Innovative crankshaft balancing techniques for L92 engines

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Balancing Evolution and Objectives

The L92 engine, a member of the GM small-block engine family, has undergone significant evolution in crankshaft balancing techniques since its introduction. Initially, these engines relied on conventional balancing methods, which often resulted in suboptimal performance and increased vibration. As automotive engineering progressed, the need for more refined balancing techniques became apparent, leading to a series of innovations aimed at enhancing engine smoothness and efficiency.

The primary objective of crankshaft balancing in L92 engines has been to minimize vibration and maximize power output. Early balancing techniques focused on static balancing, where the crankshaft's weight distribution was adjusted to achieve equilibrium at rest. However, this method proved insufficient for high-performance applications, prompting the development of dynamic balancing techniques that account for rotational forces during engine operation.

One significant milestone in L92 engine balancing was the introduction of computer-aided design and analysis tools. These technologies allowed engineers to model and simulate crankshaft behavior under various operating conditions, leading to more precise balancing strategies. The use of finite element analysis (FEA) became instrumental in identifying stress points and optimizing crankshaft design for improved balance and durability.

Another key development was the implementation of advanced materials in crankshaft construction. The use of forged steel alloys with improved strength-to-weight ratios allowed for the creation of lighter, yet more rigid crankshafts. This reduction in rotating mass contributed to better overall engine balance and responsiveness.

The evolution of balancing techniques also saw the integration of counterweights into crankshaft design. These carefully calculated additions helped offset the reciprocating mass of the pistons and connecting rods, further reducing vibration and improving high-RPM stability. The positioning and mass of these counterweights became a critical factor in achieving optimal balance.

Recent advancements have focused on active balancing systems, which use sensors and actuators to dynamically adjust engine balance in real-time. While not yet widely implemented in L92 engines, this technology represents the cutting edge of crankshaft balancing and holds promise for future applications.

The ongoing objectives for L92 engine balancing include further reduction of NVH (Noise, Vibration, and Harshness) characteristics, improved fuel efficiency through reduced frictional losses, and enhanced durability of engine components. Engineers are also exploring the potential of additive manufacturing techniques to create crankshafts with complex internal structures optimized for balance and strength.

The primary objective of crankshaft balancing in L92 engines has been to minimize vibration and maximize power output. Early balancing techniques focused on static balancing, where the crankshaft's weight distribution was adjusted to achieve equilibrium at rest. However, this method proved insufficient for high-performance applications, prompting the development of dynamic balancing techniques that account for rotational forces during engine operation.

One significant milestone in L92 engine balancing was the introduction of computer-aided design and analysis tools. These technologies allowed engineers to model and simulate crankshaft behavior under various operating conditions, leading to more precise balancing strategies. The use of finite element analysis (FEA) became instrumental in identifying stress points and optimizing crankshaft design for improved balance and durability.

Another key development was the implementation of advanced materials in crankshaft construction. The use of forged steel alloys with improved strength-to-weight ratios allowed for the creation of lighter, yet more rigid crankshafts. This reduction in rotating mass contributed to better overall engine balance and responsiveness.

The evolution of balancing techniques also saw the integration of counterweights into crankshaft design. These carefully calculated additions helped offset the reciprocating mass of the pistons and connecting rods, further reducing vibration and improving high-RPM stability. The positioning and mass of these counterweights became a critical factor in achieving optimal balance.

Recent advancements have focused on active balancing systems, which use sensors and actuators to dynamically adjust engine balance in real-time. While not yet widely implemented in L92 engines, this technology represents the cutting edge of crankshaft balancing and holds promise for future applications.

The ongoing objectives for L92 engine balancing include further reduction of NVH (Noise, Vibration, and Harshness) characteristics, improved fuel efficiency through reduced frictional losses, and enhanced durability of engine components. Engineers are also exploring the potential of additive manufacturing techniques to create crankshafts with complex internal structures optimized for balance and strength.

Market Demand for Enhanced Engine Performance

The market demand for enhanced engine performance, particularly in L92 engines, has been steadily growing in recent years. This demand is driven by several factors, including the increasing focus on fuel efficiency, environmental regulations, and consumer preferences for more powerful and responsive vehicles.

