Design considerations for L92 engine electric water pumps

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine EWP Background and Objectives

The L92 engine, a member of General Motors' Gen IV small-block V8 family, has been a cornerstone in high-performance vehicles since its introduction in 2006. As automotive technology advances, there is a growing trend towards electrification of vehicle components, including cooling systems. The electric water pump (EWP) represents a significant evolution in engine cooling technology, offering potential improvements in efficiency, performance, and emissions control.

The primary objective of integrating an electric water pump into the L92 engine is to enhance overall engine efficiency and performance. Traditional mechanical water pumps are directly driven by the engine, which results in parasitic power loss and reduced fuel economy. By transitioning to an electrically driven pump, the system can operate independently of engine speed, allowing for more precise control of coolant flow based on actual engine cooling needs.

Another key goal is to improve engine thermal management. The ability to control coolant flow electronically enables faster warm-up times, which is crucial for reducing emissions during cold starts. It also allows for more consistent engine operating temperatures across various driving conditions, potentially extending engine life and maintaining optimal performance.

Fuel efficiency improvement is a critical objective in the design of L92 engine electric water pumps. By eliminating the mechanical connection to the engine, the EWP can reduce the load on the engine, particularly at higher RPMs where traditional water pumps may overcirculate coolant. This can lead to measurable gains in fuel economy, especially in high-performance applications where the L92 engine is commonly used.

The integration of an EWP also aims to enhance the engine's power output. By freeing up the power previously used to drive the mechanical pump, more energy can be directed to the wheels. Additionally, the precise control of coolant flow can help maintain ideal operating temperatures under high-load conditions, potentially allowing for more aggressive tuning and increased power output.

Lastly, the move towards electric water pumps in the L92 engine aligns with broader industry trends towards vehicle electrification and increased electronic control of engine systems. This transition sets the stage for future advancements in engine technology, including the potential for integration with hybrid powertrains and advanced engine management systems. By developing expertise in EWP technology for the L92 engine, manufacturers can position themselves at the forefront of automotive innovation, ready to meet evolving market demands and regulatory requirements.

The primary objective of integrating an electric water pump into the L92 engine is to enhance overall engine efficiency and performance. Traditional mechanical water pumps are directly driven by the engine, which results in parasitic power loss and reduced fuel economy. By transitioning to an electrically driven pump, the system can operate independently of engine speed, allowing for more precise control of coolant flow based on actual engine cooling needs.

Another key goal is to improve engine thermal management. The ability to control coolant flow electronically enables faster warm-up times, which is crucial for reducing emissions during cold starts. It also allows for more consistent engine operating temperatures across various driving conditions, potentially extending engine life and maintaining optimal performance.

Fuel efficiency improvement is a critical objective in the design of L92 engine electric water pumps. By eliminating the mechanical connection to the engine, the EWP can reduce the load on the engine, particularly at higher RPMs where traditional water pumps may overcirculate coolant. This can lead to measurable gains in fuel economy, especially in high-performance applications where the L92 engine is commonly used.

The integration of an EWP also aims to enhance the engine's power output. By freeing up the power previously used to drive the mechanical pump, more energy can be directed to the wheels. Additionally, the precise control of coolant flow can help maintain ideal operating temperatures under high-load conditions, potentially allowing for more aggressive tuning and increased power output.

Lastly, the move towards electric water pumps in the L92 engine aligns with broader industry trends towards vehicle electrification and increased electronic control of engine systems. This transition sets the stage for future advancements in engine technology, including the potential for integration with hybrid powertrains and advanced engine management systems. By developing expertise in EWP technology for the L92 engine, manufacturers can position themselves at the forefront of automotive innovation, ready to meet evolving market demands and regulatory requirements.

Market Analysis for L92 Engine EWPs

The market for L92 engine electric water pumps (EWPs) is experiencing significant growth, driven by the automotive industry's shift towards more efficient and environmentally friendly technologies. As vehicle manufacturers strive to meet stringent emissions regulations and improve fuel economy, the demand for EWPs in high-performance engines like the L92 is on the rise.

The global automotive water pump market, which includes EWPs, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the increasing adoption of electric water pumps in premium and luxury vehicles, where the L92 engine is commonly used. The market for L92 engine EWPs specifically is expected to show strong growth, aligning with the broader trend of electrification in automotive systems.

One of the key drivers for the L92 engine EWP market is the push for improved engine thermal management. EWPs offer precise control over coolant flow, allowing for optimized engine temperatures and reduced parasitic losses compared to traditional mechanical pumps. This results in enhanced fuel efficiency and reduced emissions, which are critical factors for manufacturers looking to comply with evolving regulatory standards.

