Fuel system reliability in long-duration L92 engine use

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Fuel System Evolution and Objectives

The L92 engine, a variant of General Motors' LS series, has been a cornerstone in high-performance applications since its introduction. The fuel system of this engine has undergone significant evolution to meet the demands of long-duration use and increased reliability requirements. Initially designed for high-output, short-duration performance, the L92's fuel system has been continuously refined to address the challenges of sustained operation.

The primary objective in the evolution of the L92 engine's fuel system has been to enhance reliability without compromising performance. This has involved a multifaceted approach, focusing on improving fuel delivery consistency, optimizing fuel pressure regulation, and enhancing the durability of components under prolonged stress. Engineers have worked to minimize fuel pressure fluctuations, reduce the risk of vapor lock, and ensure consistent atomization across varying operating conditions.

One key area of development has been the fuel injectors. Early iterations faced challenges with deposit formation and wear over extended use, leading to inconsistent spray patterns and reduced efficiency. Subsequent generations have incorporated advanced materials and refined nozzle designs to maintain optimal fuel atomization over longer periods. This has been crucial in maintaining the engine's performance characteristics during extended operation.

The fuel pump system has also seen significant improvements. Initial designs were prone to overheating and reduced efficiency during prolonged high-output scenarios. Later versions introduced enhanced cooling mechanisms and more robust pump designs capable of maintaining consistent fuel pressure even under extreme conditions. This has been particularly important in applications requiring sustained high-performance output.

Fuel rail design has been another focus area. Engineers have worked to optimize fuel distribution and minimize pressure pulsations within the system. This has involved refining the internal geometry of the rails and incorporating advanced damping mechanisms to ensure uniform fuel delivery to all cylinders, even during rapid throttle changes or prolonged high-load conditions.

The evolution of the L92 engine's fuel system has also been driven by the need to accommodate various fuel types, including ethanol blends. This has necessitated the development of materials and components resistant to the corrosive effects of these fuels, ensuring long-term reliability regardless of fuel composition. The integration of flexible fuel capabilities has been a key objective in recent iterations, allowing for broader application and market adaptability.

Looking forward, the objectives for the L92 engine's fuel system continue to focus on enhancing reliability, efficiency, and adaptability. This includes further refinements in fuel atomization technology, the integration of advanced sensors for real-time system monitoring, and the development of predictive maintenance capabilities to preempt potential failures during long-duration use. The ongoing evolution of this fuel system exemplifies the continuous pursuit of excellence in engine technology, balancing high performance with sustained reliability.

The primary objective in the evolution of the L92 engine's fuel system has been to enhance reliability without compromising performance. This has involved a multifaceted approach, focusing on improving fuel delivery consistency, optimizing fuel pressure regulation, and enhancing the durability of components under prolonged stress. Engineers have worked to minimize fuel pressure fluctuations, reduce the risk of vapor lock, and ensure consistent atomization across varying operating conditions.

One key area of development has been the fuel injectors. Early iterations faced challenges with deposit formation and wear over extended use, leading to inconsistent spray patterns and reduced efficiency. Subsequent generations have incorporated advanced materials and refined nozzle designs to maintain optimal fuel atomization over longer periods. This has been crucial in maintaining the engine's performance characteristics during extended operation.

The fuel pump system has also seen significant improvements. Initial designs were prone to overheating and reduced efficiency during prolonged high-output scenarios. Later versions introduced enhanced cooling mechanisms and more robust pump designs capable of maintaining consistent fuel pressure even under extreme conditions. This has been particularly important in applications requiring sustained high-performance output.

Fuel rail design has been another focus area. Engineers have worked to optimize fuel distribution and minimize pressure pulsations within the system. This has involved refining the internal geometry of the rails and incorporating advanced damping mechanisms to ensure uniform fuel delivery to all cylinders, even during rapid throttle changes or prolonged high-load conditions.