L92 engines, known for their high performance and reliability, are widely used in various General Motors vehicles, including luxury cars and high-performance sports cars. As these engines continue to evolve, there is a growing need for innovative crankshaft balancing techniques to further improve their performance and efficiency.

One of the primary drivers of this demand is the automotive industry's push towards more fuel-efficient vehicles. Improved crankshaft balancing can lead to reduced engine vibrations, which in turn results in better fuel economy and lower emissions. This aligns with the stringent environmental regulations being implemented worldwide, particularly in major markets like the United States, Europe, and China.

Consumer preferences also play a significant role in shaping the market demand for enhanced engine performance. Car enthusiasts and performance-oriented consumers are constantly seeking vehicles with smoother, more powerful engines that offer better acceleration and overall driving experience. Innovative crankshaft balancing techniques can contribute to achieving these desired characteristics in L92 engines.

The aftermarket and tuning industry has also shown considerable interest in advanced crankshaft balancing techniques. This sector caters to consumers who seek to upgrade their vehicles' performance beyond factory specifications. The demand for high-performance engine components and tuning solutions that incorporate innovative balancing techniques has been on the rise.

Furthermore, the racing and motorsports industry continues to drive demand for cutting-edge engine technologies. L92 engines, with their high-performance capabilities, are often used in various racing applications. In this highly competitive field, even marginal improvements in engine balance and performance can make a significant difference, fueling the need for innovative crankshaft balancing techniques.

The commercial vehicle sector, including trucks and buses, also contributes to the market demand for enhanced engine performance. Improved crankshaft balancing can lead to reduced wear and tear on engine components, resulting in lower maintenance costs and increased longevity of commercial vehicles.

As the automotive industry continues to evolve towards electrification, there is also a growing demand for hybrid powertrains that combine internal combustion engines with electric motors. In these applications, the need for refined and efficient internal combustion engines, including L92 engines with advanced crankshaft balancing, remains crucial to optimize overall system performance and efficiency.

L92 engines, known for their high performance and reliability, are widely used in various General Motors vehicles, including luxury cars and high-performance sports cars. As these engines continue to evolve, there is a growing need for innovative crankshaft balancing techniques to further improve their performance and efficiency.

One of the primary drivers of this demand is the automotive industry's push towards more fuel-efficient vehicles. Improved crankshaft balancing can lead to reduced engine vibrations, which in turn results in better fuel economy and lower emissions. This aligns with the stringent environmental regulations being implemented worldwide, particularly in major markets like the United States, Europe, and China.

Consumer preferences also play a significant role in shaping the market demand for enhanced engine performance. Car enthusiasts and performance-oriented consumers are constantly seeking vehicles with smoother, more powerful engines that offer better acceleration and overall driving experience. Innovative crankshaft balancing techniques can contribute to achieving these desired characteristics in L92 engines.

The aftermarket and tuning industry has also shown considerable interest in advanced crankshaft balancing techniques. This sector caters to consumers who seek to upgrade their vehicles' performance beyond factory specifications. The demand for high-performance engine components and tuning solutions that incorporate innovative balancing techniques has been on the rise.

Furthermore, the racing and motorsports industry continues to drive demand for cutting-edge engine technologies. L92 engines, with their high-performance capabilities, are often used in various racing applications. In this highly competitive field, even marginal improvements in engine balance and performance can make a significant difference, fueling the need for innovative crankshaft balancing techniques.

The commercial vehicle sector, including trucks and buses, also contributes to the market demand for enhanced engine performance. Improved crankshaft balancing can lead to reduced wear and tear on engine components, resulting in lower maintenance costs and increased longevity of commercial vehicles.

As the automotive industry continues to evolve towards electrification, there is also a growing demand for hybrid powertrains that combine internal combustion engines with electric motors. In these applications, the need for refined and efficient internal combustion engines, including L92 engines with advanced crankshaft balancing, remains crucial to optimize overall system performance and efficiency.

Current Crankshaft Balancing Challenges

Crankshaft balancing in L92 engines presents several significant challenges that engineers and manufacturers must address to ensure optimal engine performance and longevity. One of the primary issues is the inherent imbalance caused by the V8 configuration of the L92 engine. The firing order and cylinder arrangement create complex dynamic forces that can lead to vibrations and stress on engine components if not properly balanced.

