How Closed-Loop Control Alters LS Engine Emissions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Emissions Control Background and Objectives

The development of closed-loop control systems for LS (Luxury Sport) engines marks a significant milestone in automotive engineering, particularly in the realm of emissions control. This technology has evolved over several decades, driven by increasingly stringent environmental regulations and the automotive industry's commitment to reducing the environmental impact of internal combustion engines.

The primary objective of implementing closed-loop control in LS engines is to optimize the combustion process, thereby minimizing harmful emissions while maintaining or improving engine performance. This approach represents a shift from traditional open-loop systems, which rely on predetermined fuel maps and lack real-time adjustments based on actual engine operating conditions.

Closed-loop control systems in LS engines utilize oxygen sensors in the exhaust stream to continuously monitor the air-fuel ratio. This real-time data feedback allows the engine control unit (ECU) to make instantaneous adjustments to fuel injection and ignition timing, ensuring the engine operates as close to stoichiometric conditions as possible. The stoichiometric air-fuel ratio, typically around 14.7:1 for gasoline engines, is crucial for optimal catalytic converter efficiency and minimal emissions.

The evolution of this technology can be traced back to the introduction of electronic fuel injection systems in the 1980s. However, it was the advent of more sophisticated ECUs and high-precision sensors in the 1990s and 2000s that enabled the development of truly effective closed-loop control systems for LS engines. These advancements allowed for more precise control over the combustion process, leading to significant reductions in emissions of carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

As environmental concerns have grown and emissions regulations have become more stringent, the automotive industry has continued to refine closed-loop control systems. Modern LS engines incorporate advanced features such as variable valve timing, direct fuel injection, and turbocharging, all of which work in concert with closed-loop control to further optimize engine performance and emissions.

The ongoing technological trend is towards even more sophisticated control systems, incorporating artificial intelligence and machine learning algorithms to predict and adapt to various driving conditions and engine states. This evolution aims to further reduce emissions, improve fuel efficiency, and enhance overall engine performance across a wide range of operating conditions.

In conclusion, the development and implementation of closed-loop control systems in LS engines represent a critical technological advancement in the automotive industry's efforts to address environmental concerns while maintaining high performance standards. The continuous refinement of this technology remains a key objective in the ongoing quest for cleaner, more efficient internal combustion engines.

The primary objective of implementing closed-loop control in LS engines is to optimize the combustion process, thereby minimizing harmful emissions while maintaining or improving engine performance. This approach represents a shift from traditional open-loop systems, which rely on predetermined fuel maps and lack real-time adjustments based on actual engine operating conditions.

Closed-loop control systems in LS engines utilize oxygen sensors in the exhaust stream to continuously monitor the air-fuel ratio. This real-time data feedback allows the engine control unit (ECU) to make instantaneous adjustments to fuel injection and ignition timing, ensuring the engine operates as close to stoichiometric conditions as possible. The stoichiometric air-fuel ratio, typically around 14.7:1 for gasoline engines, is crucial for optimal catalytic converter efficiency and minimal emissions.

The evolution of this technology can be traced back to the introduction of electronic fuel injection systems in the 1980s. However, it was the advent of more sophisticated ECUs and high-precision sensors in the 1990s and 2000s that enabled the development of truly effective closed-loop control systems for LS engines. These advancements allowed for more precise control over the combustion process, leading to significant reductions in emissions of carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

As environmental concerns have grown and emissions regulations have become more stringent, the automotive industry has continued to refine closed-loop control systems. Modern LS engines incorporate advanced features such as variable valve timing, direct fuel injection, and turbocharging, all of which work in concert with closed-loop control to further optimize engine performance and emissions.

The ongoing technological trend is towards even more sophisticated control systems, incorporating artificial intelligence and machine learning algorithms to predict and adapt to various driving conditions and engine states. This evolution aims to further reduce emissions, improve fuel efficiency, and enhance overall engine performance across a wide range of operating conditions.