The evolution of the L92 engine's fuel system has also been driven by the need to accommodate various fuel types, including ethanol blends. This has necessitated the development of materials and components resistant to the corrosive effects of these fuels, ensuring long-term reliability regardless of fuel composition. The integration of flexible fuel capabilities has been a key objective in recent iterations, allowing for broader application and market adaptability.

Looking forward, the objectives for the L92 engine's fuel system continue to focus on enhancing reliability, efficiency, and adaptability. This includes further refinements in fuel atomization technology, the integration of advanced sensors for real-time system monitoring, and the development of predictive maintenance capabilities to preempt potential failures during long-duration use. The ongoing evolution of this fuel system exemplifies the continuous pursuit of excellence in engine technology, balancing high performance with sustained reliability.

Market Analysis for Long-Duration Engine Applications

The market for long-duration engine applications has been experiencing significant growth in recent years, driven by increasing demand in sectors such as power generation, marine propulsion, and industrial machinery. The L92 engine, known for its robust design and high performance, has found particular favor in these applications due to its reliability and efficiency over extended operational periods.

In the power generation sector, there is a growing need for dependable backup power systems, especially in critical infrastructure facilities like hospitals, data centers, and telecommunications networks. The L92 engine's ability to operate continuously for extended periods makes it an attractive option for these applications. Market analysts project that the global backup power market will continue to expand at a compound annual growth rate (CAGR) of around 6% over the next five years, with a substantial portion of this growth attributed to long-duration engine solutions.

The marine industry represents another significant market for long-duration engine applications. As global trade continues to grow, there is an increasing demand for large cargo vessels and cruise ships that require powerful, reliable engines capable of operating for weeks or months at a time. The L92 engine's fuel efficiency and durability make it well-suited for these demanding marine environments. Industry reports indicate that the marine engine market is expected to reach a value of over $12 billion by 2025, with long-duration engines playing a crucial role in this growth.

In the industrial machinery sector, applications such as mining equipment, large-scale pumps, and heavy-duty construction machinery also require engines that can operate reliably for extended periods. The L92 engine's performance characteristics align well with these requirements, contributing to its increasing adoption in this sector. Market research suggests that the industrial machinery market is projected to grow at a CAGR of approximately 5% through 2026, with long-duration engines being a key component of this expansion.

However, the market for long-duration engine applications is not without challenges. Increasing environmental regulations and a global push towards cleaner energy sources are putting pressure on engine manufacturers to improve fuel efficiency and reduce emissions. This has led to a growing interest in alternative fuel technologies and hybrid systems that can complement or potentially replace traditional long-duration engines in certain applications.

Despite these challenges, the overall market outlook for long-duration engine applications remains positive. The L92 engine's proven track record in reliability and performance positions it well to capitalize on the growing demand across various sectors. As industries continue to prioritize operational efficiency and uptime, the market for robust, long-duration engine solutions is expected to remain strong in the foreseeable future.

In the power generation sector, there is a growing need for dependable backup power systems, especially in critical infrastructure facilities like hospitals, data centers, and telecommunications networks. The L92 engine's ability to operate continuously for extended periods makes it an attractive option for these applications. Market analysts project that the global backup power market will continue to expand at a compound annual growth rate (CAGR) of around 6% over the next five years, with a substantial portion of this growth attributed to long-duration engine solutions.

The marine industry represents another significant market for long-duration engine applications. As global trade continues to grow, there is an increasing demand for large cargo vessels and cruise ships that require powerful, reliable engines capable of operating for weeks or months at a time. The L92 engine's fuel efficiency and durability make it well-suited for these demanding marine environments. Industry reports indicate that the marine engine market is expected to reach a value of over $12 billion by 2025, with long-duration engines playing a crucial role in this growth.

In the industrial machinery sector, applications such as mining equipment, large-scale pumps, and heavy-duty construction machinery also require engines that can operate reliably for extended periods. The L92 engine's performance characteristics align well with these requirements, contributing to its increasing adoption in this sector. Market research suggests that the industrial machinery market is projected to grow at a CAGR of approximately 5% through 2026, with long-duration engines being a key component of this expansion.

