Real-time data analytics for optimizing L92 engine performance

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Analytics Background and Objectives

The L92 engine, a powerful V8 powerplant developed by General Motors, has been a cornerstone in the automotive industry since its introduction in 2006. Initially designed for high-performance applications, this engine has evolved to meet the increasing demands for both power and efficiency in modern vehicles. The technological landscape surrounding engine performance optimization has undergone significant transformations, with real-time data analytics emerging as a game-changing approach.

The evolution of engine management systems has paved the way for more sophisticated data collection and analysis techniques. Early engine control units (ECUs) relied on pre-programmed maps and limited sensor inputs to manage engine operations. However, the advent of more powerful microprocessors and advanced sensor technologies has enabled the collection and processing of vast amounts of real-time data, opening new avenues for performance optimization.

The primary objective of implementing real-time data analytics for the L92 engine is to achieve a delicate balance between maximizing performance and maintaining optimal efficiency. This involves continuously monitoring and adjusting various engine parameters such as fuel injection timing, ignition timing, valve timing, and air-fuel ratios based on real-time operating conditions. By leveraging advanced analytics, engineers aim to push the boundaries of what's possible with internal combustion engines, extracting every ounce of performance while adhering to increasingly stringent emissions regulations.

Another crucial goal is to enhance the engine's adaptability to diverse driving conditions and user preferences. Real-time analytics can enable the engine to dynamically adjust its characteristics based on factors such as ambient temperature, altitude, fuel quality, and driving style. This level of adaptability not only improves overall performance but also contributes to a more personalized and satisfying driving experience.

Furthermore, the integration of real-time data analytics aims to extend the lifespan and reliability of the L92 engine. By continuously monitoring engine health and performance metrics, potential issues can be identified and addressed proactively, reducing the likelihood of catastrophic failures and minimizing maintenance costs. This predictive maintenance approach represents a significant shift from traditional scheduled maintenance practices, offering substantial benefits to both manufacturers and end-users.

As we look towards the future, the implementation of real-time data analytics in L92 engine optimization is expected to play a crucial role in bridging the gap between conventional internal combustion engines and emerging propulsion technologies. By pushing the boundaries of efficiency and performance, these advancements may extend the viability of internal combustion engines in an increasingly electrified automotive landscape, potentially influencing the trajectory of powertrain development for years to come.

The evolution of engine management systems has paved the way for more sophisticated data collection and analysis techniques. Early engine control units (ECUs) relied on pre-programmed maps and limited sensor inputs to manage engine operations. However, the advent of more powerful microprocessors and advanced sensor technologies has enabled the collection and processing of vast amounts of real-time data, opening new avenues for performance optimization.

The primary objective of implementing real-time data analytics for the L92 engine is to achieve a delicate balance between maximizing performance and maintaining optimal efficiency. This involves continuously monitoring and adjusting various engine parameters such as fuel injection timing, ignition timing, valve timing, and air-fuel ratios based on real-time operating conditions. By leveraging advanced analytics, engineers aim to push the boundaries of what's possible with internal combustion engines, extracting every ounce of performance while adhering to increasingly stringent emissions regulations.

Another crucial goal is to enhance the engine's adaptability to diverse driving conditions and user preferences. Real-time analytics can enable the engine to dynamically adjust its characteristics based on factors such as ambient temperature, altitude, fuel quality, and driving style. This level of adaptability not only improves overall performance but also contributes to a more personalized and satisfying driving experience.

Furthermore, the integration of real-time data analytics aims to extend the lifespan and reliability of the L92 engine. By continuously monitoring engine health and performance metrics, potential issues can be identified and addressed proactively, reducing the likelihood of catastrophic failures and minimizing maintenance costs. This predictive maintenance approach represents a significant shift from traditional scheduled maintenance practices, offering substantial benefits to both manufacturers and end-users.

As we look towards the future, the implementation of real-time data analytics in L92 engine optimization is expected to play a crucial role in bridging the gap between conventional internal combustion engines and emerging propulsion technologies. By pushing the boundaries of efficiency and performance, these advancements may extend the viability of internal combustion engines in an increasingly electrified automotive landscape, potentially influencing the trajectory of powertrain development for years to come.

