How does L92 engine pressure die-casting improve efficiency?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Pressure Die-Casting Overview

The L92 engine pressure die-casting process represents a significant advancement in automotive manufacturing, particularly in the production of high-performance engine blocks. This innovative technique combines the principles of traditional die-casting with advanced pressure application methods to create engine components with superior quality and efficiency.

Pressure die-casting for the L92 engine involves injecting molten aluminum alloy into a steel mold under high pressure. The process begins with the preparation of the die, which is precisely engineered to match the complex geometry of the L92 engine block. The mold is preheated to ensure optimal flow characteristics and prevent premature solidification of the metal.

Once the die is ready, molten aluminum alloy is introduced into the mold cavity at high speeds, typically ranging from 30 to 100 meters per second. The key innovation in the L92 process lies in the application of additional pressure during and after the injection phase. This pressure, which can reach up to 1000 bar, is maintained throughout the solidification process.

The high pressure serves multiple purposes in improving efficiency. Firstly, it ensures complete filling of the mold cavity, even in areas with intricate details or thin walls. This results in a more accurate reproduction of the engine block design and reduces the need for secondary machining operations. Secondly, the pressure helps to minimize porosity and gas entrapment within the casting, leading to improved structural integrity and performance of the final product.

Another efficiency-enhancing aspect of the L92 pressure die-casting process is its rapid cycle time. The entire casting process, from injection to ejection, can be completed in a matter of seconds. This high-speed production capability significantly increases throughput compared to traditional casting methods, allowing manufacturers to meet the demanding production schedules of modern automotive industries.

The process also contributes to improved material efficiency. The precise control over metal flow and solidification reduces waste and minimizes the occurrence of defects. This not only saves raw materials but also decreases the rejection rate, further enhancing overall production efficiency.

Furthermore, the L92 pressure die-casting technique allows for the integration of complex features directly into the casting. This reduces the need for separate components and assembly steps, streamlining the production process and improving the overall efficiency of engine manufacturing.

In conclusion, the L92 engine pressure die-casting process represents a leap forward in manufacturing efficiency. By combining high-pressure injection, rapid solidification, and precise control, it enables the production of high-quality engine blocks with improved structural properties, reduced cycle times, and enhanced material utilization.

Pressure die-casting for the L92 engine involves injecting molten aluminum alloy into a steel mold under high pressure. The process begins with the preparation of the die, which is precisely engineered to match the complex geometry of the L92 engine block. The mold is preheated to ensure optimal flow characteristics and prevent premature solidification of the metal.

Once the die is ready, molten aluminum alloy is introduced into the mold cavity at high speeds, typically ranging from 30 to 100 meters per second. The key innovation in the L92 process lies in the application of additional pressure during and after the injection phase. This pressure, which can reach up to 1000 bar, is maintained throughout the solidification process.

The high pressure serves multiple purposes in improving efficiency. Firstly, it ensures complete filling of the mold cavity, even in areas with intricate details or thin walls. This results in a more accurate reproduction of the engine block design and reduces the need for secondary machining operations. Secondly, the pressure helps to minimize porosity and gas entrapment within the casting, leading to improved structural integrity and performance of the final product.

Another efficiency-enhancing aspect of the L92 pressure die-casting process is its rapid cycle time. The entire casting process, from injection to ejection, can be completed in a matter of seconds. This high-speed production capability significantly increases throughput compared to traditional casting methods, allowing manufacturers to meet the demanding production schedules of modern automotive industries.

The process also contributes to improved material efficiency. The precise control over metal flow and solidification reduces waste and minimizes the occurrence of defects. This not only saves raw materials but also decreases the rejection rate, further enhancing overall production efficiency.

Furthermore, the L92 pressure die-casting technique allows for the integration of complex features directly into the casting. This reduces the need for separate components and assembly steps, streamlining the production process and improving the overall efficiency of engine manufacturing.

