Torsional analysis of crankshafts in L92 engines

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Torsion Background and Objectives

Crankshaft torsional analysis in L92 engines has become a critical aspect of modern engine design and performance optimization. The L92 engine, known for its high-performance capabilities, requires meticulous attention to crankshaft dynamics to ensure reliability and efficiency. Torsional vibrations in crankshafts have been a concern since the early days of internal combustion engines, but their importance has grown significantly with the increasing power outputs and higher operating speeds of modern engines.

The evolution of crankshaft torsional analysis can be traced back to the early 20th century when engineers first recognized the detrimental effects of torsional vibrations on engine longevity. As engine designs progressed, particularly in high-performance applications like the L92, the need for more sophisticated analysis techniques became apparent. The advent of computer-aided engineering and finite element analysis in the latter half of the 20th century revolutionized the approach to crankshaft design and torsional analysis.

In recent years, the focus has shifted towards developing more accurate predictive models and real-time monitoring systems for crankshaft torsional vibrations. This shift is driven by the automotive industry's push for higher efficiency, lower emissions, and increased power density. The L92 engine, with its high-output V8 configuration, exemplifies the challenges faced in modern engine design, where the balance between performance and durability is crucial.

The primary objectives of crankshaft torsional analysis in L92 engines are multifaceted. Firstly, it aims to predict and mitigate harmful torsional vibrations that could lead to premature failure or reduced performance. This involves identifying critical speeds and resonant frequencies that could excite destructive vibration modes. Secondly, the analysis seeks to optimize the crankshaft design for improved power transmission and reduced energy losses due to flexing and vibration.

Another key objective is to enhance the overall engine efficiency by minimizing frictional losses and improving combustion timing through precise control of crankshaft dynamics. This is particularly important in high-performance engines like the L92, where small improvements can translate into significant gains in power output and fuel efficiency. Additionally, torsional analysis plays a crucial role in noise, vibration, and harshness (NVH) reduction, contributing to a smoother and more refined engine operation.

Looking forward, the field of crankshaft torsional analysis is expected to integrate more advanced technologies such as machine learning and real-time adaptive control systems. These developments aim to create 'smart' engines capable of self-adjusting to optimize performance and reduce wear based on real-time torsional vibration data. For L92 engines and similar high-performance powerplants, this could lead to unprecedented levels of efficiency, reliability, and performance customization.

The evolution of crankshaft torsional analysis can be traced back to the early 20th century when engineers first recognized the detrimental effects of torsional vibrations on engine longevity. As engine designs progressed, particularly in high-performance applications like the L92, the need for more sophisticated analysis techniques became apparent. The advent of computer-aided engineering and finite element analysis in the latter half of the 20th century revolutionized the approach to crankshaft design and torsional analysis.

In recent years, the focus has shifted towards developing more accurate predictive models and real-time monitoring systems for crankshaft torsional vibrations. This shift is driven by the automotive industry's push for higher efficiency, lower emissions, and increased power density. The L92 engine, with its high-output V8 configuration, exemplifies the challenges faced in modern engine design, where the balance between performance and durability is crucial.

The primary objectives of crankshaft torsional analysis in L92 engines are multifaceted. Firstly, it aims to predict and mitigate harmful torsional vibrations that could lead to premature failure or reduced performance. This involves identifying critical speeds and resonant frequencies that could excite destructive vibration modes. Secondly, the analysis seeks to optimize the crankshaft design for improved power transmission and reduced energy losses due to flexing and vibration.

Another key objective is to enhance the overall engine efficiency by minimizing frictional losses and improving combustion timing through precise control of crankshaft dynamics. This is particularly important in high-performance engines like the L92, where small improvements can translate into significant gains in power output and fuel efficiency. Additionally, torsional analysis plays a crucial role in noise, vibration, and harshness (NVH) reduction, contributing to a smoother and more refined engine operation.

