The impact of timing chain refinement on L92 engine NVH

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine NVH Background and Objectives

The L92 engine, a 6.2-liter V8 powerplant developed by General Motors, has been a cornerstone in the company's high-performance vehicle lineup. Since its introduction, this engine has been renowned for its robust power output and reliability. However, as automotive technology advances and consumer expectations evolve, there has been an increasing focus on refining the engine's noise, vibration, and harshness (NVH) characteristics.

The timing chain, a critical component in the L92 engine, plays a significant role in its overall NVH performance. As the chain drives the camshafts and synchronizes the engine's valvetrain, any imperfections or wear in this system can lead to increased noise and vibration. The refinement of the timing chain system has thus become a key area of interest for engineers seeking to enhance the L92 engine's NVH characteristics.

Historically, the automotive industry has witnessed a shift from timing belts to timing chains, primarily due to the latter's durability and longevity. However, this transition has brought new challenges in terms of NVH management. The metal-on-metal contact in chain systems can generate more noise compared to belt systems, necessitating innovative solutions to mitigate these effects.

The objectives of timing chain refinement in the L92 engine are multifaceted. Primarily, the goal is to reduce the overall noise levels generated by the timing chain system without compromising its durability or performance. This involves addressing various aspects such as chain tension, guide materials, and sprocket design. Additionally, engineers aim to minimize vibrations transmitted through the chain to the engine block and vehicle structure, thereby enhancing the overall driving experience.

Another crucial objective is to improve the engine's efficiency and performance through timing chain refinement. By optimizing the chain's operation, engineers seek to reduce friction losses and ensure more precise valve timing, which can lead to improvements in fuel economy and power output. This aligns with the broader industry trends towards increased efficiency and reduced emissions.

The pursuit of these objectives is driven by both regulatory pressures and market demands. Stricter noise regulations in various global markets necessitate continuous improvement in engine NVH characteristics. Simultaneously, consumer preferences for quieter, more refined vehicles push manufacturers to innovate in this area.

As we delve deeper into the technical aspects of timing chain refinement for the L92 engine, it's important to consider the broader context of engine development. This includes the potential impact on manufacturing processes, cost considerations, and the balance between performance enhancements and NVH improvements. The following sections will explore these aspects in detail, providing a comprehensive overview of the challenges and opportunities in refining the L92 engine's timing chain system for improved NVH performance.

The timing chain, a critical component in the L92 engine, plays a significant role in its overall NVH performance. As the chain drives the camshafts and synchronizes the engine's valvetrain, any imperfections or wear in this system can lead to increased noise and vibration. The refinement of the timing chain system has thus become a key area of interest for engineers seeking to enhance the L92 engine's NVH characteristics.

Historically, the automotive industry has witnessed a shift from timing belts to timing chains, primarily due to the latter's durability and longevity. However, this transition has brought new challenges in terms of NVH management. The metal-on-metal contact in chain systems can generate more noise compared to belt systems, necessitating innovative solutions to mitigate these effects.

The objectives of timing chain refinement in the L92 engine are multifaceted. Primarily, the goal is to reduce the overall noise levels generated by the timing chain system without compromising its durability or performance. This involves addressing various aspects such as chain tension, guide materials, and sprocket design. Additionally, engineers aim to minimize vibrations transmitted through the chain to the engine block and vehicle structure, thereby enhancing the overall driving experience.

Another crucial objective is to improve the engine's efficiency and performance through timing chain refinement. By optimizing the chain's operation, engineers seek to reduce friction losses and ensure more precise valve timing, which can lead to improvements in fuel economy and power output. This aligns with the broader industry trends towards increased efficiency and reduced emissions.

The pursuit of these objectives is driven by both regulatory pressures and market demands. Stricter noise regulations in various global markets necessitate continuous improvement in engine NVH characteristics. Simultaneously, consumer preferences for quieter, more refined vehicles push manufacturers to innovate in this area.

As we delve deeper into the technical aspects of timing chain refinement for the L92 engine, it's important to consider the broader context of engine development. This includes the potential impact on manufacturing processes, cost considerations, and the balance between performance enhancements and NVH improvements. The following sections will explore these aspects in detail, providing a comprehensive overview of the challenges and opportunities in refining the L92 engine's timing chain system for improved NVH performance.