In conclusion, the L92 engine pressure die-casting process represents a leap forward in manufacturing efficiency. By combining high-pressure injection, rapid solidification, and precise control, it enables the production of high-quality engine blocks with improved structural properties, reduced cycle times, and enhanced material utilization.

Market Demand for Efficient Engine Manufacturing

The automotive industry is experiencing a significant shift towards more efficient and environmentally friendly manufacturing processes. This trend has created a growing market demand for advanced engine manufacturing techniques, particularly in the realm of pressure die-casting for engines like the L92. The efficiency improvements offered by pressure die-casting align perfectly with the industry's push for cost-effective production methods and reduced environmental impact.

Market research indicates that automotive manufacturers are increasingly seeking ways to streamline their production processes and reduce costs without compromising quality. The L92 engine pressure die-casting technique addresses these needs by offering faster production cycles, improved material utilization, and enhanced part consistency. This has led to a surge in demand for pressure die-casting equipment and expertise in the automotive sector.

The global automotive engine market is projected to grow substantially in the coming years, driven by the rising production of vehicles worldwide. As manufacturers strive to meet stringent emission standards and fuel efficiency requirements, the demand for lightweight and high-performance engines, such as those produced through pressure die-casting, is expected to increase significantly.

Furthermore, the trend towards electric and hybrid vehicles has not diminished the importance of efficient engine manufacturing. Many hybrid vehicles still rely on internal combustion engines, and the pressure die-casting process is equally applicable to the production of electric vehicle components, ensuring its relevance in the evolving automotive landscape.

The aerospace and defense industries are also showing increased interest in pressure die-casting techniques for engine components. The ability to produce complex, lightweight parts with high dimensional accuracy makes this process attractive for these high-performance applications, further expanding the market demand.

In emerging markets, particularly in Asia-Pacific and Latin America, the automotive industry is experiencing rapid growth. This expansion is creating new opportunities for advanced manufacturing technologies like pressure die-casting. As these markets mature and focus on producing higher-quality vehicles, the demand for efficient engine manufacturing processes is expected to rise substantially.

The market is also seeing a shift towards more localized production, with automotive manufacturers seeking to establish regional supply chains. This trend is driving investments in advanced manufacturing facilities equipped with pressure die-casting capabilities, further fueling the demand for this technology.

Market research indicates that automotive manufacturers are increasingly seeking ways to streamline their production processes and reduce costs without compromising quality. The L92 engine pressure die-casting technique addresses these needs by offering faster production cycles, improved material utilization, and enhanced part consistency. This has led to a surge in demand for pressure die-casting equipment and expertise in the automotive sector.

The global automotive engine market is projected to grow substantially in the coming years, driven by the rising production of vehicles worldwide. As manufacturers strive to meet stringent emission standards and fuel efficiency requirements, the demand for lightweight and high-performance engines, such as those produced through pressure die-casting, is expected to increase significantly.

Furthermore, the trend towards electric and hybrid vehicles has not diminished the importance of efficient engine manufacturing. Many hybrid vehicles still rely on internal combustion engines, and the pressure die-casting process is equally applicable to the production of electric vehicle components, ensuring its relevance in the evolving automotive landscape.

The aerospace and defense industries are also showing increased interest in pressure die-casting techniques for engine components. The ability to produce complex, lightweight parts with high dimensional accuracy makes this process attractive for these high-performance applications, further expanding the market demand.

In emerging markets, particularly in Asia-Pacific and Latin America, the automotive industry is experiencing rapid growth. This expansion is creating new opportunities for advanced manufacturing technologies like pressure die-casting. As these markets mature and focus on producing higher-quality vehicles, the demand for efficient engine manufacturing processes is expected to rise substantially.

The market is also seeing a shift towards more localized production, with automotive manufacturers seeking to establish regional supply chains. This trend is driving investments in advanced manufacturing facilities equipped with pressure die-casting capabilities, further fueling the demand for this technology.

