Assessing the impact of biodiesel on L92 engines

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodiesel and L92 Engine Background

Biodiesel has emerged as a promising alternative fuel in recent years, gaining attention for its potential to reduce greenhouse gas emissions and decrease dependence on fossil fuels. This renewable fuel is derived from vegetable oils, animal fats, or recycled cooking oils through a process called transesterification. As the automotive industry continues to evolve, understanding the impact of biodiesel on various engine types becomes crucial for both manufacturers and consumers.

The L92 engine, developed by General Motors, is a 6.2-liter V8 engine that has been widely used in high-performance vehicles. Known for its power and efficiency, the L92 engine has been a popular choice in various GM models, including the Chevrolet Corvette and Cadillac Escalade. Originally designed to run on conventional gasoline, the L92 engine's compatibility with alternative fuels like biodiesel has become a topic of interest for researchers and engineers.

The use of biodiesel in conventional diesel engines has been studied extensively, but its effects on gasoline engines like the L92 require further investigation. Biodiesel's chemical properties differ from those of conventional diesel and gasoline, potentially affecting engine performance, emissions, and longevity. These differences include higher oxygen content, increased viscosity, and varying cetane numbers, which can impact combustion characteristics and fuel system components.

As environmental regulations become more stringent and consumers demand more sustainable transportation options, the automotive industry is exploring ways to adapt existing engine technologies to accommodate alternative fuels. The L92 engine, with its advanced design and widespread use, presents an interesting case study for assessing the viability of biodiesel in high-performance gasoline engines.

Understanding the impact of biodiesel on L92 engines involves examining several key areas, including fuel system compatibility, combustion efficiency, emissions output, and long-term durability. Researchers must consider how biodiesel's unique properties interact with the engine's components, such as fuel injectors, pistons, and catalytic converters. Additionally, the effects on engine oil degradation and overall performance metrics need to be evaluated to determine the feasibility of using biodiesel in these engines.

This technical research aims to provide a comprehensive analysis of the challenges and opportunities associated with using biodiesel in L92 engines. By exploring the background of both biodiesel and the L92 engine, we can establish a foundation for understanding the potential impacts and guide future research and development efforts in this area.

The L92 engine, developed by General Motors, is a 6.2-liter V8 engine that has been widely used in high-performance vehicles. Known for its power and efficiency, the L92 engine has been a popular choice in various GM models, including the Chevrolet Corvette and Cadillac Escalade. Originally designed to run on conventional gasoline, the L92 engine's compatibility with alternative fuels like biodiesel has become a topic of interest for researchers and engineers.

The use of biodiesel in conventional diesel engines has been studied extensively, but its effects on gasoline engines like the L92 require further investigation. Biodiesel's chemical properties differ from those of conventional diesel and gasoline, potentially affecting engine performance, emissions, and longevity. These differences include higher oxygen content, increased viscosity, and varying cetane numbers, which can impact combustion characteristics and fuel system components.

As environmental regulations become more stringent and consumers demand more sustainable transportation options, the automotive industry is exploring ways to adapt existing engine technologies to accommodate alternative fuels. The L92 engine, with its advanced design and widespread use, presents an interesting case study for assessing the viability of biodiesel in high-performance gasoline engines.

Understanding the impact of biodiesel on L92 engines involves examining several key areas, including fuel system compatibility, combustion efficiency, emissions output, and long-term durability. Researchers must consider how biodiesel's unique properties interact with the engine's components, such as fuel injectors, pistons, and catalytic converters. Additionally, the effects on engine oil degradation and overall performance metrics need to be evaluated to determine the feasibility of using biodiesel in these engines.

This technical research aims to provide a comprehensive analysis of the challenges and opportunities associated with using biodiesel in L92 engines. By exploring the background of both biodiesel and the L92 engine, we can establish a foundation for understanding the potential impacts and guide future research and development efforts in this area.

Market Demand Analysis

The market demand for biodiesel and its impact on L92 engines has been steadily growing in recent years, driven by increasing environmental concerns and the push for sustainable energy solutions. The global biodiesel market is expected to expand significantly, with projections indicating a compound annual growth rate of over 5% through 2026.

