Heat treatment processes for L92 engine durability

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Heat Treatment Background and Objectives

The L92 engine, a high-performance V8 powerplant developed by General Motors, has been a cornerstone in the automotive industry since its introduction in the mid-2000s. This engine's durability and longevity are crucial factors in its success, with heat treatment processes playing a pivotal role in achieving these qualities. The evolution of heat treatment techniques for the L92 engine reflects broader trends in metallurgical engineering and automotive manufacturing.

Historically, heat treatment processes for engine components have undergone significant advancements. From basic quenching and tempering methods to more sophisticated controlled cooling techniques, the industry has continuously sought to enhance material properties. The L92 engine, with its aluminum block and heads, presents unique challenges and opportunities in heat treatment, necessitating a tailored approach to ensure optimal performance and durability.

The primary objective of heat treatment in L92 engine manufacturing is to improve the mechanical properties of its components, particularly in terms of strength, hardness, and wear resistance. This is especially critical for parts subjected to high stresses and temperatures during operation, such as cylinder liners, crankshafts, and camshafts. By carefully controlling the heating and cooling processes, manufacturers aim to achieve an ideal balance between hardness and ductility, thereby extending the engine's operational life and reliability.

Another key goal is to reduce internal stresses within the engine components. The complex geometries of modern engine parts can lead to residual stresses during manufacturing, which, if left unaddressed, could result in premature failure or distortion. Advanced heat treatment processes seek to alleviate these stresses, ensuring dimensional stability and consistent performance over the engine's lifetime.

The automotive industry's push towards increased fuel efficiency and reduced emissions has also influenced heat treatment objectives for the L92 engine. By optimizing the microstructure of engine components through precise heat treatment, engineers can reduce friction, improve thermal efficiency, and ultimately enhance the engine's overall performance and environmental footprint.

As technology progresses, new heat treatment techniques are being explored and implemented. These include laser heat treatment for localized hardening, induction heating for rapid and precise temperature control, and cryogenic treatments for enhanced wear resistance. The ongoing research and development in this field aim to further refine the L92 engine's durability while adapting to the evolving demands of modern automotive applications.

Historically, heat treatment processes for engine components have undergone significant advancements. From basic quenching and tempering methods to more sophisticated controlled cooling techniques, the industry has continuously sought to enhance material properties. The L92 engine, with its aluminum block and heads, presents unique challenges and opportunities in heat treatment, necessitating a tailored approach to ensure optimal performance and durability.

The primary objective of heat treatment in L92 engine manufacturing is to improve the mechanical properties of its components, particularly in terms of strength, hardness, and wear resistance. This is especially critical for parts subjected to high stresses and temperatures during operation, such as cylinder liners, crankshafts, and camshafts. By carefully controlling the heating and cooling processes, manufacturers aim to achieve an ideal balance between hardness and ductility, thereby extending the engine's operational life and reliability.

Another key goal is to reduce internal stresses within the engine components. The complex geometries of modern engine parts can lead to residual stresses during manufacturing, which, if left unaddressed, could result in premature failure or distortion. Advanced heat treatment processes seek to alleviate these stresses, ensuring dimensional stability and consistent performance over the engine's lifetime.

The automotive industry's push towards increased fuel efficiency and reduced emissions has also influenced heat treatment objectives for the L92 engine. By optimizing the microstructure of engine components through precise heat treatment, engineers can reduce friction, improve thermal efficiency, and ultimately enhance the engine's overall performance and environmental footprint.

As technology progresses, new heat treatment techniques are being explored and implemented. These include laser heat treatment for localized hardening, induction heating for rapid and precise temperature control, and cryogenic treatments for enhanced wear resistance. The ongoing research and development in this field aim to further refine the L92 engine's durability while adapting to the evolving demands of modern automotive applications.

Market Analysis for Durable L92 Engines

The market for durable L92 engines has shown significant growth potential in recent years, driven by increasing demand for high-performance and long-lasting automotive powertrains. The L92 engine, known for its robust design and impressive power output, has garnered attention from both automotive manufacturers and enthusiasts seeking reliable performance solutions.

Market research indicates that the global market for high-performance engines, including the L92, is expected to expand at a compound annual growth rate of 6.5% over the next five years. This growth is primarily attributed to the rising consumer preference for vehicles with enhanced power and durability, particularly in the luxury and sports car segments.

The automotive industry's shift towards more durable and efficient engines has created a favorable environment for L92 engine applications. Manufacturers are increasingly focusing on extending engine life cycles to meet stringent environmental regulations and consumer expectations for longevity. This trend has led to a surge in demand for advanced heat treatment processes that can significantly improve the durability of L92 engines.

