Advanced sealing technologies in L92 engine applications

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Sealing Evolution

The L92 engine, a high-performance V8 developed by General Motors, has undergone significant advancements in sealing technologies throughout its evolution. Initially introduced in the mid-2000s, this engine has seen continuous improvements in its sealing systems to enhance performance, efficiency, and reliability.

In the early stages of L92 engine development, traditional gasket materials and sealing methods were employed. These included multi-layer steel (MLS) head gaskets and conventional rubber-based seals for various engine components. While effective, these early sealing solutions faced challenges in maintaining integrity under high-performance conditions and prolonged use.

As engine performance demands increased, engineers focused on developing more robust sealing technologies. Advanced elastomeric compounds were introduced for critical seals, offering improved temperature resistance and durability. These materials, often incorporating fluoroelastomers or perfluoroelastomers, provided better chemical compatibility with modern engine oils and coolants.

The evolution of head gasket technology played a crucial role in L92 engine sealing. Enhanced MLS gaskets with improved coating technologies were developed to withstand higher combustion pressures and temperatures. These gaskets featured multiple layers of embossed steel, with elastomer coatings that provided superior sealing properties and conformability to engine block and cylinder head surfaces.

Advancements in manufacturing processes also contributed to improved sealing. Precision machining techniques and tighter tolerances in engine block and cylinder head production resulted in better mating surfaces, reducing the likelihood of leaks and improving overall sealing effectiveness.

The integration of advanced sealing technologies extended to other critical areas of the L92 engine. Improved valve stem seals were developed to minimize oil consumption and emissions. These seals utilized advanced materials and designs to maintain effectiveness over a wider range of operating conditions and engine speeds.

As environmental regulations became more stringent, sealing technologies evolved to address emissions concerns. This led to the development of low-permeation materials for fuel system seals and gaskets, reducing hydrocarbon emissions from the engine.

The most recent iterations of L92 engine sealing technologies have seen the incorporation of smart materials and sensor-integrated seals. These innovations allow for real-time monitoring of seal integrity and performance, enabling predictive maintenance and further enhancing engine reliability.

Throughout its evolution, L92 engine sealing technologies have consistently pushed the boundaries of material science and engineering. The ongoing development in this area has not only improved engine performance and longevity but has also contributed to advancements in sealing technologies across the automotive industry.

In the early stages of L92 engine development, traditional gasket materials and sealing methods were employed. These included multi-layer steel (MLS) head gaskets and conventional rubber-based seals for various engine components. While effective, these early sealing solutions faced challenges in maintaining integrity under high-performance conditions and prolonged use.

As engine performance demands increased, engineers focused on developing more robust sealing technologies. Advanced elastomeric compounds were introduced for critical seals, offering improved temperature resistance and durability. These materials, often incorporating fluoroelastomers or perfluoroelastomers, provided better chemical compatibility with modern engine oils and coolants.

The evolution of head gasket technology played a crucial role in L92 engine sealing. Enhanced MLS gaskets with improved coating technologies were developed to withstand higher combustion pressures and temperatures. These gaskets featured multiple layers of embossed steel, with elastomer coatings that provided superior sealing properties and conformability to engine block and cylinder head surfaces.

Advancements in manufacturing processes also contributed to improved sealing. Precision machining techniques and tighter tolerances in engine block and cylinder head production resulted in better mating surfaces, reducing the likelihood of leaks and improving overall sealing effectiveness.

The integration of advanced sealing technologies extended to other critical areas of the L92 engine. Improved valve stem seals were developed to minimize oil consumption and emissions. These seals utilized advanced materials and designs to maintain effectiveness over a wider range of operating conditions and engine speeds.

As environmental regulations became more stringent, sealing technologies evolved to address emissions concerns. This led to the development of low-permeation materials for fuel system seals and gaskets, reducing hydrocarbon emissions from the engine.

The most recent iterations of L92 engine sealing technologies have seen the incorporation of smart materials and sensor-integrated seals. These innovations allow for real-time monitoring of seal integrity and performance, enabling predictive maintenance and further enhancing engine reliability.

Throughout its evolution, L92 engine sealing technologies have consistently pushed the boundaries of material science and engineering. The ongoing development in this area has not only improved engine performance and longevity but has also contributed to advancements in sealing technologies across the automotive industry.

Market Demand Analysis

The market demand for advanced sealing technologies in L92 engine applications has been steadily increasing due to the growing emphasis on engine efficiency, performance, and environmental regulations. As automotive manufacturers strive to meet stringent emission standards and improve fuel economy, the need for high-performance sealing solutions has become paramount.

