Heptane's Role in the Stabilization of Liquid Crystals for Display Technologies

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heptane and LCD Evolution

The evolution of liquid crystal display (LCD) technology has been closely intertwined with the development of stabilizing agents, among which heptane has played a significant role. The journey of heptane in LCD technology began in the early 1970s when researchers were exploring various organic compounds to enhance the stability and performance of liquid crystal mixtures.

Initially, liquid crystal displays faced challenges with temperature sensitivity and limited operational range. The introduction of heptane as a stabilizing agent marked a turning point in addressing these issues. Its unique molecular structure, consisting of seven carbon atoms in a straight chain, provided ideal properties for maintaining the delicate balance of liquid crystal alignment.

Throughout the 1980s and 1990s, as LCD technology gained traction in consumer electronics, the role of heptane became increasingly crucial. Its low viscosity and excellent solvent properties allowed for more uniform dispersion of liquid crystal molecules, resulting in improved contrast ratios and faster response times. This period saw intensive research into optimizing heptane concentrations and exploring synergistic effects with other stabilizing compounds.

The advent of thin-film transistor (TFT) LCDs in the late 1990s and early 2000s further emphasized the importance of heptane in display technologies. As pixel densities increased and display sizes grew, the demand for more stable and responsive liquid crystal mixtures intensified. Heptane's ability to maintain consistent performance across a wider temperature range became invaluable in meeting these evolving requirements.

In recent years, the focus has shifted towards developing more environmentally friendly and energy-efficient display technologies. This has led to renewed interest in heptane and its derivatives, exploring ways to enhance its stabilizing properties while minimizing environmental impact. Research into nano-structured heptane formulations and hybrid organic-inorganic stabilizers has opened new avenues for improving LCD performance and sustainability.

The ongoing evolution of LCD technology, including advancements in quantum dot displays and flexible screens, continues to rely on the fundamental stabilizing properties of heptane. Its role has expanded beyond mere stabilization to include functions such as improving color gamut, enhancing viewing angles, and reducing power consumption. As display technologies push the boundaries of resolution and form factor, the importance of heptane in liquid crystal stabilization remains paramount, driving innovation in both materials science and display engineering.

Initially, liquid crystal displays faced challenges with temperature sensitivity and limited operational range. The introduction of heptane as a stabilizing agent marked a turning point in addressing these issues. Its unique molecular structure, consisting of seven carbon atoms in a straight chain, provided ideal properties for maintaining the delicate balance of liquid crystal alignment.

Throughout the 1980s and 1990s, as LCD technology gained traction in consumer electronics, the role of heptane became increasingly crucial. Its low viscosity and excellent solvent properties allowed for more uniform dispersion of liquid crystal molecules, resulting in improved contrast ratios and faster response times. This period saw intensive research into optimizing heptane concentrations and exploring synergistic effects with other stabilizing compounds.

The advent of thin-film transistor (TFT) LCDs in the late 1990s and early 2000s further emphasized the importance of heptane in display technologies. As pixel densities increased and display sizes grew, the demand for more stable and responsive liquid crystal mixtures intensified. Heptane's ability to maintain consistent performance across a wider temperature range became invaluable in meeting these evolving requirements.

In recent years, the focus has shifted towards developing more environmentally friendly and energy-efficient display technologies. This has led to renewed interest in heptane and its derivatives, exploring ways to enhance its stabilizing properties while minimizing environmental impact. Research into nano-structured heptane formulations and hybrid organic-inorganic stabilizers has opened new avenues for improving LCD performance and sustainability.

The ongoing evolution of LCD technology, including advancements in quantum dot displays and flexible screens, continues to rely on the fundamental stabilizing properties of heptane. Its role has expanded beyond mere stabilization to include functions such as improving color gamut, enhancing viewing angles, and reducing power consumption. As display technologies push the boundaries of resolution and form factor, the importance of heptane in liquid crystal stabilization remains paramount, driving innovation in both materials science and display engineering.

Market Demand Analysis

The market demand for liquid crystal display (LCD) technologies continues to grow, driven by the increasing prevalence of electronic devices across various sectors. Heptane, as a key component in the stabilization of liquid crystals, plays a crucial role in meeting this demand by enhancing the performance and longevity of display technologies.