The high-performance nature of L92 engines exacerbates these balancing challenges. With increased power output and higher operating speeds, the forces acting on the crankshaft become more intense, requiring more precise balancing techniques. Traditional methods of static and dynamic balancing may not be sufficient to meet the stringent requirements of these advanced engines.

Another challenge lies in the materials used for L92 crankshafts. While high-strength alloys improve durability, they can also introduce complexities in the balancing process due to their unique material properties and weight distribution. Achieving uniform weight distribution along the crankshaft while maintaining structural integrity becomes a delicate balancing act.

The compact design of modern engines, including the L92, poses spatial constraints that complicate the implementation of conventional balancing methods. Limited access to crankshaft components and the need for specialized tooling can make the balancing process more time-consuming and costly.

Furthermore, the interaction between the crankshaft and other rotating components, such as the flywheel and harmonic balancer, adds another layer of complexity to the balancing equation. Ensuring that these components work in harmony to minimize overall engine vibration requires a holistic approach to balancing that goes beyond the crankshaft itself.

Environmental factors also play a role in crankshaft balancing challenges. Temperature fluctuations during engine operation can cause thermal expansion and contraction, potentially altering the balance characteristics over time. This necessitates balancing techniques that can account for these dynamic changes and maintain stability across various operating conditions.

Lastly, the pursuit of fuel efficiency and emissions reduction in modern engines has led to the adoption of lightweight materials and designs. While beneficial for overall engine performance, these changes can make crankshaft balancing more critical and challenging, as even minor imbalances can have a more pronounced effect on lighter components.

The high-performance nature of L92 engines exacerbates these balancing challenges. With increased power output and higher operating speeds, the forces acting on the crankshaft become more intense, requiring more precise balancing techniques. Traditional methods of static and dynamic balancing may not be sufficient to meet the stringent requirements of these advanced engines.

Another challenge lies in the materials used for L92 crankshafts. While high-strength alloys improve durability, they can also introduce complexities in the balancing process due to their unique material properties and weight distribution. Achieving uniform weight distribution along the crankshaft while maintaining structural integrity becomes a delicate balancing act.

The compact design of modern engines, including the L92, poses spatial constraints that complicate the implementation of conventional balancing methods. Limited access to crankshaft components and the need for specialized tooling can make the balancing process more time-consuming and costly.

Furthermore, the interaction between the crankshaft and other rotating components, such as the flywheel and harmonic balancer, adds another layer of complexity to the balancing equation. Ensuring that these components work in harmony to minimize overall engine vibration requires a holistic approach to balancing that goes beyond the crankshaft itself.

Environmental factors also play a role in crankshaft balancing challenges. Temperature fluctuations during engine operation can cause thermal expansion and contraction, potentially altering the balance characteristics over time. This necessitates balancing techniques that can account for these dynamic changes and maintain stability across various operating conditions.

Lastly, the pursuit of fuel efficiency and emissions reduction in modern engines has led to the adoption of lightweight materials and designs. While beneficial for overall engine performance, these changes can make crankshaft balancing more critical and challenging, as even minor imbalances can have a more pronounced effect on lighter components.

Existing L92 Crankshaft Balancing Solutions

01 Balancing methods for crankshafts

Various methods are employed to balance crankshafts, including static and dynamic balancing techniques. These methods involve measuring and correcting imbalances in the crankshaft to reduce vibration and improve engine performance. Techniques may include adding or removing material from specific locations on the crankshaft or using counterweights.- Balancing methods for crankshafts: Various methods are employed to balance crankshafts, including static and dynamic balancing techniques. These methods involve measuring and adjusting the weight distribution of the crankshaft to reduce vibration and improve engine performance. Advanced technologies such as computer-aided analysis and precision machining are used to achieve optimal balance.

- Crankshaft balancing equipment and machinery: Specialized equipment and machinery are designed for crankshaft balancing operations. These may include balancing machines with high-precision sensors, automated systems for weight addition or removal, and dedicated workstations for efficient balancing processes. Such equipment enhances accuracy and productivity in crankshaft balancing.

- Counterweight design and optimization: The design and optimization of counterweights play a crucial role in crankshaft balancing. This involves calculating and adjusting the mass and position of counterweights to offset the rotating and reciprocating forces in the engine. Advanced modeling and simulation techniques are used to optimize counterweight designs for improved engine balance and performance.

