The impact of innovative turbocharging on L92 engine efficiency

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbocharging Evolution

Turbocharging technology has undergone significant evolution since its inception in the early 20th century. The development of turbocharging can be traced through several key stages, each marked by technological advancements and improved engine performance.

In the 1920s, the first practical turbocharger was developed by Alfred Büchi, a Swiss engineer. This early design laid the foundation for future innovations. During World War II, turbochargers saw extensive use in aircraft engines, providing a crucial advantage in high-altitude performance.

The 1960s and 1970s marked a turning point for turbocharging in automotive applications. Manufacturers began incorporating turbochargers into production vehicles, with notable examples including the Oldsmobile Jetfire and the Chevrolet Corvair Monza. These early automotive applications faced challenges with reliability and turbo lag, but set the stage for future improvements.

The 1980s saw a surge in turbocharger adoption, particularly in motorsports and high-performance vehicles. This era was characterized by advancements in materials science and manufacturing techniques, leading to more durable and efficient turbochargers. The introduction of intercoolers during this period further enhanced the effectiveness of turbocharging systems.

The 1990s and early 2000s brought about significant improvements in turbocharger design and control systems. Variable geometry turbochargers (VGT) emerged, allowing for more precise boost control across a wider range of engine speeds. This technology greatly reduced turbo lag and improved overall engine responsiveness.

In recent years, the focus has shifted towards combining turbocharging with other technologies to meet increasingly stringent emissions regulations while maintaining or improving performance. Twin-scroll turbochargers, electric turbochargers, and hybrid turbo systems have emerged as innovative solutions.

The latest developments in turbocharging technology are centered around improving efficiency, reducing emissions, and enhancing engine downsizing capabilities. Advanced materials such as titanium aluminide are being employed to create lighter, more heat-resistant turbine wheels. Additionally, integrated exhaust manifolds and water-cooled housings are becoming more common, contributing to improved thermal management and overall system efficiency.

As we look towards the future, the evolution of turbocharging continues with a focus on electrification and intelligent boost control. The integration of turbochargers with mild hybrid systems and the development of electrically-assisted turbochargers promise to further push the boundaries of engine efficiency and performance, particularly in applications like the L92 engine.

In the 1920s, the first practical turbocharger was developed by Alfred Büchi, a Swiss engineer. This early design laid the foundation for future innovations. During World War II, turbochargers saw extensive use in aircraft engines, providing a crucial advantage in high-altitude performance.

The 1960s and 1970s marked a turning point for turbocharging in automotive applications. Manufacturers began incorporating turbochargers into production vehicles, with notable examples including the Oldsmobile Jetfire and the Chevrolet Corvair Monza. These early automotive applications faced challenges with reliability and turbo lag, but set the stage for future improvements.

The 1980s saw a surge in turbocharger adoption, particularly in motorsports and high-performance vehicles. This era was characterized by advancements in materials science and manufacturing techniques, leading to more durable and efficient turbochargers. The introduction of intercoolers during this period further enhanced the effectiveness of turbocharging systems.

The 1990s and early 2000s brought about significant improvements in turbocharger design and control systems. Variable geometry turbochargers (VGT) emerged, allowing for more precise boost control across a wider range of engine speeds. This technology greatly reduced turbo lag and improved overall engine responsiveness.

In recent years, the focus has shifted towards combining turbocharging with other technologies to meet increasingly stringent emissions regulations while maintaining or improving performance. Twin-scroll turbochargers, electric turbochargers, and hybrid turbo systems have emerged as innovative solutions.

The latest developments in turbocharging technology are centered around improving efficiency, reducing emissions, and enhancing engine downsizing capabilities. Advanced materials such as titanium aluminide are being employed to create lighter, more heat-resistant turbine wheels. Additionally, integrated exhaust manifolds and water-cooled housings are becoming more common, contributing to improved thermal management and overall system efficiency.

As we look towards the future, the evolution of turbocharging continues with a focus on electrification and intelligent boost control. The integration of turbochargers with mild hybrid systems and the development of electrically-assisted turbochargers promise to further push the boundaries of engine efficiency and performance, particularly in applications like the L92 engine.

L92 Engine Market Demand

The L92 engine, a high-performance V8 powerplant developed by General Motors, has garnered significant attention in the automotive market. As vehicle manufacturers strive to meet increasingly stringent emissions regulations while maintaining performance, the demand for efficient and powerful engines like the L92 has grown substantially.