The aftermarket segment for L92 engine EWPs is also showing promise. As more vehicles equipped with L92 engines age, there is an increasing demand for replacement parts, including upgraded EWPs that offer better performance and efficiency than the original equipment.

Geographically, North America remains a significant market for L92 engine EWPs, given the popularity of high-performance V8 engines in the region. However, emerging markets in Asia-Pacific and Europe are also showing growing interest in these advanced cooling systems, particularly in the luxury and sports car segments.

The competitive landscape for L92 engine EWPs is characterized by a mix of established automotive suppliers and newer entrants specializing in electric pump technology. Major players are investing heavily in research and development to improve pump efficiency, durability, and integration with engine management systems.

Customer preferences are shifting towards vehicles with advanced technologies that offer better performance and fuel economy. This trend is favorable for the L92 engine EWP market, as these pumps contribute to both aspects. Additionally, the growing awareness of environmental issues among consumers is indirectly boosting the demand for more efficient engine components, including EWPs.

Looking ahead, the market for L92 engine EWPs is expected to continue its growth trajectory. Factors such as the increasing electrification of vehicle systems, the ongoing development of hybrid and electric powertrains, and the constant pursuit of engine efficiency improvements will likely sustain this market's expansion in the foreseeable future.

The global automotive water pump market, which includes EWPs, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the increasing adoption of electric water pumps in premium and luxury vehicles, where the L92 engine is commonly used. The market for L92 engine EWPs specifically is expected to show strong growth, aligning with the broader trend of electrification in automotive systems.

One of the key drivers for the L92 engine EWP market is the push for improved engine thermal management. EWPs offer precise control over coolant flow, allowing for optimized engine temperatures and reduced parasitic losses compared to traditional mechanical pumps. This results in enhanced fuel efficiency and reduced emissions, which are critical factors for manufacturers looking to comply with evolving regulatory standards.

The aftermarket segment for L92 engine EWPs is also showing promise. As more vehicles equipped with L92 engines age, there is an increasing demand for replacement parts, including upgraded EWPs that offer better performance and efficiency than the original equipment.

Geographically, North America remains a significant market for L92 engine EWPs, given the popularity of high-performance V8 engines in the region. However, emerging markets in Asia-Pacific and Europe are also showing growing interest in these advanced cooling systems, particularly in the luxury and sports car segments.

The competitive landscape for L92 engine EWPs is characterized by a mix of established automotive suppliers and newer entrants specializing in electric pump technology. Major players are investing heavily in research and development to improve pump efficiency, durability, and integration with engine management systems.

Customer preferences are shifting towards vehicles with advanced technologies that offer better performance and fuel economy. This trend is favorable for the L92 engine EWP market, as these pumps contribute to both aspects. Additionally, the growing awareness of environmental issues among consumers is indirectly boosting the demand for more efficient engine components, including EWPs.

Looking ahead, the market for L92 engine EWPs is expected to continue its growth trajectory. Factors such as the increasing electrification of vehicle systems, the ongoing development of hybrid and electric powertrains, and the constant pursuit of engine efficiency improvements will likely sustain this market's expansion in the foreseeable future.

EWP Technology Status and Challenges

Electric water pumps (EWPs) for L92 engines have seen significant advancements in recent years, yet they still face several technological challenges. The current state of EWP technology for L92 engines is characterized by a shift from mechanical to electrically driven systems, offering improved efficiency and control over coolant flow.

One of the primary challenges in EWP design for L92 engines is thermal management. As L92 engines are high-performance V8 units, they generate substantial heat, requiring precise and responsive cooling. EWPs must be capable of rapidly adjusting coolant flow rates to maintain optimal engine temperatures across various operating conditions, from idle to full throttle.

Another significant challenge is the integration of EWPs into the existing engine architecture. L92 engines, being compact and densely packaged, present space constraints that complicate the installation of EWPs. Engineers must develop compact designs that fit within the limited space while still delivering the required performance.

Power consumption and electrical system compatibility pose additional challenges. EWPs draw power from the vehicle's electrical system, which can strain the alternator and battery, especially in high-demand situations. Balancing pump performance with power efficiency is crucial to prevent excessive electrical load on the vehicle.

Durability and reliability remain ongoing concerns in EWP development. These pumps must withstand harsh operating conditions, including extreme temperatures, vibrations, and exposure to various coolants and contaminants. Ensuring long-term reliability while maintaining cost-effectiveness is a key focus area for manufacturers.

The control systems for EWPs present another technological hurdle. Sophisticated algorithms are required to optimize pump operation based on multiple parameters such as engine load, ambient temperature, and vehicle speed. Developing robust control strategies that can adapt to various driving conditions and engine states is essential for maximizing EWP efficiency.