Looking forward, the field of crankshaft torsional analysis is expected to integrate more advanced technologies such as machine learning and real-time adaptive control systems. These developments aim to create 'smart' engines capable of self-adjusting to optimize performance and reduce wear based on real-time torsional vibration data. For L92 engines and similar high-performance powerplants, this could lead to unprecedented levels of efficiency, reliability, and performance customization.

Market Demand for L92 Engine Performance

The market demand for L92 engine performance has been steadily growing, driven by the automotive industry's pursuit of higher efficiency and power output. As emissions regulations become more stringent globally, there is an increasing need for engines that can deliver superior performance while meeting environmental standards. The L92 engine, known for its high-performance capabilities, has garnered significant attention from both manufacturers and consumers.

In the passenger vehicle segment, there is a strong demand for L92 engines in luxury and sports car markets. These engines offer the power and responsiveness desired by enthusiasts and performance-oriented drivers. The growing popularity of high-end SUVs and crossovers has also contributed to the increased demand for L92 engines, as manufacturers seek to provide powerful yet efficient powertrains for these larger vehicles.

The commercial vehicle sector has shown interest in L92 engines for applications requiring high torque and durability. This includes heavy-duty trucks, buses, and specialized industrial equipment. The ability of L92 engines to deliver consistent performance under demanding conditions makes them attractive for fleet operators and businesses that rely on robust, long-lasting engines.

Racing and motorsport industries continue to be significant drivers of demand for L92 engine performance. The engine's potential for modification and tuning makes it a favorite among racing teams and aftermarket performance shops. This sector not only consumes L92 engines but also drives innovation in engine design and performance enhancement techniques.

The aftermarket and customization industry has seen a surge in demand for L92 engine components and performance upgrades. Enthusiasts and tuning shops seek to extract maximum performance from these engines, creating a thriving market for specialized parts and services. This trend has led to the development of a robust ecosystem of suppliers and service providers catering to L92 engine enhancement.

As automotive manufacturers focus on electrification, there is a parallel demand for high-performance internal combustion engines in certain market segments. The L92 engine serves as a bridge between traditional powertrains and future technologies, appealing to consumers who desire the visceral experience of a powerful combustion engine while benefiting from modern efficiency improvements.

The marine industry has also shown interest in L92 engines for high-performance boats and yachts. The engine's power-to-weight ratio and reliability make it suitable for marine applications where performance and dependability are crucial. This niche market contributes to the overall demand for L92 engine technology and its ongoing development.

In the passenger vehicle segment, there is a strong demand for L92 engines in luxury and sports car markets. These engines offer the power and responsiveness desired by enthusiasts and performance-oriented drivers. The growing popularity of high-end SUVs and crossovers has also contributed to the increased demand for L92 engines, as manufacturers seek to provide powerful yet efficient powertrains for these larger vehicles.

The commercial vehicle sector has shown interest in L92 engines for applications requiring high torque and durability. This includes heavy-duty trucks, buses, and specialized industrial equipment. The ability of L92 engines to deliver consistent performance under demanding conditions makes them attractive for fleet operators and businesses that rely on robust, long-lasting engines.

Racing and motorsport industries continue to be significant drivers of demand for L92 engine performance. The engine's potential for modification and tuning makes it a favorite among racing teams and aftermarket performance shops. This sector not only consumes L92 engines but also drives innovation in engine design and performance enhancement techniques.

The aftermarket and customization industry has seen a surge in demand for L92 engine components and performance upgrades. Enthusiasts and tuning shops seek to extract maximum performance from these engines, creating a thriving market for specialized parts and services. This trend has led to the development of a robust ecosystem of suppliers and service providers catering to L92 engine enhancement.

As automotive manufacturers focus on electrification, there is a parallel demand for high-performance internal combustion engines in certain market segments. The L92 engine serves as a bridge between traditional powertrains and future technologies, appealing to consumers who desire the visceral experience of a powerful combustion engine while benefiting from modern efficiency improvements.