In recent years, the market for L92 engines has expanded beyond its original application in luxury SUVs and performance vehicles. This growth is driven by the engine's reputation for reliability, power output, and potential for aftermarket modifications. The L92's versatility has made it a popular choice for engine swaps in custom builds and restorations, further increasing its market appeal.

The automotive industry's shift towards electrification has paradoxically bolstered demand for high-performance internal combustion engines like the L92. Enthusiasts and collectors are increasingly seeking out these engines as they anticipate a future where such powerplants may become less common. This trend has created a niche market for L92-equipped vehicles and standalone engines for custom projects.

The aftermarket sector has played a crucial role in sustaining and growing the L92 engine market. Numerous companies offer performance parts and tuning solutions specifically designed for the L92, allowing owners to extract even more power and efficiency from their engines. This ecosystem of aftermarket support has contributed to the engine's longevity in the market and its continued popularity among performance enthusiasts.

However, the market demand for L92 engines is not without challenges. Stricter fuel economy standards and emissions regulations have put pressure on manufacturers to develop more efficient powertrains. This has led to increased interest in innovative technologies that can enhance the L92's efficiency without compromising its performance characteristics.

The potential impact of innovative turbocharging on L92 engine efficiency has emerged as a key area of interest for both manufacturers and consumers. As turbocharging technology advances, there is growing demand for solutions that can be applied to the L92 platform to boost its performance while improving fuel economy. This demand is driven by the desire to extend the viability of the L92 engine in an increasingly efficiency-focused automotive landscape.

Market analysis indicates that there is significant potential for growth in the L92 engine segment, particularly if efficiency-enhancing technologies like advanced turbocharging can be successfully implemented. The combination of the L92's established reputation for performance and the promise of improved efficiency through innovative turbocharging could create a compelling value proposition for consumers and potentially open up new market segments for L92-powered vehicles.

In recent years, the market for L92 engines has expanded beyond its original application in luxury SUVs and performance vehicles. This growth is driven by the engine's reputation for reliability, power output, and potential for aftermarket modifications. The L92's versatility has made it a popular choice for engine swaps in custom builds and restorations, further increasing its market appeal.

The automotive industry's shift towards electrification has paradoxically bolstered demand for high-performance internal combustion engines like the L92. Enthusiasts and collectors are increasingly seeking out these engines as they anticipate a future where such powerplants may become less common. This trend has created a niche market for L92-equipped vehicles and standalone engines for custom projects.

The aftermarket sector has played a crucial role in sustaining and growing the L92 engine market. Numerous companies offer performance parts and tuning solutions specifically designed for the L92, allowing owners to extract even more power and efficiency from their engines. This ecosystem of aftermarket support has contributed to the engine's longevity in the market and its continued popularity among performance enthusiasts.

However, the market demand for L92 engines is not without challenges. Stricter fuel economy standards and emissions regulations have put pressure on manufacturers to develop more efficient powertrains. This has led to increased interest in innovative technologies that can enhance the L92's efficiency without compromising its performance characteristics.

The potential impact of innovative turbocharging on L92 engine efficiency has emerged as a key area of interest for both manufacturers and consumers. As turbocharging technology advances, there is growing demand for solutions that can be applied to the L92 platform to boost its performance while improving fuel economy. This demand is driven by the desire to extend the viability of the L92 engine in an increasingly efficiency-focused automotive landscape.

Market analysis indicates that there is significant potential for growth in the L92 engine segment, particularly if efficiency-enhancing technologies like advanced turbocharging can be successfully implemented. The combination of the L92's established reputation for performance and the promise of improved efficiency through innovative turbocharging could create a compelling value proposition for consumers and potentially open up new market segments for L92-powered vehicles.

Turbocharging Challenges

Turbocharging technology, while offering significant benefits in engine efficiency and power output, faces several challenges in its application to the L92 engine. One of the primary concerns is heat management. The increased air compression in turbocharged engines leads to higher combustion temperatures, which can potentially cause engine knock and reduce overall efficiency. This issue is particularly pronounced in high-performance engines like the L92, where the balance between power output and thermal management is crucial.

Another significant challenge is turbo lag, which refers to the delay between throttle input and the turbocharger's response. This lag can affect the engine's responsiveness, particularly at lower RPMs, potentially impacting the driving experience and overall performance of L92-equipped vehicles. Engineers must carefully calibrate the turbocharger system to minimize this lag while maintaining optimal boost pressure across the engine's operating range.