Noise, vibration, and harshness (NVH) considerations also play a crucial role in EWP design for L92 engines. As these engines are often used in premium vehicles, minimizing pump noise and vibration is critical for maintaining cabin comfort and overall vehicle refinement.

Lastly, the automotive industry's push towards electrification and increased fuel efficiency standards has intensified the focus on EWP technology. Manufacturers are challenged to develop pumps that not only meet current performance requirements but also anticipate future needs, such as compatibility with mild hybrid systems and advanced thermal management strategies.

One of the primary challenges in EWP design for L92 engines is thermal management. As L92 engines are high-performance V8 units, they generate substantial heat, requiring precise and responsive cooling. EWPs must be capable of rapidly adjusting coolant flow rates to maintain optimal engine temperatures across various operating conditions, from idle to full throttle.

Another significant challenge is the integration of EWPs into the existing engine architecture. L92 engines, being compact and densely packaged, present space constraints that complicate the installation of EWPs. Engineers must develop compact designs that fit within the limited space while still delivering the required performance.

Power consumption and electrical system compatibility pose additional challenges. EWPs draw power from the vehicle's electrical system, which can strain the alternator and battery, especially in high-demand situations. Balancing pump performance with power efficiency is crucial to prevent excessive electrical load on the vehicle.

Durability and reliability remain ongoing concerns in EWP development. These pumps must withstand harsh operating conditions, including extreme temperatures, vibrations, and exposure to various coolants and contaminants. Ensuring long-term reliability while maintaining cost-effectiveness is a key focus area for manufacturers.

The control systems for EWPs present another technological hurdle. Sophisticated algorithms are required to optimize pump operation based on multiple parameters such as engine load, ambient temperature, and vehicle speed. Developing robust control strategies that can adapt to various driving conditions and engine states is essential for maximizing EWP efficiency.

Noise, vibration, and harshness (NVH) considerations also play a crucial role in EWP design for L92 engines. As these engines are often used in premium vehicles, minimizing pump noise and vibration is critical for maintaining cabin comfort and overall vehicle refinement.

Lastly, the automotive industry's push towards electrification and increased fuel efficiency standards has intensified the focus on EWP technology. Manufacturers are challenged to develop pumps that not only meet current performance requirements but also anticipate future needs, such as compatibility with mild hybrid systems and advanced thermal management strategies.

Current L92 EWP Design Solutions

01 Electric water pump design and structure

Electric water pumps are designed with specific structures to improve efficiency and performance. These designs may include features for better cooling, noise reduction, and compact sizing. Innovations in pump housing, impeller design, and motor integration contribute to enhanced functionality and durability.- Electric water pump design and efficiency: Electric water pumps are designed for improved efficiency and performance in various applications. These pumps utilize electric motors to drive the pumping mechanism, offering advantages such as precise control, reduced energy consumption, and compact design. Innovations in this area focus on optimizing pump geometry, motor efficiency, and control systems to enhance overall performance.

- Cooling systems for electric water pumps: Cooling systems are crucial for maintaining optimal performance and longevity of electric water pumps. These systems may include innovative heat dissipation methods, thermal management techniques, and coolant circulation designs. Advanced cooling solutions help prevent overheating, extend pump lifespan, and ensure consistent operation under various conditions.

- Control and monitoring systems for electric water pumps: Advanced control and monitoring systems are integrated into electric water pumps to enhance their functionality and reliability. These systems may include sensors, microcontrollers, and communication interfaces that enable precise control of pump operation, real-time monitoring of performance parameters, and remote diagnostics. Such features contribute to improved efficiency, predictive maintenance, and overall system optimization.

- Application-specific electric water pump designs: Electric water pumps are tailored for specific applications, such as automotive cooling systems, industrial processes, or residential water supply. These specialized designs consider factors like flow rate requirements, pressure ranges, and environmental conditions. Customized pump configurations ensure optimal performance and efficiency in their intended applications.

- Energy-efficient and eco-friendly electric water pump technologies: Innovations in electric water pump technology focus on improving energy efficiency and reducing environmental impact. These advancements may include the use of high-efficiency motors, intelligent control algorithms, and materials that minimize friction and wear. Such developments contribute to reduced power consumption, lower operating costs, and improved sustainability in water pumping applications.

