How L92 engine brakes optimize regenerative systems?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Brake Evolution

The L92 engine brake has undergone significant evolution since its inception, marking key milestones in the optimization of regenerative braking systems. Initially developed as a supplementary braking mechanism for heavy-duty vehicles, the L92 engine brake has transformed into an integral component of modern regenerative braking systems.

In its early stages, the L92 engine brake primarily focused on converting the engine's power into a braking force by altering the engine's valve timing. This process effectively turned the engine into an air compressor, creating resistance to slow the vehicle. However, this initial design was limited in its ability to recover and store energy.

As environmental concerns and fuel efficiency became increasingly important, engineers began exploring ways to integrate the L92 engine brake with regenerative braking systems. This led to the development of hybrid configurations that combined traditional engine braking with electric generators. These systems could capture kinetic energy during deceleration and convert it into electrical energy for storage in batteries.

The next phase of evolution saw the introduction of more sophisticated electronic control units (ECUs) that could precisely manage the interaction between the L92 engine brake and the regenerative system. These ECUs allowed for real-time adjustments based on vehicle speed, road conditions, and driver input, maximizing energy recovery while maintaining optimal braking performance.

Further advancements in materials science and manufacturing techniques enabled the creation of more efficient and durable components for the L92 engine brake. High-temperature alloys and advanced coatings improved the brake's ability to withstand the heat generated during operation, leading to increased longevity and reliability.

Recent iterations of the L92 engine brake have incorporated predictive algorithms and machine learning capabilities. These intelligent systems can anticipate braking needs based on factors such as traffic patterns, road topography, and historical driving data. By preemptively engaging the engine brake and regenerative systems, these advanced configurations further optimize energy recovery and vehicle efficiency.

The latest developments in L92 engine brake technology focus on seamless integration with fully electric and hydrogen fuel cell powertrains. In these applications, the engine brake concept has been adapted to work in conjunction with electric motors, providing additional braking force while maximizing energy recuperation. This evolution has expanded the L92 engine brake's role beyond traditional internal combustion engines, ensuring its relevance in the era of alternative propulsion systems.

In its early stages, the L92 engine brake primarily focused on converting the engine's power into a braking force by altering the engine's valve timing. This process effectively turned the engine into an air compressor, creating resistance to slow the vehicle. However, this initial design was limited in its ability to recover and store energy.

As environmental concerns and fuel efficiency became increasingly important, engineers began exploring ways to integrate the L92 engine brake with regenerative braking systems. This led to the development of hybrid configurations that combined traditional engine braking with electric generators. These systems could capture kinetic energy during deceleration and convert it into electrical energy for storage in batteries.

The next phase of evolution saw the introduction of more sophisticated electronic control units (ECUs) that could precisely manage the interaction between the L92 engine brake and the regenerative system. These ECUs allowed for real-time adjustments based on vehicle speed, road conditions, and driver input, maximizing energy recovery while maintaining optimal braking performance.

Further advancements in materials science and manufacturing techniques enabled the creation of more efficient and durable components for the L92 engine brake. High-temperature alloys and advanced coatings improved the brake's ability to withstand the heat generated during operation, leading to increased longevity and reliability.

Recent iterations of the L92 engine brake have incorporated predictive algorithms and machine learning capabilities. These intelligent systems can anticipate braking needs based on factors such as traffic patterns, road topography, and historical driving data. By preemptively engaging the engine brake and regenerative systems, these advanced configurations further optimize energy recovery and vehicle efficiency.

The latest developments in L92 engine brake technology focus on seamless integration with fully electric and hydrogen fuel cell powertrains. In these applications, the engine brake concept has been adapted to work in conjunction with electric motors, providing additional braking force while maximizing energy recuperation. This evolution has expanded the L92 engine brake's role beyond traditional internal combustion engines, ensuring its relevance in the era of alternative propulsion systems.

Regenerative Braking Market

The regenerative braking market has experienced significant growth in recent years, driven by the increasing adoption of electric and hybrid vehicles worldwide. This market segment is closely tied to the automotive industry's shift towards more sustainable and energy-efficient technologies. As governments implement stricter emissions regulations and consumers become more environmentally conscious, the demand for regenerative braking systems continues to rise.

In the context of the L92 engine brakes optimizing regenerative systems, it's important to note that while traditional engine brakes are primarily used in heavy-duty vehicles, the principles of energy recovery can be applied to enhance regenerative braking efficiency in various vehicle types. The integration of advanced engine braking technologies with regenerative systems presents a unique opportunity to maximize energy recuperation and improve overall vehicle efficiency.