Market Demand for Engine Performance Optimization

The market demand for engine performance optimization, particularly for the L92 engine, has been steadily increasing in recent years. This growth is driven by several factors, including stricter environmental regulations, rising fuel costs, and the automotive industry's push towards more efficient and powerful engines.

Engine manufacturers and automotive companies are increasingly focusing on real-time data analytics to enhance engine performance. The L92 engine, known for its high output and efficiency, has become a prime target for optimization efforts. By leveraging real-time data analytics, companies aim to fine-tune engine parameters on-the-fly, resulting in improved fuel efficiency, reduced emissions, and enhanced overall performance.

The automotive industry has seen a significant shift towards data-driven decision-making, with real-time analytics playing a crucial role. This trend is expected to continue, with the global automotive data analytics market projected to grow substantially in the coming years. The demand for advanced analytics solutions specifically tailored for engine performance optimization is a key driver of this growth.

Fleet operators and logistics companies are showing increased interest in real-time engine performance optimization technologies. These solutions offer the potential for substantial cost savings through reduced fuel consumption and improved vehicle longevity. As fuel prices continue to fluctuate and environmental concerns grow, the demand for such optimization technologies is expected to rise further.

The aftermarket sector also presents a significant opportunity for L92 engine performance optimization solutions. Performance enthusiasts and tuning shops are constantly seeking ways to extract maximum power and efficiency from their engines. Real-time data analytics tools that can provide instant feedback and optimization suggestions are highly sought after in this market segment.

Emerging markets, particularly in Asia and South America, are showing a growing appetite for advanced engine technologies. As these regions continue to develop and modernize their automotive industries, the demand for cutting-edge engine performance optimization solutions is expected to increase significantly.

However, the market also faces challenges. The complexity of implementing real-time data analytics systems and the need for specialized expertise can be barriers to adoption for some potential users. Additionally, concerns about data security and privacy in connected vehicle systems may impact market growth to some extent.

Despite these challenges, the overall market outlook for real-time data analytics in L92 engine performance optimization remains positive. As technology continues to advance and become more accessible, the demand for these solutions is expected to grow across various sectors of the automotive industry.

Engine manufacturers and automotive companies are increasingly focusing on real-time data analytics to enhance engine performance. The L92 engine, known for its high output and efficiency, has become a prime target for optimization efforts. By leveraging real-time data analytics, companies aim to fine-tune engine parameters on-the-fly, resulting in improved fuel efficiency, reduced emissions, and enhanced overall performance.

The automotive industry has seen a significant shift towards data-driven decision-making, with real-time analytics playing a crucial role. This trend is expected to continue, with the global automotive data analytics market projected to grow substantially in the coming years. The demand for advanced analytics solutions specifically tailored for engine performance optimization is a key driver of this growth.

Fleet operators and logistics companies are showing increased interest in real-time engine performance optimization technologies. These solutions offer the potential for substantial cost savings through reduced fuel consumption and improved vehicle longevity. As fuel prices continue to fluctuate and environmental concerns grow, the demand for such optimization technologies is expected to rise further.

The aftermarket sector also presents a significant opportunity for L92 engine performance optimization solutions. Performance enthusiasts and tuning shops are constantly seeking ways to extract maximum power and efficiency from their engines. Real-time data analytics tools that can provide instant feedback and optimization suggestions are highly sought after in this market segment.

Emerging markets, particularly in Asia and South America, are showing a growing appetite for advanced engine technologies. As these regions continue to develop and modernize their automotive industries, the demand for cutting-edge engine performance optimization solutions is expected to increase significantly.

However, the market also faces challenges. The complexity of implementing real-time data analytics systems and the need for specialized expertise can be barriers to adoption for some potential users. Additionally, concerns about data security and privacy in connected vehicle systems may impact market growth to some extent.

Despite these challenges, the overall market outlook for real-time data analytics in L92 engine performance optimization remains positive. As technology continues to advance and become more accessible, the demand for these solutions is expected to grow across various sectors of the automotive industry.

Current Challenges in Real-time Engine Data Analysis

Real-time data analytics for optimizing L92 engine performance faces several significant challenges that hinder its effective implementation and widespread adoption. One of the primary obstacles is the sheer volume and velocity of data generated by modern engines. The L92 engine, with its advanced sensors and control systems, produces an enormous amount of data in real-time, making it difficult to process and analyze quickly enough to provide actionable insights.