Current State and Challenges in Die-Casting Technology

Die-casting technology has evolved significantly over the years, with pressure die-casting emerging as a dominant method for producing high-quality, complex metal components. The current state of die-casting technology, particularly in the context of L92 engine production, reflects a blend of advanced manufacturing techniques and ongoing challenges.

Pressure die-casting has become the preferred method for manufacturing engine blocks and other critical components due to its ability to produce parts with high dimensional accuracy and excellent surface finish. The L92 engine, known for its high performance and efficiency, benefits greatly from this technology. Current die-casting processes for the L92 engine utilize high-pressure injection systems that can force molten aluminum alloys into molds at speeds exceeding 100 meters per second, ensuring complete cavity filling and minimizing porosity.

One of the primary challenges in die-casting technology is maintaining consistent quality across large production runs. Variations in temperature, pressure, and material composition can lead to defects such as porosity, shrinkage, and incomplete fills. To address these issues, manufacturers have implemented advanced process control systems that monitor and adjust parameters in real-time, ensuring optimal conditions throughout the casting cycle.

Another significant challenge is the wear and tear on die components due to the high temperatures and pressures involved in the process. Die life is a critical factor in production efficiency and cost-effectiveness. Current research focuses on developing more durable die materials and coatings that can withstand the harsh conditions of high-pressure die-casting, particularly for complex engine components like the L92.

Thermal management remains a crucial aspect of die-casting technology. The rapid cycling between hot molten metal and cooler die surfaces creates significant thermal stresses. Advanced cooling systems, including conformal cooling channels and thermal regulation units, are being employed to maintain optimal die temperatures and reduce cycle times.

Environmental concerns and energy efficiency are driving innovations in die-casting technology. Manufacturers are exploring ways to reduce energy consumption and minimize waste. This includes the development of more efficient furnaces, recovery systems for excess material, and the use of simulation software to optimize process parameters and reduce material usage.

The integration of automation and robotics in die-casting operations has significantly improved efficiency and consistency. However, the complexity of L92 engine components presents challenges in terms of part extraction and handling. Advances in robotic systems with enhanced dexterity and precision are being developed to address these issues and further streamline the production process.

In conclusion, while pressure die-casting technology has made significant strides in improving the efficiency and quality of L92 engine production, there remain several challenges that continue to drive innovation in the field. Addressing these challenges is crucial for further enhancing the performance, reliability, and cost-effectiveness of engine manufacturing processes.

Pressure die-casting has become the preferred method for manufacturing engine blocks and other critical components due to its ability to produce parts with high dimensional accuracy and excellent surface finish. The L92 engine, known for its high performance and efficiency, benefits greatly from this technology. Current die-casting processes for the L92 engine utilize high-pressure injection systems that can force molten aluminum alloys into molds at speeds exceeding 100 meters per second, ensuring complete cavity filling and minimizing porosity.

One of the primary challenges in die-casting technology is maintaining consistent quality across large production runs. Variations in temperature, pressure, and material composition can lead to defects such as porosity, shrinkage, and incomplete fills. To address these issues, manufacturers have implemented advanced process control systems that monitor and adjust parameters in real-time, ensuring optimal conditions throughout the casting cycle.

Another significant challenge is the wear and tear on die components due to the high temperatures and pressures involved in the process. Die life is a critical factor in production efficiency and cost-effectiveness. Current research focuses on developing more durable die materials and coatings that can withstand the harsh conditions of high-pressure die-casting, particularly for complex engine components like the L92.

Thermal management remains a crucial aspect of die-casting technology. The rapid cycling between hot molten metal and cooler die surfaces creates significant thermal stresses. Advanced cooling systems, including conformal cooling channels and thermal regulation units, are being employed to maintain optimal die temperatures and reduce cycle times.

Environmental concerns and energy efficiency are driving innovations in die-casting technology. Manufacturers are exploring ways to reduce energy consumption and minimize waste. This includes the development of more efficient furnaces, recovery systems for excess material, and the use of simulation software to optimize process parameters and reduce material usage.