Market Demand for Refined Engine Performance

The automotive industry has witnessed a growing demand for refined engine performance, particularly in the realm of noise, vibration, and harshness (NVH) reduction. This trend is driven by consumers' increasing expectations for smoother, quieter, and more comfortable driving experiences. The L92 engine, a popular V8 powerplant used in various high-performance vehicles, has become a focal point for such refinements, with timing chain improvements playing a crucial role in enhancing overall NVH characteristics.

Market research indicates that consumers are willing to pay a premium for vehicles that offer superior NVH performance. This preference is especially pronounced in the luxury and high-performance segments, where the L92 engine is commonly found. Surveys show that engine noise and vibration are among the top factors influencing customer satisfaction and brand perception in these market segments.

The demand for refined engine performance extends beyond the consumer market. Fleet operators and commercial vehicle manufacturers are also showing increased interest in NVH improvements, recognizing the potential for reduced driver fatigue, increased productivity, and lower maintenance costs associated with smoother-running engines.

Environmental regulations and fuel efficiency standards have further intensified the focus on engine refinement. As manufacturers strive to meet stringent emissions targets, the optimization of engine components, including timing chains, has become crucial. Improved NVH characteristics often correlate with better fuel economy and reduced emissions, aligning with both regulatory requirements and consumer preferences for more environmentally friendly vehicles.

The aftermarket sector has also seen a surge in demand for timing chain upgrades and NVH reduction solutions for the L92 engine. Performance enthusiasts and tuning shops are seeking ways to enhance engine smoothness without compromising power output, creating a niche market for specialized timing chain components and related technologies.

Automotive suppliers and OEMs are responding to this market demand by investing heavily in research and development of advanced timing chain technologies. This includes the exploration of new materials, innovative chain designs, and improved tensioning systems specifically tailored for the L92 engine architecture. The goal is to deliver significant NVH improvements while maintaining or enhancing the engine's renowned performance characteristics.

As the automotive industry continues to evolve towards electrification, the demand for refined internal combustion engines remains strong in the interim. Manufacturers view NVH improvements, particularly in high-performance engines like the L92, as a key differentiator in a competitive market. This focus on refinement is expected to drive innovation and technological advancements in timing chain design and implementation, ultimately benefiting consumers across various vehicle segments.

Market research indicates that consumers are willing to pay a premium for vehicles that offer superior NVH performance. This preference is especially pronounced in the luxury and high-performance segments, where the L92 engine is commonly found. Surveys show that engine noise and vibration are among the top factors influencing customer satisfaction and brand perception in these market segments.

The demand for refined engine performance extends beyond the consumer market. Fleet operators and commercial vehicle manufacturers are also showing increased interest in NVH improvements, recognizing the potential for reduced driver fatigue, increased productivity, and lower maintenance costs associated with smoother-running engines.

Environmental regulations and fuel efficiency standards have further intensified the focus on engine refinement. As manufacturers strive to meet stringent emissions targets, the optimization of engine components, including timing chains, has become crucial. Improved NVH characteristics often correlate with better fuel economy and reduced emissions, aligning with both regulatory requirements and consumer preferences for more environmentally friendly vehicles.

The aftermarket sector has also seen a surge in demand for timing chain upgrades and NVH reduction solutions for the L92 engine. Performance enthusiasts and tuning shops are seeking ways to enhance engine smoothness without compromising power output, creating a niche market for specialized timing chain components and related technologies.

Automotive suppliers and OEMs are responding to this market demand by investing heavily in research and development of advanced timing chain technologies. This includes the exploration of new materials, innovative chain designs, and improved tensioning systems specifically tailored for the L92 engine architecture. The goal is to deliver significant NVH improvements while maintaining or enhancing the engine's renowned performance characteristics.

As the automotive industry continues to evolve towards electrification, the demand for refined internal combustion engines remains strong in the interim. Manufacturers view NVH improvements, particularly in high-performance engines like the L92, as a key differentiator in a competitive market. This focus on refinement is expected to drive innovation and technological advancements in timing chain design and implementation, ultimately benefiting consumers across various vehicle segments.

Current State of Timing Chain Technology in L92 Engines

The L92 engine, a prominent member of the GM small-block engine family, has been a subject of continuous refinement, particularly in its timing chain technology. Current timing chain systems in L92 engines represent a culmination of years of engineering advancements aimed at improving engine performance, durability, and noise, vibration, and harshness (NVH) characteristics.

