Smart sensors integration in L92 engine systems

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Smart Sensors: Background and Objectives

The integration of smart sensors in L92 engine systems represents a significant advancement in automotive technology, marking a new era in engine management and performance optimization. This technological evolution builds upon decades of progress in engine design and control systems, with the L92 engine serving as a prime platform for showcasing these innovations.

The L92 engine, known for its high performance and efficiency, has been a cornerstone in General Motors' lineup since its introduction in the mid-2000s. As automotive technology has progressed, the demand for more sophisticated engine management systems has grown exponentially. This demand has driven the development and integration of smart sensors, which aim to enhance engine performance, fuel efficiency, and overall reliability.

The primary objective of incorporating smart sensors into the L92 engine system is to achieve real-time, precise monitoring and control of various engine parameters. These sensors are designed to collect and process data on critical factors such as temperature, pressure, fuel mixture, and exhaust emissions. By providing accurate and timely information, smart sensors enable the engine control unit (ECU) to make instantaneous adjustments, optimizing engine performance under varying operating conditions.

Another key goal is to improve diagnostic capabilities. Smart sensors can detect subtle changes in engine behavior, potentially identifying issues before they escalate into major problems. This predictive maintenance approach can significantly reduce downtime and repair costs, enhancing the overall reliability and longevity of the engine.

Furthermore, the integration of smart sensors aligns with the broader trend of vehicle electrification and the push towards more environmentally friendly transportation solutions. By enabling more precise control over engine operations, these sensors contribute to reducing emissions and improving fuel efficiency, helping manufacturers meet increasingly stringent environmental regulations.

The development of smart sensors for the L92 engine system also reflects the growing importance of data-driven decision-making in automotive engineering. The vast amount of data collected by these sensors can be analyzed to inform future engine designs, identify areas for improvement, and tailor engine performance to specific user needs or driving conditions.

As we look towards the future, the integration of smart sensors in L92 engine systems sets the stage for further advancements in engine technology. This includes the potential for AI-driven engine management systems, enhanced connectivity with other vehicle systems, and even predictive algorithms that can anticipate and adapt to changing driving conditions or driver preferences.

The L92 engine, known for its high performance and efficiency, has been a cornerstone in General Motors' lineup since its introduction in the mid-2000s. As automotive technology has progressed, the demand for more sophisticated engine management systems has grown exponentially. This demand has driven the development and integration of smart sensors, which aim to enhance engine performance, fuel efficiency, and overall reliability.

The primary objective of incorporating smart sensors into the L92 engine system is to achieve real-time, precise monitoring and control of various engine parameters. These sensors are designed to collect and process data on critical factors such as temperature, pressure, fuel mixture, and exhaust emissions. By providing accurate and timely information, smart sensors enable the engine control unit (ECU) to make instantaneous adjustments, optimizing engine performance under varying operating conditions.

Another key goal is to improve diagnostic capabilities. Smart sensors can detect subtle changes in engine behavior, potentially identifying issues before they escalate into major problems. This predictive maintenance approach can significantly reduce downtime and repair costs, enhancing the overall reliability and longevity of the engine.

Furthermore, the integration of smart sensors aligns with the broader trend of vehicle electrification and the push towards more environmentally friendly transportation solutions. By enabling more precise control over engine operations, these sensors contribute to reducing emissions and improving fuel efficiency, helping manufacturers meet increasingly stringent environmental regulations.

The development of smart sensors for the L92 engine system also reflects the growing importance of data-driven decision-making in automotive engineering. The vast amount of data collected by these sensors can be analyzed to inform future engine designs, identify areas for improvement, and tailor engine performance to specific user needs or driving conditions.

As we look towards the future, the integration of smart sensors in L92 engine systems sets the stage for further advancements in engine technology. This includes the potential for AI-driven engine management systems, enhanced connectivity with other vehicle systems, and even predictive algorithms that can anticipate and adapt to changing driving conditions or driver preferences.