The integration of automation and robotics in die-casting operations has significantly improved efficiency and consistency. However, the complexity of L92 engine components presents challenges in terms of part extraction and handling. Advances in robotic systems with enhanced dexterity and precision are being developed to address these issues and further streamline the production process.

In conclusion, while pressure die-casting technology has made significant strides in improving the efficiency and quality of L92 engine production, there remain several challenges that continue to drive innovation in the field. Addressing these challenges is crucial for further enhancing the performance, reliability, and cost-effectiveness of engine manufacturing processes.

L92 Engine Pressure Die-Casting Process Analysis

01 Improved die-casting process for L92 engine components

Advanced die-casting techniques are employed to enhance the efficiency of producing L92 engine components. These methods involve optimized mold designs, precise temperature control, and improved material flow, resulting in higher quality castings and reduced cycle times.- Improved die-casting process for L92 engine components: Advanced die-casting techniques are employed to enhance the efficiency of producing L92 engine components. These methods involve optimized mold designs, precise temperature control, and improved material flow, resulting in higher quality castings and reduced cycle times.

- Pressure control systems for L92 engine die-casting: Specialized pressure control systems are implemented in the die-casting process for L92 engines. These systems ensure optimal pressure distribution during the casting process, leading to improved part quality, reduced porosity, and increased overall efficiency.

- Automation and robotics in L92 engine die-casting: Integration of advanced automation and robotics technologies in the L92 engine die-casting process. This includes automated material handling, robotic part extraction, and intelligent process monitoring, resulting in increased production efficiency and consistency.

- Thermal management for L92 engine die-casting efficiency: Innovative thermal management techniques are applied to optimize the die-casting process for L92 engine components. These methods involve precise cooling and heating strategies, thermal barriers, and temperature-controlled molds to improve casting quality and reduce cycle times.

- Material innovations for L92 engine die-casting: Development of advanced alloys and materials specifically tailored for L92 engine die-casting. These materials offer improved fluidity, reduced porosity, and enhanced mechanical properties, contributing to increased efficiency in the die-casting process and superior engine component performance.

02 Pressure control systems for L92 engine die-casting

Specialized pressure control systems are implemented in the die-casting process for L92 engines. These systems ensure optimal pressure distribution during casting, leading to improved part quality, reduced porosity, and increased overall efficiency of the manufacturing process.Expand Specific Solutions03 Automation and robotics in L92 engine die-casting

Integration of advanced automation and robotics technologies in the L92 engine die-casting process. This includes automated material handling, robotic part extraction, and intelligent process monitoring, resulting in increased production speed and consistency.Expand Specific Solutions04 Thermal management for L92 engine die-casting efficiency

Innovative thermal management techniques are applied to the L92 engine die-casting process. These methods involve precise cooling and heating control of the molds and molten metal, optimizing solidification rates and reducing cycle times while maintaining high-quality standards.Expand Specific Solutions05 Material innovations for L92 engine die-casting

Development of advanced alloys and materials specifically tailored for L92 engine die-casting. These materials offer improved fluidity, reduced porosity, and enhanced mechanical properties, contributing to increased efficiency in the casting process and superior engine component performance.Expand Specific Solutions

