L92 engine's impact on supply chain and logistics operations

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Background and Objectives

The L92 engine, a revolutionary powertrain technology, has emerged as a significant player in the automotive industry, with far-reaching implications for supply chain and logistics operations. This advanced engine design represents a culmination of years of research and development, aimed at addressing the growing demands for improved fuel efficiency, reduced emissions, and enhanced performance in modern vehicles.

The evolution of the L92 engine can be traced back to the early 2000s when automotive manufacturers began intensifying their efforts to meet increasingly stringent environmental regulations while simultaneously satisfying consumer expectations for powerful and responsive vehicles. This technological progression has been marked by continuous improvements in materials science, combustion efficiency, and electronic control systems.

The primary objectives driving the development and implementation of the L92 engine include optimizing fuel consumption, minimizing environmental impact, and maximizing power output. These goals align closely with global initiatives to reduce carbon emissions and promote sustainable transportation solutions, making the L92 engine a critical component in the automotive industry's strategy to adapt to changing market demands and regulatory landscapes.

From a supply chain perspective, the introduction of the L92 engine has necessitated significant adjustments in procurement strategies, manufacturing processes, and distribution networks. The engine's complex design and advanced components have created new challenges and opportunities for suppliers, requiring them to invest in cutting-edge technologies and develop specialized expertise to meet the exacting specifications of this innovative powertrain.

The impact of the L92 engine on logistics operations has been equally profound. Its unique characteristics have influenced everything from inventory management to transportation planning. The engine's compact design and improved efficiency have implications for vehicle packaging and fuel consumption during transport, potentially leading to more cost-effective and environmentally friendly logistics solutions.

As the automotive industry continues to evolve, the L92 engine stands as a testament to the sector's commitment to innovation and sustainability. Its development and integration into vehicle platforms have set new benchmarks for performance and efficiency, driving competition and spurring further advancements in engine technology. The ongoing refinement of the L92 engine and its variants is expected to play a crucial role in shaping the future of automotive propulsion systems and, by extension, the entire automotive supply chain ecosystem.

The evolution of the L92 engine can be traced back to the early 2000s when automotive manufacturers began intensifying their efforts to meet increasingly stringent environmental regulations while simultaneously satisfying consumer expectations for powerful and responsive vehicles. This technological progression has been marked by continuous improvements in materials science, combustion efficiency, and electronic control systems.

The primary objectives driving the development and implementation of the L92 engine include optimizing fuel consumption, minimizing environmental impact, and maximizing power output. These goals align closely with global initiatives to reduce carbon emissions and promote sustainable transportation solutions, making the L92 engine a critical component in the automotive industry's strategy to adapt to changing market demands and regulatory landscapes.

From a supply chain perspective, the introduction of the L92 engine has necessitated significant adjustments in procurement strategies, manufacturing processes, and distribution networks. The engine's complex design and advanced components have created new challenges and opportunities for suppliers, requiring them to invest in cutting-edge technologies and develop specialized expertise to meet the exacting specifications of this innovative powertrain.

The impact of the L92 engine on logistics operations has been equally profound. Its unique characteristics have influenced everything from inventory management to transportation planning. The engine's compact design and improved efficiency have implications for vehicle packaging and fuel consumption during transport, potentially leading to more cost-effective and environmentally friendly logistics solutions.

As the automotive industry continues to evolve, the L92 engine stands as a testament to the sector's commitment to innovation and sustainability. Its development and integration into vehicle platforms have set new benchmarks for performance and efficiency, driving competition and spurring further advancements in engine technology. The ongoing refinement of the L92 engine and its variants is expected to play a crucial role in shaping the future of automotive propulsion systems and, by extension, the entire automotive supply chain ecosystem.

Market Demand Analysis for L92 Engine

The L92 engine, a high-performance V8 engine developed by General Motors, has sparked significant interest in the automotive market. This advanced powertrain solution has created a notable demand shift in the supply chain and logistics operations of the automotive industry. The market for L92 engines has shown robust growth, driven by the increasing consumer preference for powerful and efficient vehicles.

In the passenger vehicle segment, there is a growing demand for SUVs and high-performance cars equipped with L92 engines. This trend is particularly evident in North America and Europe, where consumers value the combination of power and fuel efficiency offered by the L92 engine. The aftermarket sector has also seen a surge in demand for L92 engines as enthusiasts seek to upgrade their vehicles for improved performance.

The commercial vehicle sector presents another significant market for L92 engines. Fleet operators and logistics companies are increasingly recognizing the benefits of L92-powered vehicles in terms of fuel economy and durability. This has led to a rise in orders for trucks and vans equipped with L92 engines, particularly in long-haul transportation and delivery services.