The global regenerative braking market is segmented based on vehicle type, including passenger cars, commercial vehicles, and two-wheelers. Among these, passenger cars currently dominate the market share due to the widespread adoption of hybrid and electric vehicles in this segment. However, the commercial vehicle sector is expected to witness rapid growth in the coming years as fleet operators seek to reduce fuel consumption and operating costs.

Geographically, the market is divided into North America, Europe, Asia-Pacific, and the rest of the world. Europe leads the market, driven by stringent emission norms and a high adoption rate of electric vehicles. Asia-Pacific is projected to be the fastest-growing region, with China and Japan at the forefront of electric vehicle production and adoption.

Key market players in the regenerative braking industry include Continental AG, Robert Bosch GmbH, Hyundai Mobis, ZF Friedrichshafen AG, and Aisin Seiki Co., Ltd. These companies are investing heavily in research and development to improve regenerative braking efficiency and integrate it with other vehicle systems for optimal performance.

The market is characterized by continuous technological advancements, with a focus on improving energy recovery rates, reducing system weight, and enhancing overall braking performance. The integration of regenerative braking with other vehicle systems, such as advanced driver assistance systems (ADAS) and autonomous driving technologies, is expected to create new growth opportunities in the market.

As the automotive industry continues to evolve, the regenerative braking market is poised for substantial growth. The increasing focus on sustainability, coupled with advancements in electric vehicle technology, is expected to drive market expansion in the coming years. The optimization of regenerative systems, including their integration with engine braking technologies like those found in the L92 engine, will play a crucial role in shaping the future of this market.

In the context of the L92 engine brakes optimizing regenerative systems, it's important to note that while traditional engine brakes are primarily used in heavy-duty vehicles, the principles of energy recovery can be applied to enhance regenerative braking efficiency in various vehicle types. The integration of advanced engine braking technologies with regenerative systems presents a unique opportunity to maximize energy recuperation and improve overall vehicle efficiency.

The global regenerative braking market is segmented based on vehicle type, including passenger cars, commercial vehicles, and two-wheelers. Among these, passenger cars currently dominate the market share due to the widespread adoption of hybrid and electric vehicles in this segment. However, the commercial vehicle sector is expected to witness rapid growth in the coming years as fleet operators seek to reduce fuel consumption and operating costs.

Geographically, the market is divided into North America, Europe, Asia-Pacific, and the rest of the world. Europe leads the market, driven by stringent emission norms and a high adoption rate of electric vehicles. Asia-Pacific is projected to be the fastest-growing region, with China and Japan at the forefront of electric vehicle production and adoption.

Key market players in the regenerative braking industry include Continental AG, Robert Bosch GmbH, Hyundai Mobis, ZF Friedrichshafen AG, and Aisin Seiki Co., Ltd. These companies are investing heavily in research and development to improve regenerative braking efficiency and integrate it with other vehicle systems for optimal performance.

The market is characterized by continuous technological advancements, with a focus on improving energy recovery rates, reducing system weight, and enhancing overall braking performance. The integration of regenerative braking with other vehicle systems, such as advanced driver assistance systems (ADAS) and autonomous driving technologies, is expected to create new growth opportunities in the market.

As the automotive industry continues to evolve, the regenerative braking market is poised for substantial growth. The increasing focus on sustainability, coupled with advancements in electric vehicle technology, is expected to drive market expansion in the coming years. The optimization of regenerative systems, including their integration with engine braking technologies like those found in the L92 engine, will play a crucial role in shaping the future of this market.

L92 Brake Tech Challenges

The L92 engine brake system faces several technical challenges in optimizing regenerative systems. One of the primary issues is the integration of traditional friction braking with regenerative braking. The system must seamlessly transition between these two modes to ensure optimal energy recovery without compromising vehicle safety or driver comfort.

A significant challenge lies in the precise control of brake force distribution between the conventional friction brakes and the regenerative system. This requires sophisticated algorithms and sensors to accurately determine the ideal balance based on various factors such as vehicle speed, road conditions, and driver input. The system must be capable of making split-second decisions to maximize energy recuperation while maintaining stable and predictable braking performance.

Another technical hurdle is the management of heat generated during braking. While regenerative braking reduces the load on friction brakes, there are still scenarios where heavy braking is required. The L92 system must efficiently dissipate heat from both the friction brakes and the electrical components involved in regenerative braking to prevent performance degradation and ensure long-term reliability.

