How do three-phase generators complement L92 engine hybrids?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Three-Phase Generator and L92 Hybrid Background

Three-phase generators and L92 engine hybrids represent two significant technological advancements in the field of power generation and automotive engineering. The integration of these technologies has led to innovative solutions for improving fuel efficiency and reducing emissions in hybrid vehicles.

Three-phase generators have been widely used in industrial and commercial power generation for decades. They operate on the principle of electromagnetic induction, producing three alternating currents that are out of phase with each other by 120 degrees. This design allows for more efficient power generation and smoother output compared to single-phase generators. In recent years, the application of three-phase generators in automotive systems has gained traction, particularly in hybrid vehicles.

The L92 engine, developed by General Motors, is a 6.2-liter V8 engine that has been utilized in various high-performance vehicles. It features advanced technologies such as variable valve timing and active fuel management, which contribute to improved fuel efficiency and power output. The L92 engine has served as a foundation for hybrid powertrains, where it is combined with electric motors to create a more efficient and powerful propulsion system.

The integration of three-phase generators with L92 engine hybrids represents a significant technological evolution in the automotive industry. This combination addresses several key challenges faced by hybrid vehicles, including power generation efficiency, energy recovery, and overall system performance. By incorporating a three-phase generator into the L92 hybrid system, engineers have been able to optimize power generation and distribution, leading to improved fuel economy and reduced emissions.

One of the primary advantages of using a three-phase generator in conjunction with the L92 engine hybrid is the ability to generate and manage electrical power more efficiently. The three-phase design allows for a more consistent power output, which is crucial for maintaining the performance of the hybrid system's electric components. This improved power generation capability enables the hybrid system to rely more heavily on electric propulsion, reducing the load on the combustion engine and further enhancing fuel efficiency.

Furthermore, the integration of three-phase generators with L92 engine hybrids has opened up new possibilities for regenerative braking systems. The three-phase generator can more effectively capture and convert kinetic energy into electrical energy during deceleration, storing it in the hybrid's battery system for later use. This enhanced energy recovery contributes to the overall efficiency of the hybrid powertrain, extending the vehicle's electric range and reducing fuel consumption.

As automotive manufacturers continue to focus on developing more sustainable and efficient vehicles, the combination of three-phase generators and L92 engine hybrids represents a promising direction for future powertrain technologies. This integration showcases the industry's commitment to leveraging advanced engineering solutions to address environmental concerns and meet increasingly stringent emissions regulations.

Three-phase generators have been widely used in industrial and commercial power generation for decades. They operate on the principle of electromagnetic induction, producing three alternating currents that are out of phase with each other by 120 degrees. This design allows for more efficient power generation and smoother output compared to single-phase generators. In recent years, the application of three-phase generators in automotive systems has gained traction, particularly in hybrid vehicles.

The L92 engine, developed by General Motors, is a 6.2-liter V8 engine that has been utilized in various high-performance vehicles. It features advanced technologies such as variable valve timing and active fuel management, which contribute to improved fuel efficiency and power output. The L92 engine has served as a foundation for hybrid powertrains, where it is combined with electric motors to create a more efficient and powerful propulsion system.

The integration of three-phase generators with L92 engine hybrids represents a significant technological evolution in the automotive industry. This combination addresses several key challenges faced by hybrid vehicles, including power generation efficiency, energy recovery, and overall system performance. By incorporating a three-phase generator into the L92 hybrid system, engineers have been able to optimize power generation and distribution, leading to improved fuel economy and reduced emissions.

One of the primary advantages of using a three-phase generator in conjunction with the L92 engine hybrid is the ability to generate and manage electrical power more efficiently. The three-phase design allows for a more consistent power output, which is crucial for maintaining the performance of the hybrid system's electric components. This improved power generation capability enables the hybrid system to rely more heavily on electric propulsion, reducing the load on the combustion engine and further enhancing fuel efficiency.

Furthermore, the integration of three-phase generators with L92 engine hybrids has opened up new possibilities for regenerative braking systems. The three-phase generator can more effectively capture and convert kinetic energy into electrical energy during deceleration, storing it in the hybrid's battery system for later use. This enhanced energy recovery contributes to the overall efficiency of the hybrid powertrain, extending the vehicle's electric range and reducing fuel consumption.