The L92 engine, known for its high output and reliability, is widely used in various General Motors vehicles, including luxury SUVs and performance cars. This widespread adoption has created a substantial market for specialized sealing technologies tailored to the L92's unique requirements. The demand is driven by both original equipment manufacturers (OEMs) and aftermarket suppliers seeking to enhance engine longevity and performance.

One of the key factors fueling market growth is the increasing focus on reducing oil consumption and emissions. Advanced sealing technologies play a crucial role in minimizing oil leaks and maintaining optimal engine compression, directly contributing to improved fuel efficiency and reduced environmental impact. This aligns with global trends towards sustainability and eco-friendly transportation solutions.

The aftermarket segment for L92 engine sealing technologies has shown significant potential, driven by the large existing fleet of vehicles equipped with these engines. As these vehicles age, the demand for high-quality replacement seals and gaskets increases, presenting opportunities for manufacturers and suppliers in the automotive aftermarket sector.

Furthermore, the racing and high-performance vehicle market has emerged as a niche but lucrative segment for advanced sealing technologies. L92 engines modified for racing applications require specialized sealing solutions capable of withstanding extreme temperatures and pressures, driving innovation in materials and design.

The market for advanced sealing technologies in L92 engines is also influenced by the broader trend of engine downsizing and turbocharging. As manufacturers explore ways to extract more power from smaller engines, the demands on sealing components increase, necessitating more robust and technologically advanced solutions.

Geographically, North America remains the largest market for L92 engine sealing technologies, given the engine's prevalence in American-made vehicles. However, emerging markets in Asia and Europe are showing increased demand as global automotive manufacturers adopt similar engine designs and technologies.

In conclusion, the market for advanced sealing technologies in L92 engine applications is characterized by steady growth, driven by regulatory pressures, performance demands, and the need for sustainable automotive solutions. The industry's focus on innovation and material science is expected to further expand this market, offering significant opportunities for manufacturers and suppliers in the coming years.

The L92 engine, known for its high output and reliability, is widely used in various General Motors vehicles, including luxury SUVs and performance cars. This widespread adoption has created a substantial market for specialized sealing technologies tailored to the L92's unique requirements. The demand is driven by both original equipment manufacturers (OEMs) and aftermarket suppliers seeking to enhance engine longevity and performance.

One of the key factors fueling market growth is the increasing focus on reducing oil consumption and emissions. Advanced sealing technologies play a crucial role in minimizing oil leaks and maintaining optimal engine compression, directly contributing to improved fuel efficiency and reduced environmental impact. This aligns with global trends towards sustainability and eco-friendly transportation solutions.

The aftermarket segment for L92 engine sealing technologies has shown significant potential, driven by the large existing fleet of vehicles equipped with these engines. As these vehicles age, the demand for high-quality replacement seals and gaskets increases, presenting opportunities for manufacturers and suppliers in the automotive aftermarket sector.

Furthermore, the racing and high-performance vehicle market has emerged as a niche but lucrative segment for advanced sealing technologies. L92 engines modified for racing applications require specialized sealing solutions capable of withstanding extreme temperatures and pressures, driving innovation in materials and design.

The market for advanced sealing technologies in L92 engines is also influenced by the broader trend of engine downsizing and turbocharging. As manufacturers explore ways to extract more power from smaller engines, the demands on sealing components increase, necessitating more robust and technologically advanced solutions.

Geographically, North America remains the largest market for L92 engine sealing technologies, given the engine's prevalence in American-made vehicles. However, emerging markets in Asia and Europe are showing increased demand as global automotive manufacturers adopt similar engine designs and technologies.

In conclusion, the market for advanced sealing technologies in L92 engine applications is characterized by steady growth, driven by regulatory pressures, performance demands, and the need for sustainable automotive solutions. The industry's focus on innovation and material science is expected to further expand this market, offering significant opportunities for manufacturers and suppliers in the coming years.

Current Sealing Challenges

The L92 engine, known for its high-performance capabilities, faces several critical sealing challenges that demand advanced solutions. One of the primary issues is the high-temperature environment within the engine, which puts significant stress on traditional sealing materials. As combustion temperatures continue to rise in pursuit of increased efficiency, conventional elastomeric seals often fail prematurely, leading to oil leaks and reduced engine performance.