Data quality and consistency pose another major challenge. Sensor readings can be affected by various factors such as environmental conditions, wear and tear, or calibration issues. Ensuring the accuracy and reliability of the data collected is crucial for meaningful analysis, but it remains a complex task in real-world operating conditions.

The heterogeneity of data sources further complicates the analysis process. Engine data comes from multiple sensors measuring different parameters, often in various formats and at different sampling rates. Integrating and synchronizing this diverse data stream in real-time requires sophisticated data management and processing capabilities.

Latency issues present a significant hurdle in real-time analytics. The time taken to collect, transmit, process, and analyze data can introduce delays that may render the insights less valuable for immediate decision-making. Minimizing this latency while maintaining analytical accuracy is a delicate balance that engineers continue to struggle with.

The complexity of engine performance models also presents a challenge. Developing accurate models that can predict and optimize engine performance in real-time requires a deep understanding of engine dynamics and the ability to create algorithms that can quickly adapt to changing conditions. These models must be both sophisticated enough to capture the intricacies of engine behavior and simple enough to run in real-time.

Resource constraints on onboard computing systems add another layer of difficulty. While the demand for more complex analytics grows, the computing power available on vehicles remains limited due to cost, space, and power consumption considerations. This constraint often necessitates trade-offs between analytical depth and real-time performance.

Lastly, the interpretation and actionability of analytics results pose a significant challenge. Translating complex data analysis into clear, actionable insights that can be used to optimize engine performance in real-time requires not only advanced algorithms but also intuitive interfaces and decision support systems. Ensuring that these insights can be effectively utilized by both automated systems and human operators adds another layer of complexity to the challenge.

Data quality and consistency pose another major challenge. Sensor readings can be affected by various factors such as environmental conditions, wear and tear, or calibration issues. Ensuring the accuracy and reliability of the data collected is crucial for meaningful analysis, but it remains a complex task in real-world operating conditions.

The heterogeneity of data sources further complicates the analysis process. Engine data comes from multiple sensors measuring different parameters, often in various formats and at different sampling rates. Integrating and synchronizing this diverse data stream in real-time requires sophisticated data management and processing capabilities.

Latency issues present a significant hurdle in real-time analytics. The time taken to collect, transmit, process, and analyze data can introduce delays that may render the insights less valuable for immediate decision-making. Minimizing this latency while maintaining analytical accuracy is a delicate balance that engineers continue to struggle with.

The complexity of engine performance models also presents a challenge. Developing accurate models that can predict and optimize engine performance in real-time requires a deep understanding of engine dynamics and the ability to create algorithms that can quickly adapt to changing conditions. These models must be both sophisticated enough to capture the intricacies of engine behavior and simple enough to run in real-time.

Resource constraints on onboard computing systems add another layer of difficulty. While the demand for more complex analytics grows, the computing power available on vehicles remains limited due to cost, space, and power consumption considerations. This constraint often necessitates trade-offs between analytical depth and real-time performance.

Lastly, the interpretation and actionability of analytics results pose a significant challenge. Translating complex data analysis into clear, actionable insights that can be used to optimize engine performance in real-time requires not only advanced algorithms but also intuitive interfaces and decision support systems. Ensuring that these insights can be effectively utilized by both automated systems and human operators adds another layer of complexity to the challenge.

Existing Real-time Data Analytics Solutions

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize L92 engine performance. These systems monitor various parameters and adjust engine settings in real-time to improve efficiency, power output, and fuel economy. Techniques include adaptive learning, predictive modeling, and intelligent control strategies.- Engine control and optimization: Various methods and systems for controlling and optimizing L92 engine performance, including electronic control units, fuel injection strategies, and adaptive learning algorithms to improve efficiency and power output.

- Performance monitoring and diagnostics: Techniques for monitoring and diagnosing L92 engine performance, including sensor systems, data analysis methods, and predictive maintenance approaches to ensure optimal engine operation and early detection of potential issues.

- Combustion efficiency improvements: Innovations focused on enhancing combustion efficiency in L92 engines, such as advanced ignition systems, cylinder design modifications, and fuel mixture optimization to increase power output and reduce emissions.