The integration of turbocharging technology with the L92 engine's existing systems presents additional complexities. The engine management system must be recalibrated to accommodate the increased airflow and fuel requirements associated with turbocharging. This involves fine-tuning various parameters such as ignition timing, fuel injection, and boost control to ensure smooth operation and optimal efficiency across all driving conditions.

Durability and reliability are also key concerns when implementing turbocharging in the L92 engine. The increased stress on engine components due to higher boost pressures and temperatures necessitates the use of more robust materials and enhanced cooling systems. This can lead to increased production costs and potential reliability issues if not properly addressed during the design and testing phases.

Furthermore, the packaging of turbocharging components within the engine bay presents a significant engineering challenge. The L92 engine, originally designed without turbocharging in mind, may require substantial modifications to accommodate the turbocharger, intercooler, and associated plumbing. This can impact the vehicle's weight distribution, aerodynamics, and overall design, potentially necessitating broader changes to the vehicle architecture.

Emissions control is another critical aspect that engineers must consider when implementing turbocharging in the L92 engine. While turbocharging can improve fuel efficiency and reduce emissions under certain conditions, it can also lead to increased NOx emissions due to higher combustion temperatures. Meeting stringent emissions regulations while maintaining performance targets requires advanced exhaust aftertreatment systems and precise engine management strategies.

Another significant challenge is turbo lag, which refers to the delay between throttle input and the turbocharger's response. This lag can affect the engine's responsiveness, particularly at lower RPMs, potentially impacting the driving experience and overall performance of L92-equipped vehicles. Engineers must carefully calibrate the turbocharger system to minimize this lag while maintaining optimal boost pressure across the engine's operating range.

The integration of turbocharging technology with the L92 engine's existing systems presents additional complexities. The engine management system must be recalibrated to accommodate the increased airflow and fuel requirements associated with turbocharging. This involves fine-tuning various parameters such as ignition timing, fuel injection, and boost control to ensure smooth operation and optimal efficiency across all driving conditions.

Durability and reliability are also key concerns when implementing turbocharging in the L92 engine. The increased stress on engine components due to higher boost pressures and temperatures necessitates the use of more robust materials and enhanced cooling systems. This can lead to increased production costs and potential reliability issues if not properly addressed during the design and testing phases.

Furthermore, the packaging of turbocharging components within the engine bay presents a significant engineering challenge. The L92 engine, originally designed without turbocharging in mind, may require substantial modifications to accommodate the turbocharger, intercooler, and associated plumbing. This can impact the vehicle's weight distribution, aerodynamics, and overall design, potentially necessitating broader changes to the vehicle architecture.

Emissions control is another critical aspect that engineers must consider when implementing turbocharging in the L92 engine. While turbocharging can improve fuel efficiency and reduce emissions under certain conditions, it can also lead to increased NOx emissions due to higher combustion temperatures. Meeting stringent emissions regulations while maintaining performance targets requires advanced exhaust aftertreatment systems and precise engine management strategies.

Current Turbo Solutions

01 Improved combustion efficiency

The L92 engine incorporates advanced technologies to enhance combustion efficiency. This includes optimized fuel injection systems, improved air intake designs, and refined combustion chamber geometries. These enhancements result in more complete fuel burning, reduced emissions, and increased overall engine performance.- Improved combustion efficiency: The L92 engine incorporates advanced technologies to enhance combustion efficiency. This includes optimized fuel injection systems, improved air intake designs, and refined combustion chamber geometries. These enhancements result in more complete fuel burning, reduced emissions, and increased overall engine performance.

- Variable valve timing and lift: The L92 engine utilizes variable valve timing and lift mechanisms to optimize engine performance across different operating conditions. This technology allows for better control of air intake and exhaust, improving fuel efficiency and power output at various engine speeds and loads.

- Advanced engine management systems: Sophisticated engine management systems are employed in the L92 engine to monitor and control various parameters in real-time. These systems optimize fuel injection, ignition timing, and other factors to maximize efficiency and performance under different driving conditions.

- Lightweight materials and design: The L92 engine incorporates lightweight materials and advanced design techniques to reduce overall engine weight. This includes the use of aluminum alloys for engine blocks and other components, as well as optimized structural designs that maintain strength while minimizing mass, contributing to improved fuel efficiency and performance.

- Thermal management and friction reduction: Various technologies are implemented in the L92 engine to improve thermal management and reduce friction. This includes advanced cooling systems, low-friction coatings on engine components, and optimized lubrication systems. These features help to minimize energy losses and improve overall engine efficiency.