Modern L92 engines typically employ a roller chain design, which offers several advantages over traditional bushing chains. These roller chains feature reduced friction between the chain links and sprockets, resulting in improved efficiency and reduced wear. The current generation of timing chains in L92 engines also incorporates advanced materials, such as high-strength alloys, to enhance durability and resistance to stretching over time.

One of the key features of contemporary timing chain systems in L92 engines is the implementation of hydraulic chain tensioners. These tensioners automatically adjust chain tension to compensate for wear and thermal expansion, maintaining optimal chain performance throughout the engine's lifecycle. This technology significantly contributes to the reduction of chain noise and vibration, addressing a critical aspect of engine NVH.

Chain guides and dampeners have also seen substantial improvements in recent years. Current L92 engines utilize advanced polymer materials for these components, which offer superior wear resistance and noise absorption properties compared to earlier metallic designs. These enhancements play a crucial role in minimizing chain slap and reducing overall engine noise levels.

Timing chain sprocket design has evolved to incorporate tooth profiles that optimize chain engagement and reduce noise. Many L92 engines now feature sprockets with involute tooth profiles, which ensure smoother chain operation and more even load distribution across the chain links. This design improvement contributes to reduced vibration and extended chain life.

The integration of variable valve timing (VVT) systems in L92 engines has also influenced timing chain technology. Current designs often incorporate additional sprockets and chain runs to accommodate VVT actuators, necessitating more complex and precisely engineered chain systems. These systems must maintain accuracy and stability across a wide range of engine operating conditions while minimizing NVH impacts.

Advancements in manufacturing processes have allowed for tighter tolerances and improved surface finishes on timing chain components. This precision engineering contributes to smoother operation, reduced wear, and lower noise levels. Additionally, enhanced quality control measures ensure consistency in timing chain performance across production runs.

In summary, the current state of timing chain technology in L92 engines reflects a sophisticated balance of performance, durability, and NVH considerations. Continuous refinements in materials, design, and manufacturing processes have resulted in timing chain systems that offer improved reliability, reduced maintenance requirements, and enhanced engine acoustics compared to earlier generations.

Modern L92 engines typically employ a roller chain design, which offers several advantages over traditional bushing chains. These roller chains feature reduced friction between the chain links and sprockets, resulting in improved efficiency and reduced wear. The current generation of timing chains in L92 engines also incorporates advanced materials, such as high-strength alloys, to enhance durability and resistance to stretching over time.

One of the key features of contemporary timing chain systems in L92 engines is the implementation of hydraulic chain tensioners. These tensioners automatically adjust chain tension to compensate for wear and thermal expansion, maintaining optimal chain performance throughout the engine's lifecycle. This technology significantly contributes to the reduction of chain noise and vibration, addressing a critical aspect of engine NVH.

Chain guides and dampeners have also seen substantial improvements in recent years. Current L92 engines utilize advanced polymer materials for these components, which offer superior wear resistance and noise absorption properties compared to earlier metallic designs. These enhancements play a crucial role in minimizing chain slap and reducing overall engine noise levels.

Timing chain sprocket design has evolved to incorporate tooth profiles that optimize chain engagement and reduce noise. Many L92 engines now feature sprockets with involute tooth profiles, which ensure smoother chain operation and more even load distribution across the chain links. This design improvement contributes to reduced vibration and extended chain life.

The integration of variable valve timing (VVT) systems in L92 engines has also influenced timing chain technology. Current designs often incorporate additional sprockets and chain runs to accommodate VVT actuators, necessitating more complex and precisely engineered chain systems. These systems must maintain accuracy and stability across a wide range of engine operating conditions while minimizing NVH impacts.

Advancements in manufacturing processes have allowed for tighter tolerances and improved surface finishes on timing chain components. This precision engineering contributes to smoother operation, reduced wear, and lower noise levels. Additionally, enhanced quality control measures ensure consistency in timing chain performance across production runs.

In summary, the current state of timing chain technology in L92 engines reflects a sophisticated balance of performance, durability, and NVH considerations. Continuous refinements in materials, design, and manufacturing processes have resulted in timing chain systems that offer improved reliability, reduced maintenance requirements, and enhanced engine acoustics compared to earlier generations.

Existing Solutions for Timing Chain NVH Reduction

01 Timing chain tensioner design

Improved tensioner designs help reduce noise, vibration, and harshness in timing chain systems. These designs may include hydraulic or mechanical tensioners with enhanced damping capabilities, optimized spring rates, and advanced materials to minimize chain slack and control vibration.- Timing chain tensioner design: Improved tensioner designs help reduce NVH in timing chain systems. These designs may include hydraulic or mechanical tensioners with enhanced damping capabilities, optimized spring rates, and advanced materials to minimize vibration and noise transmission.