As automotive manufacturers continue to focus on developing more sustainable and efficient vehicles, the combination of three-phase generators and L92 engine hybrids represents a promising direction for future powertrain technologies. This integration showcases the industry's commitment to leveraging advanced engineering solutions to address environmental concerns and meet increasingly stringent emissions regulations.

Market Demand Analysis

The market demand for three-phase generators complementing L92 engine hybrids has been steadily growing in recent years. This trend is driven by the increasing focus on energy efficiency and environmental sustainability across various industries. The automotive sector, in particular, has shown significant interest in this technology as it seeks to improve fuel economy and reduce emissions in hybrid vehicles.

The integration of three-phase generators with L92 engine hybrids offers several advantages that align with market needs. These systems provide enhanced power generation capabilities, improved energy recovery during braking, and more efficient overall energy management. As a result, vehicle manufacturers are exploring this combination to meet stringent fuel efficiency standards and consumer demands for greener transportation options.

In the commercial vehicle segment, there is a growing demand for hybrid powertrains that can deliver both power and efficiency. Fleet operators are increasingly looking for solutions that can reduce fuel consumption and operational costs while maintaining performance. The combination of three-phase generators and L92 engine hybrids presents a promising solution to address these requirements, particularly in medium and heavy-duty applications.

The marine industry has also shown interest in this technology pairing. Vessels requiring auxiliary power generation can benefit from the improved efficiency and power density offered by three-phase generators coupled with L92 engine hybrids. This market segment is driven by the need to comply with stricter maritime emissions regulations and reduce fuel costs in shipping operations.

Furthermore, the stationary power generation market has identified potential applications for this technology combination. Backup power systems and distributed energy solutions could leverage the benefits of three-phase generators complementing L92 engine hybrids to provide more reliable and efficient power supply in various settings, from industrial facilities to commercial buildings.

The market demand is also influenced by the global push towards electrification and hybrid technologies. As countries implement policies to reduce carbon emissions and promote cleaner energy solutions, the demand for advanced hybrid systems incorporating three-phase generators and efficient engines like the L92 is expected to rise.

However, the market adoption rate is tempered by factors such as initial investment costs and the need for specialized maintenance. Despite these challenges, industry analysts project a positive growth trajectory for this technology combination, driven by its potential to address key market needs for improved efficiency, reduced emissions, and enhanced performance in various applications.

The integration of three-phase generators with L92 engine hybrids offers several advantages that align with market needs. These systems provide enhanced power generation capabilities, improved energy recovery during braking, and more efficient overall energy management. As a result, vehicle manufacturers are exploring this combination to meet stringent fuel efficiency standards and consumer demands for greener transportation options.

In the commercial vehicle segment, there is a growing demand for hybrid powertrains that can deliver both power and efficiency. Fleet operators are increasingly looking for solutions that can reduce fuel consumption and operational costs while maintaining performance. The combination of three-phase generators and L92 engine hybrids presents a promising solution to address these requirements, particularly in medium and heavy-duty applications.

The marine industry has also shown interest in this technology pairing. Vessels requiring auxiliary power generation can benefit from the improved efficiency and power density offered by three-phase generators coupled with L92 engine hybrids. This market segment is driven by the need to comply with stricter maritime emissions regulations and reduce fuel costs in shipping operations.

Furthermore, the stationary power generation market has identified potential applications for this technology combination. Backup power systems and distributed energy solutions could leverage the benefits of three-phase generators complementing L92 engine hybrids to provide more reliable and efficient power supply in various settings, from industrial facilities to commercial buildings.

The market demand is also influenced by the global push towards electrification and hybrid technologies. As countries implement policies to reduce carbon emissions and promote cleaner energy solutions, the demand for advanced hybrid systems incorporating three-phase generators and efficient engines like the L92 is expected to rise.

However, the market adoption rate is tempered by factors such as initial investment costs and the need for specialized maintenance. Despite these challenges, industry analysts project a positive growth trajectory for this technology combination, driven by its potential to address key market needs for improved efficiency, reduced emissions, and enhanced performance in various applications.

Technical Challenges

The integration of three-phase generators with L92 engine hybrids presents several technical challenges that require innovative solutions. One of the primary obstacles is the synchronization between the generator and the engine. The L92 engine, known for its variable displacement technology, operates at varying speeds and loads, making it difficult to maintain a consistent output from the three-phase generator. This mismatch can lead to inefficiencies and potential power quality issues in the electrical system.