Regional analysis reveals that North America currently holds the largest market share for durable L92 engines, followed by Europe and Asia-Pacific. The North American market benefits from a strong automotive manufacturing base and a culture of performance-oriented vehicles. However, the Asia-Pacific region is projected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing disposable incomes in countries like China and India.

Key market segments for L92 engines include high-performance passenger vehicles, light-duty trucks, and specialized racing applications. The passenger vehicle segment dominates the market, accounting for approximately 60% of the total demand. However, the light-duty truck segment is expected to grow at a faster rate due to the increasing popularity of powerful pickup trucks and SUVs.

The aftermarket for L92 engine components and upgrades also presents a substantial opportunity. Performance enthusiasts and custom car builders are driving demand for enhanced durability solutions, creating a niche market for specialized heat treatment services and upgraded engine parts.

Challenges in the market include the ongoing shift towards electric vehicles, which could potentially impact the long-term growth of internal combustion engines. However, industry experts predict that high-performance engines like the L92 will continue to have a strong presence in specific market segments, particularly in regions where EV infrastructure is still developing.

In conclusion, the market for durable L92 engines shows promising growth prospects, driven by consumer demand for high-performance and long-lasting powertrains. The development of advanced heat treatment processes to enhance engine durability aligns well with market trends and presents significant opportunities for manufacturers and suppliers in the automotive industry.

Market research indicates that the global market for high-performance engines, including the L92, is expected to expand at a compound annual growth rate of 6.5% over the next five years. This growth is primarily attributed to the rising consumer preference for vehicles with enhanced power and durability, particularly in the luxury and sports car segments.

The automotive industry's shift towards more durable and efficient engines has created a favorable environment for L92 engine applications. Manufacturers are increasingly focusing on extending engine life cycles to meet stringent environmental regulations and consumer expectations for longevity. This trend has led to a surge in demand for advanced heat treatment processes that can significantly improve the durability of L92 engines.

Regional analysis reveals that North America currently holds the largest market share for durable L92 engines, followed by Europe and Asia-Pacific. The North American market benefits from a strong automotive manufacturing base and a culture of performance-oriented vehicles. However, the Asia-Pacific region is projected to witness the fastest growth rate in the coming years, driven by rapid industrialization and increasing disposable incomes in countries like China and India.

Key market segments for L92 engines include high-performance passenger vehicles, light-duty trucks, and specialized racing applications. The passenger vehicle segment dominates the market, accounting for approximately 60% of the total demand. However, the light-duty truck segment is expected to grow at a faster rate due to the increasing popularity of powerful pickup trucks and SUVs.

The aftermarket for L92 engine components and upgrades also presents a substantial opportunity. Performance enthusiasts and custom car builders are driving demand for enhanced durability solutions, creating a niche market for specialized heat treatment services and upgraded engine parts.

Challenges in the market include the ongoing shift towards electric vehicles, which could potentially impact the long-term growth of internal combustion engines. However, industry experts predict that high-performance engines like the L92 will continue to have a strong presence in specific market segments, particularly in regions where EV infrastructure is still developing.

In conclusion, the market for durable L92 engines shows promising growth prospects, driven by consumer demand for high-performance and long-lasting powertrains. The development of advanced heat treatment processes to enhance engine durability aligns well with market trends and presents significant opportunities for manufacturers and suppliers in the automotive industry.

Current Heat Treatment Challenges for L92 Engines

The L92 engine, known for its high performance and durability, faces several challenges in its heat treatment processes. One of the primary issues is achieving uniform temperature distribution throughout the engine components during heat treatment. The complex geometry of L92 engine parts, particularly the cylinder heads and engine blocks, creates difficulties in ensuring consistent heat penetration. This non-uniformity can lead to variations in material properties, potentially compromising the engine's overall performance and longevity.

Another significant challenge is the prevention of distortion and warpage during the heat treatment process. The high temperatures involved in heat treating can cause dimensional changes in engine components, especially in thin-walled sections or areas with intricate designs. Maintaining precise tolerances is crucial for the L92 engine's efficiency and reliability, making this a critical concern for manufacturers.

The selection of appropriate heat treatment parameters poses another hurdle. Determining the optimal combination of temperature, time, and cooling rate is essential to achieve the desired microstructure and mechanical properties. For the L92 engine, this balance is particularly delicate as it requires enhancing both strength and wear resistance without sacrificing ductility or toughness. The challenge lies in developing heat treatment cycles that can simultaneously address these sometimes conflicting requirements.

Residual stress management is another area of concern in L92 engine heat treatment. The thermal gradients experienced during heating and cooling can induce internal stresses within the components. These residual stresses, if not properly controlled, can lead to premature failure or reduced fatigue life of engine parts. Implementing effective stress relief techniques without compromising other material properties remains a significant challenge.