The adoption of L92 engines has had a ripple effect on the automotive supply chain. Tier 1 and Tier 2 suppliers have experienced increased demand for components specific to the L92 engine, such as high-strength pistons, advanced fuel injection systems, and specialized cooling components. This has necessitated capacity expansions and technological upgrades in the supplier network to meet the growing market requirements.

Logistics operations have also been impacted by the L92 engine's market demand. The need for specialized transportation and handling of these high-performance engines has led to the development of new logistics solutions. Companies have invested in custom packaging, temperature-controlled transportation, and advanced tracking systems to ensure the safe and efficient delivery of L92 engines and related components.

The market demand for L92 engines has also influenced inventory management strategies across the supply chain. Manufacturers and distributors have had to adapt their forecasting models and stock levels to accommodate the fluctuating demand for these engines. Just-in-time manufacturing principles have been refined to ensure a steady supply of L92 engines while minimizing inventory costs.

As environmental regulations become more stringent, the market for L92 engines is expected to evolve. There is a growing demand for more fuel-efficient versions of the L92 engine, prompting research and development efforts to enhance its performance while reducing emissions. This trend is likely to shape the future market dynamics of L92 engines and their impact on supply chain and logistics operations.

In the passenger vehicle segment, there is a growing demand for SUVs and high-performance cars equipped with L92 engines. This trend is particularly evident in North America and Europe, where consumers value the combination of power and fuel efficiency offered by the L92 engine. The aftermarket sector has also seen a surge in demand for L92 engines as enthusiasts seek to upgrade their vehicles for improved performance.

The commercial vehicle sector presents another significant market for L92 engines. Fleet operators and logistics companies are increasingly recognizing the benefits of L92-powered vehicles in terms of fuel economy and durability. This has led to a rise in orders for trucks and vans equipped with L92 engines, particularly in long-haul transportation and delivery services.

The adoption of L92 engines has had a ripple effect on the automotive supply chain. Tier 1 and Tier 2 suppliers have experienced increased demand for components specific to the L92 engine, such as high-strength pistons, advanced fuel injection systems, and specialized cooling components. This has necessitated capacity expansions and technological upgrades in the supplier network to meet the growing market requirements.

Logistics operations have also been impacted by the L92 engine's market demand. The need for specialized transportation and handling of these high-performance engines has led to the development of new logistics solutions. Companies have invested in custom packaging, temperature-controlled transportation, and advanced tracking systems to ensure the safe and efficient delivery of L92 engines and related components.

The market demand for L92 engines has also influenced inventory management strategies across the supply chain. Manufacturers and distributors have had to adapt their forecasting models and stock levels to accommodate the fluctuating demand for these engines. Just-in-time manufacturing principles have been refined to ensure a steady supply of L92 engines while minimizing inventory costs.

As environmental regulations become more stringent, the market for L92 engines is expected to evolve. There is a growing demand for more fuel-efficient versions of the L92 engine, prompting research and development efforts to enhance its performance while reducing emissions. This trend is likely to shape the future market dynamics of L92 engines and their impact on supply chain and logistics operations.

L92 Engine Supply Chain Challenges

The introduction of the L92 engine has presented significant challenges to supply chain and logistics operations across the automotive industry. This advanced engine technology, while offering improved performance and efficiency, has necessitated substantial adjustments in manufacturing processes, inventory management, and distribution networks.

One of the primary challenges stems from the complexity of the L92 engine's components. The engine's sophisticated design requires a diverse array of specialized parts, many of which are sourced from different suppliers across various geographical locations. This complexity has led to an increased risk of supply chain disruptions, as any delay or issue with a single component can potentially halt the entire production line.

The just-in-time (JIT) inventory management system, widely adopted in the automotive industry, has been particularly strained by the L92 engine's requirements. The precision timing needed for the delivery of components has become more critical, with less room for error. This has put pressure on logistics providers to enhance their delivery accuracy and speed, often necessitating investments in advanced tracking and routing technologies.

Quality control has emerged as another significant challenge in the L92 engine supply chain. The engine's high-performance nature demands stringent quality standards for all components. This has led to the need for more rigorous inspection processes and potentially higher rejection rates, impacting both costs and production timelines.

The global nature of the L92 engine's supply chain has also introduced new complexities. With components sourced from multiple countries, issues such as trade regulations, customs procedures, and geopolitical tensions have become more prominent concerns. These factors can lead to unexpected delays and increased costs, requiring supply chain managers to develop more robust contingency plans and alternative sourcing strategies.