The global LCD market has shown steady growth, with projections indicating further expansion in the coming years. This growth is primarily fueled by the rising adoption of LCD screens in smartphones, tablets, televisions, and automotive displays. The automotive industry, in particular, has seen a significant increase in the integration of LCD panels for infotainment systems and digital dashboards, creating new opportunities for liquid crystal technologies.

Consumer electronics remain the largest market segment for LCD technologies, with smartphones and tablets leading the demand. The trend towards larger, higher-resolution displays in these devices has intensified the need for advanced liquid crystal formulations that can maintain stability and performance under various operating conditions. Heptane's role in stabilizing these formulations becomes increasingly critical as manufacturers strive to meet consumer expectations for brighter, more energy-efficient displays with faster response times.

The commercial and industrial sectors also contribute significantly to the market demand for LCD technologies. Digital signage, point-of-sale displays, and industrial control panels all rely on stable liquid crystal formulations to ensure long-term reliability and performance. In these applications, the ability of heptane to enhance the stability of liquid crystals translates directly into reduced maintenance costs and improved operational efficiency for businesses.

Emerging technologies such as flexible and transparent displays are creating new market opportunities for liquid crystal technologies. These innovative display formats require even more sophisticated liquid crystal formulations to maintain stability under bending or stretching conditions. The role of stabilizing agents like heptane becomes even more crucial in these cutting-edge applications, driving research and development efforts to optimize their use in next-generation display technologies.

Environmental concerns and regulatory pressures are also shaping market demand, with a growing emphasis on energy-efficient and eco-friendly display technologies. This trend favors the development of liquid crystal formulations that can operate at lower voltages and temperatures, reducing power consumption without compromising performance. Heptane's ability to contribute to the stability of these energy-efficient formulations aligns well with these market demands, potentially driving its increased use in future display technologies.

The global LCD market has shown steady growth, with projections indicating further expansion in the coming years. This growth is primarily fueled by the rising adoption of LCD screens in smartphones, tablets, televisions, and automotive displays. The automotive industry, in particular, has seen a significant increase in the integration of LCD panels for infotainment systems and digital dashboards, creating new opportunities for liquid crystal technologies.

Consumer electronics remain the largest market segment for LCD technologies, with smartphones and tablets leading the demand. The trend towards larger, higher-resolution displays in these devices has intensified the need for advanced liquid crystal formulations that can maintain stability and performance under various operating conditions. Heptane's role in stabilizing these formulations becomes increasingly critical as manufacturers strive to meet consumer expectations for brighter, more energy-efficient displays with faster response times.

The commercial and industrial sectors also contribute significantly to the market demand for LCD technologies. Digital signage, point-of-sale displays, and industrial control panels all rely on stable liquid crystal formulations to ensure long-term reliability and performance. In these applications, the ability of heptane to enhance the stability of liquid crystals translates directly into reduced maintenance costs and improved operational efficiency for businesses.

Emerging technologies such as flexible and transparent displays are creating new market opportunities for liquid crystal technologies. These innovative display formats require even more sophisticated liquid crystal formulations to maintain stability under bending or stretching conditions. The role of stabilizing agents like heptane becomes even more crucial in these cutting-edge applications, driving research and development efforts to optimize their use in next-generation display technologies.

Environmental concerns and regulatory pressures are also shaping market demand, with a growing emphasis on energy-efficient and eco-friendly display technologies. This trend favors the development of liquid crystal formulations that can operate at lower voltages and temperatures, reducing power consumption without compromising performance. Heptane's ability to contribute to the stability of these energy-efficient formulations aligns well with these market demands, potentially driving its increased use in future display technologies.

Technical Challenges

The stabilization of liquid crystals using heptane in display technologies faces several significant technical challenges. One of the primary issues is maintaining the delicate balance between the liquid crystal molecules and the heptane solvent. The interaction between these components is crucial for achieving optimal display performance, but it is highly sensitive to environmental factors such as temperature fluctuations and external pressures.

Another challenge lies in the long-term stability of the heptane-liquid crystal mixture. Over time, there is a risk of phase separation or degradation of the liquid crystal molecules, which can lead to reduced display quality and shortened device lifespan. Researchers are continually working on developing more robust formulations that can withstand extended periods of use without compromising performance.