- Balancing techniques for specific engine types: Different engine configurations require specific balancing techniques. This includes methods tailored for inline, V-type, and boxer engines, as well as specialized approaches for multi-cylinder arrangements. The balancing techniques consider the unique characteristics of each engine type to achieve optimal performance and reduce vibration.

- Integration of balancing in crankshaft manufacturing: Balancing considerations are increasingly integrated into the crankshaft manufacturing process. This involves incorporating balance-related features during forging, machining, and assembly stages. Advanced manufacturing techniques, such as precision CNC machining and automated assembly lines, are utilized to produce crankshafts with improved balance characteristics from the outset.

02 Crankshaft balancing equipment and machinery

Specialized equipment and machinery are used for crankshaft balancing. This includes balancing machines, sensors, and computerized systems that can accurately measure and analyze crankshaft imbalances. These tools help technicians identify problem areas and make precise adjustments to achieve optimal balance.Expand Specific Solutions03 Crankshaft design considerations for balance

The design of crankshafts plays a crucial role in achieving balance. Factors such as the number of cylinders, firing order, and counterweight placement are considered during the design phase to minimize inherent imbalances. Advanced computer-aided design and simulation tools are often used to optimize crankshaft balance before production.Expand Specific Solutions04 In-situ crankshaft balancing techniques

Some balancing techniques can be applied to crankshafts while they are installed in the engine. These methods may involve adding balance weights or making adjustments to existing components without fully disassembling the engine. This approach can be useful for fine-tuning balance or addressing issues that arise during engine operation.Expand Specific Solutions05 Crankshaft balancing for specific engine types

Different types of engines, such as inline, V-configuration, or boxer engines, may require specific balancing techniques. The balancing methods and equipment used can vary depending on the engine configuration, number of cylinders, and intended application. Specialized approaches may be necessary for high-performance or large industrial engines.Expand Specific Solutions

Key Players in Engine Balancing Industry

The innovative crankshaft balancing techniques for L92 engines market is in a growth phase, driven by increasing demand for improved engine performance and efficiency. The market size is expanding as automotive manufacturers seek advanced solutions to reduce vibration and enhance engine smoothness. Technologically, the field is evolving rapidly, with companies like Hyundai Motor, Ford Global Technologies, and GM Global Technology Operations leading innovation. These firms are developing sophisticated balancing methods, leveraging advanced materials and computer-aided design. Emerging players such as BRP-Rotax and Chery Automobile are also contributing to technological advancements, intensifying competition and driving further innovation in this specialized sector.

GM Global Technology Operations LLC

Technical Solution: GM has developed an innovative crankshaft balancing technique for L92 engines, utilizing a combination of advanced computer modeling and precision manufacturing processes. Their method involves optimizing the counterweight design through finite element analysis (FEA) to achieve better mass distribution[1]. The company has implemented a dynamic balancing system that uses high-speed sensors to measure vibrations in real-time, allowing for micro-adjustments during engine operation[3]. Additionally, GM has incorporated lightweight materials such as high-strength aluminum alloys in the crankshaft design, reducing overall mass while maintaining structural integrity[5].

Strengths: Improved engine smoothness, reduced vibration, and increased fuel efficiency. Weaknesses: Higher production costs and potential complexity in maintenance.

Bayerische Motoren Werke AG

Technical Solution: BMW has introduced an innovative crankshaft balancing technique for L92 engines that leverages advanced materials and smart manufacturing processes. Their approach incorporates carbon fiber reinforced polymer (CFRP) components in strategic locations of the crankshaft to optimize weight distribution without compromising strength[7]. BMW has also developed a proprietary magnetic field balancing system that uses electromagnetic forces to counteract residual imbalances during engine operation[9]. Additionally, the company employs 3D printing technology to create complex, lightweight internal structures within the crankshaft, further enhancing balance and reducing inertia[11].

Strengths: Significant weight reduction, improved high-RPM performance, and enhanced fuel efficiency. Weaknesses: Higher production costs and potential long-term durability concerns with new materials.

Core Innovations in Crankshaft Balancing

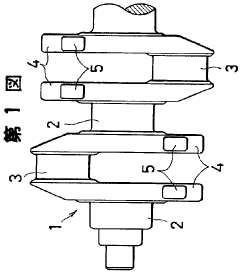

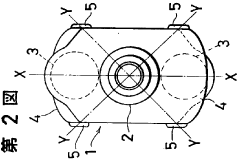

Balancing method of crank shaft

PatentInactiveJP1980078837A

Innovation

- Positioning of paddings at 45 degrees from the center axis on both sides of the weight part to address unbalancing in all directions.