- Turbocharging and forced induction: Implementation of turbocharging and other forced induction methods to boost L92 engine performance, including advanced turbocharger designs, intercooling systems, and electronic boost control mechanisms.

- Emissions reduction and environmental performance: Strategies and technologies for reducing emissions and improving the environmental performance of L92 engines, including exhaust gas recirculation systems, catalytic converters, and engine mapping techniques to meet stringent emissions standards while maintaining high performance.

02 Combustion efficiency improvements

Enhancements to the combustion process in L92 engines focus on improving fuel mixture, ignition timing, and exhaust gas management. These improvements lead to better fuel efficiency, increased power output, and reduced emissions. Technologies such as direct injection, variable valve timing, and advanced ignition systems are employed.Expand Specific Solutions03 Turbocharging and supercharging

Forced induction systems, including turbochargers and superchargers, are utilized to enhance L92 engine performance. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced designs focus on reducing lag and improving overall efficiency across various operating conditions.Expand Specific Solutions04 Thermal management and cooling systems

Effective thermal management is crucial for maintaining optimal L92 engine performance. Advanced cooling systems and heat dissipation techniques are employed to prevent overheating and ensure consistent performance under various operating conditions. This includes intelligent coolant flow control and materials with improved thermal properties.Expand Specific Solutions05 Performance monitoring and diagnostics

Sophisticated monitoring and diagnostic systems are implemented to assess L92 engine performance in real-time. These systems use sensors and data analysis to detect potential issues, optimize performance, and facilitate predictive maintenance. Advanced algorithms and machine learning techniques are employed to improve accuracy and reliability of diagnostics.Expand Specific Solutions

Key Players in Automotive Analytics Industry

The real-time data analytics for optimizing L92 engine performance is in a rapidly evolving phase, characterized by increasing market demand and technological advancements. The market is experiencing significant growth as automotive manufacturers seek to enhance engine efficiency and performance. While the technology is progressing, it's not yet fully mature, with companies at various stages of development. Key players like GM Global Technology Operations, Honeywell International Technologies, and Caterpillar are leading the charge, leveraging their extensive experience in engine manufacturing and data analytics. Emerging companies such as Beijing SinoHytec and Wuhan KOTEI Informatics are also making strides, particularly in integrating AI and IoT technologies for real-time optimization.

GM Global Technology Operations LLC

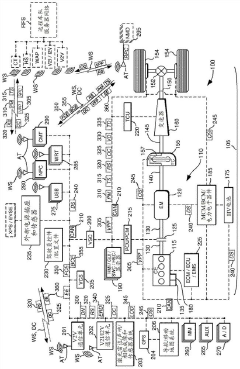

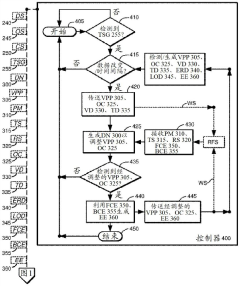

Technical Solution: GM's real-time data analytics for L92 engine optimization leverages advanced sensor technology and machine learning algorithms. The system continuously monitors key engine parameters such as fuel injection timing, air-fuel ratio, and exhaust gas recirculation. It uses predictive modeling to anticipate performance issues and adjust engine settings in real-time. GM's solution incorporates edge computing to process data locally, reducing latency and enabling faster response times. The system also utilizes cloud connectivity for more complex analytics and historical data analysis, allowing for continuous improvement of engine performance models[1][3]. GM's approach includes adaptive control strategies that can optimize engine performance based on driving conditions and driver behavior patterns.

Strengths: Comprehensive sensor integration, advanced predictive modeling, and adaptive control strategies. Weaknesses: Potential complexity in implementation and maintenance, reliance on robust data connectivity for cloud-based analytics.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell's real-time data analytics solution for L92 engine optimization leverages their expertise in industrial control systems and aerospace technology. Their approach combines advanced sensor technology with sophisticated control algorithms to continuously monitor and adjust engine performance. Honeywell's system utilizes a distributed network of smart sensors that provide high-frequency data on various engine parameters. This data is processed using their proprietary analytics platform, which employs artificial intelligence to identify patterns and anomalies in engine behavior. A key feature of Honeywell's solution is its integration with their broader Industrial Internet of Things (IIoT) ecosystem, allowing for comprehensive analysis that takes into account not just engine data, but also broader operational and environmental factors[8][10]. The system includes advanced prognostics and health management capabilities, using predictive analytics to anticipate potential engine issues and optimize maintenance schedules.