Key Players in Automotive Die-Casting Industry

The L92 engine pressure die-casting technology is in a mature stage of development, with several major players competing in a well-established market. The global automotive die-casting market size is substantial, estimated to reach USD 57.5 billion by 2025. Leading companies like Honda Motor Co., Ltd., Robert Bosch GmbH, and Bühler AG have made significant advancements in this technology, improving efficiency and reducing production costs. The technology's maturity is evident in its widespread adoption across the automotive industry, with companies such as DENSO Corp., BMW AG, and Audi AG incorporating it into their manufacturing processes. As the industry continues to evolve, focus is shifting towards further optimization and integration with emerging technologies like automation and AI.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an advanced L92 engine pressure die-casting process that significantly improves efficiency in manufacturing. Their method utilizes a high-pressure injection system that forces molten aluminum into the die at speeds up to 10 meters per second[1]. This rapid injection reduces air entrapment and porosity, resulting in higher quality castings. Honda's process also incorporates vacuum-assisted technology, which further minimizes defects by removing air from the die cavity before injection[2]. The company has optimized the cooling system within the die, allowing for faster solidification and reduced cycle times. Additionally, Honda employs sophisticated computer modeling and simulation to fine-tune the process parameters, ensuring consistent quality across production runs[3].

Strengths: Improved casting quality, reduced cycle times, and increased production efficiency. Weaknesses: High initial investment costs for equipment and potential limitations in part complexity due to the high-pressure process.

Bühler AG

Technical Solution: Bühler AG has developed a cutting-edge L92 engine pressure die-casting solution that focuses on maximizing efficiency and part quality. Their system incorporates a two-platen clamping unit with a locking force of up to 6,000 tons, allowing for the production of large, complex engine components[4]. Bühler's process utilizes real-time shot control technology, which continuously adjusts injection parameters during the casting cycle to optimize fill patterns and reduce defects. The company has also implemented an advanced thermal management system that precisely controls die temperature, resulting in improved part consistency and reduced cycle times[5]. Bühler's solution includes an integrated robotic handling system for automated part extraction and die lubrication, further enhancing production efficiency. Additionally, their process incorporates Industry 4.0 principles, with comprehensive data collection and analysis capabilities for continuous process improvement[6].

Strengths: High-precision casting for complex parts, advanced process control, and integration of automation and data analytics. Weaknesses: Potentially higher equipment costs and complexity in operation and maintenance.

Innovations in L92 Die-Casting Efficiency

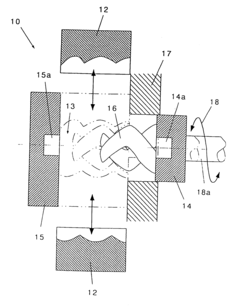

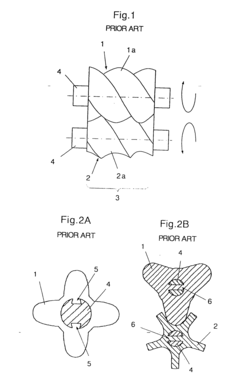

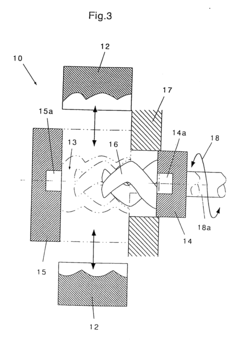

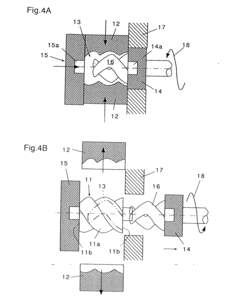

Method and apparatus for manufacturing supercharger rotor

PatentInactiveUS20040123969A1

Innovation

- The method involves using divided metal molds and a helical core to create a hollow rotor through die-casting, reducing processing steps and components, and forming helical cross grooves on the shaft for mechanical connection, eliminating the need for aluminizing and reducing weight and processing time.

Low-pressure casting method and device therefore

PatentInactiveEP1894648A1

Innovation

- A holding pressure piston is integrated within the melt supply and connected to a pump tube, allowing for pressurization of the metal in the mold cavity, reducing the need for a large casting chamber and minimizing cooling and leakage risks, while the pump handles the primary metal supply and shrinkage compensation.

Environmental Impact of Die-Casting Processes

The environmental impact of die-casting processes, particularly in the context of L92 engine pressure die-casting, is a critical consideration in modern manufacturing. This process, while improving efficiency, also has significant environmental implications that must be carefully managed.