- Chain guide and rail optimization: Optimized chain guides and rails contribute to reduced NVH by minimizing chain slap and controlling chain movement. This includes using low-friction materials, improving guide geometry, and incorporating damping elements to absorb vibrations.

- Sprocket design and materials: Advanced sprocket designs and materials play a crucial role in reducing NVH. This includes optimizing tooth profiles, using noise-reducing materials, and implementing sprocket isolation techniques to minimize vibration transfer to the engine block.

- Active noise control systems: Implementation of active noise control systems to counteract timing chain NVH. These systems may use sensors to detect chain noise and vibration, then generate counter-signals to cancel out unwanted NVH, improving overall engine refinement.

- Timing chain material and construction: Advancements in timing chain materials and construction techniques to reduce NVH. This includes using composite materials, optimizing link designs, and implementing noise-reducing coatings to minimize friction and vibration between chain components.

02 Chain guide and rail improvements

Enhanced chain guides and rails are developed to minimize friction, reduce wear, and dampen vibrations. These components may incorporate low-friction materials, optimized geometries, and integrated damping elements to improve overall NVH performance of the timing chain system.Expand Specific Solutions03 Active noise control systems

Implementation of active noise control systems to counteract timing chain noise. These systems may use sensors to detect chain vibrations and generate opposing sound waves or vibrations to cancel out unwanted noise, improving overall engine refinement.Expand Specific Solutions04 Timing chain material and design optimization

Development of advanced timing chain materials and designs to reduce noise and vibration. This may include using composite materials, optimizing link shapes, and improving chain pitch to minimize engagement noise and reduce overall system vibration.Expand Specific Solutions05 Integrated NVH monitoring and control systems

Implementation of integrated systems for monitoring and controlling timing chain NVH in real-time. These systems may use sensors, actuators, and advanced algorithms to detect and mitigate NVH issues, adjusting chain tension and engine parameters as needed to maintain optimal performance.Expand Specific Solutions

Key Players in Automotive Engine Component Industry

The timing chain refinement for L92 engine NVH is in a mature development stage, with established players and ongoing incremental improvements. The market size is significant, given the widespread use of timing chains in automotive engines. Technologically, the field is well-developed, with companies like BorgWarner, Ford Global Technologies, and GM Global Technology Operations leading innovation. These firms, along with others like Hyundai Motor and Tsubakimoto Chain, have extensive experience in powertrain components and are continuously refining their timing chain technologies to enhance engine performance and reduce noise, vibration, and harshness (NVH) characteristics.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced timing chain system for the L92 engine that incorporates several refinements to improve NVH characteristics. The system utilizes a multi-link chain design with optimized tooth profiles to reduce chain noise and vibration[1]. Ford's engineers have implemented a hydraulic tensioner with a dual-stage damping mechanism, which provides better chain control across a wider range of engine speeds[2]. Additionally, the company has introduced a novel sprocket design with micro-geometry modifications that minimize impact forces between the chain and sprockets, further reducing noise[3]. The timing chain cover has been redesigned with ribbed reinforcements and damping materials to attenuate high-frequency vibrations[4].

Strengths: Comprehensive approach addressing multiple aspects of chain dynamics; innovative sprocket design for noise reduction. Weaknesses: Potentially higher manufacturing costs; may require more frequent maintenance due to complex tensioner system.

GM Global Technology Operations LLC

Technical Solution: GM has focused on refining the L92 engine's timing chain system through a combination of material science and advanced manufacturing techniques. Their approach includes the use of a high-strength, low-friction chain material that reduces overall system mass and improves wear resistance[5]. GM has also implemented a precision-machined sprocket system with optimized tooth engagement patterns to minimize chain slap and reduce noise propagation[6]. The company has developed a computer-controlled variable tensioner that adjusts chain tension based on real-time engine operating conditions, significantly reducing NVH across the entire RPM range[7]. Furthermore, GM has integrated a sound-absorbing polymer coating on the timing chain cover to dampen vibrations and absorb high-frequency noise[8].

Strengths: Advanced materials and manufacturing processes; adaptive tensioning system for optimal performance. Weaknesses: Potential for increased complexity in maintenance; higher initial production costs.