Another significant challenge lies in the thermal management of the combined system. The L92 engine generates substantial heat, and the addition of a three-phase generator introduces another heat source. Designing an effective cooling system that can handle the thermal load from both components without compromising the overall efficiency of the hybrid system is a complex task. Engineers must consider the optimal placement of cooling components and the integration of advanced thermal management techniques to ensure reliable operation across various driving conditions.

Space constraints within the vehicle pose another technical hurdle. The L92 engine, being a V8 design, already occupies a significant portion of the engine bay. Incorporating a three-phase generator of sufficient capacity while maintaining the vehicle's design and weight distribution is challenging. This often requires a complete redesign of the powertrain layout and may necessitate compromises in other areas of the vehicle's architecture.

The control system for this hybrid configuration presents its own set of challenges. Developing an intelligent power management system that can effectively coordinate between the L92 engine, the three-phase generator, and the vehicle's electrical demands requires sophisticated algorithms and real-time processing capabilities. This system must optimize power distribution, manage battery charging, and ensure smooth transitions between different operating modes while maximizing fuel efficiency and performance.

Electromagnetic compatibility (EMC) is another critical concern. The high-power electrical systems associated with three-phase generators can produce significant electromagnetic interference. This interference may affect other electronic systems within the vehicle, such as navigation, infotainment, and safety systems. Designing appropriate shielding and implementing effective EMC mitigation strategies are essential to ensure the reliable operation of all vehicle systems.

Lastly, the durability and longevity of the integrated system pose significant challenges. The varying loads and frequent start-stop cycles typical in hybrid applications can lead to increased wear on both the L92 engine and the three-phase generator. Developing robust components that can withstand these demanding conditions while maintaining performance over the vehicle's lifetime requires extensive testing and innovative material solutions. Additionally, ensuring that the maintenance requirements for this complex system remain manageable for both vehicle owners and service technicians is a considerable challenge that impacts the overall viability of the technology.

Another significant challenge lies in the thermal management of the combined system. The L92 engine generates substantial heat, and the addition of a three-phase generator introduces another heat source. Designing an effective cooling system that can handle the thermal load from both components without compromising the overall efficiency of the hybrid system is a complex task. Engineers must consider the optimal placement of cooling components and the integration of advanced thermal management techniques to ensure reliable operation across various driving conditions.

Space constraints within the vehicle pose another technical hurdle. The L92 engine, being a V8 design, already occupies a significant portion of the engine bay. Incorporating a three-phase generator of sufficient capacity while maintaining the vehicle's design and weight distribution is challenging. This often requires a complete redesign of the powertrain layout and may necessitate compromises in other areas of the vehicle's architecture.

The control system for this hybrid configuration presents its own set of challenges. Developing an intelligent power management system that can effectively coordinate between the L92 engine, the three-phase generator, and the vehicle's electrical demands requires sophisticated algorithms and real-time processing capabilities. This system must optimize power distribution, manage battery charging, and ensure smooth transitions between different operating modes while maximizing fuel efficiency and performance.

Electromagnetic compatibility (EMC) is another critical concern. The high-power electrical systems associated with three-phase generators can produce significant electromagnetic interference. This interference may affect other electronic systems within the vehicle, such as navigation, infotainment, and safety systems. Designing appropriate shielding and implementing effective EMC mitigation strategies are essential to ensure the reliable operation of all vehicle systems.

Lastly, the durability and longevity of the integrated system pose significant challenges. The varying loads and frequent start-stop cycles typical in hybrid applications can lead to increased wear on both the L92 engine and the three-phase generator. Developing robust components that can withstand these demanding conditions while maintaining performance over the vehicle's lifetime requires extensive testing and innovative material solutions. Additionally, ensuring that the maintenance requirements for this complex system remain manageable for both vehicle owners and service technicians is a considerable challenge that impacts the overall viability of the technology.

Current Integration Solutions

01 Design and structure of three-phase generators

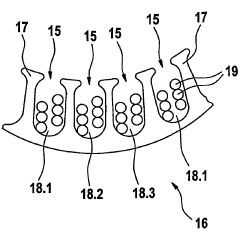

Three-phase generators are designed with specific structural elements to produce balanced three-phase power. These designs may include innovations in rotor and stator configurations, winding arrangements, and magnetic circuit optimization to enhance efficiency and power output.- Design and structure of three-phase generators: Three-phase generators are designed with specific structural elements to produce balanced three-phase power. This includes the arrangement of stator windings, rotor configuration, and magnetic field generation. The design focuses on achieving optimal efficiency and power output while maintaining phase balance.