The marine industry has also shown interest in L92 engines for high-performance boats and yachts. The engine's power-to-weight ratio and reliability make it suitable for marine applications where performance and dependability are crucial. This niche market contributes to the overall demand for L92 engine technology and its ongoing development.

Current Challenges in Crankshaft Torsional Analysis

The torsional analysis of crankshafts in L92 engines presents several significant challenges that researchers and engineers must address to ensure optimal engine performance and reliability. One of the primary difficulties lies in accurately modeling the complex geometry of the crankshaft and its interactions with other engine components. The L92 engine's V8 configuration adds an extra layer of complexity to the analysis, as the crankshaft experiences varying torsional loads from multiple cylinders firing in a specific sequence.

Another challenge is the accurate representation of material properties and their behavior under dynamic loading conditions. Crankshafts in high-performance engines like the L92 are subjected to extreme stress cycles and temperature variations, which can significantly affect their torsional characteristics. Capturing these non-linear material behaviors in analytical models remains a formidable task, often requiring sophisticated finite element analysis (FEA) techniques and extensive experimental validation.

The high operating speeds of L92 engines further complicate torsional analysis by introducing additional dynamic effects. At elevated RPMs, the crankshaft's natural frequencies may coincide with the engine's firing frequency, potentially leading to resonance and amplified torsional vibrations. Identifying and mitigating these critical speed ranges is crucial but challenging due to the multitude of variables involved in the system's dynamics.

Moreover, the integration of modern technologies such as variable valve timing and cylinder deactivation in L92 engines introduces additional variables that affect torsional behavior. These systems can alter the engine's operating characteristics dynamically, making it difficult to predict and analyze torsional loads across all operating conditions. Engineers must develop more sophisticated models that can account for these variable parameters and their impact on crankshaft torsion.

The increasing demand for fuel efficiency and reduced emissions also poses challenges in crankshaft torsional analysis. As manufacturers strive to lightweight engine components, including crankshafts, the reduced mass can alter the torsional characteristics of the system. Balancing the need for weight reduction with maintaining adequate torsional stiffness and fatigue resistance requires advanced optimization techniques and innovative material solutions.

Lastly, the validation of analytical models against real-world data remains a significant challenge. Obtaining accurate measurements of torsional vibrations in operating engines is technically demanding and often requires specialized instrumentation. The discrepancies between simulated results and experimental data can be substantial, necessitating iterative refinement of analytical models and testing methodologies to achieve reliable predictions of crankshaft torsional behavior in L92 engines.

Another challenge is the accurate representation of material properties and their behavior under dynamic loading conditions. Crankshafts in high-performance engines like the L92 are subjected to extreme stress cycles and temperature variations, which can significantly affect their torsional characteristics. Capturing these non-linear material behaviors in analytical models remains a formidable task, often requiring sophisticated finite element analysis (FEA) techniques and extensive experimental validation.

The high operating speeds of L92 engines further complicate torsional analysis by introducing additional dynamic effects. At elevated RPMs, the crankshaft's natural frequencies may coincide with the engine's firing frequency, potentially leading to resonance and amplified torsional vibrations. Identifying and mitigating these critical speed ranges is crucial but challenging due to the multitude of variables involved in the system's dynamics.

Moreover, the integration of modern technologies such as variable valve timing and cylinder deactivation in L92 engines introduces additional variables that affect torsional behavior. These systems can alter the engine's operating characteristics dynamically, making it difficult to predict and analyze torsional loads across all operating conditions. Engineers must develop more sophisticated models that can account for these variable parameters and their impact on crankshaft torsion.

The increasing demand for fuel efficiency and reduced emissions also poses challenges in crankshaft torsional analysis. As manufacturers strive to lightweight engine components, including crankshafts, the reduced mass can alter the torsional characteristics of the system. Balancing the need for weight reduction with maintaining adequate torsional stiffness and fatigue resistance requires advanced optimization techniques and innovative material solutions.