In conclusion, the development and implementation of closed-loop control systems in LS engines represent a critical technological advancement in the automotive industry's efforts to address environmental concerns while maintaining high performance standards. The continuous refinement of this technology remains a key objective in the ongoing quest for cleaner, more efficient internal combustion engines.

Market Demand for Low-Emission LS Engines

The market demand for low-emission LS engines has been steadily increasing in recent years, driven by stringent environmental regulations and growing consumer awareness of environmental issues. This trend is particularly evident in developed markets such as North America, Europe, and parts of Asia, where governments have implemented strict emission standards for vehicles.

The automotive industry has been under pressure to reduce greenhouse gas emissions and improve fuel efficiency. As a result, there has been a significant shift towards cleaner engine technologies, including those that incorporate closed-loop control systems. These systems offer real-time monitoring and adjustment of engine parameters, leading to optimized performance and reduced emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a major driver for the adoption of low-emission technologies. Automakers are required to meet increasingly stringent fuel efficiency targets, which has led to increased investment in advanced engine technologies, including those used in LS engines.

The commercial vehicle sector has also seen growing demand for low-emission engines. Fleet operators are increasingly looking for ways to reduce their carbon footprint and operating costs. Low-emission LS engines with closed-loop control systems offer a solution that can help meet both environmental and economic objectives.

The aftermarket segment presents another significant opportunity for low-emission LS engines. Performance enthusiasts are seeking ways to upgrade their vehicles while complying with emission regulations. This has created a niche market for high-performance, low-emission engine solutions.

Emerging markets are also showing increased interest in low-emission technologies. As these countries develop more stringent environmental policies, the demand for cleaner engine technologies is expected to grow. This presents an opportunity for manufacturers of low-emission LS engines to expand their global market presence.

The marine industry is another sector where demand for low-emission engines is on the rise. Stricter regulations on maritime emissions have led to increased interest in cleaner propulsion systems, including those based on LS engine technology with closed-loop control.

Overall, the market for low-emission LS engines is expected to continue growing as environmental concerns remain at the forefront of both regulatory and consumer priorities. Manufacturers who can effectively integrate closed-loop control systems to reduce emissions while maintaining or improving performance are likely to see increased demand for their products across various sectors.

The automotive industry has been under pressure to reduce greenhouse gas emissions and improve fuel efficiency. As a result, there has been a significant shift towards cleaner engine technologies, including those that incorporate closed-loop control systems. These systems offer real-time monitoring and adjustment of engine parameters, leading to optimized performance and reduced emissions.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have been a major driver for the adoption of low-emission technologies. Automakers are required to meet increasingly stringent fuel efficiency targets, which has led to increased investment in advanced engine technologies, including those used in LS engines.

The commercial vehicle sector has also seen growing demand for low-emission engines. Fleet operators are increasingly looking for ways to reduce their carbon footprint and operating costs. Low-emission LS engines with closed-loop control systems offer a solution that can help meet both environmental and economic objectives.

The aftermarket segment presents another significant opportunity for low-emission LS engines. Performance enthusiasts are seeking ways to upgrade their vehicles while complying with emission regulations. This has created a niche market for high-performance, low-emission engine solutions.

Emerging markets are also showing increased interest in low-emission technologies. As these countries develop more stringent environmental policies, the demand for cleaner engine technologies is expected to grow. This presents an opportunity for manufacturers of low-emission LS engines to expand their global market presence.

The marine industry is another sector where demand for low-emission engines is on the rise. Stricter regulations on maritime emissions have led to increased interest in cleaner propulsion systems, including those based on LS engine technology with closed-loop control.

Overall, the market for low-emission LS engines is expected to continue growing as environmental concerns remain at the forefront of both regulatory and consumer priorities. Manufacturers who can effectively integrate closed-loop control systems to reduce emissions while maintaining or improving performance are likely to see increased demand for their products across various sectors.