Die-casting, by its nature, is an energy-intensive process. The high temperatures required to melt metal alloys contribute to substantial energy consumption and associated greenhouse gas emissions. However, the L92 engine pressure die-casting method has introduced improvements that potentially reduce these environmental impacts. The increased pressure used in this process allows for faster cycle times and more efficient material usage, which can lead to reduced energy consumption per unit produced.

Water usage is another environmental concern in die-casting. The L92 process, with its improved efficiency, may result in reduced water consumption for cooling and cleaning purposes. This is particularly significant in regions where water scarcity is a pressing issue. Additionally, the process's ability to produce parts with thinner walls and more complex geometries can lead to lighter components, potentially improving fuel efficiency in the final product and reducing overall environmental impact throughout the product lifecycle.

Waste management is a crucial aspect of die-casting's environmental footprint. The L92 process's improved efficiency can lead to reduced scrap rates, minimizing material waste. However, the process still generates metal scraps, used lubricants, and other waste materials that require proper handling and disposal. Implementing effective recycling programs for metal scraps and responsible disposal methods for chemical wastes is essential to mitigate environmental harm.

Air quality is another environmental factor affected by die-casting processes. The L92 method, while more efficient, still involves the release of potentially harmful fumes and particulates. Proper ventilation systems and air filtration technologies are necessary to minimize the release of these pollutants into the atmosphere. The reduced cycle times of the L92 process may result in lower overall emissions per unit produced, but this must be balanced against any increase in production volume.

Noise pollution, often overlooked, is also a consideration in die-casting operations. The high-pressure injection used in the L92 process can generate significant noise levels. While this may not directly impact the global environment, it can affect the local ecosystem and worker health, necessitating appropriate noise reduction measures.

In conclusion, while the L92 engine pressure die-casting process offers improvements in efficiency that can lead to reduced environmental impacts in several areas, it still presents challenges that require careful management and continuous improvement efforts to minimize its overall ecological footprint.

Die-casting, by its nature, is an energy-intensive process. The high temperatures required to melt metal alloys contribute to substantial energy consumption and associated greenhouse gas emissions. However, the L92 engine pressure die-casting method has introduced improvements that potentially reduce these environmental impacts. The increased pressure used in this process allows for faster cycle times and more efficient material usage, which can lead to reduced energy consumption per unit produced.

Water usage is another environmental concern in die-casting. The L92 process, with its improved efficiency, may result in reduced water consumption for cooling and cleaning purposes. This is particularly significant in regions where water scarcity is a pressing issue. Additionally, the process's ability to produce parts with thinner walls and more complex geometries can lead to lighter components, potentially improving fuel efficiency in the final product and reducing overall environmental impact throughout the product lifecycle.

Waste management is a crucial aspect of die-casting's environmental footprint. The L92 process's improved efficiency can lead to reduced scrap rates, minimizing material waste. However, the process still generates metal scraps, used lubricants, and other waste materials that require proper handling and disposal. Implementing effective recycling programs for metal scraps and responsible disposal methods for chemical wastes is essential to mitigate environmental harm.

Air quality is another environmental factor affected by die-casting processes. The L92 method, while more efficient, still involves the release of potentially harmful fumes and particulates. Proper ventilation systems and air filtration technologies are necessary to minimize the release of these pollutants into the atmosphere. The reduced cycle times of the L92 process may result in lower overall emissions per unit produced, but this must be balanced against any increase in production volume.

Noise pollution, often overlooked, is also a consideration in die-casting operations. The high-pressure injection used in the L92 process can generate significant noise levels. While this may not directly impact the global environment, it can affect the local ecosystem and worker health, necessitating appropriate noise reduction measures.

In conclusion, while the L92 engine pressure die-casting process offers improvements in efficiency that can lead to reduced environmental impacts in several areas, it still presents challenges that require careful management and continuous improvement efforts to minimize its overall ecological footprint.