Lastly, the validation of analytical models against real-world data remains a significant challenge. Obtaining accurate measurements of torsional vibrations in operating engines is technically demanding and often requires specialized instrumentation. The discrepancies between simulated results and experimental data can be substantial, necessitating iterative refinement of analytical models and testing methodologies to achieve reliable predictions of crankshaft torsional behavior in L92 engines.

Existing Torsional Analysis Methods for Crankshafts

01 Torsional vibration analysis methods

Various methods are employed to analyze torsional vibrations in crankshafts. These include computational models, finite element analysis, and experimental techniques. Such analyses help in understanding the dynamic behavior of crankshafts under different operating conditions, allowing for optimization of design and performance.- Torsional vibration analysis methods: Various methods are employed to analyze torsional vibrations in crankshafts. These include mathematical modeling, finite element analysis, and experimental techniques. Such analyses help in understanding the dynamic behavior of crankshafts under different operating conditions, allowing for optimization of design and performance.

- Crankshaft design optimization: Optimizing crankshaft design is crucial for minimizing torsional vibrations. This involves considerations such as material selection, geometry optimization, and weight distribution. Advanced design techniques aim to enhance the crankshaft's ability to withstand torsional stresses while maintaining overall engine efficiency.

- Damping mechanisms for torsional vibrations: Various damping mechanisms are implemented to reduce torsional vibrations in crankshafts. These may include torsional dampers, viscous dampers, or rubber dampers. The selection and design of these damping systems are critical for maintaining crankshaft integrity and overall engine performance.

- Sensor-based monitoring and analysis: Advanced sensor technologies are utilized for real-time monitoring and analysis of crankshaft torsional vibrations. These systems can provide valuable data for predictive maintenance, performance optimization, and early detection of potential issues related to torsional stresses in the crankshaft.

- Integration with engine management systems: Torsional analysis results are increasingly integrated with engine management systems. This integration allows for dynamic adjustments to engine parameters based on real-time torsional vibration data, enhancing overall engine performance and longevity while minimizing the impact of torsional stresses on the crankshaft.

02 Crankshaft design optimization

Optimizing crankshaft design is crucial for minimizing torsional vibrations. This involves considerations such as material selection, geometry modifications, and weight distribution. Advanced design techniques aim to enhance the crankshaft's ability to withstand torsional stresses while maintaining overall engine efficiency.Expand Specific Solutions03 Damping mechanisms for torsional vibrations

Various damping mechanisms are implemented to reduce torsional vibrations in crankshafts. These may include torsional dampers, viscous dampers, or rubber dampers. The selection and design of these damping systems are critical for maintaining crankshaft integrity and improving engine performance.Expand Specific Solutions04 Sensor-based monitoring and analysis

Advanced sensor technologies are utilized for real-time monitoring and analysis of crankshaft torsional vibrations. These systems can detect abnormal vibrations, predict potential failures, and provide valuable data for ongoing optimization of engine performance and maintenance schedules.Expand Specific Solutions05 Integration with engine control systems

Torsional analysis results are increasingly integrated with engine control systems. This integration allows for dynamic adjustments to engine parameters based on real-time torsional vibration data, enhancing overall engine performance, efficiency, and longevity.Expand Specific Solutions

Key Players in L92 Engine Manufacturing

The torsional analysis of crankshafts in L92 engines represents a mature technology within the automotive industry, with the market in a consolidation phase. Major players like Robert Bosch GmbH, Honda Motor Co., Ltd., and Toyota Motor Corp. have established strong positions in this field. The market size is substantial, driven by the ongoing demand for high-performance engines. Technological advancements focus on improving efficiency and reducing vibrations, with companies like GM Global Technology Operations LLC and Mercedes-Benz Group AG investing in research and development to maintain their competitive edge in this critical component of engine design.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive torsional analysis approach for crankshafts, applicable to various engine types including those similar to L92 engines. Their methodology combines advanced simulation techniques with innovative sensor technologies for validation. Bosch utilizes a multi-physics simulation platform that integrates structural, thermal, and fluid dynamics analyses to provide a holistic view of crankshaft behavior under various operating conditions[9]. They have also developed specialized torsional vibration sensors that can be integrated into engine components for real-time monitoring and analysis. Bosch's approach incorporates machine learning algorithms to optimize crankshaft design based on vast amounts of simulation and experimental data, enabling rapid iteration and performance improvements[10].