Furthermore, the introduction of the L92 engine has necessitated changes in warehousing and distribution strategies. The engine's unique specifications may require specialized handling and storage conditions, potentially leading to increased costs for climate-controlled facilities or custom packaging solutions. This has prompted a reevaluation of existing logistics infrastructure and the potential need for significant investments in new facilities or equipment.

The impact on workforce skills and training cannot be overlooked. The L92 engine's advanced technology requires specialized knowledge for handling, assembly, and maintenance. This has created a need for extensive training programs and the recruitment of skilled technicians, putting pressure on human resource departments and potentially leading to increased labor costs.

One of the primary challenges stems from the complexity of the L92 engine's components. The engine's sophisticated design requires a diverse array of specialized parts, many of which are sourced from different suppliers across various geographical locations. This complexity has led to an increased risk of supply chain disruptions, as any delay or issue with a single component can potentially halt the entire production line.

The just-in-time (JIT) inventory management system, widely adopted in the automotive industry, has been particularly strained by the L92 engine's requirements. The precision timing needed for the delivery of components has become more critical, with less room for error. This has put pressure on logistics providers to enhance their delivery accuracy and speed, often necessitating investments in advanced tracking and routing technologies.

Quality control has emerged as another significant challenge in the L92 engine supply chain. The engine's high-performance nature demands stringent quality standards for all components. This has led to the need for more rigorous inspection processes and potentially higher rejection rates, impacting both costs and production timelines.

The global nature of the L92 engine's supply chain has also introduced new complexities. With components sourced from multiple countries, issues such as trade regulations, customs procedures, and geopolitical tensions have become more prominent concerns. These factors can lead to unexpected delays and increased costs, requiring supply chain managers to develop more robust contingency plans and alternative sourcing strategies.

Furthermore, the introduction of the L92 engine has necessitated changes in warehousing and distribution strategies. The engine's unique specifications may require specialized handling and storage conditions, potentially leading to increased costs for climate-controlled facilities or custom packaging solutions. This has prompted a reevaluation of existing logistics infrastructure and the potential need for significant investments in new facilities or equipment.

The impact on workforce skills and training cannot be overlooked. The L92 engine's advanced technology requires specialized knowledge for handling, assembly, and maintenance. This has created a need for extensive training programs and the recruitment of skilled technicians, putting pressure on human resource departments and potentially leading to increased labor costs.

Current L92 Supply Chain Solutions

01 Engine design and configuration

The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and overall engine architecture to optimize power output and fuel economy.- Engine design and configuration: The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies such as variable valve timing and direct fuel injection. The engine's design focuses on optimizing power output, fuel economy, and emissions control.

- Fuel injection system: The L92 engine incorporates a sophisticated fuel injection system, likely utilizing direct injection technology. This system enhances fuel atomization and combustion efficiency, resulting in improved power output and reduced emissions. The fuel injection components are designed for precise control and optimal fuel delivery.

- Valve train and timing mechanism: Advanced valve train components and timing mechanisms are employed in the L92 engine. This may include variable valve timing systems, which allow for optimized engine performance across different operating conditions. The valve train design contributes to improved engine breathing and overall efficiency.

- Engine control and management systems: The L92 engine utilizes sophisticated engine control and management systems. These systems monitor and adjust various engine parameters to optimize performance, fuel efficiency, and emissions. Advanced sensors and electronic control units are likely employed to ensure precise engine operation.

- Emissions control technologies: Various emissions control technologies are integrated into the L92 engine design. These may include exhaust gas recirculation systems, catalytic converters, and other aftertreatment devices. The engine's combustion process and overall design are optimized to meet stringent emissions regulations while maintaining performance.

02 Fuel injection system

The L92 engine incorporates a sophisticated fuel injection system to enhance combustion efficiency and power delivery. This system may include direct injection technology or other advanced fuel delivery methods to improve engine performance and reduce emissions.Expand Specific Solutions03 Variable valve timing

Variable valve timing technology is implemented in the L92 engine to optimize engine performance across different operating conditions. This system allows for improved power output, fuel efficiency, and reduced emissions by adjusting valve timing based on engine speed and load.Expand Specific Solutions04 Engine management system

The L92 engine utilizes an advanced engine management system to control various aspects of engine operation. This system may include electronic control units, sensors, and actuators to optimize fuel injection, ignition timing, and other parameters for improved performance and efficiency.Expand Specific Solutions05 Exhaust system design

The exhaust system of the L92 engine is designed to enhance engine performance and reduce emissions. It may incorporate features such as catalytic converters, exhaust gas recirculation systems, or variable exhaust geometry to optimize engine breathing and meet emissions standards.Expand Specific Solutions

Key Players in L92 Engine Industry

The L92 engine's impact on supply chain and logistics operations is in a nascent stage, with the market still developing. The technology's maturity varies among key players, with established automotive giants like Toyota, Honda, and Hyundai leading the way. Emerging companies such as LiquidPiston are also making strides in innovative engine technologies. The market size is expected to grow as the industry shifts towards more efficient and environmentally friendly engines. This transition is likely to create new challenges and opportunities in supply chain management, requiring adaptations in logistics operations to accommodate the unique requirements of L92 engine production and distribution.

