, cleaning products, and oil recovery, to stabilize emulsions and reduce surface tension.

- Alkyl halide chemistry: This area involves the synthesis, reactions, and applications of alkyl halides. These compounds are important intermediates in organic synthesis and are used in the production of various chemicals, pharmaceuticals, and materials.

- Alkyl-modified catalysts: This technology focuses on the development and application of catalysts modified with alkyl groups. These catalysts are used in various chemical processes, including polymerization, hydrogenation, and fine chemical synthesis, to improve reaction efficiency and selectivity.

02 Alkyl-substituted compounds in chemical processes

This area involves the use of alkyl-substituted compounds in various chemical processes, including catalysis, organic synthesis, and the production of specialty chemicals. The alkyl groups can be used to modify the properties and reactivity of molecules for specific applications.Expand Specific Solutions03 Alkyl-based surfactants and emulsifiers

This technology focuses on the development and application of alkyl-based surfactants and emulsifiers. These compounds are used in various industries, including personal care, detergents, and oil recovery, due to their ability to reduce surface tension and stabilize emulsions.Expand Specific Solutions04 Alkyl halide chemistry and applications

This area covers the chemistry and applications of alkyl halides, including their synthesis, reactions, and use as intermediates in organic synthesis. Alkyl halides play a crucial role in various industrial processes and the production of pharmaceuticals and agrochemicals.Expand Specific Solutions05 Alkyl-modified materials for enhanced properties

This technology involves the modification of materials with alkyl groups to enhance their properties, such as hydrophobicity, thermal stability, and chemical resistance. Applications include coatings, textiles, and advanced materials for various industries.Expand Specific Solutions

Key Industry Players

The alkyl technology market is in a growth phase, driven by increasing demand across various industries. The global market size is expanding, with significant potential in petrochemicals, pharmaceuticals, and specialty chemicals. Technological maturity varies across applications, with established players like China Petroleum & Chemical Corp., Sinopec Research Institute, and PetroChina leading in petrochemicals. In pharmaceuticals, companies such as F. Hoffmann-La Roche and Sunshine Lake Pharma are advancing alkyl-based drug development. Specialty chemical firms like Kao Corp., 3M Innovative Properties, and SI Group are pushing innovation in niche applications. The competitive landscape is characterized by a mix of large conglomerates and specialized research institutions, indicating a dynamic and evolving market with opportunities for both incremental improvements and breakthrough innovations.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) is at the forefront of alkyl technology research and development. Their approach focuses on improving alkylation processes for cleaner and more efficient fuel production. Sinopec has developed a solid acid alkylation technology that operates at lower temperatures and pressures compared to traditional sulfuric acid alkylation[1]. This innovative process reduces energy consumption by up to 85% and eliminates the need for hazardous acid handling[2]. Additionally, Sinopec is exploring the use of ionic liquids as catalysts in alkylation reactions, which could potentially increase octane ratings and reduce environmental impact[3]. The company is also investing in research on bio-based alkyl compounds as sustainable alternatives to petroleum-derived products[4].

Strengths: Advanced solid acid alkylation technology, reduced environmental impact, and energy efficiency. Weaknesses: High initial investment costs for new technologies and potential challenges in scaling up novel processes.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. is advancing alkyl technology through its focus on fluoroalkyl compounds and their applications. The company has developed novel fluoroalkyl-containing polymers with enhanced surface properties, including water and oil repellency[5]. These materials find applications in protective coatings, textiles, and electronics. 3M is also exploring the use of perfluoroalkyl substances (PFAS) alternatives, addressing environmental concerns while maintaining performance[6]. Their research extends to alkyl-modified silicones for personal care products, offering improved stability and sensory attributes[7]. Additionally, 3M is investigating alkyl-functionalized nanoparticles for advanced drug delivery systems and biomedical applications[8].

Strengths: Diverse applications of alkyl technology, strong focus on environmentally friendly alternatives. Weaknesses: Regulatory challenges associated with certain fluoroalkyl compounds, potential market resistance to new materials.