Another major challenge is the need for seals that can withstand the increased pressure levels in modern high-compression engines. The L92's design pushes the limits of conventional sealing technologies, requiring materials and designs that can maintain their integrity under extreme pressure fluctuations. This is particularly crucial in areas such as cylinder head gaskets and valve stem seals, where even minor leaks can lead to significant performance degradation.

The dynamic nature of engine operation also presents a unique set of challenges for sealing technologies. Rapid temperature changes and constant vibration can cause seals to deform or lose their sealing properties over time. This is especially problematic in areas like crankshaft seals and oil pan gaskets, where maintaining a perfect seal is critical for preventing oil leaks and ensuring proper lubrication.

Compatibility with modern engine oils and coolants is another area of concern. As engine fluids become more advanced, with complex additive packages designed to improve performance and longevity, sealing materials must be able to resist chemical degradation. This challenge is particularly acute in the L92 engine, where high-performance fluids are often used to maximize engine output.

The quest for weight reduction in automotive design also impacts sealing technologies. Traditional metal gaskets and heavy-duty seals contribute to the overall weight of the engine, conflicting with efforts to improve fuel efficiency. Developing lightweight yet durable sealing solutions that can withstand the harsh environment of the L92 engine remains a significant challenge for engineers and material scientists.

Lastly, the increasing complexity of engine designs, including the integration of advanced technologies like direct injection and variable valve timing, creates new sealing challenges. These systems often require intricate sealing solutions to prevent cross-contamination between different fluid systems and to maintain precise tolerances necessary for optimal performance.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and rigorous testing protocols. The development of new composite materials, nano-engineered surfaces, and smart sealing systems that can adapt to changing conditions are all areas of active research in the quest to overcome the current sealing challenges in L92 engine applications.

Another major challenge is the need for seals that can withstand the increased pressure levels in modern high-compression engines. The L92's design pushes the limits of conventional sealing technologies, requiring materials and designs that can maintain their integrity under extreme pressure fluctuations. This is particularly crucial in areas such as cylinder head gaskets and valve stem seals, where even minor leaks can lead to significant performance degradation.

The dynamic nature of engine operation also presents a unique set of challenges for sealing technologies. Rapid temperature changes and constant vibration can cause seals to deform or lose their sealing properties over time. This is especially problematic in areas like crankshaft seals and oil pan gaskets, where maintaining a perfect seal is critical for preventing oil leaks and ensuring proper lubrication.

Compatibility with modern engine oils and coolants is another area of concern. As engine fluids become more advanced, with complex additive packages designed to improve performance and longevity, sealing materials must be able to resist chemical degradation. This challenge is particularly acute in the L92 engine, where high-performance fluids are often used to maximize engine output.

The quest for weight reduction in automotive design also impacts sealing technologies. Traditional metal gaskets and heavy-duty seals contribute to the overall weight of the engine, conflicting with efforts to improve fuel efficiency. Developing lightweight yet durable sealing solutions that can withstand the harsh environment of the L92 engine remains a significant challenge for engineers and material scientists.

Lastly, the increasing complexity of engine designs, including the integration of advanced technologies like direct injection and variable valve timing, creates new sealing challenges. These systems often require intricate sealing solutions to prevent cross-contamination between different fluid systems and to maintain precise tolerances necessary for optimal performance.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, innovative design techniques, and rigorous testing protocols. The development of new composite materials, nano-engineered surfaces, and smart sealing systems that can adapt to changing conditions are all areas of active research in the quest to overcome the current sealing challenges in L92 engine applications.

Existing Sealing Solutions

01 Mechanical sealing technologies

Mechanical sealing technologies involve the use of physical components to create a barrier against leakage. These can include gaskets, O-rings, and other sealing elements designed to fit tightly between two surfaces. The performance of mechanical seals depends on factors such as material selection, surface finish, and applied pressure.- Mechanical sealing technologies: Mechanical sealing technologies involve the use of physical components to create a barrier against leakage. These can include gaskets, O-rings, and other sealing elements designed to fit tightly between two surfaces. The performance of mechanical seals depends on factors such as material selection, surface finish, and applied pressure.

- Fluid sealing systems: Fluid sealing systems utilize liquids or gases to create a barrier against leakage. These systems can include hydraulic or pneumatic seals, which rely on pressure differentials to maintain their sealing performance. Advanced fluid sealing technologies may incorporate smart materials or adaptive systems to respond to changing conditions.

- Electronic sealing performance monitoring: Electronic systems are used to monitor and evaluate sealing performance in real-time. These technologies may include sensors, data acquisition systems, and analysis software to detect leaks, measure pressure, or assess seal integrity. Such systems can provide early warning of potential failures and optimize maintenance schedules.