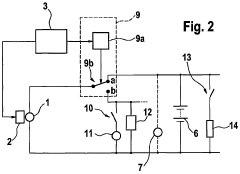

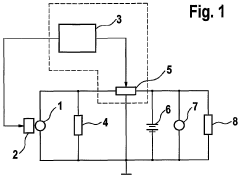

- Control systems for three-phase generators: Advanced control systems are implemented in three-phase generators to regulate voltage, frequency, and power output. These systems often incorporate digital controllers, power electronics, and feedback mechanisms to ensure stable operation and synchronization with the grid or other power sources.

- Cooling and thermal management: Effective cooling and thermal management are crucial for three-phase generators to maintain efficiency and prevent overheating. This includes the use of advanced cooling systems, heat dissipation techniques, and temperature monitoring to ensure optimal performance and longevity of the generator.

- Integration with renewable energy systems: Three-phase generators are increasingly integrated with renewable energy systems such as wind turbines and solar installations. This integration requires specialized designs to handle variable input power, grid connection requirements, and energy storage solutions for improved reliability and efficiency.

- Efficiency improvements and power quality enhancement: Ongoing research and development focus on improving the efficiency of three-phase generators and enhancing power quality. This includes the use of advanced materials, optimized winding designs, and innovative power conversion techniques to reduce losses and improve overall performance.

02 Control systems for three-phase generators

Advanced control systems are implemented in three-phase generators to regulate voltage, frequency, and power factor. These systems may incorporate digital controllers, power electronics, and feedback mechanisms to ensure stable and reliable operation under various load conditions.Expand Specific Solutions03 Cooling and thermal management

Effective cooling and thermal management solutions are crucial for three-phase generators to maintain optimal performance and longevity. Innovations in this area may include advanced cooling systems, heat dissipation techniques, and temperature monitoring mechanisms.Expand Specific Solutions04 Integration with renewable energy sources

Three-phase generators are increasingly integrated with renewable energy sources such as wind and solar power. This integration requires specialized designs and control strategies to handle variable input and maintain grid stability.Expand Specific Solutions05 Efficiency improvements and power quality enhancement

Ongoing research focuses on improving the efficiency of three-phase generators and enhancing power quality. This includes advancements in materials, magnetic design, and harmonic reduction techniques to optimize performance and reduce losses.Expand Specific Solutions

Key Industry Players

The competition landscape for three-phase generators complementing L92 engine hybrids is in an early growth stage, with a moderate market size and evolving technological maturity. Key players like Robert Bosch GmbH, Mitsubishi Electric Corp., and Honda Motor Co., Ltd. are driving innovation in this niche. The technology is gaining traction as automotive manufacturers seek more efficient hybrid powertrain solutions. Companies such as GM Global Technology Operations LLC and Siemens AG are also contributing to advancements in this field, indicating a growing interest from both automotive and industrial sectors in developing integrated hybrid power systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed an innovative three-phase generator system that complements their L92 engine hybrids. The system utilizes a compact, high-efficiency generator design integrated directly with the L92 engine. This configuration allows for seamless power generation and distribution between the combustion engine and electric motor. The generator employs advanced magnetic materials and optimized winding patterns to achieve high power density and reduced losses. Honda's system also incorporates intelligent power management algorithms that dynamically adjust generator output based on driving conditions and battery state of charge[1][3]. This enables the hybrid powertrain to operate in its most efficient mode, whether that's pure electric, engine-only, or combined power.

Strengths: Seamless integration with L92 engine, high efficiency, compact design. Weaknesses: May require specialized manufacturing, potentially higher initial cost.

GM Global Technology Operations LLC

Technical Solution: GM's approach to integrating three-phase generators with L92 engine hybrids focuses on scalability and modularity. Their system utilizes a standardized generator design that can be easily adapted to different vehicle platforms. The generator features a high-speed rotor design capable of operating efficiently at engine speeds up to 6500 RPM[2]. GM's solution incorporates advanced power electronics with wide bandgap semiconductors, enabling high-frequency switching and improved thermal management. The system also includes a sophisticated control unit that optimizes power flow between the generator, battery, and electric drive motors, maximizing overall powertrain efficiency. GM has implemented a regenerative braking system that works in conjunction with the three-phase generator to capture and store energy during deceleration[4].

Strengths: Scalable design, advanced power electronics, efficient energy recovery. Weaknesses: May have higher complexity in control systems, potential for increased maintenance requirements.