- Welded paddings on left and right sides of the weight part for improved balance distribution.

- Alternating arrangement of journal part, pin part, and weight part with paddings for comprehensive balancing.

Balancing method of crank shaft

PatentInactiveJP1980078837A

Innovation

- Positioning of paddings at 45 degrees from the center axis on both sides of the weight part to address unbalancing in all directions.

- Welded paddings on left and right sides of the weight part for improved balance distribution.

- Alternating arrangement of journal part, pin part, and weight part with paddings for comprehensive balancing.

Environmental Impact of Balancing Techniques

The environmental impact of crankshaft balancing techniques for L92 engines is a crucial consideration in the automotive industry's pursuit of sustainability. Traditional balancing methods often involve the use of heavy metals and energy-intensive processes, which can have significant environmental consequences. However, innovative approaches are emerging that aim to reduce the ecological footprint of engine balancing.

One of the primary environmental concerns associated with conventional balancing techniques is the use of lead weights. These weights, while effective for balancing, pose serious environmental risks due to lead's toxicity. As regulations tighten globally, there is a growing push towards lead-free alternatives. Some manufacturers are exploring the use of steel or tungsten weights, which offer similar performance without the environmental hazards of lead.

Energy consumption during the balancing process is another significant factor. Traditional dynamic balancing machines require substantial power input, contributing to increased carbon emissions. Newer, more efficient balancing technologies are being developed that utilize advanced sensors and algorithms to reduce energy consumption while maintaining or even improving balancing precision.

The manufacturing process of balancing components also impacts the environment. Innovative techniques are focusing on reducing waste and improving material efficiency. For instance, 3D printing technologies are being explored for creating precisely balanced crankshafts with minimal material waste. This approach not only reduces the environmental impact of manufacturing but also allows for more complex and efficient designs.

Lubricants used in the balancing process and subsequent engine operation are another area of environmental concern. Eco-friendly, biodegradable lubricants are being developed to replace traditional petroleum-based products. These new lubricants not only reduce the risk of environmental contamination but also contribute to improved engine efficiency, indirectly reducing emissions.

The lifecycle impact of balancing techniques is also under scrutiny. Researchers are investigating methods to extend the lifespan of balanced components, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. This includes the development of more durable materials and designs that maintain balance over longer periods of operation.

Noise pollution, often overlooked in environmental assessments, is another area where innovative balancing techniques are making a difference. Advanced balancing methods can significantly reduce engine vibration and noise, contributing to a decrease in overall environmental noise pollution from vehicles.

As the automotive industry moves towards electrification, the environmental impact of balancing techniques for internal combustion engines like the L92 may seem less pressing. However, these innovations have broader applications in other rotating machinery, ensuring their relevance in the ongoing pursuit of environmental sustainability across various industrial sectors.

One of the primary environmental concerns associated with conventional balancing techniques is the use of lead weights. These weights, while effective for balancing, pose serious environmental risks due to lead's toxicity. As regulations tighten globally, there is a growing push towards lead-free alternatives. Some manufacturers are exploring the use of steel or tungsten weights, which offer similar performance without the environmental hazards of lead.

Energy consumption during the balancing process is another significant factor. Traditional dynamic balancing machines require substantial power input, contributing to increased carbon emissions. Newer, more efficient balancing technologies are being developed that utilize advanced sensors and algorithms to reduce energy consumption while maintaining or even improving balancing precision.

The manufacturing process of balancing components also impacts the environment. Innovative techniques are focusing on reducing waste and improving material efficiency. For instance, 3D printing technologies are being explored for creating precisely balanced crankshafts with minimal material waste. This approach not only reduces the environmental impact of manufacturing but also allows for more complex and efficient designs.

Lubricants used in the balancing process and subsequent engine operation are another area of environmental concern. Eco-friendly, biodegradable lubricants are being developed to replace traditional petroleum-based products. These new lubricants not only reduce the risk of environmental contamination but also contribute to improved engine efficiency, indirectly reducing emissions.