Market Analysis for Smart Engine Systems

The market for smart engine systems, particularly those integrating advanced sensors in L92 engines, is experiencing significant growth and transformation. This trend is driven by the increasing demand for more efficient, reliable, and environmentally friendly automotive solutions. The global automotive sensor market, which includes smart sensors for engine systems, is projected to reach a substantial value in the coming years, with a compound annual growth rate outpacing many other automotive components.

The integration of smart sensors in L92 engine systems addresses several key market needs. Firstly, there is a growing emphasis on fuel efficiency and emissions reduction, driven by stringent environmental regulations and consumer preferences for eco-friendly vehicles. Smart sensors enable real-time monitoring and optimization of engine performance, leading to improved fuel economy and reduced emissions. This aligns with the global push towards sustainable transportation solutions.

Secondly, the market is witnessing an increased focus on vehicle safety and reliability. Smart sensors in engine systems provide critical data for predictive maintenance, allowing for early detection of potential issues and reducing the risk of unexpected breakdowns. This capability is particularly valuable in commercial and fleet applications, where vehicle downtime can result in significant financial losses.

The automotive industry's shift towards electrification and hybridization is also influencing the market for smart engine systems. While traditional internal combustion engines like the L92 remain prevalent, there is a growing need for sensors that can seamlessly integrate with hybrid powertrains. This trend is creating new opportunities for sensor manufacturers and system integrators to develop solutions that bridge the gap between conventional and electrified propulsion systems.

In terms of regional market dynamics, North America and Europe are currently leading in the adoption of smart sensor technologies for engine systems. This is largely due to the presence of major automotive manufacturers and stringent emissions regulations in these regions. However, the Asia-Pacific market is expected to show the fastest growth rate in the coming years, driven by the rapid expansion of the automotive industry in countries like China and India.

The market for smart sensors in L92 engine systems is characterized by intense competition and rapid technological advancements. Key players in this space are investing heavily in research and development to create more sophisticated, compact, and cost-effective sensor solutions. There is a particular focus on developing sensors with enhanced durability and accuracy under extreme engine conditions, as well as improving their integration with advanced engine control units.

Looking ahead, the market for smart engine systems is expected to continue its growth trajectory. Factors such as the increasing complexity of engine designs, the rise of connected and autonomous vehicles, and the ongoing push for improved performance and efficiency will drive further innovation in sensor technologies. As these systems become more advanced, they will play an increasingly critical role in enabling the next generation of intelligent, efficient, and environmentally friendly vehicles.

The integration of smart sensors in L92 engine systems addresses several key market needs. Firstly, there is a growing emphasis on fuel efficiency and emissions reduction, driven by stringent environmental regulations and consumer preferences for eco-friendly vehicles. Smart sensors enable real-time monitoring and optimization of engine performance, leading to improved fuel economy and reduced emissions. This aligns with the global push towards sustainable transportation solutions.

Secondly, the market is witnessing an increased focus on vehicle safety and reliability. Smart sensors in engine systems provide critical data for predictive maintenance, allowing for early detection of potential issues and reducing the risk of unexpected breakdowns. This capability is particularly valuable in commercial and fleet applications, where vehicle downtime can result in significant financial losses.

The automotive industry's shift towards electrification and hybridization is also influencing the market for smart engine systems. While traditional internal combustion engines like the L92 remain prevalent, there is a growing need for sensors that can seamlessly integrate with hybrid powertrains. This trend is creating new opportunities for sensor manufacturers and system integrators to develop solutions that bridge the gap between conventional and electrified propulsion systems.

In terms of regional market dynamics, North America and Europe are currently leading in the adoption of smart sensor technologies for engine systems. This is largely due to the presence of major automotive manufacturers and stringent emissions regulations in these regions. However, the Asia-Pacific market is expected to show the fastest growth rate in the coming years, driven by the rapid expansion of the automotive industry in countries like China and India.