Furthermore, the heat treatment of advanced materials used in L92 engines, such as high-strength aluminum alloys or specialized steel grades, presents its own set of challenges. These materials often require precise control over heating rates, holding times, and quenching conditions to achieve the desired microstructure and properties. The complexity of these processes increases the risk of defects and inconsistencies in the final product.

Lastly, environmental and energy efficiency considerations add another layer of complexity to L92 engine heat treatment. There is a growing need to develop more sustainable heat treatment processes that reduce energy consumption and minimize environmental impact. This includes exploring alternative heating methods, optimizing furnace designs, and implementing heat recovery systems. Balancing these sustainability goals with the stringent performance requirements of L92 engines remains an ongoing challenge in the industry.

Another significant challenge is the prevention of distortion and warpage during the heat treatment process. The high temperatures involved in heat treating can cause dimensional changes in engine components, especially in thin-walled sections or areas with intricate designs. Maintaining precise tolerances is crucial for the L92 engine's efficiency and reliability, making this a critical concern for manufacturers.

The selection of appropriate heat treatment parameters poses another hurdle. Determining the optimal combination of temperature, time, and cooling rate is essential to achieve the desired microstructure and mechanical properties. For the L92 engine, this balance is particularly delicate as it requires enhancing both strength and wear resistance without sacrificing ductility or toughness. The challenge lies in developing heat treatment cycles that can simultaneously address these sometimes conflicting requirements.

Residual stress management is another area of concern in L92 engine heat treatment. The thermal gradients experienced during heating and cooling can induce internal stresses within the components. These residual stresses, if not properly controlled, can lead to premature failure or reduced fatigue life of engine parts. Implementing effective stress relief techniques without compromising other material properties remains a significant challenge.

Furthermore, the heat treatment of advanced materials used in L92 engines, such as high-strength aluminum alloys or specialized steel grades, presents its own set of challenges. These materials often require precise control over heating rates, holding times, and quenching conditions to achieve the desired microstructure and properties. The complexity of these processes increases the risk of defects and inconsistencies in the final product.

Lastly, environmental and energy efficiency considerations add another layer of complexity to L92 engine heat treatment. There is a growing need to develop more sustainable heat treatment processes that reduce energy consumption and minimize environmental impact. This includes exploring alternative heating methods, optimizing furnace designs, and implementing heat recovery systems. Balancing these sustainability goals with the stringent performance requirements of L92 engines remains an ongoing challenge in the industry.

Existing L92 Heat Treatment Solutions

01 Improved engine component design

Enhancing the durability of L92 engines through improved design of critical components. This includes optimizing the structure of pistons, cylinders, and other key parts to withstand high temperatures and pressures, reducing wear and extending engine life.- Engine component design for improved durability: Enhancing the durability of L92 engines involves optimizing the design of various components. This includes improvements in piston design, cylinder liners, and valve train components to withstand high temperatures and pressures. Advanced materials and coatings are utilized to reduce wear and increase longevity. The overall engine structure is reinforced to handle increased stress and maintain performance over extended periods.