Closed-Loop Control Challenges in LS Engines

Closed-loop control systems in LS engines face several significant challenges that impact their ability to effectively manage emissions. One of the primary obstacles is the inherent delay in the feedback loop. The time it takes for exhaust gases to travel from the combustion chamber to the oxygen sensors, and for the engine control unit (ECU) to process this information and adjust fuel injection, can lead to suboptimal air-fuel ratios during transient operating conditions.

Another challenge lies in the complexity of modern engine systems. LS engines often incorporate variable valve timing, direct injection, and forced induction, which can introduce additional variables that complicate the control algorithm. These advanced features require more sophisticated closed-loop control strategies to maintain optimal emissions performance across a wide range of operating conditions.

Sensor accuracy and reliability present ongoing challenges for closed-loop control systems. Oxygen sensors, which are critical components in the feedback loop, can degrade over time or become contaminated, leading to inaccurate readings. This degradation can result in improper fuel mixture adjustments and increased emissions. Additionally, the harsh environment of the exhaust system, with its high temperatures and corrosive gases, puts significant stress on these sensors, potentially shortening their lifespan and reliability.

The wide-ranging operating conditions of LS engines also pose a challenge for closed-loop control systems. From cold starts to high-load situations, the control system must adapt quickly to maintain optimal emissions performance. This adaptability becomes particularly crucial during rapid acceleration or deceleration, where the air-fuel ratio can fluctuate dramatically.

Calibration of the closed-loop control system presents another significant challenge. Engineers must fine-tune the control algorithms to balance performance, fuel efficiency, and emissions across various driving conditions. This process is time-consuming and requires extensive testing to ensure compliance with increasingly stringent emissions regulations.

Furthermore, the integration of closed-loop control with other engine management systems, such as exhaust gas recirculation (EGR) and catalytic converters, adds another layer of complexity. These systems must work in harmony to achieve the best overall emissions performance, requiring sophisticated coordination and control strategies.

Lastly, as emissions standards continue to tighten, closed-loop control systems in LS engines face the ongoing challenge of meeting these regulations while maintaining engine performance and efficiency. This necessitates continuous innovation in sensor technology, control algorithms, and system integration to push the boundaries of emissions control capabilities in LS engines.

Another challenge lies in the complexity of modern engine systems. LS engines often incorporate variable valve timing, direct injection, and forced induction, which can introduce additional variables that complicate the control algorithm. These advanced features require more sophisticated closed-loop control strategies to maintain optimal emissions performance across a wide range of operating conditions.

Sensor accuracy and reliability present ongoing challenges for closed-loop control systems. Oxygen sensors, which are critical components in the feedback loop, can degrade over time or become contaminated, leading to inaccurate readings. This degradation can result in improper fuel mixture adjustments and increased emissions. Additionally, the harsh environment of the exhaust system, with its high temperatures and corrosive gases, puts significant stress on these sensors, potentially shortening their lifespan and reliability.

The wide-ranging operating conditions of LS engines also pose a challenge for closed-loop control systems. From cold starts to high-load situations, the control system must adapt quickly to maintain optimal emissions performance. This adaptability becomes particularly crucial during rapid acceleration or deceleration, where the air-fuel ratio can fluctuate dramatically.

Calibration of the closed-loop control system presents another significant challenge. Engineers must fine-tune the control algorithms to balance performance, fuel efficiency, and emissions across various driving conditions. This process is time-consuming and requires extensive testing to ensure compliance with increasingly stringent emissions regulations.

Furthermore, the integration of closed-loop control with other engine management systems, such as exhaust gas recirculation (EGR) and catalytic converters, adds another layer of complexity. These systems must work in harmony to achieve the best overall emissions performance, requiring sophisticated coordination and control strategies.

Lastly, as emissions standards continue to tighten, closed-loop control systems in LS engines face the ongoing challenge of meeting these regulations while maintaining engine performance and efficiency. This necessitates continuous innovation in sensor technology, control algorithms, and system integration to push the boundaries of emissions control capabilities in LS engines.