Strengths: Multi-physics simulation capabilities, innovative sensor technologies, and data-driven optimization techniques. Weaknesses: Potential complexity in integrating multiple analysis domains and the need for extensive data collection and processing infrastructure.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated torsional analysis methodology for crankshafts in their engine designs, including those similar to L92 engines. Their approach combines experimental measurements with advanced computational models. Toyota utilizes high-precision torsional vibration measurement systems, including laser torsional vibrometers, to capture real-world data[2]. This data is then integrated into their proprietary simulation software, which incorporates both linear and non-linear analysis techniques. Toyota's method also considers the impact of oil film dynamics on crankshaft behavior, providing a more accurate representation of real-world conditions[4]. Additionally, they have implemented a unique optimization algorithm that balances performance, durability, and manufacturing constraints in crankshaft design.

Strengths: Integration of experimental and computational methods, consideration of oil film dynamics, and optimization for multiple design criteria. Weaknesses: Reliance on specialized measurement equipment and potential complexity in model calibration.

Core Innovations in Crankshaft Torsional Analysis

Method of controlling an air-fuel ratio of an engine

PatentInactiveEP0849456A3

Innovation

- A method that involves detecting the first and second angular velocities of the crankshaft within specific crank angle ranges, calculating the output fluctuation of cylinders, and judging whether the vehicle is driving over a rough road based on the amplitude and cycle of vehicle speed fluctuations, thereby prohibiting air-fuel ratio corrections during such conditions.

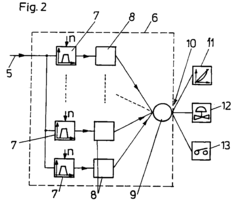

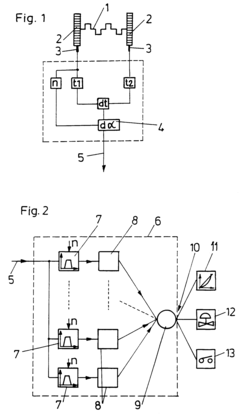

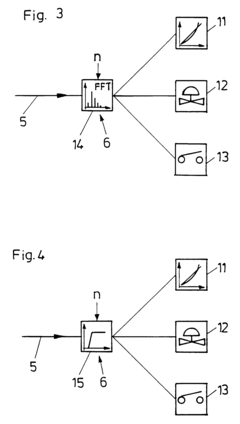

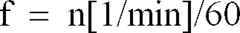

Identification of irregular working conditions of a combustion engine by revolution dependent torsional vibrations of the crankshaft

PatentInactiveEP0762101A1

Innovation

- A device that continuously detects the torsion angle of the crankshaft by emitting an electrical torsion signal and evaluates the amplitude of torsional vibration components at frequencies corresponding to the engine speed and its multiples, allowing for the analysis of oscillations over multiple revolutions, using toothed disks and pulse generators to determine the angle difference and process the torsion signal through bandpass filters to identify relevant harmonics.

Material Advancements for Crankshaft Design

Material advancements have played a crucial role in enhancing the performance and durability of crankshafts in L92 engines, particularly in relation to torsional analysis. The evolution of materials used in crankshaft design has been driven by the need for improved strength, fatigue resistance, and overall reliability under high-stress conditions.

Traditionally, forged steel has been the material of choice for crankshafts due to its excellent mechanical properties and cost-effectiveness. However, recent developments have led to the introduction of advanced alloys and composite materials that offer superior characteristics for torsional stability and vibration damping.