Honda Motor Co., Ltd.

Technical Solution: Honda's strategy for addressing the L92 engine's impact on supply chain and logistics operations focuses on flexibility and localization. The company has implemented a modular production system that allows for rapid reconfiguration of assembly lines to accommodate changes in L92 engine demand[10]. Honda has also invested in regional production hubs for L92 engines, reducing transportation costs and improving responsiveness to local market demands. The company utilizes advanced demand forecasting algorithms that incorporate machine learning to optimize inventory levels and production schedules for L92 engine components[11]. Furthermore, Honda has developed a collaborative platform that enables real-time information sharing with suppliers, improving coordination and reducing lead times in the L92 engine supply chain[12].

Strengths: Flexible production capabilities, improved local market responsiveness, and enhanced supplier collaboration. Weaknesses: Potential for increased complexity in managing multiple regional production hubs.

Toyota Motor Corp.

Technical Solution: Toyota's approach to managing the L92 engine's impact on supply chain and logistics operations is rooted in its renowned Toyota Production System (TPS) and Just-In-Time (JIT) philosophy. The company has adapted these principles to the specific requirements of L92 engine production, implementing a pull-based production system that minimizes inventory and reduces waste[7]. Toyota has also developed a sophisticated supplier management program that includes collaborative forecasting and capacity planning for L92 engine components. The company utilizes advanced IoT sensors and RFID technology to track L92 engine parts throughout the supply chain, enabling real-time inventory management and quality control[8]. Additionally, Toyota has invested in blockchain technology to enhance traceability and transparency in its L92 engine supply chain, improving supplier accountability and reducing the risk of counterfeit parts[9].

Strengths: Lean and efficient supply chain, strong supplier relationships, and enhanced traceability. Weaknesses: Potential vulnerability to supply chain disruptions due to low inventory levels.