- Advanced materials for sealing applications: The development of advanced materials has significantly improved sealing performance. These materials may include high-performance polymers, composites, or nanomaterials designed to withstand extreme temperatures, pressures, or chemical environments. Some materials may also have self-healing properties to extend seal life.

- Computational modeling for seal design: Computational modeling and simulation techniques are used to optimize seal designs and predict sealing performance. These methods may include finite element analysis, computational fluid dynamics, or machine learning algorithms to analyze complex sealing scenarios and improve design before physical prototyping.

02 Fluid sealing systems

Fluid sealing systems utilize liquids or gases to create a barrier against leakage. These systems can include hydraulic or pneumatic seals, which rely on pressure differentials to maintain their sealing performance. Advanced fluid sealing technologies may incorporate smart materials or adaptive systems to respond to changing conditions.Expand Specific Solutions03 Sealing performance optimization through simulation

Computer simulations and modeling techniques are used to optimize sealing performance. These methods allow engineers to predict seal behavior under various conditions, analyze stress distributions, and identify potential failure modes. By using simulation tools, designers can improve seal designs and materials before physical prototyping.Expand Specific Solutions04 Smart sealing technologies

Smart sealing technologies incorporate sensors, actuators, and control systems to monitor and adjust sealing performance in real-time. These advanced systems can detect leaks, compensate for wear, and adapt to changing environmental conditions. Smart seals may also integrate with IoT platforms for remote monitoring and predictive maintenance.Expand Specific Solutions05 Nano-engineered sealing materials

Nanotechnology is being applied to develop advanced sealing materials with enhanced properties. These nano-engineered materials can offer improved wear resistance, self-healing capabilities, and better conformability to surface irregularities. The use of nanocomposites and nanostructured coatings can significantly enhance sealing performance in challenging environments.Expand Specific Solutions

Key Industry Players

The advanced sealing technologies in L92 engine applications market is in a growth phase, driven by increasing demand for high-performance engines across industries. The market size is expanding as more companies invest in research and development of innovative sealing solutions. Technologically, the field is advancing rapidly, with companies like Stein Seal Co., United Technologies Corp., and RTX Corp. leading the way in developing cutting-edge sealing technologies. These firms are focusing on materials science and precision engineering to create more durable, efficient, and environmentally friendly seals for L92 engines. The competitive landscape is characterized by a mix of established players and newer entrants, all vying to capture market share through technological differentiation and strategic partnerships.

Stein Seal Co.

Technical Solution: Stein Seal Co. has developed advanced sealing technologies specifically for L92 engine applications, focusing on high-performance mechanical seals. Their solution incorporates innovative materials such as carbon-graphite composites and silicon carbide, which offer superior wear resistance and thermal stability[1]. The company's sealing system utilizes a patented floating ring design that allows for dynamic adjustment to varying operating conditions, ensuring consistent sealing performance across a wide range of temperatures and pressures[2]. Additionally, Stein Seal has implemented advanced surface treatments and coatings to enhance the durability and longevity of their seals, resulting in extended maintenance intervals for L92 engines[3].

Strengths: Highly specialized in mechanical seals, patented floating ring design, advanced materials. Weaknesses: Potentially higher cost due to specialized materials, may require specific installation procedures.

United Technologies Corp.

Technical Solution: United Technologies Corp. (UTC) has developed a comprehensive sealing solution for L92 engine applications, leveraging their extensive experience in aerospace and industrial technologies. Their approach integrates advanced materials science with precision engineering to create a multi-layered sealing system. UTC's solution incorporates nano-engineered surfaces that minimize friction and wear, while also providing enhanced heat dissipation properties[4]. The company has also developed smart sealing technologies that incorporate sensors to monitor seal performance and predict maintenance needs in real-time, improving overall engine reliability and efficiency[5]. UTC's sealing system for L92 engines also features adaptive geometries that can respond to changes in operating conditions, maintaining optimal sealing performance throughout the engine's operational envelope[6].

Strengths: Comprehensive solution, smart sealing technologies, aerospace-grade materials. Weaknesses: Potentially complex integration with existing systems, higher initial investment.