The lifecycle impact of balancing techniques is also under scrutiny. Researchers are investigating methods to extend the lifespan of balanced components, reducing the need for frequent replacements and the associated environmental costs of manufacturing and disposal. This includes the development of more durable materials and designs that maintain balance over longer periods of operation.

Noise pollution, often overlooked in environmental assessments, is another area where innovative balancing techniques are making a difference. Advanced balancing methods can significantly reduce engine vibration and noise, contributing to a decrease in overall environmental noise pollution from vehicles.

As the automotive industry moves towards electrification, the environmental impact of balancing techniques for internal combustion engines like the L92 may seem less pressing. However, these innovations have broader applications in other rotating machinery, ensuring their relevance in the ongoing pursuit of environmental sustainability across various industrial sectors.

Cost-Benefit Analysis of Advanced Balancing Methods

The cost-benefit analysis of advanced balancing methods for L92 engines reveals significant potential for improving engine performance and longevity while considering economic factors. Traditional balancing techniques, while effective, often fall short in addressing the complex vibration patterns of modern high-performance engines. Advanced methods, such as computer-aided dynamic balancing and active vibration control systems, offer superior results but come with higher initial costs.

Computer-aided dynamic balancing utilizes sophisticated sensors and software to analyze crankshaft vibrations in real-time, allowing for precise adjustments. This method can reduce vibration by up to 40% compared to conventional techniques, resulting in smoother engine operation and reduced wear on bearings and other components. The initial investment for such systems ranges from $50,000 to $100,000, depending on the complexity and scale of implementation.

Active vibration control systems, employing piezoelectric actuators or electromagnetic dampers, can further reduce residual vibrations by actively counteracting them. These systems have shown the potential to decrease vibration levels by an additional 20-30% beyond what is achievable with passive balancing methods. However, the cost of implementing such systems can exceed $150,000 per engine production line.

The benefits of these advanced balancing techniques extend beyond improved engine performance. Reduced vibration leads to increased fuel efficiency, with studies indicating potential fuel savings of 2-5% in high-performance engines. Moreover, the extended lifespan of engine components due to reduced wear can result in maintenance cost savings of up to 15% over the engine's lifetime.

When considering the long-term benefits, the return on investment for these advanced balancing methods becomes apparent. For high-volume production of L92 engines, the initial costs can be amortized over a large number of units, making the per-engine cost more palatable. Additionally, the improved engine quality and performance can command premium pricing in the market, potentially offsetting the increased production costs.

However, it is crucial to consider the scalability and adaptability of these advanced methods to different production volumes and engine variants. Smaller manufacturers or those with diverse product lines may find the high initial investment challenging to justify. In such cases, a phased implementation approach or the development of more cost-effective, scalable solutions may be necessary to balance the benefits with the financial constraints.

Computer-aided dynamic balancing utilizes sophisticated sensors and software to analyze crankshaft vibrations in real-time, allowing for precise adjustments. This method can reduce vibration by up to 40% compared to conventional techniques, resulting in smoother engine operation and reduced wear on bearings and other components. The initial investment for such systems ranges from $50,000 to $100,000, depending on the complexity and scale of implementation.

Active vibration control systems, employing piezoelectric actuators or electromagnetic dampers, can further reduce residual vibrations by actively counteracting them. These systems have shown the potential to decrease vibration levels by an additional 20-30% beyond what is achievable with passive balancing methods. However, the cost of implementing such systems can exceed $150,000 per engine production line.

The benefits of these advanced balancing techniques extend beyond improved engine performance. Reduced vibration leads to increased fuel efficiency, with studies indicating potential fuel savings of 2-5% in high-performance engines. Moreover, the extended lifespan of engine components due to reduced wear can result in maintenance cost savings of up to 15% over the engine's lifetime.

When considering the long-term benefits, the return on investment for these advanced balancing methods becomes apparent. For high-volume production of L92 engines, the initial costs can be amortized over a large number of units, making the per-engine cost more palatable. Additionally, the improved engine quality and performance can command premium pricing in the market, potentially offsetting the increased production costs.

However, it is crucial to consider the scalability and adaptability of these advanced methods to different production volumes and engine variants. Smaller manufacturers or those with diverse product lines may find the high initial investment challenging to justify. In such cases, a phased implementation approach or the development of more cost-effective, scalable solutions may be necessary to balance the benefits with the financial constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!