02 Variable valve timing and lift

Implementation of variable valve timing and lift mechanisms in the L92 engine allows for dynamic control of valve operation. This technology optimizes air intake and exhaust flow across different engine speeds and loads, leading to improved fuel efficiency, increased power output, and reduced emissions.Expand Specific Solutions03 Advanced thermal management

The L92 engine employs sophisticated thermal management systems to maintain optimal operating temperatures. This includes improved cooling systems, heat recovery mechanisms, and thermal insulation techniques. Effective thermal management contributes to increased engine efficiency, reduced friction losses, and enhanced overall performance.Expand Specific Solutions04 Friction reduction technologies

Various friction reduction technologies are incorporated into the L92 engine design. These may include advanced surface treatments, low-friction coatings, and optimized component geometries. Reducing internal friction leads to improved mechanical efficiency, lower fuel consumption, and increased engine longevity.Expand Specific Solutions05 Electronic engine management

The L92 engine utilizes advanced electronic engine management systems to optimize performance and efficiency. These systems continuously monitor and adjust various engine parameters such as fuel injection timing, ignition timing, and air-fuel ratios. This real-time optimization ensures the engine operates at peak efficiency across a wide range of operating conditions.Expand Specific Solutions

Key Turbocharger Makers

The innovative turbocharging technology for L92 engines is in a growth phase, with increasing market size and evolving technical maturity. Key players like BorgWarner, Honeywell, and ABB Turbo Systems are driving advancements, while automotive giants such as Ford, Toyota, and Mercedes-Benz are integrating these solutions. The market is characterized by a mix of established turbocharger specialists and major automakers, indicating a competitive landscape with opportunities for both innovation and large-scale implementation. As efficiency demands grow, this technology is likely to see continued development and adoption across the automotive industry.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed innovative turbocharging solutions for L92 engines, focusing on improving efficiency and performance. Their advanced eTurbo technology combines a traditional turbocharger with an electric motor, allowing for faster response times and improved low-end torque[1]. This system can generate electricity during high-load conditions, contributing to overall engine efficiency. BorgWarner's dual-volute turbocharger design separates exhaust pulses for improved energy utilization, resulting in up to 5% better fuel economy[2]. Additionally, their variable turbine geometry (VTG) technology adapts to various engine speeds, optimizing airflow and boosting efficiency across a wider operating range[3].

Strengths: Cutting-edge eTurbo technology, improved low-end torque, and fuel economy gains. Weaknesses: Potential complexity and cost increase for implementation in L92 engines.

Toyota Motor Corp.

Technical Solution: Toyota has made significant strides in turbocharging technology for their L92 engine variants. Their Dynamic Force Engine series incorporates a twin-scroll turbocharger design, which effectively separates exhaust pulses to reduce interference and improve overall efficiency[4]. Toyota's turbocharging system utilizes advanced waste gate control and intercooling techniques to optimize boost pressure and reduce intake air temperature. This results in a thermal efficiency of up to 40% in gasoline engines, a notable improvement over traditional naturally aspirated engines[5]. Furthermore, Toyota has integrated their D-4S direct and port fuel injection system with turbocharging, allowing for precise fuel delivery and combustion control, contributing to both performance and efficiency gains in L92-based engines[6].

Strengths: High thermal efficiency, advanced waste gate control, and integration with direct injection technology. Weaknesses: Potential increased complexity in engine management systems.

Innovative Turbo Tech

Increasing the fuel efficiency of four stroke engine by using turbocharger

PatentPendingIN202341044672A

Innovation

- The integration of a turbocharger system, where exhaust gases drive a turbine connected to a compressor, increasing air density and facilitating more efficient combustion, is enhanced by careful design and engineering considerations, including intercooling and advanced engine management systems to optimize performance and fuel efficiency.