The automotive industry, particularly the heavy-duty vehicle sector, has shown a keen interest in biodiesel as an alternative fuel source. L92 engines, known for their high performance and efficiency, are increasingly being tested and modified to accommodate higher biodiesel blends. This trend is largely influenced by stringent emission regulations and the need for reduced carbon footprints in transportation.

Fleet operators and logistics companies are among the primary drivers of biodiesel demand for L92 engines. These organizations are seeking ways to lower their operational costs while meeting sustainability targets. The potential for biodiesel to reduce maintenance costs and extend engine life, when used properly, has further stimulated market interest.

However, the market demand is not without challenges. Concerns about the long-term effects of biodiesel on engine performance and durability have led to cautious adoption rates in some sectors. Engine manufacturers and biodiesel producers are actively collaborating to address these concerns, focusing on developing biodiesel formulations that are fully compatible with L92 engines without compromising performance or longevity.

The agricultural sector plays a dual role in this market dynamic. As both a producer of biodiesel feedstock and a consumer of biodiesel-powered machinery, including those with L92 engines, this sector significantly influences market demand. Government policies promoting the use of biofuels in agriculture have further bolstered this trend.

Regional variations in biodiesel demand for L92 engines are notable. Europe leads in adoption rates, driven by progressive environmental policies and a well-established biodiesel production infrastructure. North America and Asia-Pacific regions are showing rapid growth, with increasing government support and rising awareness of biodiesel benefits.

The market is also seeing a shift towards higher biodiesel blends. While B5 (5% biodiesel) and B20 (20% biodiesel) have been common, there is growing interest in B30 and even B100 (pure biodiesel) for specially modified L92 engines. This trend is expected to drive innovation in engine design and fuel system components to ensure compatibility with these higher blends.

The automotive industry, particularly the heavy-duty vehicle sector, has shown a keen interest in biodiesel as an alternative fuel source. L92 engines, known for their high performance and efficiency, are increasingly being tested and modified to accommodate higher biodiesel blends. This trend is largely influenced by stringent emission regulations and the need for reduced carbon footprints in transportation.

Fleet operators and logistics companies are among the primary drivers of biodiesel demand for L92 engines. These organizations are seeking ways to lower their operational costs while meeting sustainability targets. The potential for biodiesel to reduce maintenance costs and extend engine life, when used properly, has further stimulated market interest.

However, the market demand is not without challenges. Concerns about the long-term effects of biodiesel on engine performance and durability have led to cautious adoption rates in some sectors. Engine manufacturers and biodiesel producers are actively collaborating to address these concerns, focusing on developing biodiesel formulations that are fully compatible with L92 engines without compromising performance or longevity.

The agricultural sector plays a dual role in this market dynamic. As both a producer of biodiesel feedstock and a consumer of biodiesel-powered machinery, including those with L92 engines, this sector significantly influences market demand. Government policies promoting the use of biofuels in agriculture have further bolstered this trend.

Regional variations in biodiesel demand for L92 engines are notable. Europe leads in adoption rates, driven by progressive environmental policies and a well-established biodiesel production infrastructure. North America and Asia-Pacific regions are showing rapid growth, with increasing government support and rising awareness of biodiesel benefits.

The market is also seeing a shift towards higher biodiesel blends. While B5 (5% biodiesel) and B20 (20% biodiesel) have been common, there is growing interest in B30 and even B100 (pure biodiesel) for specially modified L92 engines. This trend is expected to drive innovation in engine design and fuel system components to ensure compatibility with these higher blends.

Current Challenges

The current challenges in assessing the impact of biodiesel on L92 engines are multifaceted and complex. One of the primary issues is the variability in biodiesel composition, which can significantly affect engine performance and durability. Biodiesel derived from different feedstocks may have varying chemical properties, leading to inconsistent results in engine tests and making it difficult to establish standardized assessment protocols.

Another challenge lies in the long-term effects of biodiesel usage on L92 engines. While short-term studies have been conducted, there is a lack of comprehensive data on the extended use of biodiesel and its impact on engine components over time. This gap in knowledge makes it challenging for manufacturers and users to predict maintenance requirements and engine lifespan accurately.