Innovative Sealing Patents

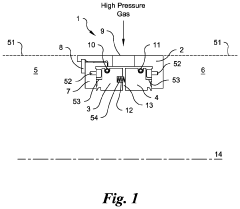

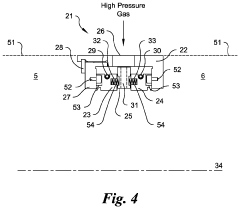

Reduced radial clearance seal system

PatentActiveUS20210348523A1

Innovation

- A seal system utilizing a Molybdenum alloy seal runner and an electrographitic carbon seal ring, with specific coefficients of thermal expansion, forming a sealing interface that adjusts between hot and cold operating conditions to achieve a significantly smaller effective sealing interface, particularly at cold conditions, while maintaining minimal air leakage at high temperatures.

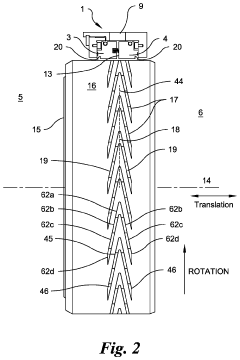

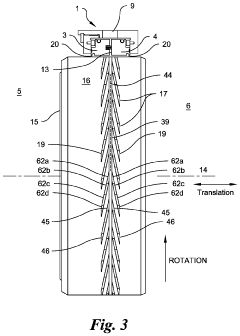

Circumferential Back-to-Back Seal Assembly with Bifurcated Flow

PatentActiveUS20200224718A1

Innovation

- A circumferential back-to-back seal assembly with annular seal rings and groove structures on a rotatable runner, where the groove structures bifurcate gas flow to form thin-film layers between the runner and seal rings, and optional springs and center rings enhance separation and stability.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and implementation of advanced sealing technologies in L92 engine applications. These regulations are designed to reduce emissions, improve fuel efficiency, and minimize the environmental impact of internal combustion engines.

One of the primary drivers for advanced sealing technologies is the increasingly stringent emission standards imposed by regulatory bodies worldwide. In the United States, the Environmental Protection Agency (EPA) has established progressively tighter limits on vehicle emissions through the Clean Air Act. Similarly, the European Union has implemented Euro emission standards, which have become more rigorous with each iteration.

These regulations have led to the development of advanced sealing technologies that focus on reducing leakage and improving overall engine efficiency. For instance, enhanced piston ring designs and materials have been introduced to minimize blow-by gases and oil consumption. Advanced cylinder head gaskets have also been developed to withstand higher combustion pressures while maintaining a tight seal.

The push for improved fuel economy has further influenced sealing technology advancements. Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other countries have prompted manufacturers to explore innovative sealing solutions that reduce friction and improve engine performance. This has resulted in the adoption of low-friction coatings and advanced seal designs that contribute to overall fuel efficiency gains.

Environmental regulations have also driven the development of more durable and long-lasting sealing technologies. As engines are required to maintain their emission performance over extended periods, seals must withstand higher temperatures, pressures, and chemical exposure without degradation. This has led to the use of advanced materials such as fluoroelastomers and perfluoroelastomers in critical sealing applications.

The focus on reducing evaporative emissions has also impacted sealing technologies in fuel systems. Regulations such as the EPA's Tier 3 standards have necessitated the development of low-permeation materials and improved sealing designs for fuel tanks, lines, and connectors to minimize hydrocarbon emissions.

As environmental regulations continue to evolve, sealing technologies in L92 engine applications will need to adapt accordingly. Future trends may include the integration of smart sealing systems that can monitor and adjust their performance in real-time, as well as the development of bio-based or recyclable sealing materials to address end-of-life environmental concerns.

One of the primary drivers for advanced sealing technologies is the increasingly stringent emission standards imposed by regulatory bodies worldwide. In the United States, the Environmental Protection Agency (EPA) has established progressively tighter limits on vehicle emissions through the Clean Air Act. Similarly, the European Union has implemented Euro emission standards, which have become more rigorous with each iteration.

These regulations have led to the development of advanced sealing technologies that focus on reducing leakage and improving overall engine efficiency. For instance, enhanced piston ring designs and materials have been introduced to minimize blow-by gases and oil consumption. Advanced cylinder head gaskets have also been developed to withstand higher combustion pressures while maintaining a tight seal.

The push for improved fuel economy has further influenced sealing technology advancements. Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other countries have prompted manufacturers to explore innovative sealing solutions that reduce friction and improve engine performance. This has resulted in the adoption of low-friction coatings and advanced seal designs that contribute to overall fuel efficiency gains.

Environmental regulations have also driven the development of more durable and long-lasting sealing technologies. As engines are required to maintain their emission performance over extended periods, seals must withstand higher temperatures, pressures, and chemical exposure without degradation. This has led to the use of advanced materials such as fluoroelastomers and perfluoroelastomers in critical sealing applications.