The uniformity of the liquid crystal alignment across large display areas presents a significant hurdle. Heptane's role in maintaining this alignment is critical, but achieving consistent results over expansive surfaces remains technically demanding. This challenge becomes even more pronounced as display sizes continue to increase, particularly in applications such as large-format televisions and public information displays.

Addressing the environmental and health concerns associated with heptane usage is another technical obstacle. As regulations become more stringent, there is a growing need to develop alternative stabilization methods or find more environmentally friendly solvents that can match or exceed heptane's performance in liquid crystal displays.

The manufacturing process itself poses several technical challenges. Precise control over the heptane concentration and its distribution within the liquid crystal matrix is essential for consistent display quality. However, achieving this level of control in large-scale production environments is complex and requires sophisticated manufacturing techniques and quality control measures.

Furthermore, the integration of heptane-stabilized liquid crystals with other display components, such as color filters, polarizers, and backlight systems, presents additional technical hurdles. Ensuring compatibility and optimal performance across all these elements while maintaining the stability provided by heptane is a multifaceted challenge that requires ongoing research and development efforts.

Lastly, as display technologies continue to evolve, there is a constant push for higher refresh rates, improved color gamut, and enhanced energy efficiency. These advancements often place additional demands on the liquid crystal-heptane system, necessitating continuous innovation in stabilization techniques to meet the ever-increasing performance requirements of modern display technologies.

Another challenge lies in the long-term stability of the heptane-liquid crystal mixture. Over time, there is a risk of phase separation or degradation of the liquid crystal molecules, which can lead to reduced display quality and shortened device lifespan. Researchers are continually working on developing more robust formulations that can withstand extended periods of use without compromising performance.

The uniformity of the liquid crystal alignment across large display areas presents a significant hurdle. Heptane's role in maintaining this alignment is critical, but achieving consistent results over expansive surfaces remains technically demanding. This challenge becomes even more pronounced as display sizes continue to increase, particularly in applications such as large-format televisions and public information displays.

Addressing the environmental and health concerns associated with heptane usage is another technical obstacle. As regulations become more stringent, there is a growing need to develop alternative stabilization methods or find more environmentally friendly solvents that can match or exceed heptane's performance in liquid crystal displays.

The manufacturing process itself poses several technical challenges. Precise control over the heptane concentration and its distribution within the liquid crystal matrix is essential for consistent display quality. However, achieving this level of control in large-scale production environments is complex and requires sophisticated manufacturing techniques and quality control measures.

Furthermore, the integration of heptane-stabilized liquid crystals with other display components, such as color filters, polarizers, and backlight systems, presents additional technical hurdles. Ensuring compatibility and optimal performance across all these elements while maintaining the stability provided by heptane is a multifaceted challenge that requires ongoing research and development efforts.

Lastly, as display technologies continue to evolve, there is a constant push for higher refresh rates, improved color gamut, and enhanced energy efficiency. These advancements often place additional demands on the liquid crystal-heptane system, necessitating continuous innovation in stabilization techniques to meet the ever-increasing performance requirements of modern display technologies.

Current Stabilization

01 Chemical stabilization methods

Various chemical methods can be employed to stabilize heptane. These may include the addition of antioxidants, stabilizers, or other chemical compounds that prevent degradation or unwanted reactions. The specific chemicals used depend on the intended application and storage conditions of the heptane.- Chemical stabilization methods: Various chemical methods can be employed to stabilize heptane. These may include the addition of antioxidants, stabilizers, or other chemical compounds that prevent degradation or unwanted reactions. The specific chemicals used depend on the intended application and storage conditions of the heptane.

- Physical stabilization techniques: Physical methods can be used to enhance heptane stability. These may involve controlling storage conditions such as temperature, pressure, and light exposure. Specialized containers or packaging materials may also be employed to prevent contamination or evaporation, thereby maintaining the stability of heptane over extended periods.

- Purification processes for improved stability: Purification techniques can be applied to remove impurities that may contribute to heptane instability. These processes may include distillation, adsorption, or membrane separation. By eliminating destabilizing contaminants, the overall stability of heptane can be significantly enhanced for various applications.