However, the market for long-duration engine applications is not without challenges. Increasing environmental regulations and a global push towards cleaner energy sources are putting pressure on engine manufacturers to improve fuel efficiency and reduce emissions. This has led to a growing interest in alternative fuel technologies and hybrid systems that can complement or potentially replace traditional long-duration engines in certain applications.

Despite these challenges, the overall market outlook for long-duration engine applications remains positive. The L92 engine's proven track record in reliability and performance positions it well to capitalize on the growing demand across various sectors. As industries continue to prioritize operational efficiency and uptime, the market for robust, long-duration engine solutions is expected to remain strong in the foreseeable future.

Current Challenges in L92 Fuel System Reliability

The L92 engine, known for its long-duration operation capabilities, faces several critical challenges in maintaining fuel system reliability. One of the primary issues is the degradation of fuel system components over extended periods of use. Prolonged exposure to fuel and operational stresses can lead to wear and tear on critical parts such as fuel injectors, fuel pumps, and fuel lines. This degradation can result in reduced fuel efficiency, inconsistent fuel delivery, and potential system failures.

Another significant challenge is the accumulation of deposits within the fuel system. Over time, carbon deposits and other contaminants can build up in fuel injectors, valves, and combustion chambers. These deposits can disrupt the precise fuel spray patterns required for optimal combustion, leading to decreased engine performance and increased emissions. The long-duration operation of the L92 engine exacerbates this issue, as there are fewer opportunities for routine maintenance and cleaning.

Fuel quality consistency is also a major concern for L92 engine reliability. Long-term operation often involves exposure to varying fuel qualities, which can introduce impurities and cause corrosion or clogging in fuel system components. Maintaining consistent fuel quality over extended periods can be challenging, especially in diverse operational environments.

The thermal management of the fuel system presents another hurdle. Prolonged operation can lead to heat soak in fuel system components, potentially causing vapor lock or fuel vaporization issues. This can result in poor engine performance, starting difficulties, and increased wear on fuel pumps and injectors.

Sealing and containment of fuel under long-duration use conditions also pose significant challenges. Gaskets, O-rings, and other sealing components may degrade over time, leading to fuel leaks or air intrusion into the fuel system. This can compromise the system's integrity and pose safety risks.

Electronic control systems governing fuel delivery face reliability issues during extended operation. Sensors, wiring harnesses, and control modules may experience failures or degradation in accuracy over time, affecting the precision of fuel metering and engine management.

Lastly, the challenge of maintaining proper fuel pressure and flow rates over long periods is critical. Fluctuations in these parameters can lead to inconsistent engine performance and potential damage to fuel system components. Ensuring stable fuel delivery under varying operational conditions and over extended timeframes remains a key area of focus for improving L92 engine reliability.

Another significant challenge is the accumulation of deposits within the fuel system. Over time, carbon deposits and other contaminants can build up in fuel injectors, valves, and combustion chambers. These deposits can disrupt the precise fuel spray patterns required for optimal combustion, leading to decreased engine performance and increased emissions. The long-duration operation of the L92 engine exacerbates this issue, as there are fewer opportunities for routine maintenance and cleaning.

Fuel quality consistency is also a major concern for L92 engine reliability. Long-term operation often involves exposure to varying fuel qualities, which can introduce impurities and cause corrosion or clogging in fuel system components. Maintaining consistent fuel quality over extended periods can be challenging, especially in diverse operational environments.

The thermal management of the fuel system presents another hurdle. Prolonged operation can lead to heat soak in fuel system components, potentially causing vapor lock or fuel vaporization issues. This can result in poor engine performance, starting difficulties, and increased wear on fuel pumps and injectors.

Sealing and containment of fuel under long-duration use conditions also pose significant challenges. Gaskets, O-rings, and other sealing components may degrade over time, leading to fuel leaks or air intrusion into the fuel system. This can compromise the system's integrity and pose safety risks.