The compatibility of biodiesel with existing engine materials presents another hurdle. L92 engines, designed primarily for conventional diesel fuel, may experience accelerated wear or degradation of certain components when exposed to biodiesel. This includes potential issues with seals, gaskets, and fuel system components that may not be fully resistant to the chemical properties of biodiesel.

Furthermore, the impact of biodiesel on engine emissions and performance under various operating conditions remains a complex area of study. While biodiesel generally reduces certain emissions, its effects on NOx levels and overall engine efficiency can vary depending on factors such as blend ratio, engine load, and ambient conditions. This variability complicates the assessment process and makes it challenging to draw definitive conclusions about the overall environmental impact of biodiesel use in L92 engines.

The lack of standardized testing methodologies specifically tailored for biodiesel in L92 engines also poses a significant challenge. Current assessment protocols may not fully capture the unique characteristics of biodiesel-engine interactions, leading to potential gaps in understanding and inconsistencies in results across different studies.

Additionally, the economic feasibility of widespread biodiesel adoption in L92 engines remains a concern. The cost of biodiesel production, potential modifications required for engines, and the overall lifecycle costs need to be carefully evaluated against the environmental benefits and performance characteristics. This economic aspect adds another layer of complexity to the assessment process.

Lastly, the regulatory landscape surrounding biodiesel use in engines is still evolving. Different regions may have varying standards and requirements for biodiesel blends, making it challenging for engine manufacturers to develop globally applicable solutions. This regulatory uncertainty can hinder comprehensive assessment efforts and slow down the adoption of biodiesel in L92 engines.

Another challenge lies in the long-term effects of biodiesel usage on L92 engines. While short-term studies have been conducted, there is a lack of comprehensive data on the extended use of biodiesel and its impact on engine components over time. This gap in knowledge makes it challenging for manufacturers and users to predict maintenance requirements and engine lifespan accurately.

The compatibility of biodiesel with existing engine materials presents another hurdle. L92 engines, designed primarily for conventional diesel fuel, may experience accelerated wear or degradation of certain components when exposed to biodiesel. This includes potential issues with seals, gaskets, and fuel system components that may not be fully resistant to the chemical properties of biodiesel.

Furthermore, the impact of biodiesel on engine emissions and performance under various operating conditions remains a complex area of study. While biodiesel generally reduces certain emissions, its effects on NOx levels and overall engine efficiency can vary depending on factors such as blend ratio, engine load, and ambient conditions. This variability complicates the assessment process and makes it challenging to draw definitive conclusions about the overall environmental impact of biodiesel use in L92 engines.

The lack of standardized testing methodologies specifically tailored for biodiesel in L92 engines also poses a significant challenge. Current assessment protocols may not fully capture the unique characteristics of biodiesel-engine interactions, leading to potential gaps in understanding and inconsistencies in results across different studies.

Additionally, the economic feasibility of widespread biodiesel adoption in L92 engines remains a concern. The cost of biodiesel production, potential modifications required for engines, and the overall lifecycle costs need to be carefully evaluated against the environmental benefits and performance characteristics. This economic aspect adds another layer of complexity to the assessment process.

Lastly, the regulatory landscape surrounding biodiesel use in engines is still evolving. Different regions may have varying standards and requirements for biodiesel blends, making it challenging for engine manufacturers to develop globally applicable solutions. This regulatory uncertainty can hinder comprehensive assessment efforts and slow down the adoption of biodiesel in L92 engines.

Existing Compatibility Solutions

01 L92 engine design and components

The L92 engine is a specific type of internal combustion engine, likely a V8 configuration. It may have unique design features or components that distinguish it from other engine types. This could include aspects such as cylinder arrangement, valve configuration, or specific performance characteristics.- L92 engine design and components: The L92 engine is a specific type of internal combustion engine, likely developed by General Motors. It features unique design elements and components that contribute to its performance characteristics. The engine may include specialized parts such as cylinder heads, valvetrain components, and fuel injection systems tailored for this particular model.

- Historical development of L92 engines: The L92 engine has a history of development and evolution, potentially tracing back to earlier engine designs. This point covers the progression of the engine's design, including improvements and modifications made over time to enhance its performance, efficiency, and reliability.

- Performance optimization for L92 engines: Various techniques and technologies may be employed to optimize the performance of L92 engines. This could include advancements in fuel injection, ignition timing, valve control, and other engine management systems to improve power output, fuel efficiency, and emissions control.