The market for smart sensors in L92 engine systems is characterized by intense competition and rapid technological advancements. Key players in this space are investing heavily in research and development to create more sophisticated, compact, and cost-effective sensor solutions. There is a particular focus on developing sensors with enhanced durability and accuracy under extreme engine conditions, as well as improving their integration with advanced engine control units.

Looking ahead, the market for smart engine systems is expected to continue its growth trajectory. Factors such as the increasing complexity of engine designs, the rise of connected and autonomous vehicles, and the ongoing push for improved performance and efficiency will drive further innovation in sensor technologies. As these systems become more advanced, they will play an increasingly critical role in enabling the next generation of intelligent, efficient, and environmentally friendly vehicles.

Current State and Challenges in L92 Smart Sensor Integration

The integration of smart sensors in L92 engine systems represents a significant advancement in engine technology, offering enhanced performance, efficiency, and reliability. Currently, the L92 engine system incorporates a range of smart sensors, including temperature sensors, pressure sensors, and position sensors, which provide real-time data on various engine parameters.

One of the primary challenges in smart sensor integration for L92 engines is the need for miniaturization and durability. As engine compartments become more compact, sensors must be designed to fit into increasingly tight spaces while withstanding harsh operating conditions, including high temperatures, vibrations, and exposure to various fluids and contaminants.

Another significant challenge is the development of robust communication protocols and data processing capabilities. The L92 engine system requires seamless integration of multiple sensors, necessitating efficient data transmission and interpretation. Current efforts focus on implementing advanced networking technologies, such as CAN (Controller Area Network) and FlexRay, to ensure reliable and high-speed data exchange between sensors and the engine control unit (ECU).

The accuracy and reliability of sensor measurements remain critical challenges in L92 smart sensor integration. Ensuring precise readings across a wide range of operating conditions is essential for optimal engine performance and emissions control. Ongoing research aims to improve sensor calibration techniques and develop self-diagnostic capabilities to maintain measurement accuracy over time.

Power management and energy efficiency pose additional challenges in smart sensor integration. As the number of sensors in the L92 engine system increases, so does the overall power consumption. Developing low-power sensors and implementing intelligent power management strategies are crucial to minimize the impact on the vehicle's electrical system and fuel efficiency.

Cybersecurity concerns have also emerged as a significant challenge in smart sensor integration. As engine systems become more connected and reliant on digital technologies, protecting against potential cyber threats and ensuring the integrity of sensor data have become paramount. Implementing robust encryption and authentication mechanisms is essential to safeguard the L92 engine system against unauthorized access and data manipulation.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms in smart sensor systems presents both opportunities and challenges. While these technologies offer the potential for advanced predictive maintenance and performance optimization, their implementation requires significant computational resources and careful validation to ensure reliability in safety-critical applications.

Lastly, the standardization of sensor interfaces and communication protocols across different vehicle models and manufacturers remains a challenge. Efforts are underway to develop industry-wide standards that facilitate interoperability and reduce development costs, but achieving consensus among stakeholders is an ongoing process.

One of the primary challenges in smart sensor integration for L92 engines is the need for miniaturization and durability. As engine compartments become more compact, sensors must be designed to fit into increasingly tight spaces while withstanding harsh operating conditions, including high temperatures, vibrations, and exposure to various fluids and contaminants.

Another significant challenge is the development of robust communication protocols and data processing capabilities. The L92 engine system requires seamless integration of multiple sensors, necessitating efficient data transmission and interpretation. Current efforts focus on implementing advanced networking technologies, such as CAN (Controller Area Network) and FlexRay, to ensure reliable and high-speed data exchange between sensors and the engine control unit (ECU).

The accuracy and reliability of sensor measurements remain critical challenges in L92 smart sensor integration. Ensuring precise readings across a wide range of operating conditions is essential for optimal engine performance and emissions control. Ongoing research aims to improve sensor calibration techniques and develop self-diagnostic capabilities to maintain measurement accuracy over time.