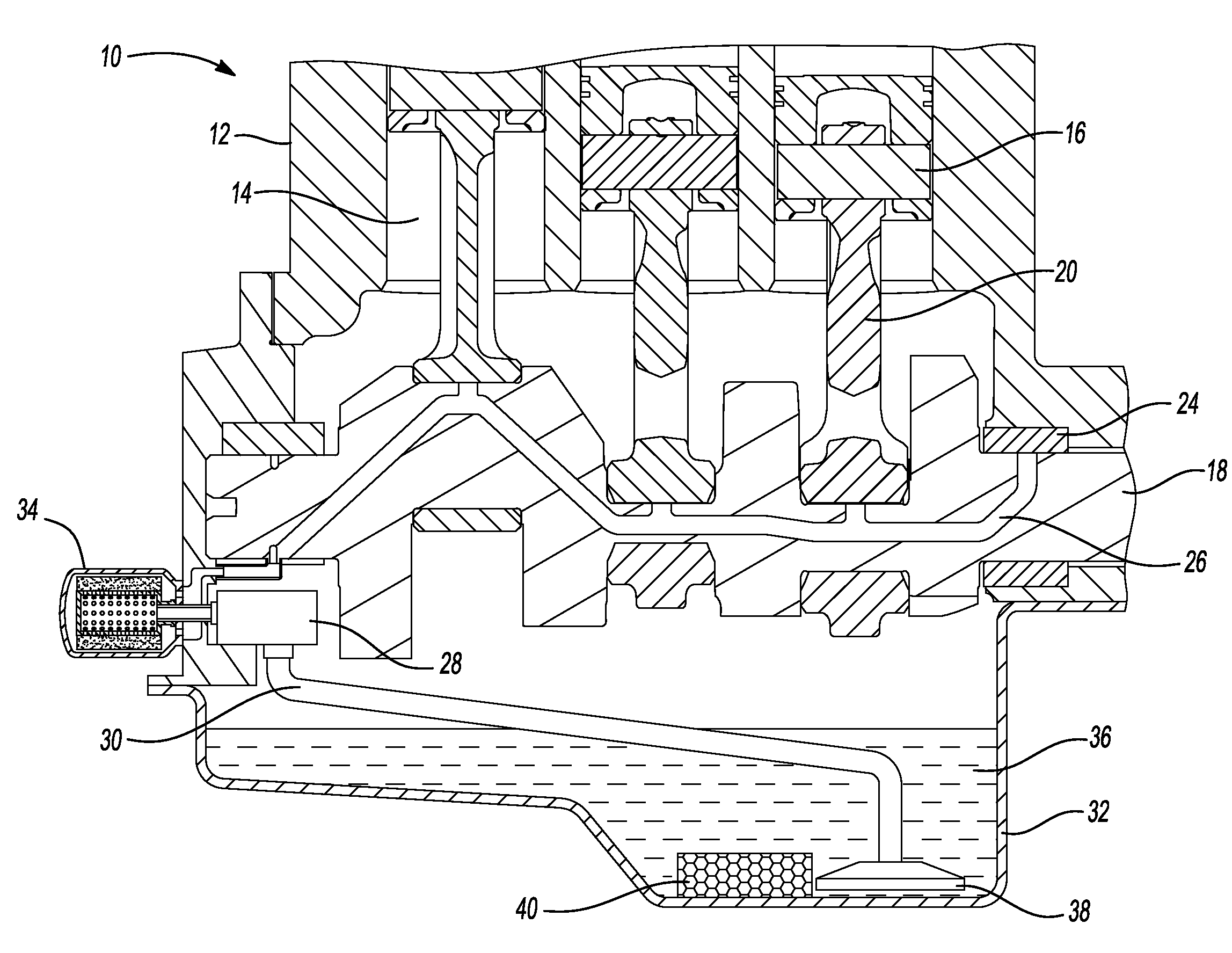

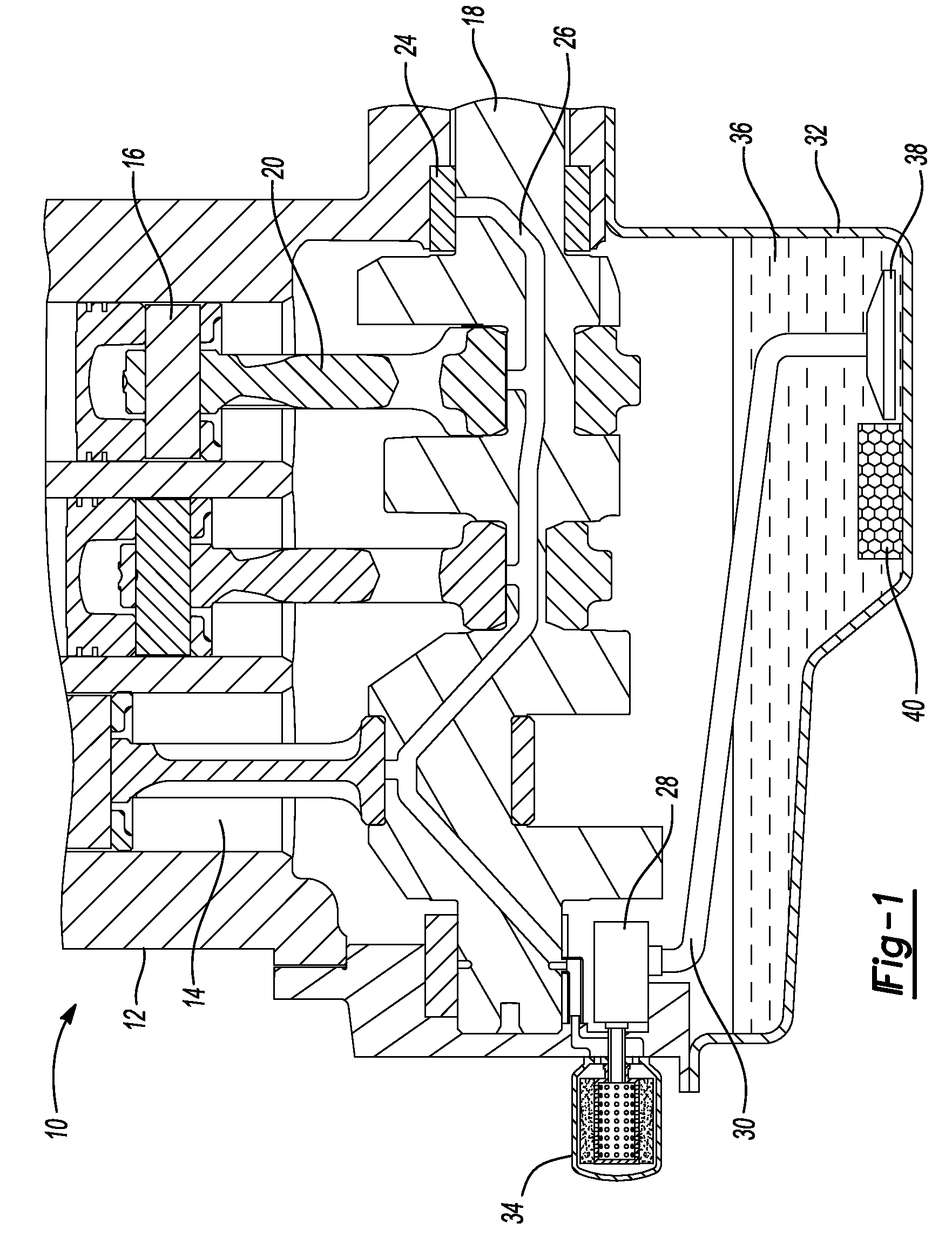

- Lubrication system enhancements: Improving the lubrication system is crucial for L92 engine durability. This involves optimizing oil flow paths, enhancing oil pump efficiency, and implementing advanced oil filtration systems. Specialized lubricants formulated for high-performance engines are used to reduce friction and wear. Oil cooling systems are also improved to maintain optimal oil temperature under various operating conditions.