- Manufacturing processes for L92 engines: The production of L92 engines involves specific manufacturing processes and techniques. This point covers the methods used in engine assembly, quality control measures, and any specialized tooling or equipment required for the production of these engines.

- Integration of L92 engines in vehicle systems: This point addresses how L92 engines are integrated into vehicle systems, including considerations for engine mounting, cooling systems, exhaust systems, and electronic control interfaces. It may also cover adaptations required for different vehicle types or applications.

02 Performance optimization for L92 engines

Various methods and systems may be employed to optimize the performance of L92 engines. This could involve improvements in fuel efficiency, power output, or overall engine reliability. Techniques might include advanced fuel injection systems, improved combustion chamber designs, or enhanced cooling systems.Expand Specific Solutions03 Control systems for L92 engines

L92 engines may incorporate sophisticated control systems to manage various aspects of engine operation. This could include electronic control units (ECUs), sensors, and actuators that work together to optimize engine performance, monitor conditions, and adjust parameters in real-time.Expand Specific Solutions04 Manufacturing processes for L92 engines

Specific manufacturing techniques and processes may be employed in the production of L92 engines. This could involve precision machining, advanced assembly methods, or quality control procedures to ensure consistent performance and reliability across all produced units.Expand Specific Solutions05 Innovations and improvements in L92 engine technology

Ongoing research and development efforts may lead to innovations and improvements in L92 engine technology. This could include advancements in materials science, integration of hybrid or electric components, or novel approaches to increasing efficiency and reducing emissions.Expand Specific Solutions

Key Industry Players

The biodiesel impact assessment on L92 engines is in a nascent stage, with the market still developing and technology maturity varying across players. Major oil companies like China Petroleum & Chemical Corp., ConocoPhillips, and Phillips 66 are investing in research, while specialized firms such as Afton Chemical Corp. and Lubrizol Corp. focus on additive solutions. Academic institutions like Yale University and Tianjin University contribute to fundamental research. The competitive landscape is diverse, with automotive giants like GM, Ford, and Volkswagen also actively involved, indicating the technology's growing importance in the transportation sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to assess the impact of biodiesel on L92 engines. Their research focuses on optimizing biodiesel blends for improved engine performance and reduced emissions. Sinopec has conducted extensive testing on various biodiesel feedstocks, including waste cooking oil and non-edible plant oils, to determine their suitability for L92 engines[1]. They have implemented advanced fuel analysis techniques, such as gas chromatography and mass spectrometry, to characterize biodiesel properties and their effects on engine components[3]. Sinopec has also developed proprietary additives to enhance biodiesel stability and reduce its corrosive effects on engine parts, particularly in L92 engines[5].

Strengths: Extensive research capabilities, access to diverse feedstocks, and proprietary additive technology. Weaknesses: Potential higher production costs and limited long-term data on engine durability with biodiesel blends.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations LLC has developed a comprehensive approach to assess the impact of biodiesel on L92 engines, focusing on performance, emissions, and long-term durability. Their research involves advanced engine mapping techniques to optimize fuel injection timing and pressure for various biodiesel blends[2]. GM has implemented sophisticated sensors and data acquisition systems to monitor real-time engine performance parameters, including combustion characteristics and exhaust emissions[4]. They have also developed accelerated aging tests to simulate long-term effects of biodiesel use on L92 engine components, particularly focusing on fuel system components and lubricant degradation[6]. Additionally, GM has explored the use of advanced materials and coatings to enhance engine durability when using biodiesel fuels[8].

Strengths: Extensive experience with engine development, advanced testing facilities, and integration with vehicle systems. Weaknesses: Potential increased costs for engine modifications and limited field data on long-term biodiesel use in diverse operating conditions.

Core Biodiesel-L92 Innovations

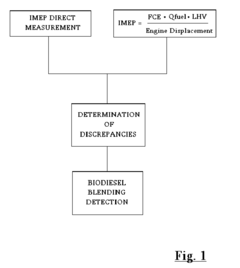

Method for biodiesel blending detection based on internal mean effective pressure evaluation

PatentInactiveUS20110093181A1

Innovation

- A method utilizing existing engine sensors and data from the Electronic Control Unit (ECU) to evaluate internal mean effective pressure (IMEP) through direct measurement and fuel conversion efficiency, allowing for biodiesel detection by comparing discrepancies in IMEP values, without additional hardware or costs.