Power management and energy efficiency pose additional challenges in smart sensor integration. As the number of sensors in the L92 engine system increases, so does the overall power consumption. Developing low-power sensors and implementing intelligent power management strategies are crucial to minimize the impact on the vehicle's electrical system and fuel efficiency.

Cybersecurity concerns have also emerged as a significant challenge in smart sensor integration. As engine systems become more connected and reliant on digital technologies, protecting against potential cyber threats and ensuring the integrity of sensor data have become paramount. Implementing robust encryption and authentication mechanisms is essential to safeguard the L92 engine system against unauthorized access and data manipulation.

The integration of artificial intelligence (AI) and machine learning (ML) algorithms in smart sensor systems presents both opportunities and challenges. While these technologies offer the potential for advanced predictive maintenance and performance optimization, their implementation requires significant computational resources and careful validation to ensure reliability in safety-critical applications.

Lastly, the standardization of sensor interfaces and communication protocols across different vehicle models and manufacturers remains a challenge. Efforts are underway to develop industry-wide standards that facilitate interoperability and reduce development costs, but achieving consensus among stakeholders is an ongoing process.

Existing Smart Sensor Solutions for L92 Engines

01 Environmental monitoring and sensing

Smart sensors are utilized for environmental monitoring, capable of detecting various parameters such as temperature, humidity, air quality, and pollution levels. These sensors can be integrated into IoT systems for real-time data collection and analysis, enabling better environmental management and decision-making.- Smart sensor systems for environmental monitoring: Advanced sensor systems designed for monitoring various environmental parameters such as air quality, water pollution, and climate conditions. These systems often incorporate multiple sensors, data processing capabilities, and wireless communication for real-time monitoring and analysis.

- Wearable smart sensors for health monitoring: Innovative wearable devices equipped with smart sensors to track vital signs, physical activity, and other health-related metrics. These sensors can provide continuous monitoring and early detection of potential health issues, improving preventive care and personalized medicine.

- Smart sensors for industrial automation and IoT: Intelligent sensor technologies integrated into industrial processes and Internet of Things (IoT) ecosystems. These sensors enable predictive maintenance, process optimization, and enhanced efficiency in manufacturing and other industrial applications.

- Smart sensors for autonomous vehicles and transportation: Advanced sensing technologies designed for use in autonomous vehicles and smart transportation systems. These sensors include LiDAR, radar, and camera systems that enable vehicle navigation, obstacle detection, and improved road safety.

- Energy-efficient and self-powered smart sensors: Innovative sensor designs that focus on minimizing power consumption or harvesting energy from their environment. These sensors can operate for extended periods without external power sources, making them ideal for remote or hard-to-reach locations.

02 Wearable health monitoring devices

Smart sensors are incorporated into wearable devices for continuous health monitoring. These sensors can track vital signs, physical activity, sleep patterns, and other health-related metrics. The data collected can be used for personal health management and remote patient monitoring in healthcare settings.Expand Specific Solutions03 Industrial automation and process control

Smart sensors play a crucial role in industrial automation and process control applications. They can monitor equipment performance, detect anomalies, and optimize manufacturing processes. These sensors enable predictive maintenance, improve efficiency, and enhance overall productivity in industrial settings.Expand Specific Solutions04 Smart home and building management

Smart sensors are integrated into home and building automation systems to enhance energy efficiency, security, and comfort. These sensors can control lighting, temperature, and security systems based on occupancy and environmental conditions, leading to improved energy management and user experience.Expand Specific Solutions05 Automotive and transportation applications

Smart sensors are extensively used in automotive and transportation systems for various applications such as advanced driver assistance systems (ADAS), vehicle diagnostics, and traffic management. These sensors improve safety, efficiency, and performance in transportation infrastructure and vehicles.Expand Specific Solutions