L92 Engine Logistics Innovations

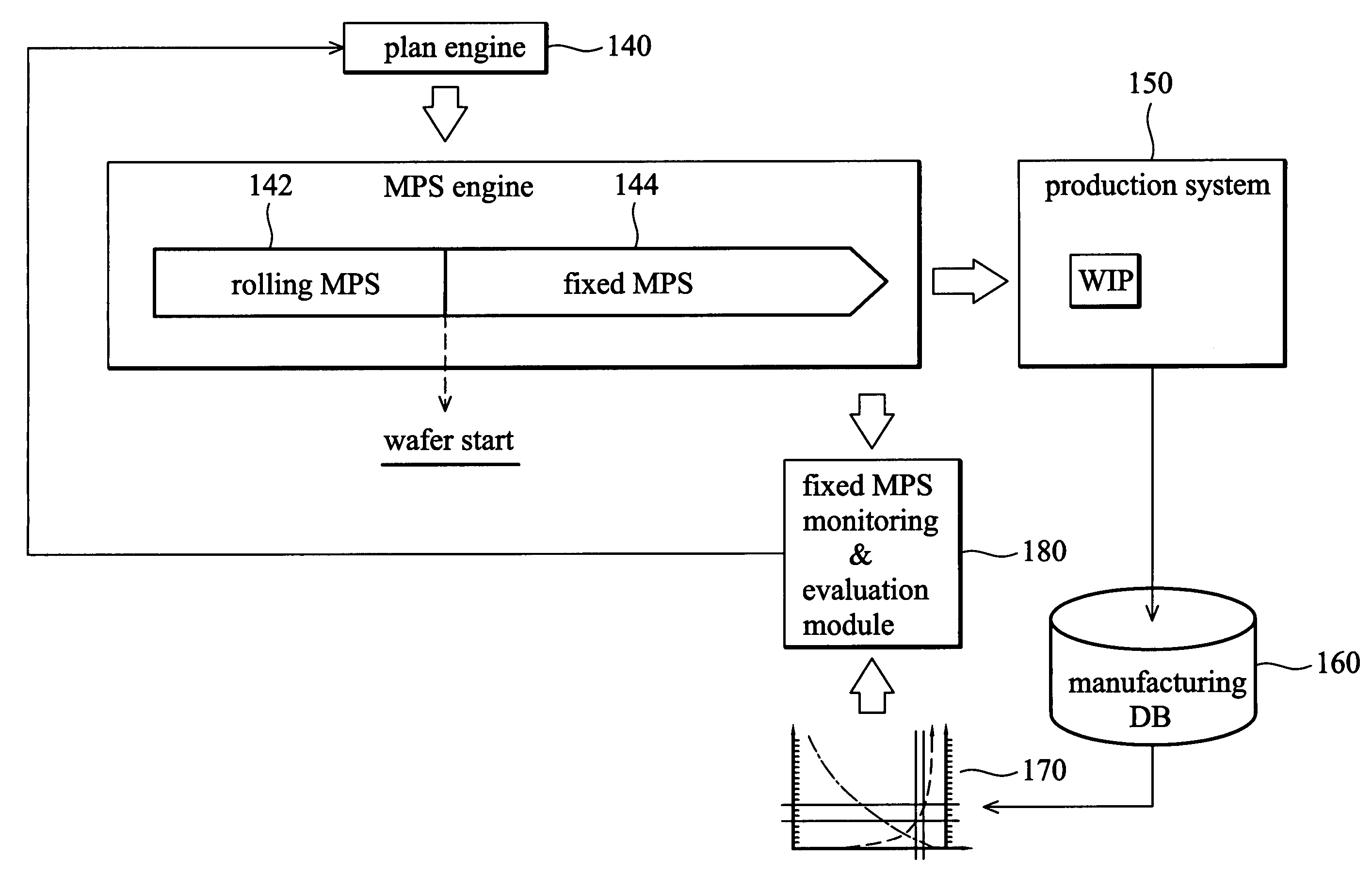

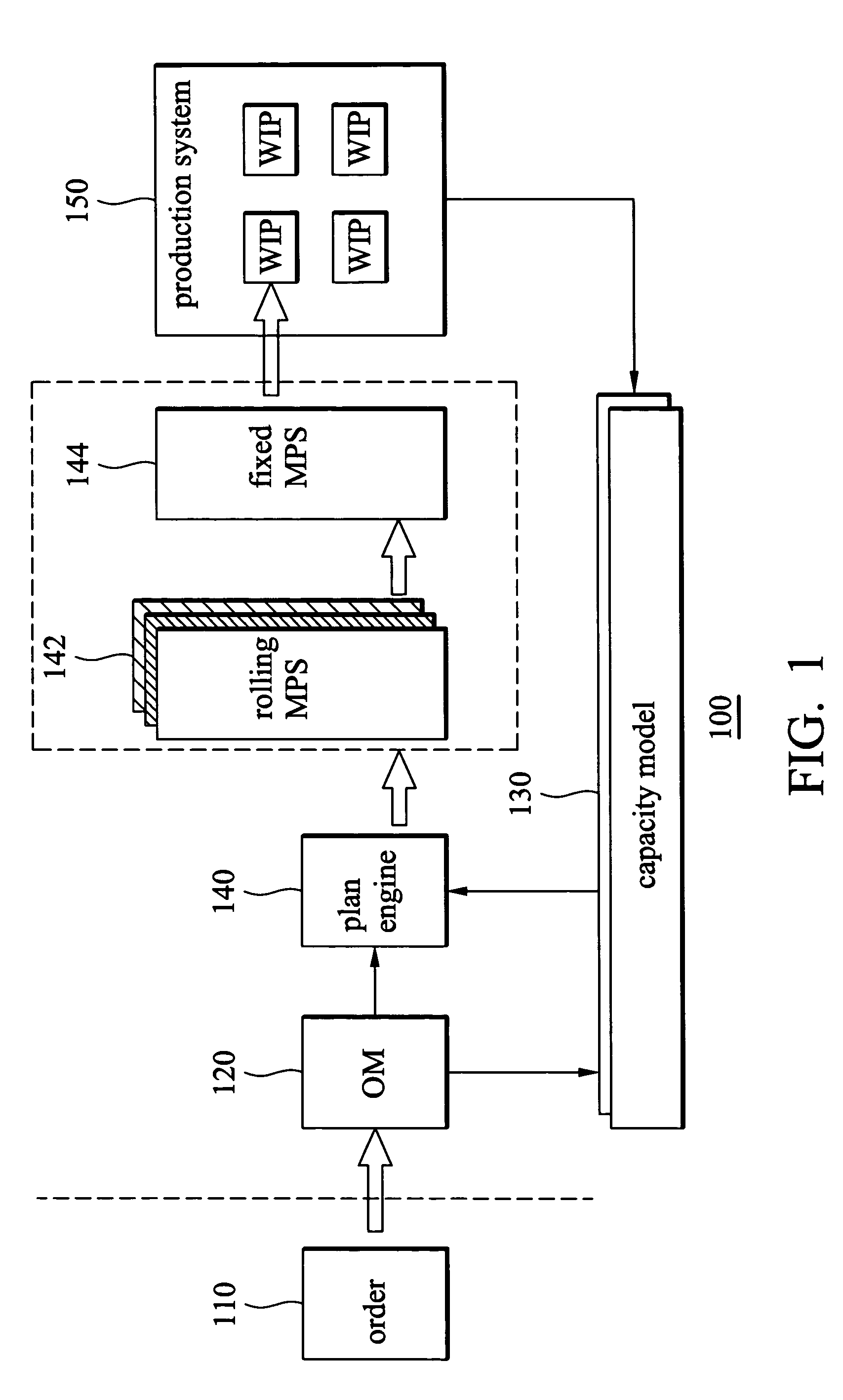

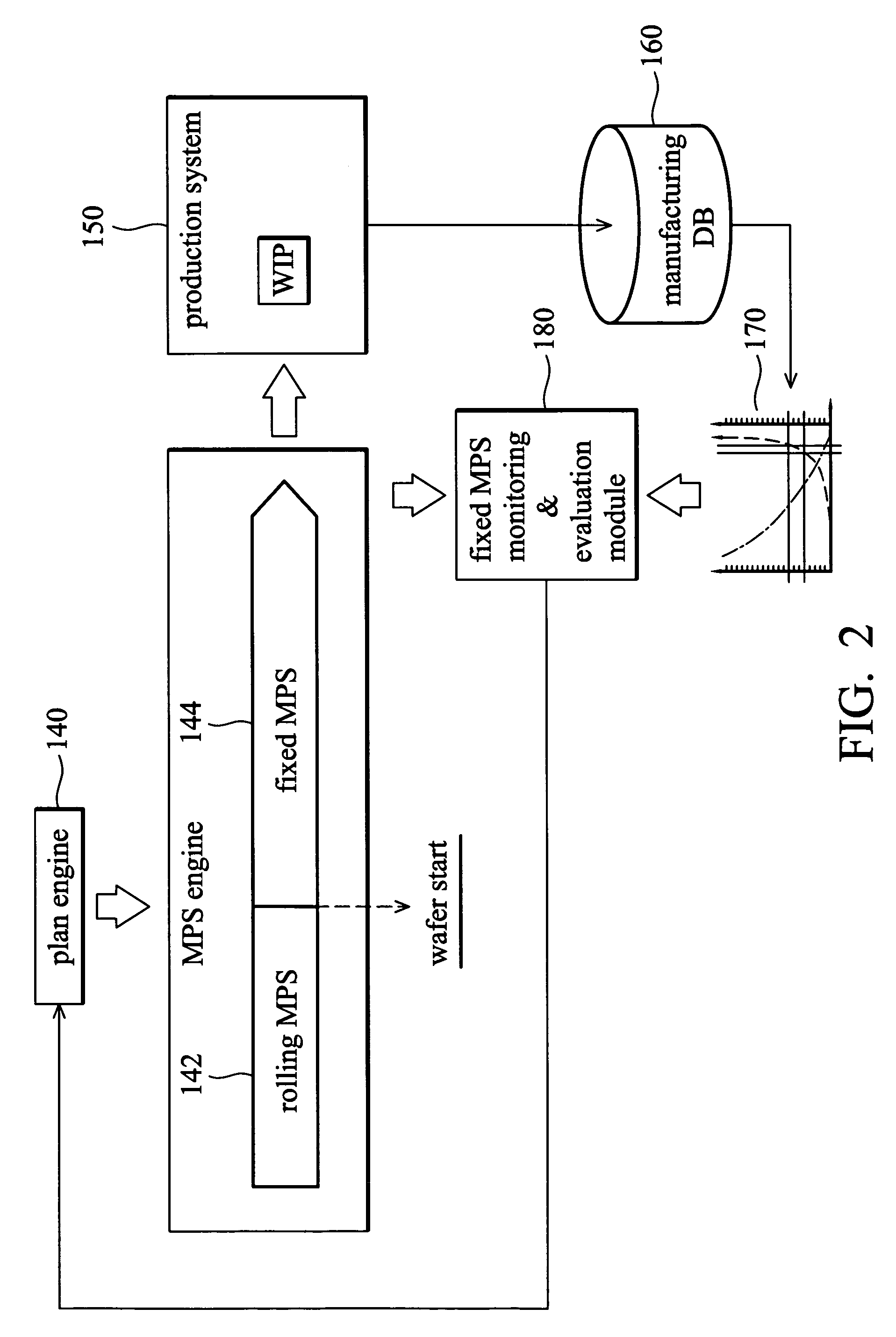

System and method for manufacturing planning and control

PatentInactiveUS7130707B2

Innovation

- A computer-implemented system and method that generates a fixed production schedule using a capacity model, monitors conformity with a statistical process control (SPC) method, and adjusts the schedule dynamically based on historical data to ensure on-time delivery and prioritize orders, thereby maintaining alignment between manufacturing plans and execution.