Current Closed-Loop Control Solutions for LS Engines

01 Exhaust gas recirculation (EGR) systems

EGR systems are used to reduce nitrogen oxide emissions in LS engines by recirculating a portion of exhaust gases back into the combustion chamber. This lowers combustion temperatures and reduces the formation of nitrogen oxides. Advanced EGR systems may include cooling mechanisms and precise control strategies to optimize emission reduction while maintaining engine performance.- Exhaust gas recirculation (EGR) systems: EGR systems are used to reduce nitrogen oxide emissions in LS engines by recirculating a portion of exhaust gases back into the combustion chamber. This lowers combustion temperatures and reduces the formation of NOx. Advanced EGR systems may include cooling mechanisms and precise control strategies to optimize emission reduction while maintaining engine performance.

- Catalytic converters and aftertreatment systems: LS engines employ catalytic converters and other aftertreatment systems to reduce harmful emissions. These systems may include three-way catalysts, diesel particulate filters, and selective catalytic reduction (SCR) technology. Advanced sensors and control algorithms are used to monitor and optimize the performance of these emission control devices.

- Engine management and control strategies: Sophisticated engine management systems are implemented in LS engines to optimize combustion and reduce emissions. These systems use advanced sensors, electronic control units, and software algorithms to precisely control fuel injection timing, air-fuel ratio, and other parameters. Adaptive strategies may be employed to maintain optimal performance and emissions control over time.

- Fuel injection and combustion optimization: LS engines utilize advanced fuel injection systems and combustion chamber designs to improve fuel atomization and mixing. This leads to more complete combustion and reduced emissions. Technologies such as direct injection, variable valve timing, and cylinder deactivation may be employed to further optimize the combustion process and reduce fuel consumption.

- On-board diagnostics and emission monitoring: LS engines incorporate sophisticated on-board diagnostic systems to monitor emissions performance and detect potential issues. These systems use various sensors to continuously monitor exhaust gases, engine parameters, and the performance of emission control devices. Advanced algorithms are employed to analyze this data and alert the driver or technician to any problems that may affect emissions compliance.

02 Catalytic converters and aftertreatment systems

Catalytic converters and other aftertreatment systems are crucial components for reducing emissions in LS engines. These systems use catalysts to convert harmful exhaust gases into less harmful substances. Advanced aftertreatment technologies may include selective catalytic reduction (SCR) systems, diesel particulate filters (DPF), and oxidation catalysts to target specific pollutants.Expand Specific Solutions03 Engine control strategies for emission reduction

Sophisticated engine control strategies are implemented to optimize combustion and reduce emissions in LS engines. These may include advanced fuel injection timing, variable valve timing, and air-fuel ratio management. Engine control modules use complex algorithms and sensor data to continuously adjust engine parameters for optimal performance and emissions control.Expand Specific Solutions04 Fuel system improvements

Enhancements to fuel systems play a significant role in reducing emissions from LS engines. This includes high-pressure fuel injection systems, improved fuel atomization, and precise fuel metering. Advanced fuel systems may also incorporate multiple injection events per combustion cycle to optimize fuel burn and reduce particulate emissions.Expand Specific Solutions05 Emission monitoring and diagnostics

Advanced emission monitoring and diagnostic systems are integrated into LS engines to ensure compliance with emission standards. These systems may include on-board diagnostics (OBD), real-time emission sensors, and predictive maintenance algorithms. Such technologies help identify and address potential emission-related issues before they become significant problems.Expand Specific Solutions