Key Players in Automotive Sensor Industry

The integration of smart sensors in L92 engine systems represents a rapidly evolving technological landscape within the automotive industry. This field is currently in a growth phase, with increasing market demand driven by the push for more efficient and intelligent vehicle systems. The global market for automotive smart sensors is expanding, with projections indicating significant growth in the coming years. Technologically, the maturity varies among key players. Companies like Robert Bosch GmbH, DENSO Corp., and Continental AG (through Vitesco Technologies) are at the forefront, leveraging their extensive automotive expertise to develop advanced sensor solutions. Other major automakers such as Honda, Renault, and Ford are also actively investing in this technology, indicating its strategic importance across the industry.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced smart sensor integration system for L92 engine systems. Their solution incorporates a network of intelligent sensors that communicate with a central Engine Control Unit (ECU) using a high-speed CAN-FD bus. These sensors include advanced knock sensors, temperature sensors, and pressure sensors that provide real-time data for optimal engine performance[1]. The system utilizes machine learning algorithms to adapt to changing engine conditions and driver behavior, continuously optimizing fuel efficiency and emissions control[3]. Bosch's smart sensors also feature built-in diagnostics capabilities, allowing for predictive maintenance and reducing downtime[5]. The integration of these sensors with Bosch's proprietary software enables precise control of fuel injection timing, ignition timing, and valve actuation, resulting in improved engine efficiency and reduced emissions[7].

Strengths: Comprehensive sensor network, advanced data processing capabilities, and seamless integration with ECU. Weaknesses: Potentially higher initial cost and complexity in implementation compared to traditional sensor systems.

DENSO Corp.

Technical Solution: DENSO Corp. has developed a cutting-edge smart sensor integration system for L92 engine applications. Their solution incorporates a suite of highly sensitive MEMS-based sensors, including accelerometers, gyroscopes, and pressure sensors, all integrated into a compact, modular package[2]. DENSO's system utilizes advanced signal processing techniques and AI algorithms to filter out noise and provide highly accurate engine performance data[4]. The sensors are designed with built-in self-calibration capabilities, ensuring long-term reliability and accuracy. DENSO's smart sensor network communicates via a robust, automotive-grade Ethernet network, allowing for high-speed data transmission and real-time engine management[6]. The system also incorporates edge computing capabilities, enabling some data processing to occur directly at the sensor level, reducing the load on the central ECU and improving overall system responsiveness[8].

Strengths: High accuracy and reliability, advanced signal processing, and modular design for easy integration. Weaknesses: May require specialized training for maintenance personnel due to the advanced technology used.

Core Innovations in Engine Sensor Integration

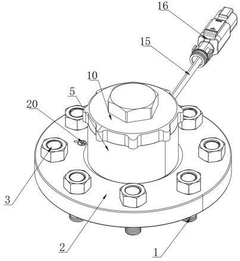

Intelligent monitoring flange

PatentActiveCN221915751U

Innovation

- Design an intelligent monitoring flange that integrates temperature, pressure and liquid level sensors. It uses equal-length double-headed studs and nuts to connect the flange and the cylinder. It has built-in radar sensors, pressure sensors and temperature sensors, and uses cable interfaces and explosion-proof sleeves. Pipe connection to achieve non-contact liquid level measurement and multi-function sensor integration.

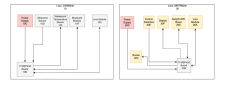

A lora-connected device enabling real-time data transmission, proactive maintenance, and enhanced operational safety for diesel-electric locomotive engine cooling water

PatentPendingIN202311082107A

Innovation

- A LoRa-connected device system comprising Loco_CWSMote and Loco_MNTRMote, where Loco_CWSMote monitors engine cooling water parameters within the locomotive and transmits data via LoRa to Loco_MNTRMote, which processes and alerts maintenance teams through a web dashboard, enabling proactive maintenance and real-time monitoring.