Hybrid cycle rotary engine

PatentWO2008016979A9

Innovation

- A hybrid cycle rotary engine design that includes a source of pressurized working medium, an expander with a housing, piston, intake and exhaust ports, and a septum, where the working chamber experiences constant volume combustion, and a controller operates fuel and air valves to manage the engine cycle, allowing for efficient mixing and ignition of the fuel-working medium mixture, and optional turbulence-inducing geometry to enhance mixing.

Environmental Impact of L92 Engine

The L92 engine, known for its advanced design and improved fuel efficiency, has significant environmental implications that extend beyond its immediate operational impact. This engine's design focuses on reducing emissions and improving overall environmental performance, aligning with increasingly stringent global environmental regulations.

One of the primary environmental benefits of the L92 engine is its reduced carbon footprint. The engine's improved combustion efficiency results in lower fuel consumption, directly translating to decreased carbon dioxide emissions. This reduction in greenhouse gas emissions contributes to mitigating climate change impacts, a critical concern in the automotive and transportation sectors.

The L92 engine also addresses other pollutants, such as nitrogen oxides (NOx) and particulate matter. Its advanced emission control systems, including catalytic converters and exhaust gas recirculation, effectively minimize these harmful emissions. This improvement in air quality has positive implications for public health, particularly in urban areas where vehicle emissions are a significant contributor to air pollution.

From a lifecycle perspective, the L92 engine's durability and longevity play a role in its environmental impact. The engine's robust design and high-quality materials contribute to an extended operational life, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines.

The engine's compatibility with alternative fuels, such as biofuels and synthetic fuels, further enhances its environmental credentials. This flexibility allows for the potential use of more sustainable fuel sources, reducing dependence on fossil fuels and supporting the transition to cleaner energy alternatives in the transportation sector.

However, the environmental impact of the L92 engine is not solely positive. The production process of these advanced engines may involve energy-intensive manufacturing techniques and the use of rare or precious metals in catalytic converters. These factors contribute to the engine's overall environmental footprint and must be considered in a comprehensive assessment.

The end-of-life considerations for the L92 engine also play a role in its environmental impact. The recyclability of engine components and the proper disposal of materials that cannot be recycled are important factors. Advancements in recycling technologies and circular economy principles are increasingly being applied to engine design and disposal, aiming to minimize waste and maximize resource recovery.

In conclusion, while the L92 engine represents a significant step forward in reducing the environmental impact of internal combustion engines, its overall environmental footprint must be evaluated across its entire lifecycle. The engine's contributions to reduced emissions and improved fuel efficiency are clear, but ongoing research and development are necessary to further minimize its environmental impact and align with global sustainability goals.

One of the primary environmental benefits of the L92 engine is its reduced carbon footprint. The engine's improved combustion efficiency results in lower fuel consumption, directly translating to decreased carbon dioxide emissions. This reduction in greenhouse gas emissions contributes to mitigating climate change impacts, a critical concern in the automotive and transportation sectors.

The L92 engine also addresses other pollutants, such as nitrogen oxides (NOx) and particulate matter. Its advanced emission control systems, including catalytic converters and exhaust gas recirculation, effectively minimize these harmful emissions. This improvement in air quality has positive implications for public health, particularly in urban areas where vehicle emissions are a significant contributor to air pollution.

From a lifecycle perspective, the L92 engine's durability and longevity play a role in its environmental impact. The engine's robust design and high-quality materials contribute to an extended operational life, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines.

The engine's compatibility with alternative fuels, such as biofuels and synthetic fuels, further enhances its environmental credentials. This flexibility allows for the potential use of more sustainable fuel sources, reducing dependence on fossil fuels and supporting the transition to cleaner energy alternatives in the transportation sector.

However, the environmental impact of the L92 engine is not solely positive. The production process of these advanced engines may involve energy-intensive manufacturing techniques and the use of rare or precious metals in catalytic converters. These factors contribute to the engine's overall environmental footprint and must be considered in a comprehensive assessment.