Electronic control systems governing fuel delivery face reliability issues during extended operation. Sensors, wiring harnesses, and control modules may experience failures or degradation in accuracy over time, affecting the precision of fuel metering and engine management.

Lastly, the challenge of maintaining proper fuel pressure and flow rates over long periods is critical. Fluctuations in these parameters can lead to inconsistent engine performance and potential damage to fuel system components. Ensuring stable fuel delivery under varying operational conditions and over extended timeframes remains a key area of focus for improving L92 engine reliability.

Existing L92 Fuel System Reliability Solutions

01 Fuel injection system optimization

Improving the fuel injection system is crucial for enhancing the reliability of the L92 engine fuel system. This includes optimizing fuel injector design, spray patterns, and injection timing to ensure precise fuel delivery and combustion efficiency. Advanced electronic control systems can be implemented to monitor and adjust fuel injection parameters in real-time, adapting to various operating conditions.- Fuel injection system optimization: Improving the fuel injection system is crucial for enhancing the reliability of the L92 engine fuel system. This includes optimizing injector design, fuel pressure regulation, and injection timing to ensure precise fuel delivery and combustion efficiency. Advanced electronic control systems can be implemented to monitor and adjust fuel injection parameters in real-time, adapting to various operating conditions and maintaining optimal performance.

- Fuel pressure regulation and stabilization: Maintaining stable fuel pressure is essential for consistent engine performance and reliability. This can be achieved through advanced pressure regulators, dampers, and accumulators that minimize pressure fluctuations in the fuel system. Implementing a return-less fuel system design can also contribute to pressure stability and reduce the risk of vapor lock, enhancing overall system reliability.

- Fuel filtration and contamination prevention: Enhancing fuel filtration systems and implementing measures to prevent contamination are critical for maintaining long-term reliability of the L92 engine fuel system. This includes using high-efficiency fuel filters, designing fuel tanks with improved sediment traps, and incorporating water separation systems to protect sensitive fuel system components from damage caused by impurities or moisture in the fuel.

- Electronic monitoring and diagnostic systems: Integrating advanced electronic monitoring and diagnostic systems can significantly improve the reliability of the L92 engine fuel system. These systems can continuously monitor fuel pressure, flow rates, and injector performance, providing real-time feedback and early detection of potential issues. Implementing self-diagnostic capabilities and fault detection algorithms can help prevent system failures and facilitate timely maintenance.

- Thermal management and vapor handling: Effective thermal management and vapor handling are crucial for maintaining fuel system reliability, especially in high-performance engines like the L92. This includes designing fuel lines and components to minimize heat absorption, implementing efficient fuel cooling systems, and incorporating advanced vapor separation and purge systems to prevent vapor lock and ensure consistent fuel delivery under various operating conditions.

02 Fuel pressure regulation and control

Maintaining consistent fuel pressure is essential for the L92 engine's fuel system reliability. This involves implementing robust fuel pressure regulators and sensors to ensure stable fuel delivery across different engine loads and speeds. Advanced pressure control algorithms can be integrated into the engine management system to optimize fuel pressure based on real-time operating conditions.Expand Specific Solutions03 Fuel system component durability

Enhancing the durability of fuel system components is critical for long-term reliability. This includes using high-quality materials and coatings for fuel lines, pumps, and filters to resist corrosion and wear. Implementing advanced manufacturing techniques and quality control processes can improve the longevity and performance of critical fuel system components.Expand Specific Solutions04 Fuel filtration and contamination prevention

Effective fuel filtration is crucial for preventing contaminants from entering the L92 engine's fuel system. This involves designing advanced fuel filters with higher efficiency and capacity, as well as implementing secondary filtration systems. Strategies for preventing fuel contamination during storage and transfer can also be developed to enhance overall system reliability.Expand Specific Solutions05 Diagnostic and monitoring systems