One significant advancement has been the use of micro-alloyed steels, which incorporate small amounts of elements such as vanadium, niobium, or titanium. These additions result in finer grain structures and improved strength-to-weight ratios, allowing for more compact and efficient crankshaft designs without compromising torsional rigidity.

Another promising material innovation is the application of bimetallic composites in crankshaft construction. By combining different metals with complementary properties, engineers have created crankshafts that exhibit enhanced torsional stiffness while maintaining the necessary ductility to withstand cyclic loading.

Carbon fiber reinforced polymers (CFRP) have also emerged as a potential material for crankshaft design, particularly in high-performance applications. While still in the experimental stage for mass-production engines, CFRP crankshafts offer significant weight reduction and improved damping characteristics, which can lead to better torsional behavior in L92 engines.

Surface treatment technologies have evolved to complement these material advancements. Techniques such as nitriding, carburizing, and shot peening have been refined to enhance the surface properties of crankshafts, improving wear resistance and fatigue life without altering the core material properties that affect torsional performance.

The integration of advanced materials with sophisticated manufacturing processes, such as precision forging and CNC machining, has allowed for more complex crankshaft geometries. These designs can incorporate optimized counterweights and web configurations that contribute to improved torsional characteristics and overall engine balance.

Looking forward, research is ongoing into the potential of nanomaterials and metal matrix composites for crankshaft applications. These cutting-edge materials promise to offer unprecedented combinations of strength, lightness, and damping properties, which could revolutionize torsional analysis and design considerations for future L92 engine crankshafts.

Traditionally, forged steel has been the material of choice for crankshafts due to its excellent mechanical properties and cost-effectiveness. However, recent developments have led to the introduction of advanced alloys and composite materials that offer superior characteristics for torsional stability and vibration damping.

One significant advancement has been the use of micro-alloyed steels, which incorporate small amounts of elements such as vanadium, niobium, or titanium. These additions result in finer grain structures and improved strength-to-weight ratios, allowing for more compact and efficient crankshaft designs without compromising torsional rigidity.

Another promising material innovation is the application of bimetallic composites in crankshaft construction. By combining different metals with complementary properties, engineers have created crankshafts that exhibit enhanced torsional stiffness while maintaining the necessary ductility to withstand cyclic loading.

Carbon fiber reinforced polymers (CFRP) have also emerged as a potential material for crankshaft design, particularly in high-performance applications. While still in the experimental stage for mass-production engines, CFRP crankshafts offer significant weight reduction and improved damping characteristics, which can lead to better torsional behavior in L92 engines.

Surface treatment technologies have evolved to complement these material advancements. Techniques such as nitriding, carburizing, and shot peening have been refined to enhance the surface properties of crankshafts, improving wear resistance and fatigue life without altering the core material properties that affect torsional performance.

The integration of advanced materials with sophisticated manufacturing processes, such as precision forging and CNC machining, has allowed for more complex crankshaft geometries. These designs can incorporate optimized counterweights and web configurations that contribute to improved torsional characteristics and overall engine balance.

Looking forward, research is ongoing into the potential of nanomaterials and metal matrix composites for crankshaft applications. These cutting-edge materials promise to offer unprecedented combinations of strength, lightness, and damping properties, which could revolutionize torsional analysis and design considerations for future L92 engine crankshafts.

Environmental Impact of L92 Engine Efficiency

The environmental impact of L92 engine efficiency is a critical consideration in the automotive industry's pursuit of sustainable transportation solutions. The L92 engine, known for its high performance and power output, has undergone significant improvements in efficiency over the years, resulting in reduced fuel consumption and emissions.

One of the primary environmental benefits of increased L92 engine efficiency is the reduction in greenhouse gas emissions. As the engine becomes more efficient, it requires less fuel to produce the same amount of power, leading to a decrease in carbon dioxide (CO2) emissions. This improvement directly contributes to mitigating climate change and helps automotive manufacturers meet increasingly stringent emissions regulations worldwide.