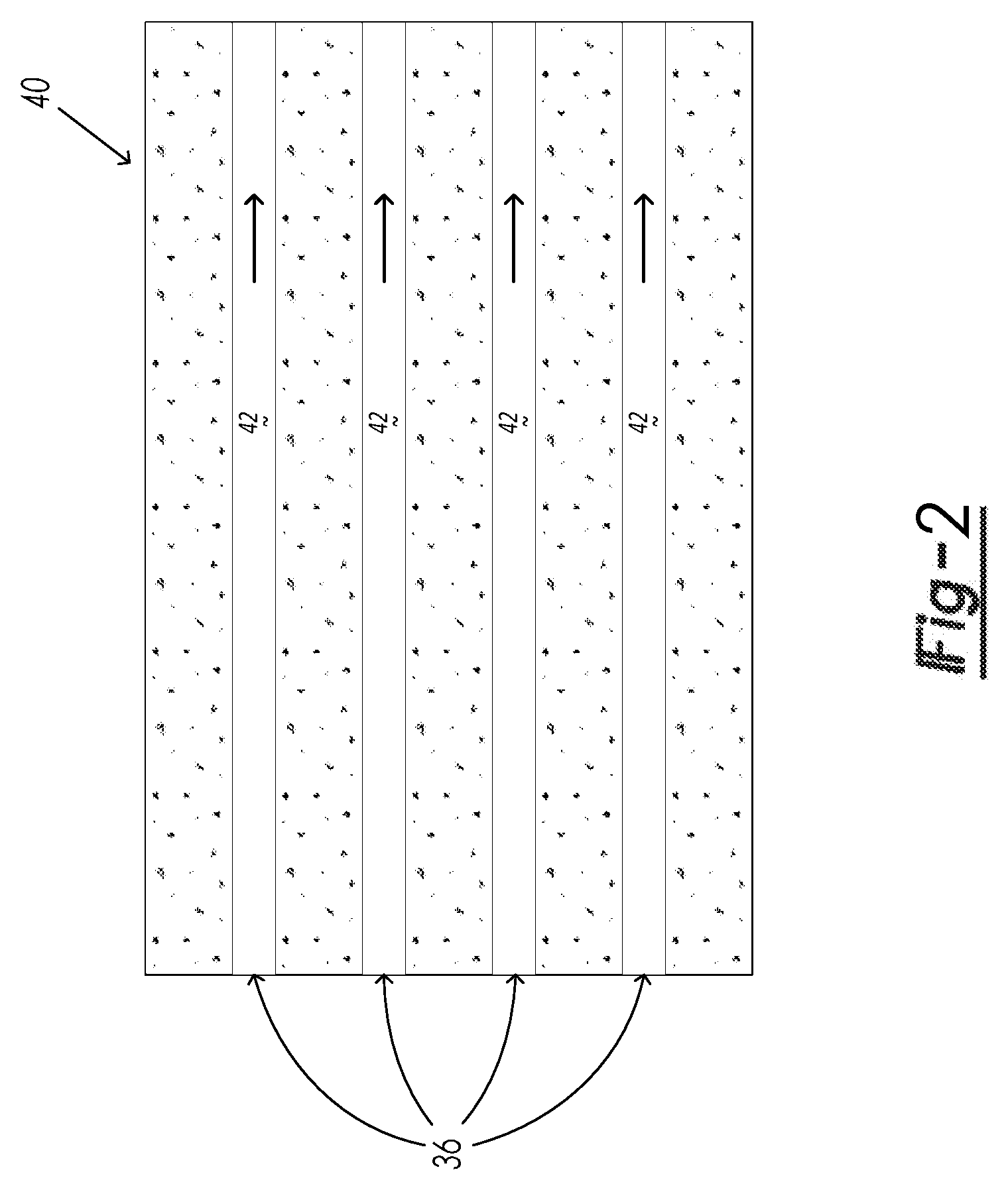

- Cooling system optimization: Effective cooling is essential for L92 engine durability. This includes redesigning coolant passages, improving water pump efficiency, and implementing advanced thermostat systems. The use of high-performance radiators and electric cooling fans helps maintain optimal engine temperature. Some designs incorporate precision cooling techniques to target specific high-heat areas of the engine.

- Electronic control and monitoring systems: Advanced electronic control systems are implemented to enhance L92 engine durability. These systems monitor various engine parameters in real-time, adjusting fuel injection, ignition timing, and valve timing for optimal performance and longevity. Sophisticated diagnostic systems are integrated to detect potential issues early, preventing major failures and extending engine life.

- Fuel system improvements: Enhancing the fuel system contributes to L92 engine durability. This includes upgrading fuel injectors for more precise fuel delivery, implementing advanced fuel filtration systems, and optimizing fuel pressure regulation. Some designs incorporate flex-fuel capabilities, allowing the engine to run on various fuel types without compromising longevity. Fuel system components are also designed to withstand the corrosive effects of modern fuels.

02 Advanced materials and coatings

Utilizing advanced materials and coatings to increase the durability of L92 engine components. This involves the application of wear-resistant coatings and the use of high-strength alloys to improve resistance to corrosion, friction, and thermal stress.Expand Specific Solutions03 Lubrication system enhancements

Improving the lubrication system of L92 engines to enhance durability. This includes optimizing oil flow, developing advanced oil formulations, and implementing more efficient filtration systems to reduce wear on engine components.Expand Specific Solutions04 Thermal management solutions

Implementing advanced thermal management solutions to improve L92 engine durability. This involves developing more efficient cooling systems, optimizing heat dissipation, and managing temperature distribution to prevent thermal stress and component failure.Expand Specific Solutions05 Engine control and monitoring systems

Developing sophisticated engine control and monitoring systems to enhance L92 engine durability. This includes implementing advanced sensors, real-time diagnostics, and adaptive control algorithms to optimize engine performance and prevent excessive wear or damage.Expand Specific Solutions

Key Players in L92 Engine Manufacturing

The heat treatment processes for L92 engine durability market is in a mature stage, with established players and proven technologies. The market size is significant, driven by the automotive and aerospace industries' demand for high-performance engines. Technologically, the field is advanced, with companies like General Electric, Siemens Energy, and Rolls-Royce leading innovation. These firms, along with specialized heat treatment providers such as Bharat Heavy Electricals and Haynes International, are continuously refining processes to enhance engine durability and efficiency. The competitive landscape is characterized by a mix of large conglomerates and niche players, with ongoing research at institutions like Xi'an Jiaotong University and Tianjin University contributing to technological advancements.

General Electric Company

Technical Solution: General Electric has developed advanced heat treatment processes for L92 engine durability, focusing on precision controlled heating and cooling cycles. Their approach involves a multi-stage heat treatment process, including solution treatment, quenching, and aging, tailored specifically for the L92 engine's aluminum alloy components[1]. GE utilizes state-of-the-art furnaces with precise temperature control and uniform heat distribution to ensure consistent material properties throughout the engine parts[2]. The company has also implemented advanced quenching techniques, such as high-pressure gas quenching, to minimize distortion and improve dimensional stability of critical engine components[3]. Additionally, GE has developed proprietary aging processes that optimize the microstructure of the alloy, enhancing strength and durability while maintaining the necessary ductility for engine operation[4].

Strengths: Precise control over heat treatment parameters, resulting in consistent and high-quality components. Advanced quenching techniques minimize distortion. Weaknesses: Potentially higher costs due to specialized equipment and longer processing times.

DENSO Corp.