Core Innovations in Timing Chain Design

Chain wheel and timing chain drive for the compensation of dynamic loads

PatentInactiveEP2005035A1

Innovation

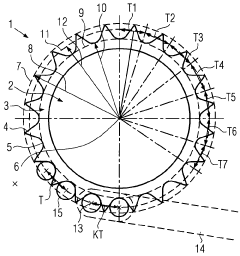

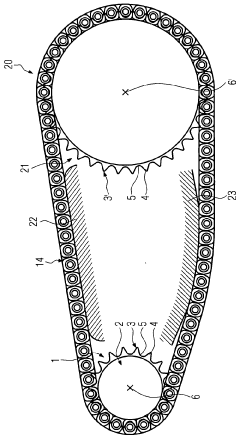

- A sprocket with a chain guide featuring a non-circular peripheral profile, which introduces targeted additional excitation to reduce chain forces and improve NVH behavior, allowing for smaller component sizing and reduced dynamic loads by varying distances between the chain guide and sprocket center, and incorporating elliptical profiles to compensate for specific excitations.

Sprocket with alternating pitch spacings

PatentWO2008011924A1

Innovation

- A sprocket with alternating pitch spacings that continuously increase and decrease around its circumference, creating additional vibrational excitations that counteract the dominant vibration loads, allowing for reduced chain forces and improved NVH behavior, enabling smaller and more cost-effective timing chain drive designs.

Environmental Impact of Engine Refinement Technologies

The refinement of timing chains in L92 engines, while primarily aimed at improving Noise, Vibration, and Harshness (NVH) characteristics, also has significant environmental implications. This technological advancement contributes to the broader trend of engine refinement technologies that seek to balance performance with environmental sustainability.

One of the key environmental benefits of timing chain refinement is the potential reduction in fuel consumption. By optimizing the timing chain's operation, engine efficiency can be improved, leading to better fuel economy. This translates directly into reduced carbon emissions per mile driven, contributing to overall efforts to mitigate climate change impacts from the transportation sector.

Moreover, the enhanced durability of refined timing chains can lead to extended engine life. This longevity reduces the frequency of engine replacements and major repairs, thereby decreasing the environmental impact associated with manufacturing and disposing of engine components. The reduction in material waste and energy consumption in production processes represents a significant environmental advantage.

Refined timing chains also contribute to reduced oil consumption. By minimizing friction and wear within the engine, these improvements can lead to less frequent oil changes and reduced oil burn-off. This not only conserves resources but also minimizes the potential for oil leaks and spills, which can have detrimental effects on soil and water ecosystems.

The NVH improvements resulting from timing chain refinement can indirectly benefit the environment by reducing noise pollution. While not typically considered a primary environmental concern, noise pollution can have significant impacts on wildlife and urban ecosystems. Quieter engines contribute to more livable urban environments and less disturbance to natural habitats.

However, it's important to note that the manufacturing process for refined timing chains may initially require more energy and resources. The use of advanced materials and precision engineering techniques could potentially offset some of the environmental gains in the short term. This underscores the need for life cycle assessments to fully understand the net environmental impact of such technological advancements.

In the context of broader engine refinement technologies, timing chain improvements represent just one aspect of a multifaceted approach to enhancing engine performance while reducing environmental impact. When combined with other technologies such as advanced combustion strategies, lightweight materials, and electrification, the cumulative effect can be substantial in moving towards more sustainable transportation solutions.

One of the key environmental benefits of timing chain refinement is the potential reduction in fuel consumption. By optimizing the timing chain's operation, engine efficiency can be improved, leading to better fuel economy. This translates directly into reduced carbon emissions per mile driven, contributing to overall efforts to mitigate climate change impacts from the transportation sector.

Moreover, the enhanced durability of refined timing chains can lead to extended engine life. This longevity reduces the frequency of engine replacements and major repairs, thereby decreasing the environmental impact associated with manufacturing and disposing of engine components. The reduction in material waste and energy consumption in production processes represents a significant environmental advantage.

Refined timing chains also contribute to reduced oil consumption. By minimizing friction and wear within the engine, these improvements can lead to less frequent oil changes and reduced oil burn-off. This not only conserves resources but also minimizes the potential for oil leaks and spills, which can have detrimental effects on soil and water ecosystems.

The NVH improvements resulting from timing chain refinement can indirectly benefit the environment by reducing noise pollution. While not typically considered a primary environmental concern, noise pollution can have significant impacts on wildlife and urban ecosystems. Quieter engines contribute to more livable urban environments and less disturbance to natural habitats.