Environmental Regulations

Environmental regulations play a crucial role in shaping the adoption and implementation of biodiesel in L92 engines. These regulations are designed to address the growing concerns over air quality, greenhouse gas emissions, and overall environmental impact of transportation fuels.

The United States Environmental Protection Agency (EPA) has established stringent standards for vehicle emissions and fuel quality. Under the Clean Air Act, the EPA has implemented the Renewable Fuel Standard (RFS) program, which mandates the blending of renewable fuels, including biodiesel, into transportation fuels. This program aims to reduce greenhouse gas emissions and promote energy independence.

In the European Union, the Renewable Energy Directive (RED) sets targets for renewable energy use in transportation. The directive requires member states to ensure that at least 10% of their transport fuel comes from renewable sources by 2020. This has led to increased biodiesel production and consumption across Europe, impacting the use of biodiesel in L92 engines.

Many countries have introduced tax incentives and subsidies to promote the use of biodiesel. These financial measures aim to make biodiesel more competitive with conventional diesel fuel and encourage its adoption in various engine types, including L92 engines.

Emissions regulations, such as the Euro 6 standards in Europe and Tier 3 standards in the United States, have become increasingly stringent. These regulations set limits on particulate matter, nitrogen oxides, and other pollutants emitted by diesel engines. Biodiesel's potential to reduce certain emissions makes it an attractive option for meeting these standards in L92 engines.

However, the impact of biodiesel on L92 engines must be carefully assessed to ensure compliance with these regulations. While biodiesel generally produces lower emissions of particulate matter and carbon monoxide, it may lead to slightly higher nitrogen oxide emissions in some cases. Engine manufacturers and fuel producers must work together to optimize biodiesel blends and engine calibrations to meet emission standards.

The use of biodiesel in L92 engines is also subject to fuel quality standards. Organizations such as ASTM International and the European Committee for Standardization (CEN) have developed specifications for biodiesel fuel. These standards ensure that biodiesel meets certain quality criteria, including oxidation stability, cold flow properties, and compatibility with engine components.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This may lead to increased pressure on engine manufacturers to develop L92 engines that can efficiently utilize higher biodiesel blends while meeting emission standards. Additionally, lifecycle assessment requirements may be introduced to evaluate the overall environmental impact of biodiesel production and use in L92 engines.

The United States Environmental Protection Agency (EPA) has established stringent standards for vehicle emissions and fuel quality. Under the Clean Air Act, the EPA has implemented the Renewable Fuel Standard (RFS) program, which mandates the blending of renewable fuels, including biodiesel, into transportation fuels. This program aims to reduce greenhouse gas emissions and promote energy independence.

In the European Union, the Renewable Energy Directive (RED) sets targets for renewable energy use in transportation. The directive requires member states to ensure that at least 10% of their transport fuel comes from renewable sources by 2020. This has led to increased biodiesel production and consumption across Europe, impacting the use of biodiesel in L92 engines.

Many countries have introduced tax incentives and subsidies to promote the use of biodiesel. These financial measures aim to make biodiesel more competitive with conventional diesel fuel and encourage its adoption in various engine types, including L92 engines.

Emissions regulations, such as the Euro 6 standards in Europe and Tier 3 standards in the United States, have become increasingly stringent. These regulations set limits on particulate matter, nitrogen oxides, and other pollutants emitted by diesel engines. Biodiesel's potential to reduce certain emissions makes it an attractive option for meeting these standards in L92 engines.

However, the impact of biodiesel on L92 engines must be carefully assessed to ensure compliance with these regulations. While biodiesel generally produces lower emissions of particulate matter and carbon monoxide, it may lead to slightly higher nitrogen oxide emissions in some cases. Engine manufacturers and fuel producers must work together to optimize biodiesel blends and engine calibrations to meet emission standards.

The use of biodiesel in L92 engines is also subject to fuel quality standards. Organizations such as ASTM International and the European Committee for Standardization (CEN) have developed specifications for biodiesel fuel. These standards ensure that biodiesel meets certain quality criteria, including oxidation stability, cold flow properties, and compatibility with engine components.