Innovative Alkyl Patents

Catalytic reactions involving alkenes

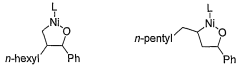

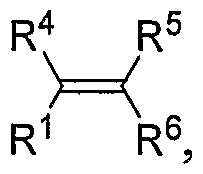

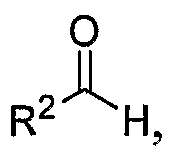

PatentWO2007027752A1

Innovation

- A nickel-catalyzed method involving a catalyst system with a Group 9, 10, or 11 metal, using a nickel-containing compound, a phosphorus-containing ligand, a silicon-containing compound, and a base, such as dicyclohexylphenylphosphine or tri(ortho-anisyl)phosphine, to facilitate the coupling of alkenes and aldehydes, forming allylic alcohols or their precursors like silyl ethers in a one-pot reaction.

Alkyd dispersion, and a process for producing the same

PatentInactiveEP2493955A1

Innovation

- Aqueous, high-solid, solvent-free alkyd dispersion with alkyds having an acid value of less than 20 and molecular weight greater than 1000 Dalton, combined with less than 10% stabilizing agents and 30-55% water, produced through a continuous process involving emulsification and neutralization, resulting in a dispersion with particle sizes between 0.05 to 5 μm, providing improved scrub resistance and tannin stain resistance.

Environmental Impact

The environmental impact of alkyl technology and its applications is a critical consideration as the industry continues to evolve. Alkyl compounds, widely used in various sectors, have both positive and negative effects on the environment. Their production and use can contribute to air and water pollution, greenhouse gas emissions, and potential soil contamination.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during the manufacturing and application of alkyl-based products. These emissions can lead to the formation of ground-level ozone, a major component of smog, which has detrimental effects on human health and ecosystems. Additionally, some alkyl compounds have been identified as persistent organic pollutants (POPs), which can accumulate in the environment and food chain, posing long-term risks to wildlife and human health.

However, advancements in alkyl technology are also driving positive environmental changes. The development of bio-based alkyl compounds derived from renewable resources is reducing reliance on fossil fuels and decreasing the carbon footprint of many industrial processes. These sustainable alternatives often have lower toxicity profiles and improved biodegradability compared to their petrochemical counterparts.

In the realm of energy production, alkyl-based technologies are playing a crucial role in improving the efficiency and environmental performance of fuels. Alkyl-lead compounds, once widely used as anti-knock agents in gasoline, have been phased out due to their severe environmental and health impacts. They have been replaced by more environmentally friendly alkyl ethers and other oxygenates, which enhance fuel combustion and reduce harmful emissions.

The use of alkyl technology in water treatment and environmental remediation is another area of significant positive impact. Alkyl-based surfactants and flocculants are instrumental in removing contaminants from water sources, improving water quality, and reducing the environmental burden of industrial and municipal wastewater.

As environmental regulations become more stringent globally, the alkyl industry is increasingly focusing on developing greener processes and products. This includes the implementation of closed-loop systems to minimize waste, the adoption of catalytic processes that reduce energy consumption and byproduct formation, and the design of alkyl compounds that are inherently safer and more environmentally benign.

Looking ahead, the environmental impact of alkyl technology will likely be shaped by ongoing research into more sustainable production methods, improved end-of-life management for alkyl-containing products, and the development of novel applications that directly address environmental challenges. The industry's commitment to circular economy principles and life cycle assessments will be crucial in minimizing negative environmental impacts while maximizing the benefits of alkyl technology across various sectors.

One of the primary environmental concerns is the release of volatile organic compounds (VOCs) during the manufacturing and application of alkyl-based products. These emissions can lead to the formation of ground-level ozone, a major component of smog, which has detrimental effects on human health and ecosystems. Additionally, some alkyl compounds have been identified as persistent organic pollutants (POPs), which can accumulate in the environment and food chain, posing long-term risks to wildlife and human health.

However, advancements in alkyl technology are also driving positive environmental changes. The development of bio-based alkyl compounds derived from renewable resources is reducing reliance on fossil fuels and decreasing the carbon footprint of many industrial processes. These sustainable alternatives often have lower toxicity profiles and improved biodegradability compared to their petrochemical counterparts.

In the realm of energy production, alkyl-based technologies are playing a crucial role in improving the efficiency and environmental performance of fuels. Alkyl-lead compounds, once widely used as anti-knock agents in gasoline, have been phased out due to their severe environmental and health impacts. They have been replaced by more environmentally friendly alkyl ethers and other oxygenates, which enhance fuel combustion and reduce harmful emissions.

The use of alkyl technology in water treatment and environmental remediation is another area of significant positive impact. Alkyl-based surfactants and flocculants are instrumental in removing contaminants from water sources, improving water quality, and reducing the environmental burden of industrial and municipal wastewater.