- Stabilization through blending or formulation: Heptane can be stabilized by blending it with other compatible substances or incorporating it into specific formulations. This approach may involve creating mixtures with other hydrocarbons or adding stabilizing agents. The resulting blends or formulations can exhibit improved stability characteristics compared to pure heptane.

- Monitoring and control systems for heptane stability: Advanced monitoring and control systems can be implemented to maintain heptane stability. These may include sensors, analytical instruments, and automated control mechanisms that continuously assess and adjust conditions to ensure optimal stability. Such systems can be particularly useful in industrial processes or storage facilities handling large quantities of heptane.

02 Physical stabilization techniques

Physical methods can be used to stabilize heptane, such as controlling temperature and pressure during storage and handling. This may involve specialized containers, cooling systems, or pressure regulation equipment to maintain the stability of heptane under various environmental conditions.Expand Specific Solutions03 Purification processes for heptane stability

Purification processes can enhance the stability of heptane by removing impurities that may cause degradation or unwanted reactions. These processes may include distillation, adsorption, or membrane separation techniques to produce high-purity heptane with improved stability characteristics.Expand Specific Solutions04 Stabilization through blending or formulation

Heptane can be stabilized by blending it with other compatible substances or incorporating it into specific formulations. This approach may involve creating mixtures with other hydrocarbons or additives that enhance overall stability while maintaining desired properties for the intended application.Expand Specific Solutions05 Monitoring and control systems for heptane stability

Advanced monitoring and control systems can be implemented to ensure the ongoing stability of heptane during storage, transportation, and use. These systems may include sensors, real-time analysis tools, and automated adjustment mechanisms to maintain optimal conditions for heptane stability.Expand Specific Solutions

Key Industry Players

The market for heptane in liquid crystal stabilization for display technologies is in a mature growth phase, with established players and ongoing innovation. The global liquid crystal materials market size is estimated to be over $4 billion, driven by demand for LCD displays. Technologically, the field is well-developed but continues to evolve, with companies like Merck Patent GmbH, DIC Corp., and Chisso Corp. leading research into advanced formulations. Chinese firms such as Beijing Bayi Space LCD Technology and Jiangsu Hecheng Display Technology are also making significant contributions, indicating a competitive and globally diverse landscape. Major display manufacturers like BOE Technology and TCL China Star Optoelectronics are key customers, driving continued development in this specialized chemical sector.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has developed advanced liquid crystal mixtures incorporating heptane-based compounds for improved stability in display technologies. Their approach involves synthesizing novel heptane derivatives with optimized molecular structures to enhance the overall performance of liquid crystal displays (LCDs). The company's research has shown that carefully designed heptane-containing compounds can significantly improve the voltage holding ratio (VHR) of LCD panels, resulting in better image retention and reduced flickering [1]. Additionally, Merck's heptane-based liquid crystal mixtures have demonstrated superior thermal stability, allowing for a wider operating temperature range in various display applications [3]. The company has also focused on developing eco-friendly heptane derivatives that meet stringent environmental regulations while maintaining high performance in LCD technologies [5].

Strengths: Extensive expertise in liquid crystal chemistry, strong R&D capabilities, and a wide patent portfolio. Weaknesses: Potential higher production costs due to specialized heptane derivatives, and dependency on the LCD market's overall growth.

DIC Corp.

Technical Solution: DIC Corp. has pioneered the use of heptane-based compounds in their liquid crystal formulations to enhance the stability and performance of display technologies. Their approach involves incorporating heptane derivatives as key components in their proprietary liquid crystal mixtures, which have shown remarkable improvements in display quality and longevity. DIC's research has demonstrated that heptane-based additives can significantly reduce the occurrence of image sticking and improve the response time of LCD panels [2]. The company has also developed a unique process for synthesizing heptane-modified liquid crystal molecules that exhibit enhanced resistance to UV degradation, thereby extending the lifespan of displays in high-brightness environments [4]. Furthermore, DIC's heptane-stabilized liquid crystal mixtures have shown excellent compatibility with various alignment layer materials, leading to improved viewing angles and color reproduction in advanced display technologies [6].

Strengths: Strong innovation in liquid crystal formulations, diverse product portfolio, and established presence in the display materials market. Weaknesses: Potential challenges in scaling up production of specialized heptane-based compounds and adapting to rapidly evolving display technologies.