Implementing advanced diagnostic and monitoring systems can significantly improve the L92 engine's fuel system reliability. This includes integrating sensors and software algorithms to detect potential issues before they lead to system failures. Real-time monitoring of fuel system parameters, such as pressure, flow rate, and temperature, can enable predictive maintenance and early fault detection.Expand Specific Solutions

Key Players in L92 Engine Manufacturing

The research on fuel system reliability in long-duration L92 engine use is at a mature stage, with significant market potential in the automotive and heavy machinery sectors. The global market for reliable fuel systems is expanding, driven by increasing demand for efficient and durable engines. Key players like Caterpillar, Hyundai Motor, GM, Toyota, and Cummins are investing heavily in R&D to enhance fuel system reliability. These companies are leveraging advanced technologies such as precision engineering, smart sensors, and predictive maintenance algorithms to improve system performance and longevity. The competitive landscape is characterized by a mix of established manufacturers and innovative startups, fostering continuous technological advancements in this field.

Caterpillar, Inc.

Technical Solution: Caterpillar's approach to fuel system reliability in long-duration L92 engine use focuses on their ACERT (Advanced Combustion Emission Reduction Technology) system. This technology incorporates a high-pressure fuel injection system with multiple injection events per combustion cycle, optimizing fuel efficiency and reducing emissions. Caterpillar has developed proprietary fuel injectors with advanced nozzle designs that improve fuel atomization and spray patterns, enhancing combustion efficiency and reducing wear on components. Their fuel system also includes an intelligent electronic control unit that continuously adjusts injection timing and duration based on operating conditions. To address long-duration reliability, Caterpillar has implemented advanced materials and surface treatments for fuel system components, significantly extending service life. They have also integrated a sophisticated fuel filtration system with real-time contamination monitoring to ensure fuel quality and protect critical components [2][4].

Strengths: Robust design for extreme conditions, extensive field testing, and global service network. Weaknesses: Proprietary technology may limit third-party repair options and could lead to higher maintenance costs.

GM Global Technology Operations LLC

Technical Solution: GM's approach to fuel system reliability in long-duration engine use, including applications similar to the L92 engine, involves a comprehensive strategy combining advanced hardware and software solutions. Their fuel system incorporates a high-pressure direct injection system with piezoelectric injectors, allowing for precise fuel delivery and multiple injection events per cycle. GM has developed a sophisticated engine control module (ECM) that utilizes adaptive learning algorithms to optimize fuel injection parameters over time, ensuring consistent performance and efficiency throughout the engine's lifespan. To enhance long-term reliability, GM has implemented advanced materials and coatings for fuel system components, particularly focusing on reducing friction and wear in high-stress areas. Their fuel system also includes an intelligent filtration system with predictive maintenance capabilities, using sensors to monitor fuel quality and system performance in real-time [5][6].

Strengths: Extensive research and development resources, integration with vehicle-wide systems for holistic optimization. Weaknesses: Solutions may be more oriented towards passenger vehicles and light-duty applications, potentially requiring adaptation for heavy-duty use.

Core Innovations in Fuel System Longevity

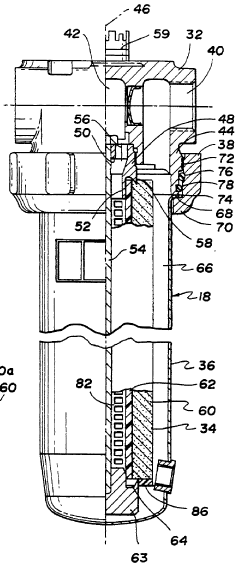

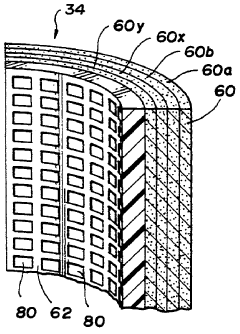

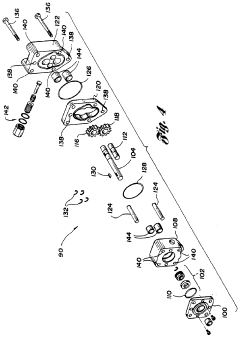

Fuel system for methanol fueled diesel cycle internal combustion engine

PatentInactiveUS5372115A

Innovation

- A fuel system designed specifically for methanol and low cetane fuels, featuring stainless steel and methanol-compatible materials, advanced filtration with primary and secondary filters, a durable gear-type fuel pump, and electronic unit fuel injectors with specific design modifications to prevent scoring and ensure reliable operation.