02 Control systems for electric water pumps

Advanced control systems are implemented in electric water pumps to optimize operation. These systems may include electronic controllers, sensors, and variable speed drives to adjust pump performance based on demand, temperature, or other parameters. Smart control features can improve energy efficiency and extend pump lifespan.Expand Specific Solutions03 Energy-efficient electric water pump technologies

Innovations focus on improving the energy efficiency of electric water pumps. This includes the development of high-efficiency motors, optimized hydraulic designs, and intelligent power management systems. These technologies aim to reduce power consumption while maintaining or improving pump performance.Expand Specific Solutions04 Application-specific electric water pump designs

Electric water pumps are tailored for specific applications such as automotive cooling systems, HVAC, industrial processes, and marine use. These specialized designs consider factors like flow rate, pressure requirements, fluid properties, and environmental conditions to ensure optimal performance in their intended use cases.Expand Specific Solutions05 Integration of electric water pumps in larger systems

Electric water pumps are increasingly integrated into larger systems for improved overall efficiency. This includes integration with renewable energy systems, smart home technologies, or industrial automation platforms. The focus is on seamless communication and coordination with other system components for optimal performance and energy management.Expand Specific Solutions

Key EWP Manufacturers and Suppliers

The electric water pump market for L92 engines is in a growth phase, driven by increasing demand for efficient cooling systems in high-performance engines. The market size is expanding, with major automotive manufacturers and suppliers investing in this technology. The technical maturity is advancing rapidly, with companies like Hyundai Motor, Kia, and BorgWarner leading innovation. Established players such as Aisin and Nidec GPM are competing with newer entrants like Astemo and Hanon Systems, pushing the boundaries of pump efficiency and integration with engine management systems. The competitive landscape is characterized by a mix of large automotive conglomerates and specialized component manufacturers, all vying for market share in this growing segment.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's design for L92 engine electric water pumps focuses on integration and smart control. They employ a compact brushless DC motor with integrated power electronics for precise speed control[1]. Hyundai's approach includes a variable flow rate system that adapts to different driving conditions and engine loads[2]. The pump design incorporates advanced composite materials for the impeller and housing to reduce weight and improve corrosion resistance[3]. Hyundai also implements a smart thermal management system that coordinates the electric water pump with other cooling components for optimal engine temperature control[4]. Their design features built-in diagnostics and predictive maintenance capabilities to enhance reliability and ease of servicing[5].

Strengths: Smart integration with vehicle systems, lightweight design, and adaptive control. Weaknesses: Potential for increased system complexity and higher production costs.

Toyota Motor Corp.

Technical Solution: Toyota's approach to L92 engine electric water pump design emphasizes reliability and energy efficiency. They utilize a brushless DC motor with an integrated controller for smooth operation and reduced electromagnetic interference[1]. Toyota's design incorporates a unique impeller geometry that optimizes coolant flow patterns, reducing turbulence and improving overall system efficiency[2]. The pump housing is constructed from lightweight, corrosion-resistant materials to enhance longevity[3]. Toyota also implements an advanced thermal management system that integrates the electric water pump with other cooling components, allowing for more precise temperature control across various engine operating conditions[4]. Their design includes fail-safe features and diagnostic capabilities to ensure consistent performance and easy maintenance[5].

Strengths: High reliability, energy efficiency, and integration with overall thermal management system. Weaknesses: Potentially higher production costs and complexity in diagnostics and repair.