Heptane Innovation

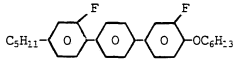

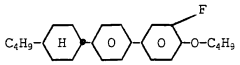

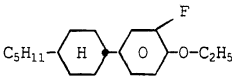

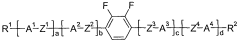

Liquid-crystal compounds

PatentWO1993003113A1

Innovation

- Development of liquid-crystalline compounds with specific molecular structures that offer low viscosity, high dielectric anisotropy, and nematogenicity, allowing for stable liquid-crystalline media with broad mesophase ranges and improved optical and dielectric properties, while suppressing smectic phases.

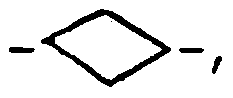

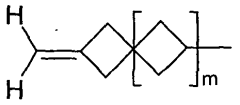

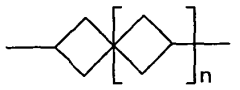

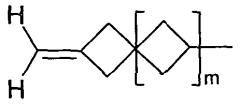

Cyclobutane and spiro[3.3]heptane compounds

PatentWO2007033732A1

Innovation

- Development of cyclobutane and spiro[3.3]heptane compounds with specific structural elements and functional groups that exhibit negative dielectric anisotropy, allowing for improved molecular orientation and reduced viewing angle dependency, along with the use of these compounds in liquid-crystalline media to enhance display performance.

Environmental Impact

The use of heptane in liquid crystal display (LCD) technologies has significant environmental implications that warrant careful consideration. As a hydrocarbon solvent, heptane's production, use, and disposal can impact various aspects of the environment.

During the manufacturing process of LCDs, heptane is utilized as a stabilizing agent for liquid crystals. This application helps improve the performance and longevity of display devices. However, the production of heptane involves the refining of crude oil, which is associated with greenhouse gas emissions and potential environmental contamination. The extraction and processing of fossil fuels contribute to climate change and can lead to localized pollution if not properly managed.

In the context of LCD production, the use of heptane may result in volatile organic compound (VOC) emissions. These emissions can contribute to the formation of ground-level ozone and smog, potentially impacting air quality in manufacturing regions. Proper ventilation systems and emission control technologies are crucial to mitigate these effects and ensure compliance with environmental regulations.

The disposal of heptane-containing waste from LCD manufacturing processes presents another environmental challenge. Improper handling or disposal can lead to soil and water contamination. Heptane, being a hydrocarbon, can persist in the environment and potentially harm aquatic ecosystems if released into water bodies. Implementing robust waste management protocols and recycling initiatives is essential to minimize these risks.

From a lifecycle perspective, the environmental impact of heptane extends beyond its immediate use in LCD production. The transportation of heptane from production facilities to manufacturing sites contributes to carbon emissions. Additionally, the end-of-life disposal of LCD devices containing heptane residues requires careful consideration to prevent environmental contamination.

On a positive note, the stabilizing effect of heptane on liquid crystals can potentially extend the lifespan of LCD devices. This longevity may reduce the frequency of device replacement, indirectly mitigating the environmental impact associated with electronic waste generation. However, this benefit must be weighed against the environmental costs of heptane production and use.

As the electronics industry continues to evolve, there is growing interest in developing more environmentally friendly alternatives to traditional LCD technologies. This includes research into bio-based solvents and stabilizers that could potentially replace heptane in display applications. Such innovations aim to reduce the environmental footprint of electronic devices while maintaining or improving performance characteristics.

During the manufacturing process of LCDs, heptane is utilized as a stabilizing agent for liquid crystals. This application helps improve the performance and longevity of display devices. However, the production of heptane involves the refining of crude oil, which is associated with greenhouse gas emissions and potential environmental contamination. The extraction and processing of fossil fuels contribute to climate change and can lead to localized pollution if not properly managed.

In the context of LCD production, the use of heptane may result in volatile organic compound (VOC) emissions. These emissions can contribute to the formation of ground-level ozone and smog, potentially impacting air quality in manufacturing regions. Proper ventilation systems and emission control technologies are crucial to mitigate these effects and ensure compliance with environmental regulations.