Technical Solution: DENSO has developed an innovative heat treatment approach for L92 engine durability, focusing on precision control and energy efficiency. Their process incorporates advanced vacuum carburizing techniques for case hardening of critical engine components, ensuring improved wear resistance and fatigue strength[1]. DENSO utilizes a proprietary low-pressure carburizing process that allows for more uniform carbon penetration and reduced distortion compared to traditional atmospheric carburizing[2]. The company has implemented a sophisticated quenching system that combines high-pressure gas quenching with oil quenching, optimized for different engine components to achieve desired microstructures and mechanical properties[3]. DENSO's heat treatment strategy also includes advanced tempering processes with precise temperature control and multiple tempering cycles to optimize the balance between strength and ductility[4]. Additionally, they have developed an innovative surface treatment process that combines heat treatment with plasma nitriding for enhanced surface hardness and corrosion resistance of specific engine parts[5].

Strengths: Advanced vacuum carburizing techniques for improved wear resistance. Sophisticated quenching system optimized for different components. Weaknesses: Potentially higher initial costs due to specialized equipment for vacuum and plasma processes.

Innovative Heat Treatment Techniques for L92

A method for managing temperatures in an aftertreatment system

PatentPendingEP3196448A1

Innovation

- The method involves alternating between combusting rich and lean air/diesel mixtures in engine cylinders, with the frequency of these cycles based on desired aftertreatment system temperatures, utilizing CO's low oxidation temperature to generate exothermic reactions and raise temperatures in the aftertreatment system.

Release and Retention of Viscosity Modifiers Based on Oil Temperature

PatentInactiveUS20130248292A1

Innovation

- Incorporating a molecular sieve material that adsorbs viscosity modifier molecules at lower temperatures and releases them at a threshold temperature, thereby controlling lubricant viscosity and reducing exposure to mechanical shear and heat, which is achieved by selecting a material with thermal expansion properties that change pore size to desorb the viscosity modifiers into the lubricant at higher temperatures.

Environmental Impact of Heat Treatment Processes

Heat treatment processes for L92 engine components have significant environmental implications that must be carefully considered. These processes, while essential for enhancing engine durability, can contribute to various environmental concerns. The primary environmental impacts stem from energy consumption, emissions, and waste generation.

Energy consumption is a major factor in the environmental footprint of heat treatment processes. High-temperature furnaces and quenching systems require substantial amounts of electricity or fossil fuels, contributing to greenhouse gas emissions and resource depletion. Advanced heat treatment facilities are increasingly adopting energy-efficient technologies and renewable energy sources to mitigate these impacts.

Emissions from heat treatment processes can include volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter. These pollutants can contribute to air quality degradation and potential health risks in surrounding areas. Modern heat treatment facilities employ sophisticated emission control systems, such as scrubbers and filters, to minimize these environmental hazards.

Waste generation is another environmental concern associated with heat treatment processes. Quenching oils, cleaning solvents, and spent furnace linings can produce hazardous waste that requires proper disposal or recycling. Implementing closed-loop systems and adopting environmentally friendly quenchants can significantly reduce waste generation and associated environmental risks.

Water usage in quenching processes can also have environmental implications, particularly in water-stressed regions. Recycling and treatment of quenching water can help conserve this valuable resource and reduce the overall environmental impact of heat treatment operations.

The choice of heat treatment methods can influence the environmental impact. For instance, induction hardening may have a lower environmental footprint compared to traditional furnace-based methods due to its localized heating and reduced energy requirements. Similarly, vacuum heat treatment processes can minimize oxidation and reduce the need for post-treatment cleaning, thereby lowering chemical usage and waste generation.

As environmental regulations become more stringent, heat treatment facilities are increasingly adopting cleaner technologies and practices. This includes the use of computer-controlled processes to optimize energy consumption, implementation of heat recovery systems, and the adoption of environmentally friendly quenchants and cleaning agents.

In conclusion, while heat treatment processes are crucial for L92 engine durability, their environmental impact must be carefully managed. Continuous improvement in process efficiency, adoption of cleaner technologies, and implementation of robust environmental management systems are essential for minimizing the ecological footprint of these vital manufacturing processes.

Energy consumption is a major factor in the environmental footprint of heat treatment processes. High-temperature furnaces and quenching systems require substantial amounts of electricity or fossil fuels, contributing to greenhouse gas emissions and resource depletion. Advanced heat treatment facilities are increasingly adopting energy-efficient technologies and renewable energy sources to mitigate these impacts.

Emissions from heat treatment processes can include volatile organic compounds (VOCs), nitrogen oxides (NOx), and particulate matter. These pollutants can contribute to air quality degradation and potential health risks in surrounding areas. Modern heat treatment facilities employ sophisticated emission control systems, such as scrubbers and filters, to minimize these environmental hazards.

Waste generation is another environmental concern associated with heat treatment processes. Quenching oils, cleaning solvents, and spent furnace linings can produce hazardous waste that requires proper disposal or recycling. Implementing closed-loop systems and adopting environmentally friendly quenchants can significantly reduce waste generation and associated environmental risks.