The end-of-life considerations for the L92 engine also play a role in its environmental impact. The recyclability of engine components and the proper disposal of materials that cannot be recycled are important factors. Advancements in recycling technologies and circular economy principles are increasingly being applied to engine design and disposal, aiming to minimize waste and maximize resource recovery.

In conclusion, while the L92 engine represents a significant step forward in reducing the environmental impact of internal combustion engines, its overall environmental footprint must be evaluated across its entire lifecycle. The engine's contributions to reduced emissions and improved fuel efficiency are clear, but ongoing research and development are necessary to further minimize its environmental impact and align with global sustainability goals.

L92 Engine Cost-Benefit Analysis

The cost-benefit analysis of the L92 engine reveals significant implications for supply chain and logistics operations. This advanced engine design offers improved fuel efficiency and performance, which translates to potential cost savings and operational advantages for businesses in the transportation sector.

From a supply chain perspective, the L92 engine's enhanced fuel efficiency can lead to reduced fuel consumption across the fleet. This translates to lower operating costs for logistics companies, potentially improving profit margins or allowing for more competitive pricing strategies. The improved fuel economy also contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals.

The engine's superior performance characteristics may enable faster transit times and increased payload capacity. This could result in more efficient route planning and higher throughput in logistics operations. Consequently, companies may be able to optimize their fleet size, potentially reducing the number of vehicles required to meet demand and lowering overall capital expenditure.

However, the initial investment in L92 engines may be higher compared to conventional alternatives. This upfront cost needs to be carefully weighed against the long-term operational savings. Additionally, the introduction of new engine technology may necessitate training for maintenance staff and updates to service protocols, incurring short-term costs but potentially leading to long-term efficiency gains in fleet maintenance.

The L92 engine's impact on supply chain resilience should also be considered. Its improved reliability could reduce the frequency of breakdowns and unscheduled maintenance, minimizing disruptions to supply chain operations. This increased uptime can lead to more consistent service delivery and improved customer satisfaction.

From a logistics standpoint, the L92 engine's performance characteristics may allow for more flexible routing options. This could enable companies to adapt more readily to changing market conditions or unexpected disruptions, enhancing overall supply chain agility.

The cost-benefit analysis should also account for potential impacts on inventory management. If the L92 engine enables faster transit times, it could lead to reduced inventory holding costs and improved cash flow. However, this may require adjustments to inventory planning and forecasting models to fully capitalize on the engine's capabilities.

In conclusion, while the L92 engine presents significant potential benefits for supply chain and logistics operations, a comprehensive cost-benefit analysis must consider both the immediate financial implications and the long-term strategic advantages. Companies must carefully evaluate their specific operational contexts and strategic objectives to determine the overall value proposition of adopting this advanced engine technology.

From a supply chain perspective, the L92 engine's enhanced fuel efficiency can lead to reduced fuel consumption across the fleet. This translates to lower operating costs for logistics companies, potentially improving profit margins or allowing for more competitive pricing strategies. The improved fuel economy also contributes to reduced carbon emissions, aligning with increasingly stringent environmental regulations and corporate sustainability goals.

The engine's superior performance characteristics may enable faster transit times and increased payload capacity. This could result in more efficient route planning and higher throughput in logistics operations. Consequently, companies may be able to optimize their fleet size, potentially reducing the number of vehicles required to meet demand and lowering overall capital expenditure.

However, the initial investment in L92 engines may be higher compared to conventional alternatives. This upfront cost needs to be carefully weighed against the long-term operational savings. Additionally, the introduction of new engine technology may necessitate training for maintenance staff and updates to service protocols, incurring short-term costs but potentially leading to long-term efficiency gains in fleet maintenance.

The L92 engine's impact on supply chain resilience should also be considered. Its improved reliability could reduce the frequency of breakdowns and unscheduled maintenance, minimizing disruptions to supply chain operations. This increased uptime can lead to more consistent service delivery and improved customer satisfaction.

From a logistics standpoint, the L92 engine's performance characteristics may allow for more flexible routing options. This could enable companies to adapt more readily to changing market conditions or unexpected disruptions, enhancing overall supply chain agility.

The cost-benefit analysis should also account for potential impacts on inventory management. If the L92 engine enables faster transit times, it could lead to reduced inventory holding costs and improved cash flow. However, this may require adjustments to inventory planning and forecasting models to fully capitalize on the engine's capabilities.

In conclusion, while the L92 engine presents significant potential benefits for supply chain and logistics operations, a comprehensive cost-benefit analysis must consider both the immediate financial implications and the long-term strategic advantages. Companies must carefully evaluate their specific operational contexts and strategic objectives to determine the overall value proposition of adopting this advanced engine technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!