The enhanced efficiency of L92 engines also translates to reduced consumption of fossil fuels. This not only conserves non-renewable resources but also decreases the environmental impact associated with oil extraction, refining, and transportation. By extending the range of vehicles equipped with L92 engines, fewer refueling stops are required, potentially reducing the overall carbon footprint of transportation.

Advancements in L92 engine efficiency have led to improved air quality in urban areas. The reduction in particulate matter and nitrogen oxide emissions contributes to cleaner air, benefiting public health and reducing the formation of smog. This is particularly important in densely populated areas where air pollution from vehicle emissions is a significant concern.

The efficiency gains in L92 engines have also resulted in reduced noise pollution. As engines become more efficient, they often operate more quietly, contributing to a better quality of life in urban environments and reducing the negative impact on wildlife in rural areas.

Furthermore, the improved efficiency of L92 engines has implications for the entire vehicle lifecycle. More efficient engines typically have longer lifespans, reducing the frequency of engine replacements and the associated environmental costs of manufacturing and disposing of engine components. This extended lifespan contributes to a more sustainable approach to vehicle production and use.

The environmental benefits of L92 engine efficiency extend beyond direct emissions and fuel consumption. The reduced strain on engine components due to improved efficiency can lead to less frequent maintenance and fewer replacement parts required over the engine's lifetime. This, in turn, reduces the environmental impact associated with the production, transportation, and disposal of spare parts.

In conclusion, the environmental impact of L92 engine efficiency is multifaceted and far-reaching. From reduced greenhouse gas emissions and improved air quality to conservation of resources and extended engine lifespans, the advancements in L92 engine efficiency play a crucial role in the automotive industry's efforts to minimize its environmental footprint and contribute to a more sustainable future.

One of the primary environmental benefits of increased L92 engine efficiency is the reduction in greenhouse gas emissions. As the engine becomes more efficient, it requires less fuel to produce the same amount of power, leading to a decrease in carbon dioxide (CO2) emissions. This improvement directly contributes to mitigating climate change and helps automotive manufacturers meet increasingly stringent emissions regulations worldwide.

The enhanced efficiency of L92 engines also translates to reduced consumption of fossil fuels. This not only conserves non-renewable resources but also decreases the environmental impact associated with oil extraction, refining, and transportation. By extending the range of vehicles equipped with L92 engines, fewer refueling stops are required, potentially reducing the overall carbon footprint of transportation.

Advancements in L92 engine efficiency have led to improved air quality in urban areas. The reduction in particulate matter and nitrogen oxide emissions contributes to cleaner air, benefiting public health and reducing the formation of smog. This is particularly important in densely populated areas where air pollution from vehicle emissions is a significant concern.

The efficiency gains in L92 engines have also resulted in reduced noise pollution. As engines become more efficient, they often operate more quietly, contributing to a better quality of life in urban environments and reducing the negative impact on wildlife in rural areas.

Furthermore, the improved efficiency of L92 engines has implications for the entire vehicle lifecycle. More efficient engines typically have longer lifespans, reducing the frequency of engine replacements and the associated environmental costs of manufacturing and disposing of engine components. This extended lifespan contributes to a more sustainable approach to vehicle production and use.

The environmental benefits of L92 engine efficiency extend beyond direct emissions and fuel consumption. The reduced strain on engine components due to improved efficiency can lead to less frequent maintenance and fewer replacement parts required over the engine's lifetime. This, in turn, reduces the environmental impact associated with the production, transportation, and disposal of spare parts.

In conclusion, the environmental impact of L92 engine efficiency is multifaceted and far-reaching. From reduced greenhouse gas emissions and improved air quality to conservation of resources and extended engine lifespans, the advancements in L92 engine efficiency play a crucial role in the automotive industry's efforts to minimize its environmental footprint and contribute to a more sustainable future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!