Environmental Impact of Long-Duration Engine Use

The environmental impact of long-duration L92 engine use is a critical consideration in the research on fuel system reliability. As these engines operate for extended periods, their emissions and overall ecological footprint become increasingly significant. The L92 engine, known for its high performance and durability, presents unique challenges in terms of environmental sustainability.

One of the primary concerns is the emission of greenhouse gases, particularly carbon dioxide (CO2). Long-duration use of L92 engines contributes to increased CO2 emissions, which are directly linked to global warming and climate change. The cumulative effect of these emissions over time can be substantial, especially in industries where continuous engine operation is common, such as in power generation or marine applications.

Nitrogen oxides (NOx) emissions are another significant environmental factor. L92 engines, especially when operating at high temperatures for extended periods, can produce elevated levels of NOx. These compounds contribute to the formation of smog and acid rain, negatively impacting air quality and ecosystem health.

Particulate matter (PM) emissions are also a concern with long-duration engine use. While modern L92 engines are designed to minimize PM emissions, the cumulative effect over extended operational periods can still be significant. These fine particles can have adverse effects on both human health and the environment, contributing to respiratory issues and reduced visibility in affected areas.

The fuel efficiency of L92 engines during long-duration use is a crucial factor in their environmental impact. As engines operate continuously, any inefficiencies in fuel consumption are magnified, leading to increased resource depletion and higher overall emissions. Improving fuel system reliability can directly contribute to better fuel efficiency, thereby reducing the environmental footprint of these engines.

Noise pollution is another environmental concern, particularly in urban or sensitive ecological areas. Long-duration operation of L92 engines can contribute to sustained noise levels, potentially disrupting local ecosystems and human communities. This aspect of environmental impact often requires specific mitigation strategies, such as improved engine design or the use of sound-dampening technologies.

The disposal and recycling of engine components after long-term use also present environmental challenges. As parts wear out or require replacement, proper disposal methods are essential to minimize the impact on landfills and prevent the release of harmful substances into the environment. Additionally, the production of replacement parts and maintenance activities contribute to the overall environmental footprint of long-duration engine use.

One of the primary concerns is the emission of greenhouse gases, particularly carbon dioxide (CO2). Long-duration use of L92 engines contributes to increased CO2 emissions, which are directly linked to global warming and climate change. The cumulative effect of these emissions over time can be substantial, especially in industries where continuous engine operation is common, such as in power generation or marine applications.

Nitrogen oxides (NOx) emissions are another significant environmental factor. L92 engines, especially when operating at high temperatures for extended periods, can produce elevated levels of NOx. These compounds contribute to the formation of smog and acid rain, negatively impacting air quality and ecosystem health.

Particulate matter (PM) emissions are also a concern with long-duration engine use. While modern L92 engines are designed to minimize PM emissions, the cumulative effect over extended operational periods can still be significant. These fine particles can have adverse effects on both human health and the environment, contributing to respiratory issues and reduced visibility in affected areas.

The fuel efficiency of L92 engines during long-duration use is a crucial factor in their environmental impact. As engines operate continuously, any inefficiencies in fuel consumption are magnified, leading to increased resource depletion and higher overall emissions. Improving fuel system reliability can directly contribute to better fuel efficiency, thereby reducing the environmental footprint of these engines.