Environmental Impact of Smart Engine Systems

The integration of smart sensors in L92 engine systems has significant implications for environmental sustainability. These advanced sensor networks enable real-time monitoring and optimization of engine performance, leading to reduced fuel consumption and emissions. By continuously adjusting engine parameters based on operating conditions, smart sensors help maintain optimal combustion efficiency, minimizing the release of harmful pollutants.

One of the key environmental benefits of smart engine systems is their ability to enhance fuel economy. Through precise control of fuel injection timing, air-fuel mixture, and ignition timing, these systems can achieve substantial improvements in fuel efficiency. This not only reduces the overall carbon footprint of vehicles equipped with L92 engines but also contributes to the conservation of fossil fuel resources.

Smart sensors also play a crucial role in emissions reduction. By providing accurate data on exhaust gas composition, temperature, and pressure, these sensors enable advanced emission control strategies. This includes more effective operation of catalytic converters and particulate filters, ensuring that harmful pollutants are minimized before being released into the atmosphere.

Furthermore, the integration of smart sensors allows for predictive maintenance and early detection of potential issues. This proactive approach helps prevent catastrophic engine failures that could lead to sudden increases in emissions or oil leaks, which can have severe environmental consequences. By maintaining optimal engine health, these systems extend the operational life of engines, reducing the need for premature replacements and the associated environmental impact of manufacturing new engines.

The environmental benefits of smart engine systems extend beyond direct emissions reduction. These systems contribute to the development of more efficient and environmentally friendly transportation solutions. For instance, the data collected by smart sensors can be used to optimize route planning and driving behavior, further reducing fuel consumption and emissions in real-world driving conditions.

In the broader context of environmental sustainability, smart sensor integration in L92 engine systems aligns with global efforts to combat climate change and improve air quality. As regulations on vehicle emissions become increasingly stringent, these advanced systems provide a technological pathway for meeting and exceeding environmental standards without compromising performance.

One of the key environmental benefits of smart engine systems is their ability to enhance fuel economy. Through precise control of fuel injection timing, air-fuel mixture, and ignition timing, these systems can achieve substantial improvements in fuel efficiency. This not only reduces the overall carbon footprint of vehicles equipped with L92 engines but also contributes to the conservation of fossil fuel resources.

Smart sensors also play a crucial role in emissions reduction. By providing accurate data on exhaust gas composition, temperature, and pressure, these sensors enable advanced emission control strategies. This includes more effective operation of catalytic converters and particulate filters, ensuring that harmful pollutants are minimized before being released into the atmosphere.

Furthermore, the integration of smart sensors allows for predictive maintenance and early detection of potential issues. This proactive approach helps prevent catastrophic engine failures that could lead to sudden increases in emissions or oil leaks, which can have severe environmental consequences. By maintaining optimal engine health, these systems extend the operational life of engines, reducing the need for premature replacements and the associated environmental impact of manufacturing new engines.

The environmental benefits of smart engine systems extend beyond direct emissions reduction. These systems contribute to the development of more efficient and environmentally friendly transportation solutions. For instance, the data collected by smart sensors can be used to optimize route planning and driving behavior, further reducing fuel consumption and emissions in real-world driving conditions.

In the broader context of environmental sustainability, smart sensor integration in L92 engine systems aligns with global efforts to combat climate change and improve air quality. As regulations on vehicle emissions become increasingly stringent, these advanced systems provide a technological pathway for meeting and exceeding environmental standards without compromising performance.

Cybersecurity in Connected Engine Technologies

As connected engine technologies continue to evolve, cybersecurity has become a critical concern in the automotive industry. The integration of smart sensors and advanced connectivity features in L92 engine systems has opened up new vulnerabilities that malicious actors could potentially exploit. To address these challenges, automotive manufacturers and suppliers are implementing multi-layered security approaches.