Strengths: Integration with broader IIoT ecosystem, advanced prognostics capabilities, and leveraging of aerospace technology expertise. Weaknesses: Potential high costs associated with full IIoT integration, may require significant infrastructure changes for implementation.

Core Innovations in L92 Engine Performance Monitoring

Vehicle real-time performance feedback system

PatentInactiveCN111868791A

Innovation

- Cloud-based neural networks are used to analyze real-time vehicle data, and deep learning neural networks are used to identify patterns in vehicle fleets and generate feedback notifications to adjust driver behavior, optimize vehicle performance parameters, and reduce fuel and battery consumption.

Engine transient performance simulation optimization method and system based on digital twinning

PatentPendingCN118795800A

Innovation

- By obtaining the actual operating data of the engine, preprocessing and building a digital twin model are performed to analyze performance bottlenecks, generate an optimization strategy and verify it in the digital twin model, and determine whether the optimization results meet the preset threshold. If so, a second optimization strategy is generated.

Regulatory Framework for Automotive Data Analytics

The regulatory framework for automotive data analytics in the context of real-time data analytics for optimizing L92 engine performance is a complex and evolving landscape. Governments and regulatory bodies worldwide are increasingly recognizing the importance of data-driven technologies in the automotive sector, particularly in engine optimization and performance enhancement.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has been at the forefront of developing guidelines for automotive data analytics. These guidelines emphasize the need for robust data security measures and privacy protection for vehicle owners. The NHTSA has also outlined requirements for data collection and usage transparency, ensuring that consumers are aware of how their vehicle data is being utilized for performance optimization.

The European Union has implemented the General Data Protection Regulation (GDPR), which has significant implications for automotive data analytics. Under GDPR, automotive manufacturers and service providers must obtain explicit consent from vehicle owners before collecting and processing their data for engine performance optimization. This regulation also mandates the implementation of data minimization principles and the right to data portability.

In China, the Cybersecurity Law and the Data Security Law provide the regulatory framework for automotive data analytics. These laws require automotive companies to store critical data within Chinese borders and undergo security assessments before transferring data overseas. This has implications for global automotive manufacturers implementing real-time data analytics for L92 engine optimization across different markets.

The International Organization for Standardization (ISO) has developed several standards relevant to automotive data analytics, including ISO 26262 for functional safety and ISO/SAE 21434 for cybersecurity. These standards provide a framework for ensuring the reliability and security of data-driven systems in vehicles, including those used for real-time engine performance optimization.

Regulatory bodies are also addressing the environmental impact of engine performance optimization. The Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) have set stringent emissions standards that influence how real-time data analytics can be applied to engine optimization. These regulations require manufacturers to balance performance improvements with emissions reduction, necessitating sophisticated data analytics approaches.

As the field of automotive data analytics continues to advance, regulatory frameworks are likely to evolve. There is a growing trend towards harmonization of regulations across different regions to facilitate global implementation of data-driven technologies. However, challenges remain in balancing innovation with data protection and privacy concerns, particularly as real-time data analytics become more sophisticated and integral to engine performance optimization.

In the United States, the National Highway Traffic Safety Administration (NHTSA) has been at the forefront of developing guidelines for automotive data analytics. These guidelines emphasize the need for robust data security measures and privacy protection for vehicle owners. The NHTSA has also outlined requirements for data collection and usage transparency, ensuring that consumers are aware of how their vehicle data is being utilized for performance optimization.

The European Union has implemented the General Data Protection Regulation (GDPR), which has significant implications for automotive data analytics. Under GDPR, automotive manufacturers and service providers must obtain explicit consent from vehicle owners before collecting and processing their data for engine performance optimization. This regulation also mandates the implementation of data minimization principles and the right to data portability.

In China, the Cybersecurity Law and the Data Security Law provide the regulatory framework for automotive data analytics. These laws require automotive companies to store critical data within Chinese borders and undergo security assessments before transferring data overseas. This has implications for global automotive manufacturers implementing real-time data analytics for L92 engine optimization across different markets.