As environmental regulations become more stringent globally, the alkyl industry is increasingly focusing on developing greener processes and products. This includes the implementation of closed-loop systems to minimize waste, the adoption of catalytic processes that reduce energy consumption and byproduct formation, and the design of alkyl compounds that are inherently safer and more environmentally benign.

Looking ahead, the environmental impact of alkyl technology will likely be shaped by ongoing research into more sustainable production methods, improved end-of-life management for alkyl-containing products, and the development of novel applications that directly address environmental challenges. The industry's commitment to circular economy principles and life cycle assessments will be crucial in minimizing negative environmental impacts while maximizing the benefits of alkyl technology across various sectors.

Regulatory Landscape

The regulatory landscape for alkyl technology and applications is evolving rapidly, reflecting growing environmental concerns and the push for sustainable practices. Governments worldwide are implementing stricter regulations on the production, use, and disposal of alkyl compounds, particularly those with potential environmental or health impacts. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation continues to be a benchmark for chemical regulation, influencing global standards and practices in the alkyl industry.

In the United States, the Environmental Protection Agency (EPA) has been revising its policies under the Toxic Substances Control Act (TSCA), with increased scrutiny on alkyl compounds used in various industries. This includes more rigorous testing requirements and restrictions on certain alkyl derivatives known to have adverse environmental effects. Similarly, countries like China and Japan have been strengthening their chemical management regulations, impacting the global alkyl supply chain and forcing companies to adapt their production processes and product formulations.

The regulatory focus is increasingly shifting towards promoting green chemistry principles in alkyl technology. This trend is driving research and development efforts towards more environmentally friendly alkyl compounds and production methods. Biodegradability, reduced toxicity, and lower carbon footprints are becoming key factors in regulatory compliance for alkyl-based products.

Emerging regulations are also addressing the end-of-life management of alkyl-containing products. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This is prompting innovations in alkyl technology to facilitate easier recycling and reduce environmental impact.

The global nature of the alkyl industry necessitates harmonization of regulations across different regions. International bodies such as the Organization for Economic Co-operation and Development (OECD) are working towards creating unified guidelines for the assessment and management of chemical risks, including those associated with alkyl compounds. This harmonization effort aims to reduce trade barriers while ensuring consistent environmental and health protection standards worldwide.

As climate change concerns intensify, regulations are increasingly linking alkyl technology to carbon emissions reduction goals. This is manifesting in policies that incentivize the development of bio-based alkyl alternatives and more energy-efficient production processes. The regulatory landscape is thus not only restricting certain practices but also actively shaping the future direction of alkyl technology towards more sustainable and environmentally compatible solutions.

In the United States, the Environmental Protection Agency (EPA) has been revising its policies under the Toxic Substances Control Act (TSCA), with increased scrutiny on alkyl compounds used in various industries. This includes more rigorous testing requirements and restrictions on certain alkyl derivatives known to have adverse environmental effects. Similarly, countries like China and Japan have been strengthening their chemical management regulations, impacting the global alkyl supply chain and forcing companies to adapt their production processes and product formulations.

The regulatory focus is increasingly shifting towards promoting green chemistry principles in alkyl technology. This trend is driving research and development efforts towards more environmentally friendly alkyl compounds and production methods. Biodegradability, reduced toxicity, and lower carbon footprints are becoming key factors in regulatory compliance for alkyl-based products.

Emerging regulations are also addressing the end-of-life management of alkyl-containing products. Extended Producer Responsibility (EPR) schemes are being implemented in various jurisdictions, requiring manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. This is prompting innovations in alkyl technology to facilitate easier recycling and reduce environmental impact.

The global nature of the alkyl industry necessitates harmonization of regulations across different regions. International bodies such as the Organization for Economic Co-operation and Development (OECD) are working towards creating unified guidelines for the assessment and management of chemical risks, including those associated with alkyl compounds. This harmonization effort aims to reduce trade barriers while ensuring consistent environmental and health protection standards worldwide.

As climate change concerns intensify, regulations are increasingly linking alkyl technology to carbon emissions reduction goals. This is manifesting in policies that incentivize the development of bio-based alkyl alternatives and more energy-efficient production processes. The regulatory landscape is thus not only restricting certain practices but also actively shaping the future direction of alkyl technology towards more sustainable and environmentally compatible solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!