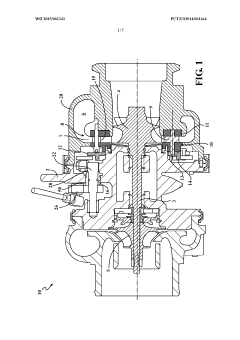

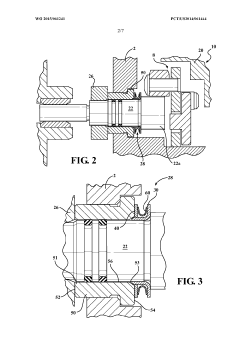

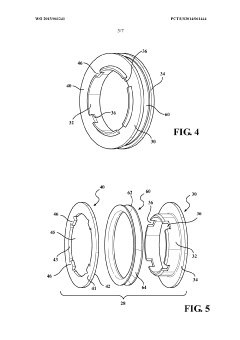

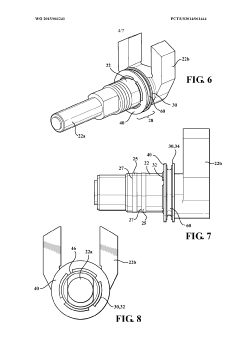

Actuation pivot shaft face seal with u seal

PatentWO2015061241A1

Innovation

- A face seal assembly using a metal U-seal ring between a disc and an inner ring, which are rotationally fixed to the actuation pivot shaft, reduces wear and accommodates misalignment by applying a seating force and providing compliance, with the disc being robust to handle high temperatures and wear, and the U-seal ring energized by either external or internal pressure to maintain the seal.

Emissions Regulations

Emissions regulations have become increasingly stringent in recent years, significantly impacting the development of automotive technologies, including turbocharging systems for engines like the L92. These regulations aim to reduce harmful emissions and improve overall air quality, driving manufacturers to innovate and adapt their engine designs.

The implementation of stricter emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has placed considerable pressure on automakers to reduce nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These regulations have directly influenced the development of turbocharging technologies for the L92 engine, as manufacturers seek to balance performance with environmental compliance.

Turbocharging has emerged as a key solution for meeting these emissions targets while maintaining or improving engine efficiency. By increasing the air density in the combustion chamber, turbochargers allow for more complete fuel combustion, resulting in reduced emissions and improved fuel economy. This is particularly relevant for the L92 engine, as innovative turbocharging techniques can help it meet stringent emissions standards without sacrificing performance.

One of the primary challenges in meeting emissions regulations with turbocharged engines is controlling NOx formation. Higher combustion temperatures associated with turbocharging can lead to increased NOx emissions. To address this, manufacturers have developed advanced turbocharger designs that incorporate features such as variable geometry turbines and electric assistance, allowing for more precise control over boost pressure and exhaust gas recirculation (EGR).

Particulate matter emissions have also been a focus of recent regulations, especially for gasoline direct injection (GDI) engines. Turbocharging, when combined with GDI technology, can help reduce PM emissions by promoting more efficient fuel atomization and combustion. However, it requires careful calibration and integration with other emission control systems to achieve optimal results.

The push for lower CO2 emissions has led to the development of downsized, turbocharged engines as an alternative to larger naturally aspirated units. This trend has influenced the evolution of the L92 engine, with manufacturers exploring ways to maintain its power output while reducing displacement and improving fuel efficiency through advanced turbocharging techniques.

As emissions regulations continue to evolve, the impact on turbocharging technology for the L92 engine is expected to intensify. Future standards may require even more sophisticated turbocharging solutions, potentially including multi-stage systems, electric turbochargers, or hybrid powertrains that combine turbocharging with electrification to further reduce emissions while enhancing performance.

The implementation of stricter emissions standards, such as Euro 6 in Europe and Tier 3 in the United States, has placed considerable pressure on automakers to reduce nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions. These regulations have directly influenced the development of turbocharging technologies for the L92 engine, as manufacturers seek to balance performance with environmental compliance.

Turbocharging has emerged as a key solution for meeting these emissions targets while maintaining or improving engine efficiency. By increasing the air density in the combustion chamber, turbochargers allow for more complete fuel combustion, resulting in reduced emissions and improved fuel economy. This is particularly relevant for the L92 engine, as innovative turbocharging techniques can help it meet stringent emissions standards without sacrificing performance.

One of the primary challenges in meeting emissions regulations with turbocharged engines is controlling NOx formation. Higher combustion temperatures associated with turbocharging can lead to increased NOx emissions. To address this, manufacturers have developed advanced turbocharger designs that incorporate features such as variable geometry turbines and electric assistance, allowing for more precise control over boost pressure and exhaust gas recirculation (EGR).

Particulate matter emissions have also been a focus of recent regulations, especially for gasoline direct injection (GDI) engines. Turbocharging, when combined with GDI technology, can help reduce PM emissions by promoting more efficient fuel atomization and combustion. However, it requires careful calibration and integration with other emission control systems to achieve optimal results.