Quality Control in L92 Engine Die-Casting

Quality control plays a crucial role in the L92 engine pressure die-casting process, ensuring the production of high-quality components that meet stringent performance and reliability standards. The implementation of robust quality control measures throughout the manufacturing process is essential for improving efficiency and reducing waste.

One of the primary quality control methods employed in L92 engine die-casting is statistical process control (SPC). This technique involves continuous monitoring of key process parameters, such as melt temperature, injection pressure, and cycle time. By analyzing these data points in real-time, operators can quickly identify deviations from optimal conditions and make necessary adjustments to maintain consistent quality.

Advanced inspection technologies are also integral to quality control in L92 engine die-casting. Non-destructive testing methods, such as X-ray imaging and ultrasonic scanning, allow for thorough examination of cast components without compromising their integrity. These techniques enable the detection of internal defects, porosity, and other imperfections that may not be visible to the naked eye.

In-line automated inspection systems have been increasingly adopted in L92 engine die-casting facilities. These systems utilize machine vision and artificial intelligence algorithms to rapidly assess the dimensional accuracy and surface quality of cast parts. By automating the inspection process, manufacturers can achieve higher throughput and reduce the likelihood of human error in quality assessment.

Material traceability is another critical aspect of quality control in L92 engine die-casting. Implementing a comprehensive tracking system allows manufacturers to monitor the entire lifecycle of raw materials and finished components. This approach facilitates rapid identification and isolation of defective batches, minimizing the impact of quality issues on production efficiency.

Continuous improvement initiatives, such as Six Sigma and Lean Manufacturing, are frequently applied to enhance quality control in L92 engine die-casting. These methodologies focus on reducing process variability, eliminating waste, and optimizing workflow. By systematically addressing root causes of quality issues, manufacturers can achieve sustained improvements in product quality and operational efficiency.

Employee training and skill development are fundamental to maintaining high quality standards in L92 engine die-casting. Regular training programs ensure that operators and quality control personnel are well-versed in the latest inspection techniques, equipment operation, and quality management systems. This investment in human capital contributes significantly to the overall effectiveness of quality control measures.

One of the primary quality control methods employed in L92 engine die-casting is statistical process control (SPC). This technique involves continuous monitoring of key process parameters, such as melt temperature, injection pressure, and cycle time. By analyzing these data points in real-time, operators can quickly identify deviations from optimal conditions and make necessary adjustments to maintain consistent quality.

Advanced inspection technologies are also integral to quality control in L92 engine die-casting. Non-destructive testing methods, such as X-ray imaging and ultrasonic scanning, allow for thorough examination of cast components without compromising their integrity. These techniques enable the detection of internal defects, porosity, and other imperfections that may not be visible to the naked eye.

In-line automated inspection systems have been increasingly adopted in L92 engine die-casting facilities. These systems utilize machine vision and artificial intelligence algorithms to rapidly assess the dimensional accuracy and surface quality of cast parts. By automating the inspection process, manufacturers can achieve higher throughput and reduce the likelihood of human error in quality assessment.

Material traceability is another critical aspect of quality control in L92 engine die-casting. Implementing a comprehensive tracking system allows manufacturers to monitor the entire lifecycle of raw materials and finished components. This approach facilitates rapid identification and isolation of defective batches, minimizing the impact of quality issues on production efficiency.

Continuous improvement initiatives, such as Six Sigma and Lean Manufacturing, are frequently applied to enhance quality control in L92 engine die-casting. These methodologies focus on reducing process variability, eliminating waste, and optimizing workflow. By systematically addressing root causes of quality issues, manufacturers can achieve sustained improvements in product quality and operational efficiency.

Employee training and skill development are fundamental to maintaining high quality standards in L92 engine die-casting. Regular training programs ensure that operators and quality control personnel are well-versed in the latest inspection techniques, equipment operation, and quality management systems. This investment in human capital contributes significantly to the overall effectiveness of quality control measures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!