Noise pollution is another environmental concern, particularly in urban or sensitive ecological areas. Long-duration operation of L92 engines can contribute to sustained noise levels, potentially disrupting local ecosystems and human communities. This aspect of environmental impact often requires specific mitigation strategies, such as improved engine design or the use of sound-dampening technologies.

The disposal and recycling of engine components after long-term use also present environmental challenges. As parts wear out or require replacement, proper disposal methods are essential to minimize the impact on landfills and prevent the release of harmful substances into the environment. Additionally, the production of replacement parts and maintenance activities contribute to the overall environmental footprint of long-duration engine use.

Regulatory Framework for Engine Reliability Standards

The regulatory framework for engine reliability standards plays a crucial role in ensuring the safety, performance, and environmental compliance of long-duration L92 engines. These standards are typically established and enforced by government agencies and industry organizations to maintain consistent quality and reliability across the automotive sector.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) are the primary regulatory bodies responsible for setting and enforcing engine reliability standards. The EPA focuses on emissions control and fuel efficiency, while the NHTSA oversees safety-related aspects of engine performance.

For long-duration L92 engine use, specific regulations address fuel system reliability. These include requirements for fuel system integrity, durability testing, and performance under various operating conditions. The standards often mandate extensive testing procedures to simulate long-term use and ensure that fuel systems maintain their reliability over extended periods.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory framework for engine reliability. ISO 16750, for example, provides guidelines for testing automotive electrical and electronic equipment, including fuel system components, under various environmental conditions.

The regulatory framework often includes provisions for ongoing monitoring and reporting of engine reliability data. Manufacturers are required to conduct regular assessments and provide detailed reports on fuel system performance, failure rates, and any identified issues. This data helps regulatory bodies refine and update standards as technology evolves and new challenges emerge.

Compliance with these standards is typically demonstrated through a combination of laboratory testing, field trials, and documentation of design and manufacturing processes. Manufacturers must provide evidence that their fuel systems meet or exceed the minimum reliability requirements set forth in the regulations.

Penalties for non-compliance can be severe, including fines, mandatory recalls, and damage to brand reputation. As such, adherence to these standards is a critical consideration in the design, development, and production of long-duration L92 engines and their fuel systems.

The regulatory framework also addresses the need for adaptability in light of emerging technologies and changing environmental concerns. As alternative fuels and advanced engine technologies become more prevalent, standards are evolving to encompass these innovations while maintaining a focus on reliability and safety.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) are the primary regulatory bodies responsible for setting and enforcing engine reliability standards. The EPA focuses on emissions control and fuel efficiency, while the NHTSA oversees safety-related aspects of engine performance.

For long-duration L92 engine use, specific regulations address fuel system reliability. These include requirements for fuel system integrity, durability testing, and performance under various operating conditions. The standards often mandate extensive testing procedures to simulate long-term use and ensure that fuel systems maintain their reliability over extended periods.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the regulatory framework for engine reliability. ISO 16750, for example, provides guidelines for testing automotive electrical and electronic equipment, including fuel system components, under various environmental conditions.

The regulatory framework often includes provisions for ongoing monitoring and reporting of engine reliability data. Manufacturers are required to conduct regular assessments and provide detailed reports on fuel system performance, failure rates, and any identified issues. This data helps regulatory bodies refine and update standards as technology evolves and new challenges emerge.

Compliance with these standards is typically demonstrated through a combination of laboratory testing, field trials, and documentation of design and manufacturing processes. Manufacturers must provide evidence that their fuel systems meet or exceed the minimum reliability requirements set forth in the regulations.

Penalties for non-compliance can be severe, including fines, mandatory recalls, and damage to brand reputation. As such, adherence to these standards is a critical consideration in the design, development, and production of long-duration L92 engines and their fuel systems.

The regulatory framework also addresses the need for adaptability in light of emerging technologies and changing environmental concerns. As alternative fuels and advanced engine technologies become more prevalent, standards are evolving to encompass these innovations while maintaining a focus on reliability and safety.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!