However, it's important to note that the manufacturing process for refined timing chains may initially require more energy and resources. The use of advanced materials and precision engineering techniques could potentially offset some of the environmental gains in the short term. This underscores the need for life cycle assessments to fully understand the net environmental impact of such technological advancements.

In the context of broader engine refinement technologies, timing chain improvements represent just one aspect of a multifaceted approach to enhancing engine performance while reducing environmental impact. When combined with other technologies such as advanced combustion strategies, lightweight materials, and electrification, the cumulative effect can be substantial in moving towards more sustainable transportation solutions.

Cost-Benefit Analysis of Timing Chain Improvements

The cost-benefit analysis of timing chain improvements for the L92 engine's NVH (Noise, Vibration, and Harshness) performance requires a comprehensive evaluation of both financial implications and technical advantages. Initial investment in refined timing chain technology may present a significant upfront cost, encompassing research and development, tooling modifications, and potential supply chain adjustments. However, these expenses should be weighed against the long-term benefits of enhanced engine performance and customer satisfaction.

Improved timing chain designs can lead to reduced friction, resulting in better fuel efficiency and lower emissions. This not only aligns with increasingly stringent environmental regulations but also provides a marketable advantage in terms of reduced operating costs for end-users. The refined timing chain's impact on NVH characteristics can significantly enhance the perceived quality of the engine, potentially commanding a premium price point or increasing market share in competitive segments.

From a manufacturing perspective, timing chain refinements may initially increase production costs. However, these could be offset by reduced warranty claims and improved brand reputation stemming from enhanced reliability and durability. The potential for standardization across multiple engine variants could also lead to economies of scale, ultimately reducing per-unit costs over time.

It's crucial to consider the lifecycle costs associated with timing chain improvements. While the initial investment may be substantial, the extended service life and reduced maintenance requirements of an optimized timing chain system can result in significant savings for both the manufacturer and the end-user. This can be particularly impactful in commercial applications where vehicle downtime translates directly to lost revenue.

The intangible benefits of improved NVH characteristics should not be underestimated. Enhanced driver comfort and reduced cabin noise can significantly influence customer perception and satisfaction, potentially leading to increased brand loyalty and positive word-of-mouth marketing. In luxury and performance vehicle segments, where NVH refinement is a key differentiator, the impact on sales and brand positioning could justify higher development costs.

Quantifying these benefits requires a multi-faceted approach, including projected sales increases, reduced warranty costs, and potential price premiums. Additionally, the competitive landscape must be considered, as failing to invest in timing chain refinement could result in lost market share if competitors make similar improvements. The analysis should also factor in the potential for technology transfer to other engine models, spreading the development costs across a broader product range.

Improved timing chain designs can lead to reduced friction, resulting in better fuel efficiency and lower emissions. This not only aligns with increasingly stringent environmental regulations but also provides a marketable advantage in terms of reduced operating costs for end-users. The refined timing chain's impact on NVH characteristics can significantly enhance the perceived quality of the engine, potentially commanding a premium price point or increasing market share in competitive segments.

From a manufacturing perspective, timing chain refinements may initially increase production costs. However, these could be offset by reduced warranty claims and improved brand reputation stemming from enhanced reliability and durability. The potential for standardization across multiple engine variants could also lead to economies of scale, ultimately reducing per-unit costs over time.

It's crucial to consider the lifecycle costs associated with timing chain improvements. While the initial investment may be substantial, the extended service life and reduced maintenance requirements of an optimized timing chain system can result in significant savings for both the manufacturer and the end-user. This can be particularly impactful in commercial applications where vehicle downtime translates directly to lost revenue.

The intangible benefits of improved NVH characteristics should not be underestimated. Enhanced driver comfort and reduced cabin noise can significantly influence customer perception and satisfaction, potentially leading to increased brand loyalty and positive word-of-mouth marketing. In luxury and performance vehicle segments, where NVH refinement is a key differentiator, the impact on sales and brand positioning could justify higher development costs.

Quantifying these benefits requires a multi-faceted approach, including projected sales increases, reduced warranty costs, and potential price premiums. Additionally, the competitive landscape must be considered, as failing to invest in timing chain refinement could result in lost market share if competitors make similar improvements. The analysis should also factor in the potential for technology transfer to other engine models, spreading the development costs across a broader product range.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!