One key aspect of cybersecurity in connected engine technologies is the protection of communication channels between sensors, control units, and external systems. Encryption protocols, such as Transport Layer Security (TLS) and Secure Sockets Layer (SSL), are widely employed to safeguard data transmission. Additionally, authentication mechanisms are implemented to ensure that only authorized devices and systems can access sensitive engine data and control functions.

Intrusion detection and prevention systems (IDPS) are being integrated into connected engine ecosystems to monitor network traffic and identify potential security threats in real-time. These systems utilize machine learning algorithms to detect anomalies and patterns that may indicate malicious activities, allowing for rapid response and mitigation of security breaches.

Secure over-the-air (OTA) update capabilities are becoming increasingly important in maintaining the cybersecurity of connected engine technologies. OTA updates enable manufacturers to quickly address vulnerabilities and deploy security patches without requiring physical access to the vehicle. However, these update mechanisms themselves must be secured to prevent unauthorized modifications or the introduction of malware.

Hardware security modules (HSMs) are being incorporated into engine control units to provide a secure environment for cryptographic operations and storage of sensitive data. These tamper-resistant modules offer protection against physical attacks and help maintain the integrity of critical engine systems.

The automotive industry is also focusing on developing secure software development practices and conducting rigorous security testing throughout the product lifecycle. This includes vulnerability assessments, penetration testing, and code reviews to identify and address potential security weaknesses before they can be exploited.

Collaboration between automotive manufacturers, suppliers, and cybersecurity experts is crucial in addressing the evolving threat landscape. Industry-wide initiatives, such as the Automotive Information Sharing and Analysis Center (Auto-ISAC), facilitate the sharing of cybersecurity intelligence and best practices among stakeholders.

As connected engine technologies continue to advance, cybersecurity measures must evolve to keep pace with emerging threats. The integration of artificial intelligence and blockchain technologies shows promise in enhancing the security and resilience of connected engine systems, paving the way for safer and more secure automotive experiences in the future.

One key aspect of cybersecurity in connected engine technologies is the protection of communication channels between sensors, control units, and external systems. Encryption protocols, such as Transport Layer Security (TLS) and Secure Sockets Layer (SSL), are widely employed to safeguard data transmission. Additionally, authentication mechanisms are implemented to ensure that only authorized devices and systems can access sensitive engine data and control functions.

Intrusion detection and prevention systems (IDPS) are being integrated into connected engine ecosystems to monitor network traffic and identify potential security threats in real-time. These systems utilize machine learning algorithms to detect anomalies and patterns that may indicate malicious activities, allowing for rapid response and mitigation of security breaches.

Secure over-the-air (OTA) update capabilities are becoming increasingly important in maintaining the cybersecurity of connected engine technologies. OTA updates enable manufacturers to quickly address vulnerabilities and deploy security patches without requiring physical access to the vehicle. However, these update mechanisms themselves must be secured to prevent unauthorized modifications or the introduction of malware.

Hardware security modules (HSMs) are being incorporated into engine control units to provide a secure environment for cryptographic operations and storage of sensitive data. These tamper-resistant modules offer protection against physical attacks and help maintain the integrity of critical engine systems.

The automotive industry is also focusing on developing secure software development practices and conducting rigorous security testing throughout the product lifecycle. This includes vulnerability assessments, penetration testing, and code reviews to identify and address potential security weaknesses before they can be exploited.

Collaboration between automotive manufacturers, suppliers, and cybersecurity experts is crucial in addressing the evolving threat landscape. Industry-wide initiatives, such as the Automotive Information Sharing and Analysis Center (Auto-ISAC), facilitate the sharing of cybersecurity intelligence and best practices among stakeholders.

As connected engine technologies continue to advance, cybersecurity measures must evolve to keep pace with emerging threats. The integration of artificial intelligence and blockchain technologies shows promise in enhancing the security and resilience of connected engine systems, paving the way for safer and more secure automotive experiences in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!