Innovative EWP Technologies for L92

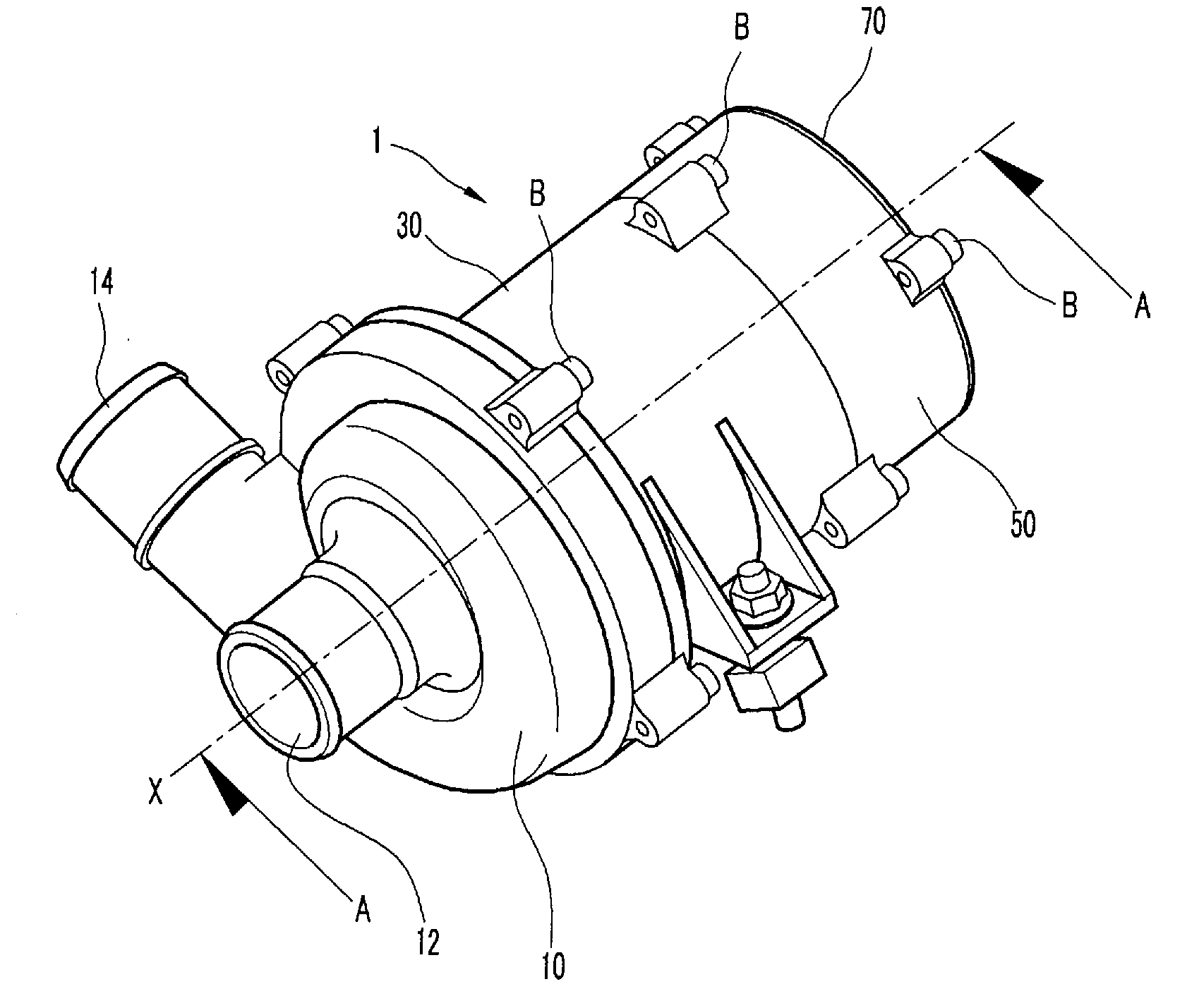

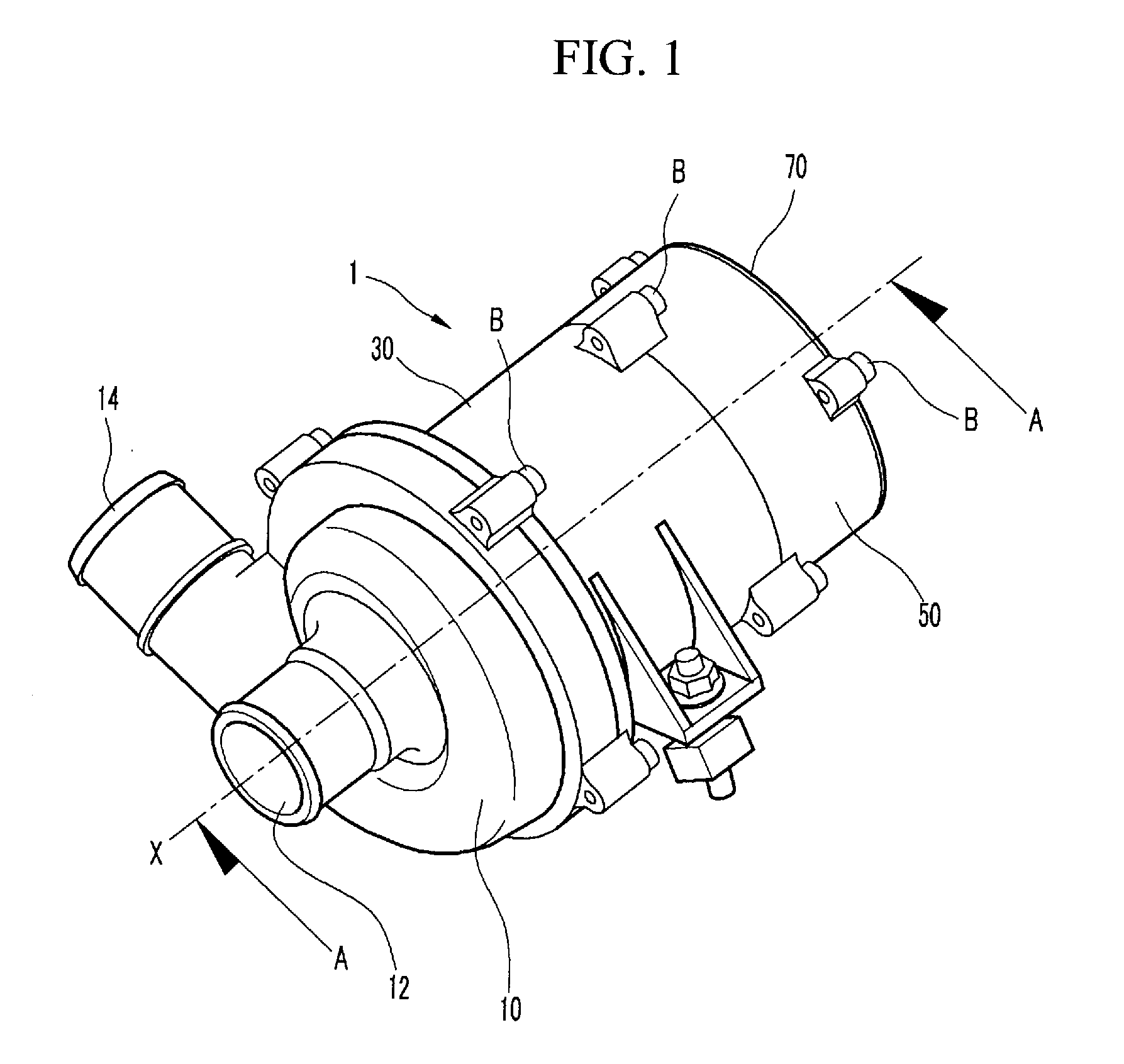

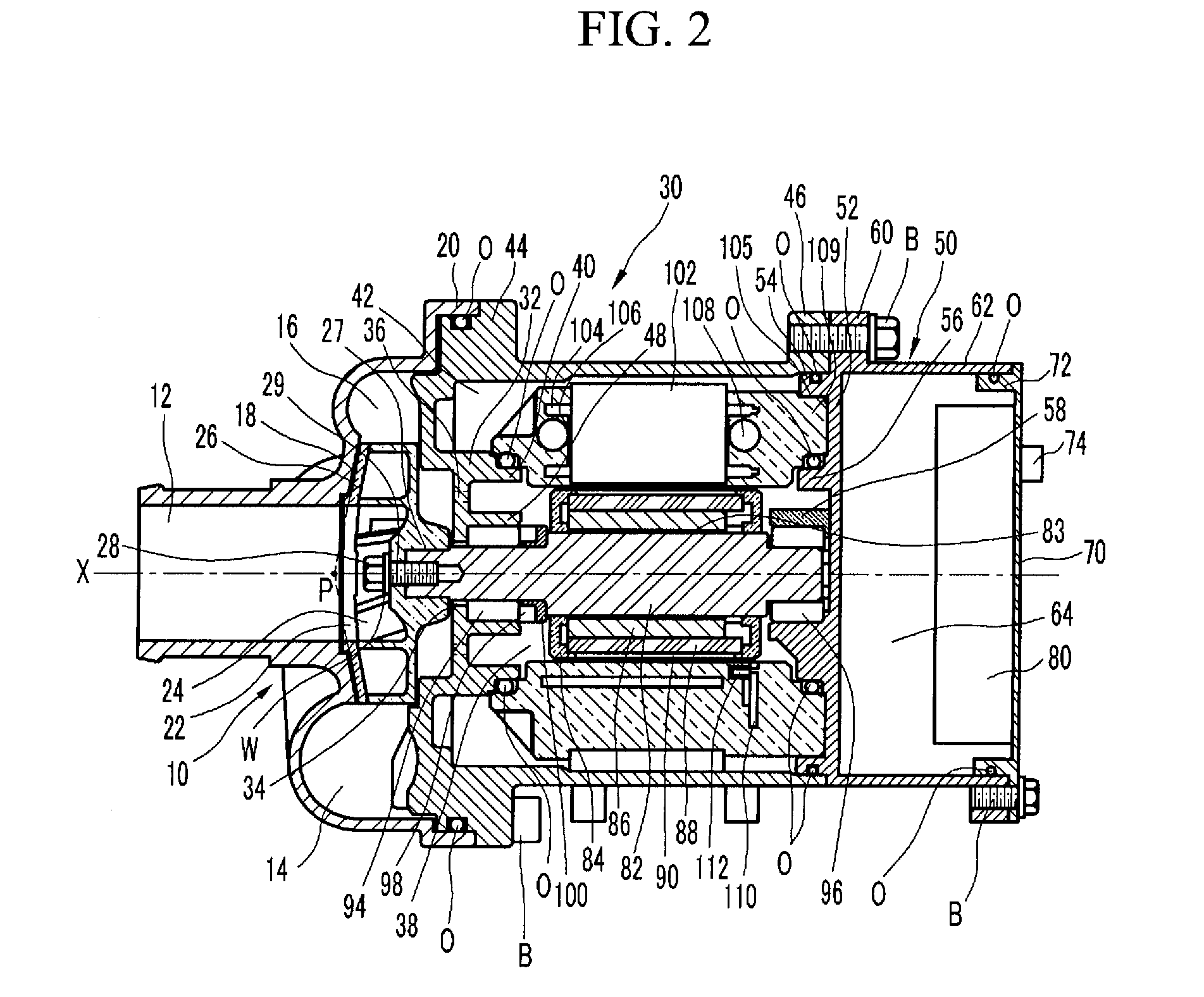

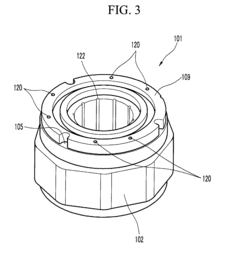

Electric Water Pump

PatentInactiveUS20110116953A1

Innovation

- An electric water pump design featuring a stator and rotor with a magnetic field control system, a pump cover with a volute chamber, and a driver case with a driver chamber, utilizing a shaft with bearings and an impeller for coolant pressurization, along with a stator and rotor case made of bulk mold compound for reduced contraction and improved sealing, and a Hall sensor for position detection and control signal management.

Water pump for vehicle

PatentInactiveUS20110132294A1

Innovation

- A vehicle water pump equipped with an electric clutch that selectively operates based on engine driving conditions and coolant temperature, using a pulley with a through bore, clutch disk with nonmagnetic adhesive ring members, and a field coil to control torque transmission to the impeller, allowing for selective coolant pumping.

Thermal Management Strategies

Thermal management strategies for L92 engine electric water pumps are crucial for maintaining optimal engine performance and efficiency. These strategies focus on controlling the engine's temperature within the ideal operating range, which is typically between 190°F and 220°F (88°C to 104°C). Effective thermal management not only enhances engine longevity but also improves fuel economy and reduces emissions.