The focus on reducing evaporative emissions has also impacted sealing technologies in fuel systems. Regulations such as the EPA's Tier 3 standards have necessitated the development of low-permeation materials and improved sealing designs for fuel tanks, lines, and connectors to minimize hydrocarbon emissions.

As environmental regulations continue to evolve, sealing technologies in L92 engine applications will need to adapt accordingly. Future trends may include the integration of smart sealing systems that can monitor and adjust their performance in real-time, as well as the development of bio-based or recyclable sealing materials to address end-of-life environmental concerns.

Material Advancements

Material advancements play a crucial role in enhancing the performance and efficiency of advanced sealing technologies in L92 engine applications. The development of innovative materials has led to significant improvements in seal durability, temperature resistance, and overall engine performance.

One of the key areas of material advancement is in the realm of high-temperature polymers. These materials, such as fluoroelastomers and perfluoroelastomers, have been engineered to withstand extreme temperatures and harsh chemical environments commonly found in modern engines. These advanced polymers offer excellent resistance to oil, fuel, and coolant degradation, ensuring prolonged seal life and reduced maintenance requirements.

Composite materials have also emerged as a game-changer in sealing technology. Carbon fiber-reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are being increasingly utilized in critical sealing components. These materials offer superior strength-to-weight ratios, thermal stability, and wear resistance compared to traditional metallic seals.

Nanotechnology has opened up new possibilities in material engineering for sealing applications. Nanocomposites, which incorporate nanoscale particles into polymer matrices, have shown remarkable improvements in mechanical properties, thermal conductivity, and chemical resistance. These advancements have led to the development of seals that can maintain their integrity under extreme pressure and temperature fluctuations.

Surface engineering techniques have also contributed significantly to material advancements in sealing technologies. Plasma-enhanced chemical vapor deposition (PECVD) and physical vapor deposition (PVD) processes are being used to create ultra-thin, highly durable coatings on seal surfaces. These coatings enhance wear resistance, reduce friction, and improve overall seal performance in high-stress environments.

Smart materials are another frontier in sealing technology advancements. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to create adaptive seals that can respond to changes in temperature, pressure, or electrical stimuli. These materials offer the possibility of self-adjusting seals that can optimize their performance based on real-time engine conditions.

The integration of these advanced materials into L92 engine sealing applications has resulted in significant improvements in engine efficiency, reliability, and longevity. As material science continues to evolve, we can expect further innovations that will push the boundaries of what is possible in engine sealing technology, ultimately leading to more powerful, efficient, and environmentally friendly engines.

One of the key areas of material advancement is in the realm of high-temperature polymers. These materials, such as fluoroelastomers and perfluoroelastomers, have been engineered to withstand extreme temperatures and harsh chemical environments commonly found in modern engines. These advanced polymers offer excellent resistance to oil, fuel, and coolant degradation, ensuring prolonged seal life and reduced maintenance requirements.

Composite materials have also emerged as a game-changer in sealing technology. Carbon fiber-reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are being increasingly utilized in critical sealing components. These materials offer superior strength-to-weight ratios, thermal stability, and wear resistance compared to traditional metallic seals.

Nanotechnology has opened up new possibilities in material engineering for sealing applications. Nanocomposites, which incorporate nanoscale particles into polymer matrices, have shown remarkable improvements in mechanical properties, thermal conductivity, and chemical resistance. These advancements have led to the development of seals that can maintain their integrity under extreme pressure and temperature fluctuations.

Surface engineering techniques have also contributed significantly to material advancements in sealing technologies. Plasma-enhanced chemical vapor deposition (PECVD) and physical vapor deposition (PVD) processes are being used to create ultra-thin, highly durable coatings on seal surfaces. These coatings enhance wear resistance, reduce friction, and improve overall seal performance in high-stress environments.

Smart materials are another frontier in sealing technology advancements. Shape memory alloys (SMAs) and piezoelectric materials are being explored for their potential to create adaptive seals that can respond to changes in temperature, pressure, or electrical stimuli. These materials offer the possibility of self-adjusting seals that can optimize their performance based on real-time engine conditions.

The integration of these advanced materials into L92 engine sealing applications has resulted in significant improvements in engine efficiency, reliability, and longevity. As material science continues to evolve, we can expect further innovations that will push the boundaries of what is possible in engine sealing technology, ultimately leading to more powerful, efficient, and environmentally friendly engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!