As environmental concerns continue to grow, it is likely that regulations will become even more stringent in the future. This may lead to increased pressure on engine manufacturers to develop L92 engines that can efficiently utilize higher biodiesel blends while meeting emission standards. Additionally, lifecycle assessment requirements may be introduced to evaluate the overall environmental impact of biodiesel production and use in L92 engines.

Economic Feasibility Study

The economic feasibility of implementing biodiesel in L92 engines depends on several factors, including production costs, market demand, and regulatory environment. Biodiesel production costs have decreased over the years due to technological advancements and economies of scale. However, they still remain higher than conventional diesel fuel production costs. The price differential between biodiesel and petroleum diesel varies depending on feedstock prices, production efficiency, and government incentives.

Market demand for biodiesel has been growing steadily, driven by environmental concerns and government mandates. Many countries have implemented policies to promote biodiesel usage, such as blending mandates and tax incentives. These policies significantly impact the economic viability of biodiesel in L92 engines. The European Union, for instance, has set targets for renewable energy in transport, creating a substantial market for biodiesel.

The economic feasibility also depends on the performance and durability of L92 engines when using biodiesel. While biodiesel generally performs well in diesel engines, it may require some modifications or adjustments to optimize performance and prevent potential issues. These modifications could add to the overall cost of implementation but may be offset by potential benefits such as reduced maintenance costs and extended engine life.

Fuel efficiency is another crucial factor in the economic equation. Biodiesel typically has a slightly lower energy content compared to petroleum diesel, which can result in marginally reduced fuel economy. However, this difference is often negligible in real-world applications, especially with lower blend ratios.

The availability and cost of feedstock play a significant role in the economic feasibility of biodiesel for L92 engines. Feedstock costs can account for up to 80% of biodiesel production costs. The diversity of potential feedstocks, including vegetable oils, animal fats, and waste oils, provides flexibility but also introduces price volatility based on agricultural markets and competing uses.

Infrastructure requirements for biodiesel distribution and storage should also be considered in the economic assessment. While biodiesel can use existing diesel infrastructure, some modifications may be necessary, particularly for higher blend ratios. These costs should be factored into the overall economic analysis.

Long-term economic viability will depend on technological advancements in biodiesel production and engine design. Ongoing research aims to improve production efficiency, reduce costs, and enhance engine compatibility. As these technologies mature, the economic feasibility of biodiesel in L92 engines is likely to improve.

Market demand for biodiesel has been growing steadily, driven by environmental concerns and government mandates. Many countries have implemented policies to promote biodiesel usage, such as blending mandates and tax incentives. These policies significantly impact the economic viability of biodiesel in L92 engines. The European Union, for instance, has set targets for renewable energy in transport, creating a substantial market for biodiesel.

The economic feasibility also depends on the performance and durability of L92 engines when using biodiesel. While biodiesel generally performs well in diesel engines, it may require some modifications or adjustments to optimize performance and prevent potential issues. These modifications could add to the overall cost of implementation but may be offset by potential benefits such as reduced maintenance costs and extended engine life.

Fuel efficiency is another crucial factor in the economic equation. Biodiesel typically has a slightly lower energy content compared to petroleum diesel, which can result in marginally reduced fuel economy. However, this difference is often negligible in real-world applications, especially with lower blend ratios.

The availability and cost of feedstock play a significant role in the economic feasibility of biodiesel for L92 engines. Feedstock costs can account for up to 80% of biodiesel production costs. The diversity of potential feedstocks, including vegetable oils, animal fats, and waste oils, provides flexibility but also introduces price volatility based on agricultural markets and competing uses.

Infrastructure requirements for biodiesel distribution and storage should also be considered in the economic assessment. While biodiesel can use existing diesel infrastructure, some modifications may be necessary, particularly for higher blend ratios. These costs should be factored into the overall economic analysis.

Long-term economic viability will depend on technological advancements in biodiesel production and engine design. Ongoing research aims to improve production efficiency, reduce costs, and enhance engine compatibility. As these technologies mature, the economic feasibility of biodiesel in L92 engines is likely to improve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!