Core Innovations

Three-phase generator

PatentInactiveEP1784905A1

Innovation

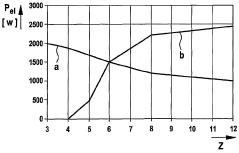

- A three-phase generator design with a controlled output voltage system, incorporating an in-phase regulator and a control unit to manage voltage between 14 V and 42 V, and optimized conductor configurations per slot to achieve balanced power ratios and low starting speeds, allowing for efficient operation across varying voltage ranges.

Three-phase generator

PatentWO2006024578A1

Innovation

- A three-phase generator design with a control unit that sets output voltage between 14 V and 42 V, utilizing an in-phase regulator and a switching device to supply different voltage levels to consumer groups, and optimizing the number of conductors per slot in the three-phase winding to achieve balanced power ratios and low starting speeds.

Energy Efficiency Assessment

The integration of three-phase generators with L92 engine hybrids presents a significant opportunity for enhancing energy efficiency in automotive applications. This combination leverages the strengths of both technologies to create a more robust and efficient power generation system.

Three-phase generators offer several advantages in terms of energy efficiency. They provide a smoother and more consistent power output compared to single-phase generators, reducing energy losses associated with power fluctuations. The balanced nature of three-phase power also allows for more efficient transmission and distribution of electrical energy within the vehicle system.

When coupled with L92 engine hybrids, these generators can significantly improve the overall energy efficiency of the powertrain. The L92 engine, known for its advanced design and fuel efficiency, benefits from the additional power management capabilities provided by the three-phase generator. This synergy allows for optimized energy distribution between the combustion engine and the electrical systems.

One of the key efficiency gains comes from the ability to capture and utilize regenerative braking energy more effectively. The three-phase generator can convert kinetic energy into electrical energy with higher efficiency during deceleration, storing it in the hybrid system's batteries for later use. This reduces the load on the L92 engine during acceleration and low-speed operations, further improving fuel economy.

The combination also enables more sophisticated power management strategies. During periods of low power demand, the three-phase generator can operate at its most efficient point, supplying electrical power to the vehicle's systems while allowing the L92 engine to run at its optimal efficiency or even shut off completely. This load balancing contributes to reduced fuel consumption and lower emissions.

Furthermore, the integration of three-phase generators with L92 engine hybrids allows for enhanced thermal management. The more efficient power generation and distribution reduce overall heat generation in the system, leading to improved cooling efficiency and potentially smaller, lighter cooling systems. This cascading effect contributes to the vehicle's overall energy efficiency by reducing weight and parasitic losses.

In summary, the complementary nature of three-phase generators and L92 engine hybrids creates a synergistic effect that significantly enhances energy efficiency. This integration optimizes power generation, distribution, and utilization across various driving conditions, resulting in improved fuel economy, reduced emissions, and enhanced overall vehicle performance.

Three-phase generators offer several advantages in terms of energy efficiency. They provide a smoother and more consistent power output compared to single-phase generators, reducing energy losses associated with power fluctuations. The balanced nature of three-phase power also allows for more efficient transmission and distribution of electrical energy within the vehicle system.

When coupled with L92 engine hybrids, these generators can significantly improve the overall energy efficiency of the powertrain. The L92 engine, known for its advanced design and fuel efficiency, benefits from the additional power management capabilities provided by the three-phase generator. This synergy allows for optimized energy distribution between the combustion engine and the electrical systems.

One of the key efficiency gains comes from the ability to capture and utilize regenerative braking energy more effectively. The three-phase generator can convert kinetic energy into electrical energy with higher efficiency during deceleration, storing it in the hybrid system's batteries for later use. This reduces the load on the L92 engine during acceleration and low-speed operations, further improving fuel economy.

The combination also enables more sophisticated power management strategies. During periods of low power demand, the three-phase generator can operate at its most efficient point, supplying electrical power to the vehicle's systems while allowing the L92 engine to run at its optimal efficiency or even shut off completely. This load balancing contributes to reduced fuel consumption and lower emissions.

Furthermore, the integration of three-phase generators with L92 engine hybrids allows for enhanced thermal management. The more efficient power generation and distribution reduce overall heat generation in the system, leading to improved cooling efficiency and potentially smaller, lighter cooling systems. This cascading effect contributes to the vehicle's overall energy efficiency by reducing weight and parasitic losses.