Key Players in LS Engine and Emission Control Industry

The closed-loop control technology for LS engine emissions is in a mature development stage, with significant market potential as automotive manufacturers strive to meet stringent emissions regulations. The global market for engine control systems is projected to grow substantially in the coming years. Major players like GM, Ford, Volkswagen, and BMW are at the forefront of implementing advanced closed-loop control systems to optimize engine performance and reduce emissions. Suppliers such as Bosch and Continental are also key contributors, providing sophisticated sensors and control modules. The technology's maturity is evident in its widespread adoption across various vehicle segments, from passenger cars to commercial vehicles, with ongoing refinements focused on enhancing efficiency and meeting evolving environmental standards.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced closed-loop control system for LS engines that utilizes real-time feedback from oxygen sensors to continuously adjust fuel injection and ignition timing. This system employs a model-based control algorithm that predicts emissions based on engine operating conditions and adjusts parameters accordingly. The closed-loop control integrates with GM's Active Fuel Management (AFM) technology, allowing for cylinder deactivation to further reduce emissions during light load conditions[1][3]. GM's system also incorporates a rapid warm-up strategy for the catalytic converter, significantly reducing cold-start emissions[5].

Strengths: Precise emissions control, integration with existing fuel-saving technologies, and improved cold-start performance. Weaknesses: Complexity may lead to higher costs and potential reliability issues in the long term.

Robert Bosch GmbH

Technical Solution: Bosch has developed a sophisticated closed-loop control system for LS engines that combines advanced sensor technology with intelligent software algorithms. Their system utilizes wide-band lambda sensors for precise air-fuel ratio control and NOx sensors for direct feedback on nitrogen oxide emissions. Bosch's control strategy incorporates predictive elements based on machine learning algorithms that adapt to individual driving patterns and environmental conditions[2]. The system also features integrated on-board diagnostics (OBD) capabilities, allowing for real-time monitoring of emissions performance and early detection of potential issues[4].

Strengths: High precision emissions control, adaptability to various driving conditions, and advanced diagnostic capabilities. Weaknesses: May require more expensive sensor technology and complex calibration processes.

Innovative Closed-Loop Control Technologies for Emissions

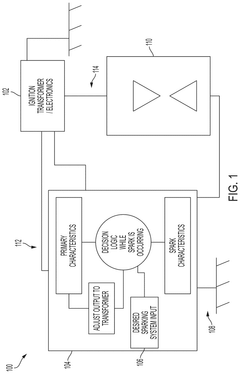

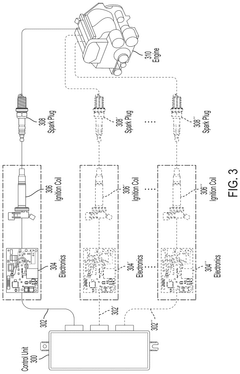

Adaptive spark energy control

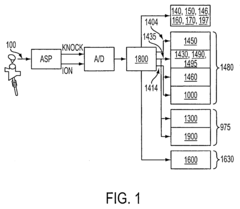

PatentPendingUS20250146465A1

Innovation

- A closed-loop ignition system that includes an ignition assembly with an ignition transformer, sensors to measure spark characteristics, and a control unit that adjusts spark parameters based on real-time feedback and reference data to optimize spark energy delivery.

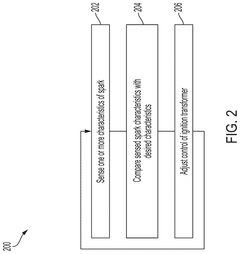

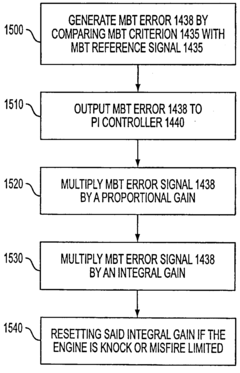

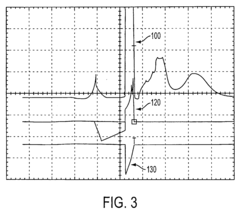

Closed loop MBT timing control using ionization feedback

PatentInactiveUS20040084019A1

Innovation

- A method using estimated MBT timing criteria and ignition diagnostics to control engine ignition timing, incorporating proportional and integral controllers, knock and misfire limit managers, and saturation management to adjust ignition timing based on ionization signals, ensuring balanced air-to-fuel ratios across cylinders.