One key strategy involves the implementation of variable-speed electric water pumps. Unlike traditional mechanical pumps, electric water pumps can adjust their flow rate based on the engine's cooling needs. This adaptive approach ensures that the engine receives the right amount of coolant circulation at different operating conditions, from cold starts to high-load scenarios.

Advanced control algorithms play a vital role in optimizing the electric water pump's performance. These algorithms take into account various parameters such as engine load, ambient temperature, and coolant temperature to determine the optimal pump speed. By continuously monitoring these factors, the system can proactively adjust coolant flow to maintain ideal engine temperatures.

Integration with the engine control unit (ECU) is another critical aspect of thermal management. The ECU can communicate with the electric water pump to coordinate cooling efforts with other engine systems, such as the thermostat and radiator fan. This integrated approach allows for more precise temperature control and can contribute to improved overall engine efficiency.

Thermal mapping and zonal cooling strategies are also employed to address specific heat management needs within the engine. By identifying hot spots and areas requiring more intensive cooling, engineers can design targeted cooling solutions. This may involve directing coolant flow to particular engine components or implementing additional cooling channels in high-heat areas.

Material selection plays a significant role in thermal management strategies. The use of high-conductivity materials for pump components can enhance heat transfer efficiency. Additionally, incorporating thermal barrier coatings on certain engine parts can help manage heat distribution and reduce thermal stress on critical components.

Lastly, the implementation of smart diagnostics and predictive maintenance features in electric water pump systems contributes to long-term thermal management. These features can detect early signs of pump wear or coolant system issues, allowing for timely interventions to maintain optimal cooling performance throughout the engine's lifecycle.

One key strategy involves the implementation of variable-speed electric water pumps. Unlike traditional mechanical pumps, electric water pumps can adjust their flow rate based on the engine's cooling needs. This adaptive approach ensures that the engine receives the right amount of coolant circulation at different operating conditions, from cold starts to high-load scenarios.

Advanced control algorithms play a vital role in optimizing the electric water pump's performance. These algorithms take into account various parameters such as engine load, ambient temperature, and coolant temperature to determine the optimal pump speed. By continuously monitoring these factors, the system can proactively adjust coolant flow to maintain ideal engine temperatures.

Integration with the engine control unit (ECU) is another critical aspect of thermal management. The ECU can communicate with the electric water pump to coordinate cooling efforts with other engine systems, such as the thermostat and radiator fan. This integrated approach allows for more precise temperature control and can contribute to improved overall engine efficiency.