In summary, the complementary nature of three-phase generators and L92 engine hybrids creates a synergistic effect that significantly enhances energy efficiency. This integration optimizes power generation, distribution, and utilization across various driving conditions, resulting in improved fuel economy, reduced emissions, and enhanced overall vehicle performance.

Environmental Impact Analysis

The integration of three-phase generators with L92 engine hybrids presents a significant opportunity for enhancing environmental sustainability in the automotive sector. This combination offers several key benefits that contribute to reduced emissions and improved energy efficiency.

Firstly, the three-phase generator system allows for more efficient power generation and distribution within the hybrid powertrain. By utilizing a three-phase alternating current, the generator can produce electricity with lower losses and higher overall efficiency compared to single-phase systems. This increased efficiency translates directly to reduced fuel consumption and, consequently, lower greenhouse gas emissions.

The L92 engine, known for its advanced combustion technology and variable valve timing, already provides a solid foundation for fuel efficiency. When coupled with a three-phase generator, the system can optimize power generation during various driving conditions, further enhancing the overall environmental performance of the hybrid vehicle.

Moreover, the three-phase generator enables more effective regenerative braking, a crucial feature in hybrid vehicles. This system can capture and convert a higher percentage of kinetic energy into electrical energy during deceleration, which is then stored in the vehicle's battery for later use. The improved energy recovery leads to reduced reliance on the internal combustion engine, thereby decreasing fuel consumption and emissions.

The combination also allows for more precise control of the power flow between the engine, generator, and electric motor. This enhanced power management capability enables the hybrid system to operate in its most efficient mode more frequently, minimizing unnecessary fuel consumption and emissions.

Furthermore, the integration of three-phase generators with L92 engine hybrids can potentially reduce the overall weight of the powertrain system. The higher power density of three-phase generators means that smaller, lighter units can be used without compromising performance. This weight reduction contributes to improved fuel efficiency and reduced environmental impact across the vehicle's lifecycle.

In terms of manufacturing and materials, the use of three-phase generators may lead to a reduction in the use of rare earth metals, which are often required in larger quantities for less efficient generator designs. This aspect not only has positive implications for resource conservation but also reduces the environmental impact associated with the mining and processing of these materials.

Lastly, the improved efficiency and performance of this hybrid system may encourage wider adoption of hybrid vehicles, potentially accelerating the transition away from conventional internal combustion engines. This shift could have a significant cumulative effect on reducing transportation-related emissions and improving air quality in urban areas.

Firstly, the three-phase generator system allows for more efficient power generation and distribution within the hybrid powertrain. By utilizing a three-phase alternating current, the generator can produce electricity with lower losses and higher overall efficiency compared to single-phase systems. This increased efficiency translates directly to reduced fuel consumption and, consequently, lower greenhouse gas emissions.

The L92 engine, known for its advanced combustion technology and variable valve timing, already provides a solid foundation for fuel efficiency. When coupled with a three-phase generator, the system can optimize power generation during various driving conditions, further enhancing the overall environmental performance of the hybrid vehicle.

Moreover, the three-phase generator enables more effective regenerative braking, a crucial feature in hybrid vehicles. This system can capture and convert a higher percentage of kinetic energy into electrical energy during deceleration, which is then stored in the vehicle's battery for later use. The improved energy recovery leads to reduced reliance on the internal combustion engine, thereby decreasing fuel consumption and emissions.

The combination also allows for more precise control of the power flow between the engine, generator, and electric motor. This enhanced power management capability enables the hybrid system to operate in its most efficient mode more frequently, minimizing unnecessary fuel consumption and emissions.

Furthermore, the integration of three-phase generators with L92 engine hybrids can potentially reduce the overall weight of the powertrain system. The higher power density of three-phase generators means that smaller, lighter units can be used without compromising performance. This weight reduction contributes to improved fuel efficiency and reduced environmental impact across the vehicle's lifecycle.

In terms of manufacturing and materials, the use of three-phase generators may lead to a reduction in the use of rare earth metals, which are often required in larger quantities for less efficient generator designs. This aspect not only has positive implications for resource conservation but also reduces the environmental impact associated with the mining and processing of these materials.

Lastly, the improved efficiency and performance of this hybrid system may encourage wider adoption of hybrid vehicles, potentially accelerating the transition away from conventional internal combustion engines. This shift could have a significant cumulative effect on reducing transportation-related emissions and improving air quality in urban areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!