Environmental Impact and Regulations

The implementation of closed-loop control systems in LS engines has significant implications for environmental impact and regulatory compliance. These systems have been developed in response to increasingly stringent emissions regulations worldwide, particularly in developed countries where air quality concerns have driven policy changes.

Closed-loop control alters LS engine emissions by continuously monitoring and adjusting the air-fuel ratio, ensuring optimal combustion efficiency. This results in reduced emissions of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons (HC). The precise control offered by these systems allows engines to meet strict emissions standards while maintaining performance and fuel efficiency.

Environmental regulations have played a crucial role in driving the adoption of closed-loop control technology. In the United States, the Environmental Protection Agency (EPA) has established progressively tighter emissions standards for vehicles, with similar regulations implemented in the European Union and other regions. These standards have necessitated the development and implementation of advanced engine control systems to achieve compliance.

The impact of closed-loop control on LS engine emissions extends beyond regulatory compliance. By reducing harmful emissions, these systems contribute to improved air quality in urban areas, where vehicle emissions are a significant source of pollution. This has potential long-term benefits for public health, as reduced exposure to air pollutants is associated with lower rates of respiratory and cardiovascular diseases.

Furthermore, the improved fuel efficiency resulting from closed-loop control systems indirectly contributes to reduced greenhouse gas emissions. As engines operate more efficiently, they consume less fuel per mile traveled, leading to lower carbon dioxide (CO2) emissions. This aligns with global efforts to mitigate climate change and reduce the carbon footprint of the transportation sector.

The regulatory landscape continues to evolve, with many countries implementing increasingly stringent emissions standards. For instance, the introduction of Euro 6 standards in the European Union and Tier 3 standards in the United States has further tightened the limits on allowable emissions. Closed-loop control systems are expected to play a crucial role in meeting these new standards and future regulations.

As environmental concerns grow and regulations become more stringent, the importance of closed-loop control in LS engines is likely to increase. Future developments may include more advanced sensors and control algorithms, further optimizing engine performance and emissions reduction. This ongoing evolution of engine control technology will continue to shape the environmental impact of LS engines and their compliance with global emissions regulations.

Closed-loop control alters LS engine emissions by continuously monitoring and adjusting the air-fuel ratio, ensuring optimal combustion efficiency. This results in reduced emissions of harmful pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons (HC). The precise control offered by these systems allows engines to meet strict emissions standards while maintaining performance and fuel efficiency.

Environmental regulations have played a crucial role in driving the adoption of closed-loop control technology. In the United States, the Environmental Protection Agency (EPA) has established progressively tighter emissions standards for vehicles, with similar regulations implemented in the European Union and other regions. These standards have necessitated the development and implementation of advanced engine control systems to achieve compliance.

The impact of closed-loop control on LS engine emissions extends beyond regulatory compliance. By reducing harmful emissions, these systems contribute to improved air quality in urban areas, where vehicle emissions are a significant source of pollution. This has potential long-term benefits for public health, as reduced exposure to air pollutants is associated with lower rates of respiratory and cardiovascular diseases.

Furthermore, the improved fuel efficiency resulting from closed-loop control systems indirectly contributes to reduced greenhouse gas emissions. As engines operate more efficiently, they consume less fuel per mile traveled, leading to lower carbon dioxide (CO2) emissions. This aligns with global efforts to mitigate climate change and reduce the carbon footprint of the transportation sector.

The regulatory landscape continues to evolve, with many countries implementing increasingly stringent emissions standards. For instance, the introduction of Euro 6 standards in the European Union and Tier 3 standards in the United States has further tightened the limits on allowable emissions. Closed-loop control systems are expected to play a crucial role in meeting these new standards and future regulations.

As environmental concerns grow and regulations become more stringent, the importance of closed-loop control in LS engines is likely to increase. Future developments may include more advanced sensors and control algorithms, further optimizing engine performance and emissions reduction. This ongoing evolution of engine control technology will continue to shape the environmental impact of LS engines and their compliance with global emissions regulations.