Water usage in quenching processes can also have environmental implications, particularly in water-stressed regions. Recycling and treatment of quenching water can help conserve this valuable resource and reduce the overall environmental impact of heat treatment operations.

The choice of heat treatment methods can influence the environmental impact. For instance, induction hardening may have a lower environmental footprint compared to traditional furnace-based methods due to its localized heating and reduced energy requirements. Similarly, vacuum heat treatment processes can minimize oxidation and reduce the need for post-treatment cleaning, thereby lowering chemical usage and waste generation.

As environmental regulations become more stringent, heat treatment facilities are increasingly adopting cleaner technologies and practices. This includes the use of computer-controlled processes to optimize energy consumption, implementation of heat recovery systems, and the adoption of environmentally friendly quenchants and cleaning agents.

In conclusion, while heat treatment processes are crucial for L92 engine durability, their environmental impact must be carefully managed. Continuous improvement in process efficiency, adoption of cleaner technologies, and implementation of robust environmental management systems are essential for minimizing the ecological footprint of these vital manufacturing processes.

Cost-Benefit Analysis of Advanced Heat Treatments

The cost-benefit analysis of advanced heat treatments for L92 engine durability reveals significant potential for long-term economic advantages. Initial implementation costs for advanced heat treatment processes, such as controlled atmosphere heat treatment or precision quenching, may be substantial due to equipment upgrades and process modifications. However, these investments can lead to considerable savings over the engine's lifecycle.

Advanced heat treatments can significantly enhance the durability of L92 engine components, particularly those subjected to high temperatures and mechanical stress. This increased durability translates to extended service intervals, reduced maintenance costs, and improved overall engine reliability. For instance, precision-controlled carburizing can enhance the surface hardness of critical components, potentially doubling their lifespan compared to conventional heat treatment methods.

The reduction in warranty claims and recalls associated with premature component failure presents a major cost benefit. By improving the consistency and quality of heat-treated parts, manufacturers can minimize the risk of in-field failures, thereby reducing warranty expenses and preserving brand reputation. This aspect alone can justify the initial investment in advanced heat treatment technologies.

Energy efficiency improvements in modern heat treatment processes contribute to long-term cost savings. Techniques such as induction heating or vacuum heat treatment often consume less energy than traditional furnace-based methods, leading to reduced operational costs and a smaller carbon footprint. This aligns with increasingly stringent environmental regulations and can result in potential tax incentives or improved corporate sustainability ratings.

The ability to achieve more precise and consistent material properties through advanced heat treatments can also lead to weight reduction in engine components without compromising strength. This weight reduction can contribute to improved fuel efficiency, a critical factor in the automotive industry's pursuit of better performance and reduced emissions.

While the upfront costs of implementing advanced heat treatments may be significant, the long-term benefits in terms of improved product quality, reduced warranty costs, enhanced energy efficiency, and potential for lightweight design make a compelling case for investment. As competition in the automotive sector intensifies and environmental regulations become more stringent, the adoption of advanced heat treatment processes for L92 engine durability becomes not just a technical advantage but a strategic necessity for maintaining market competitiveness and meeting future regulatory requirements.

Advanced heat treatments can significantly enhance the durability of L92 engine components, particularly those subjected to high temperatures and mechanical stress. This increased durability translates to extended service intervals, reduced maintenance costs, and improved overall engine reliability. For instance, precision-controlled carburizing can enhance the surface hardness of critical components, potentially doubling their lifespan compared to conventional heat treatment methods.

The reduction in warranty claims and recalls associated with premature component failure presents a major cost benefit. By improving the consistency and quality of heat-treated parts, manufacturers can minimize the risk of in-field failures, thereby reducing warranty expenses and preserving brand reputation. This aspect alone can justify the initial investment in advanced heat treatment technologies.

Energy efficiency improvements in modern heat treatment processes contribute to long-term cost savings. Techniques such as induction heating or vacuum heat treatment often consume less energy than traditional furnace-based methods, leading to reduced operational costs and a smaller carbon footprint. This aligns with increasingly stringent environmental regulations and can result in potential tax incentives or improved corporate sustainability ratings.

The ability to achieve more precise and consistent material properties through advanced heat treatments can also lead to weight reduction in engine components without compromising strength. This weight reduction can contribute to improved fuel efficiency, a critical factor in the automotive industry's pursuit of better performance and reduced emissions.

While the upfront costs of implementing advanced heat treatments may be significant, the long-term benefits in terms of improved product quality, reduced warranty costs, enhanced energy efficiency, and potential for lightweight design make a compelling case for investment. As competition in the automotive sector intensifies and environmental regulations become more stringent, the adoption of advanced heat treatment processes for L92 engine durability becomes not just a technical advantage but a strategic necessity for maintaining market competitiveness and meeting future regulatory requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!