The push for lower CO2 emissions has led to the development of downsized, turbocharged engines as an alternative to larger naturally aspirated units. This trend has influenced the evolution of the L92 engine, with manufacturers exploring ways to maintain its power output while reducing displacement and improving fuel efficiency through advanced turbocharging techniques.

As emissions regulations continue to evolve, the impact on turbocharging technology for the L92 engine is expected to intensify. Future standards may require even more sophisticated turbocharging solutions, potentially including multi-stage systems, electric turbochargers, or hybrid powertrains that combine turbocharging with electrification to further reduce emissions while enhancing performance.

Turbo Cost-Benefit

The implementation of innovative turbocharging technology on the L92 engine presents a compelling cost-benefit analysis. The initial investment in turbocharging technology may seem substantial, but the long-term benefits often outweigh the upfront costs.

From a performance perspective, turbocharging significantly enhances the L92 engine's power output and torque, particularly at lower RPMs. This improvement translates to better acceleration and overall driving experience, which can be a major selling point for consumers. The increased power-to-weight ratio also allows for potential downsizing of the engine, leading to weight reduction and improved vehicle dynamics.

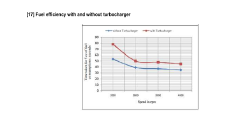

In terms of fuel efficiency, turbocharging enables the L92 engine to achieve better fuel economy, especially under partial load conditions. This improvement is particularly valuable in light of increasingly stringent emissions regulations and rising fuel costs. The reduced fuel consumption not only benefits the end-user but also helps manufacturers meet corporate average fuel economy (CAFE) standards.

However, the implementation of turbocharging technology does come with additional costs. These include the expenses associated with the turbocharger unit itself, as well as the necessary modifications to the engine's intake, exhaust, and cooling systems. There may also be increased complexity in engine management systems, potentially leading to higher maintenance costs over the vehicle's lifetime.

Despite these costs, the long-term benefits of turbocharging often prove advantageous. The improved performance and efficiency can command higher prices in the market, offsetting the increased production costs. Additionally, the ability to meet stricter emissions standards without sacrificing performance allows manufacturers to maintain competitiveness in markets with tightening regulations.

From a manufacturing perspective, the adoption of turbocharging technology may require initial investments in tooling and production processes. However, these costs can be amortized over large production volumes, especially if the technology is implemented across multiple engine families.

In conclusion, while the implementation of innovative turbocharging on the L92 engine does incur additional costs, the benefits in terms of performance, efficiency, and regulatory compliance often justify the investment. The exact cost-benefit ratio will depend on factors such as production volume, market positioning, and regulatory environment, but for many applications, turbocharging proves to be a sound technological and economic choice.

From a performance perspective, turbocharging significantly enhances the L92 engine's power output and torque, particularly at lower RPMs. This improvement translates to better acceleration and overall driving experience, which can be a major selling point for consumers. The increased power-to-weight ratio also allows for potential downsizing of the engine, leading to weight reduction and improved vehicle dynamics.

In terms of fuel efficiency, turbocharging enables the L92 engine to achieve better fuel economy, especially under partial load conditions. This improvement is particularly valuable in light of increasingly stringent emissions regulations and rising fuel costs. The reduced fuel consumption not only benefits the end-user but also helps manufacturers meet corporate average fuel economy (CAFE) standards.

However, the implementation of turbocharging technology does come with additional costs. These include the expenses associated with the turbocharger unit itself, as well as the necessary modifications to the engine's intake, exhaust, and cooling systems. There may also be increased complexity in engine management systems, potentially leading to higher maintenance costs over the vehicle's lifetime.

Despite these costs, the long-term benefits of turbocharging often prove advantageous. The improved performance and efficiency can command higher prices in the market, offsetting the increased production costs. Additionally, the ability to meet stricter emissions standards without sacrificing performance allows manufacturers to maintain competitiveness in markets with tightening regulations.

From a manufacturing perspective, the adoption of turbocharging technology may require initial investments in tooling and production processes. However, these costs can be amortized over large production volumes, especially if the technology is implemented across multiple engine families.

In conclusion, while the implementation of innovative turbocharging on the L92 engine does incur additional costs, the benefits in terms of performance, efficiency, and regulatory compliance often justify the investment. The exact cost-benefit ratio will depend on factors such as production volume, market positioning, and regulatory environment, but for many applications, turbocharging proves to be a sound technological and economic choice.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!