Cost-Benefit Analysis of Closed-Loop Control Implementation

Implementing closed-loop control systems in LS engines presents a complex cost-benefit scenario that requires careful analysis. The initial investment in closed-loop technology can be substantial, encompassing hardware upgrades, sensor integration, and software development. These costs typically include the installation of oxygen sensors, advanced engine control units (ECUs), and the necessary wiring and connectors. Additionally, there may be expenses related to recalibration and testing to ensure optimal performance.

However, the benefits of closed-loop control can be significant and multifaceted. Primarily, these systems offer improved fuel efficiency, which can lead to substantial cost savings over the engine's lifetime. By continuously adjusting the air-fuel ratio, closed-loop control minimizes fuel waste and optimizes combustion, potentially reducing fuel consumption by 5-10% depending on driving conditions and engine specifications.

Emissions reduction is another crucial benefit, with closed-loop systems capable of dramatically lowering harmful exhaust emissions. This can result in compliance with stricter environmental regulations without the need for more expensive aftertreatment systems. In regions with emissions-based taxation or incentives, this could translate to direct financial benefits for vehicle owners or fleet operators.

Maintenance costs may also be reduced in the long term. Closed-loop systems can help prevent engine damage caused by improper air-fuel mixtures, potentially extending engine life and reducing the frequency of major repairs. However, it's important to note that the additional sensors and electronic components may introduce new potential points of failure, which could offset some of these savings.

From a performance perspective, closed-loop control can enhance engine responsiveness and power output consistency across various operating conditions. This improvement in drivability and performance can contribute to customer satisfaction and potentially higher resale values, though these benefits are more challenging to quantify directly.

The return on investment (ROI) for implementing closed-loop control varies depending on factors such as vehicle usage patterns, fuel prices, and local emissions regulations. For high-mileage applications or in areas with strict emissions standards, the payback period can be relatively short, potentially within 2-3 years. However, for low-mileage or specialized applications, the cost recovery may take longer or may not be fully realized in financial terms alone.

In conclusion, while the upfront costs of implementing closed-loop control in LS engines are significant, the long-term benefits in fuel efficiency, emissions reduction, and potentially reduced maintenance costs present a compelling case for adoption, particularly in markets with stringent environmental regulations or high fuel costs.

However, the benefits of closed-loop control can be significant and multifaceted. Primarily, these systems offer improved fuel efficiency, which can lead to substantial cost savings over the engine's lifetime. By continuously adjusting the air-fuel ratio, closed-loop control minimizes fuel waste and optimizes combustion, potentially reducing fuel consumption by 5-10% depending on driving conditions and engine specifications.

Emissions reduction is another crucial benefit, with closed-loop systems capable of dramatically lowering harmful exhaust emissions. This can result in compliance with stricter environmental regulations without the need for more expensive aftertreatment systems. In regions with emissions-based taxation or incentives, this could translate to direct financial benefits for vehicle owners or fleet operators.

Maintenance costs may also be reduced in the long term. Closed-loop systems can help prevent engine damage caused by improper air-fuel mixtures, potentially extending engine life and reducing the frequency of major repairs. However, it's important to note that the additional sensors and electronic components may introduce new potential points of failure, which could offset some of these savings.

From a performance perspective, closed-loop control can enhance engine responsiveness and power output consistency across various operating conditions. This improvement in drivability and performance can contribute to customer satisfaction and potentially higher resale values, though these benefits are more challenging to quantify directly.

The return on investment (ROI) for implementing closed-loop control varies depending on factors such as vehicle usage patterns, fuel prices, and local emissions regulations. For high-mileage applications or in areas with strict emissions standards, the payback period can be relatively short, potentially within 2-3 years. However, for low-mileage or specialized applications, the cost recovery may take longer or may not be fully realized in financial terms alone.

In conclusion, while the upfront costs of implementing closed-loop control in LS engines are significant, the long-term benefits in fuel efficiency, emissions reduction, and potentially reduced maintenance costs present a compelling case for adoption, particularly in markets with stringent environmental regulations or high fuel costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!