The International Organization for Standardization (ISO) has developed several standards relevant to automotive data analytics, including ISO 26262 for functional safety and ISO/SAE 21434 for cybersecurity. These standards provide a framework for ensuring the reliability and security of data-driven systems in vehicles, including those used for real-time engine performance optimization.

Regulatory bodies are also addressing the environmental impact of engine performance optimization. The Environmental Protection Agency (EPA) in the United States and the European Environment Agency (EEA) have set stringent emissions standards that influence how real-time data analytics can be applied to engine optimization. These regulations require manufacturers to balance performance improvements with emissions reduction, necessitating sophisticated data analytics approaches.

As the field of automotive data analytics continues to advance, regulatory frameworks are likely to evolve. There is a growing trend towards harmonization of regulations across different regions to facilitate global implementation of data-driven technologies. However, challenges remain in balancing innovation with data protection and privacy concerns, particularly as real-time data analytics become more sophisticated and integral to engine performance optimization.

Environmental Impact of Optimized Engine Performance

The optimization of L92 engine performance through real-time data analytics has significant implications for environmental impact. As engines become more efficient, they consume less fuel and produce fewer emissions per unit of power output. This reduction in fuel consumption directly translates to lower carbon dioxide emissions, a primary contributor to global warming. Moreover, optimized engine performance often leads to more complete combustion, reducing the release of harmful pollutants such as carbon monoxide, nitrogen oxides, and particulate matter.

Real-time data analytics enable dynamic adjustments to engine parameters, ensuring optimal performance across various operating conditions. This adaptability results in consistent efficiency improvements, even under challenging environmental circumstances or varying driving patterns. By maintaining peak performance, these systems minimize instances of inefficient operation that could lead to increased emissions or fuel waste.

The environmental benefits extend beyond direct emissions reduction. Improved engine efficiency can lead to longer engine life spans, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines. Additionally, the data collected through these analytics systems can inform future engine designs, potentially leading to even more environmentally friendly iterations.

However, it is crucial to consider the potential environmental trade-offs. The implementation of real-time data analytics systems may require additional electronic components, which have their own environmental footprint in terms of production and eventual disposal. The increased complexity of these systems might also lead to more challenging recycling processes at the end of the engine's life cycle.

Furthermore, the energy consumption of the data processing and transmission systems necessary for real-time analytics must be factored into the overall environmental impact assessment. While the net effect is likely positive, a comprehensive life cycle analysis would be necessary to quantify the exact environmental benefits of these optimized engines.

In the broader context, the widespread adoption of such optimized engines could contribute significantly to meeting emissions reduction targets in the transportation sector. As regulations become increasingly stringent, the ability to demonstrate continuous improvement in engine efficiency and emissions reduction through data-driven optimization could become a critical factor in compliance and market competitiveness for engine manufacturers.

Real-time data analytics enable dynamic adjustments to engine parameters, ensuring optimal performance across various operating conditions. This adaptability results in consistent efficiency improvements, even under challenging environmental circumstances or varying driving patterns. By maintaining peak performance, these systems minimize instances of inefficient operation that could lead to increased emissions or fuel waste.

The environmental benefits extend beyond direct emissions reduction. Improved engine efficiency can lead to longer engine life spans, reducing the frequency of replacements and the associated environmental costs of manufacturing new engines. Additionally, the data collected through these analytics systems can inform future engine designs, potentially leading to even more environmentally friendly iterations.

However, it is crucial to consider the potential environmental trade-offs. The implementation of real-time data analytics systems may require additional electronic components, which have their own environmental footprint in terms of production and eventual disposal. The increased complexity of these systems might also lead to more challenging recycling processes at the end of the engine's life cycle.

Furthermore, the energy consumption of the data processing and transmission systems necessary for real-time analytics must be factored into the overall environmental impact assessment. While the net effect is likely positive, a comprehensive life cycle analysis would be necessary to quantify the exact environmental benefits of these optimized engines.

In the broader context, the widespread adoption of such optimized engines could contribute significantly to meeting emissions reduction targets in the transportation sector. As regulations become increasingly stringent, the ability to demonstrate continuous improvement in engine efficiency and emissions reduction through data-driven optimization could become a critical factor in compliance and market competitiveness for engine manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!