The disposal of heptane-containing waste from LCD manufacturing processes presents another environmental challenge. Improper handling or disposal can lead to soil and water contamination. Heptane, being a hydrocarbon, can persist in the environment and potentially harm aquatic ecosystems if released into water bodies. Implementing robust waste management protocols and recycling initiatives is essential to minimize these risks.

From a lifecycle perspective, the environmental impact of heptane extends beyond its immediate use in LCD production. The transportation of heptane from production facilities to manufacturing sites contributes to carbon emissions. Additionally, the end-of-life disposal of LCD devices containing heptane residues requires careful consideration to prevent environmental contamination.

On a positive note, the stabilizing effect of heptane on liquid crystals can potentially extend the lifespan of LCD devices. This longevity may reduce the frequency of device replacement, indirectly mitigating the environmental impact associated with electronic waste generation. However, this benefit must be weighed against the environmental costs of heptane production and use.

As the electronics industry continues to evolve, there is growing interest in developing more environmentally friendly alternatives to traditional LCD technologies. This includes research into bio-based solvents and stabilizers that could potentially replace heptane in display applications. Such innovations aim to reduce the environmental footprint of electronic devices while maintaining or improving performance characteristics.

Regulatory Compliance

The regulatory landscape surrounding the use of heptane in liquid crystal display (LCD) technologies is complex and multifaceted. As a key component in the stabilization of liquid crystals, heptane falls under the purview of several regulatory bodies and standards. The European Union's Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation is particularly relevant, as it requires manufacturers and importers to register substances used in quantities over one tonne per year. Heptane, being a chemical substance, must comply with REACH requirements, including safety assessments and risk management measures.

In the United States, the Environmental Protection Agency (EPA) regulates heptane under the Toxic Substances Control Act (TSCA). Manufacturers and importers must adhere to reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) also sets permissible exposure limits for heptane in workplace environments, ensuring worker safety during the production and handling of LCD components.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. LCD manufacturers using heptane must comply with GHS labeling and safety data sheet requirements, facilitating international trade and ensuring consistent safety information across borders.

Environmental regulations also play a crucial role in the use of heptane for LCD technologies. Many countries have implemented volatile organic compound (VOC) emission standards, which may impact the use and disposal of heptane in manufacturing processes. Compliance with these regulations often requires investment in emission control technologies and careful monitoring of production processes.

As the electronics industry moves towards more sustainable practices, regulations promoting the circular economy are becoming increasingly relevant. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for instance, sets collection, recycling, and recovery targets for electronic waste. This impacts the entire lifecycle of LCD products, including the end-of-life management of components containing heptane.

Manufacturers must also consider product-specific regulations, such as the Restriction of Hazardous Substances (RoHS) Directive, which limits the use of certain hazardous substances in electrical and electronic equipment. While heptane is not directly restricted under RoHS, its interaction with other materials in LCD devices must be carefully managed to ensure compliance.

In the United States, the Environmental Protection Agency (EPA) regulates heptane under the Toxic Substances Control Act (TSCA). Manufacturers and importers must adhere to reporting, record-keeping, and testing requirements. The Occupational Safety and Health Administration (OSHA) also sets permissible exposure limits for heptane in workplace environments, ensuring worker safety during the production and handling of LCD components.

Globally, the United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides a standardized approach to communicating chemical hazards. LCD manufacturers using heptane must comply with GHS labeling and safety data sheet requirements, facilitating international trade and ensuring consistent safety information across borders.

Environmental regulations also play a crucial role in the use of heptane for LCD technologies. Many countries have implemented volatile organic compound (VOC) emission standards, which may impact the use and disposal of heptane in manufacturing processes. Compliance with these regulations often requires investment in emission control technologies and careful monitoring of production processes.

As the electronics industry moves towards more sustainable practices, regulations promoting the circular economy are becoming increasingly relevant. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for instance, sets collection, recycling, and recovery targets for electronic waste. This impacts the entire lifecycle of LCD products, including the end-of-life management of components containing heptane.

Manufacturers must also consider product-specific regulations, such as the Restriction of Hazardous Substances (RoHS) Directive, which limits the use of certain hazardous substances in electrical and electronic equipment. While heptane is not directly restricted under RoHS, its interaction with other materials in LCD devices must be carefully managed to ensure compliance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!