Thermal mapping and zonal cooling strategies are also employed to address specific heat management needs within the engine. By identifying hot spots and areas requiring more intensive cooling, engineers can design targeted cooling solutions. This may involve directing coolant flow to particular engine components or implementing additional cooling channels in high-heat areas.

Material selection plays a significant role in thermal management strategies. The use of high-conductivity materials for pump components can enhance heat transfer efficiency. Additionally, incorporating thermal barrier coatings on certain engine parts can help manage heat distribution and reduce thermal stress on critical components.

Lastly, the implementation of smart diagnostics and predictive maintenance features in electric water pump systems contributes to long-term thermal management. These features can detect early signs of pump wear or coolant system issues, allowing for timely interventions to maintain optimal cooling performance throughout the engine's lifecycle.

EWP Integration and Control Systems

The integration of electric water pumps (EWPs) into the L92 engine requires careful consideration of control systems and overall system integration. EWPs offer significant advantages over traditional mechanical pumps, including improved efficiency, precise coolant flow control, and reduced parasitic losses. However, their implementation necessitates a sophisticated control strategy to optimize performance and reliability.

The control system for L92 engine EWPs typically consists of a dedicated electronic control unit (ECU) that interfaces with the engine management system. This ECU monitors various parameters such as engine temperature, load, and speed to determine the optimal coolant flow rate. Advanced algorithms are employed to predict cooling requirements and adjust pump speed proactively, ensuring optimal thermal management under all operating conditions.

Integration of the EWP into the L92 engine's cooling system involves redesigning the coolant circuit to accommodate the electric pump. This may include modifications to the water jacket, radiator, and associated plumbing. The placement of the EWP is critical, as it must be positioned to provide efficient coolant circulation while minimizing electrical losses and ensuring adequate protection from heat and vibration.

Power management is a crucial aspect of EWP integration. The L92 engine's electrical system must be capable of supplying the necessary power to the pump, which may require upgrading the alternator or battery capacity. Additionally, a robust wiring harness and connectors are essential to withstand the harsh underhood environment and ensure reliable operation.

Fail-safe mechanisms are integral to the EWP control system design. These may include redundant sensors, backup power supplies, and fault detection algorithms. In the event of a pump failure or control system malfunction, the system should be capable of reverting to a safe operating mode to prevent engine damage.

Calibration of the EWP control system is a complex process that requires extensive testing and optimization. This involves fine-tuning the control algorithms to balance cooling performance with energy efficiency across the entire operating range of the L92 engine. Considerations must be given to various driving scenarios, including high-load conditions, idle, and cold starts.

The integration of EWPs also presents opportunities for advanced thermal management strategies. For instance, the precise control offered by EWPs allows for rapid warm-up cycles, which can improve fuel efficiency and reduce emissions during cold starts. Furthermore, the ability to vary coolant flow independently of engine speed enables more effective temperature control in specific engine components, potentially enhancing performance and longevity.

The control system for L92 engine EWPs typically consists of a dedicated electronic control unit (ECU) that interfaces with the engine management system. This ECU monitors various parameters such as engine temperature, load, and speed to determine the optimal coolant flow rate. Advanced algorithms are employed to predict cooling requirements and adjust pump speed proactively, ensuring optimal thermal management under all operating conditions.

Integration of the EWP into the L92 engine's cooling system involves redesigning the coolant circuit to accommodate the electric pump. This may include modifications to the water jacket, radiator, and associated plumbing. The placement of the EWP is critical, as it must be positioned to provide efficient coolant circulation while minimizing electrical losses and ensuring adequate protection from heat and vibration.

Power management is a crucial aspect of EWP integration. The L92 engine's electrical system must be capable of supplying the necessary power to the pump, which may require upgrading the alternator or battery capacity. Additionally, a robust wiring harness and connectors are essential to withstand the harsh underhood environment and ensure reliable operation.

Fail-safe mechanisms are integral to the EWP control system design. These may include redundant sensors, backup power supplies, and fault detection algorithms. In the event of a pump failure or control system malfunction, the system should be capable of reverting to a safe operating mode to prevent engine damage.

Calibration of the EWP control system is a complex process that requires extensive testing and optimization. This involves fine-tuning the control algorithms to balance cooling performance with energy efficiency across the entire operating range of the L92 engine. Considerations must be given to various driving scenarios, including high-load conditions, idle, and cold starts.

The integration of EWPs also presents opportunities for advanced thermal management strategies. For instance, the precise control offered by EWPs allows for rapid warm-up cycles, which can improve fuel efficiency and reduce emissions during cold starts. Furthermore, the ability to vary coolant flow independently of engine speed enables more effective temperature control in specific engine components, potentially enhancing performance and longevity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!