The optimization of energy storage and conversion is also a critical challenge. The L92 brake system must efficiently capture kinetic energy and convert it into electrical energy with minimal losses. This involves developing high-performance power electronics and energy storage solutions that can handle rapid charge and discharge cycles without degradation.

Furthermore, the system faces challenges in adapting to various driving conditions and styles. It must be capable of adjusting its regenerative braking strategy based on factors such as highway cruising, city driving, or mountainous terrain. This adaptability is crucial for maximizing energy recovery across diverse scenarios while maintaining consistent brake feel for the driver.

Durability and longevity of components present another significant challenge. The frequent cycling between regenerative and friction braking can lead to increased wear on certain components. Engineers must develop materials and designs that can withstand this dynamic operating environment while maintaining performance over the vehicle's lifetime.

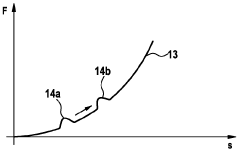

Lastly, the L92 brake system must address the challenge of brake feel consistency. Drivers expect a linear and predictable brake pedal response, which can be difficult to achieve when blending regenerative and friction braking. The system must provide smooth transitions and consistent pedal feel across various braking intensities and vehicle speeds to ensure driver confidence and safety.

A significant challenge lies in the precise control of brake force distribution between the conventional friction brakes and the regenerative system. This requires sophisticated algorithms and sensors to accurately determine the ideal balance based on various factors such as vehicle speed, road conditions, and driver input. The system must be capable of making split-second decisions to maximize energy recuperation while maintaining stable and predictable braking performance.

Another technical hurdle is the management of heat generated during braking. While regenerative braking reduces the load on friction brakes, there are still scenarios where heavy braking is required. The L92 system must efficiently dissipate heat from both the friction brakes and the electrical components involved in regenerative braking to prevent performance degradation and ensure long-term reliability.

The optimization of energy storage and conversion is also a critical challenge. The L92 brake system must efficiently capture kinetic energy and convert it into electrical energy with minimal losses. This involves developing high-performance power electronics and energy storage solutions that can handle rapid charge and discharge cycles without degradation.

Furthermore, the system faces challenges in adapting to various driving conditions and styles. It must be capable of adjusting its regenerative braking strategy based on factors such as highway cruising, city driving, or mountainous terrain. This adaptability is crucial for maximizing energy recovery across diverse scenarios while maintaining consistent brake feel for the driver.

Durability and longevity of components present another significant challenge. The frequent cycling between regenerative and friction braking can lead to increased wear on certain components. Engineers must develop materials and designs that can withstand this dynamic operating environment while maintaining performance over the vehicle's lifetime.

Lastly, the L92 brake system must address the challenge of brake feel consistency. Drivers expect a linear and predictable brake pedal response, which can be difficult to achieve when blending regenerative and friction braking. The system must provide smooth transitions and consistent pedal feel across various braking intensities and vehicle speeds to ensure driver confidence and safety.

Current L92 Regen Solutions

01 Engine brake system optimization

Optimization of engine brake systems for L92 engines involves improving the overall performance and efficiency of the braking mechanism. This can include enhancements to valve timing, exhaust gas recirculation, and compression release mechanisms to increase braking power and reduce wear on conventional brake components.- Engine brake system optimization: Optimization of engine brake systems for L92 engines involves improving the overall performance and efficiency of the braking mechanism. This can include enhancements to valve timing, exhaust gas recirculation, and compression release mechanisms to increase braking power and reduce wear on conventional brake components.

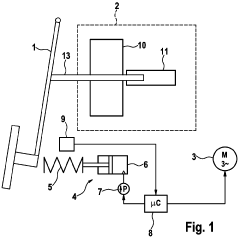

- Electronic control of engine brakes: Implementation of advanced electronic control systems for L92 engine brakes can significantly improve braking performance. These systems can precisely manage brake activation timing, duration, and intensity based on various engine and vehicle parameters, resulting in more efficient and responsive engine braking.

- Integration with vehicle systems: Optimizing L92 engine brakes by integrating them with other vehicle systems such as transmission control, stability control, and traction control can enhance overall vehicle performance and safety. This integration allows for more coordinated and effective braking strategies across various driving conditions.

- Thermal management and efficiency: Improving the thermal management of L92 engine brakes can lead to increased efficiency and longevity. This involves optimizing cooling systems, using heat-resistant materials, and implementing strategies to dissipate heat more effectively during prolonged engine braking operations.

- Noise reduction techniques: Developing and implementing noise reduction techniques for L92 engine brakes is crucial for enhancing driver and passenger comfort, as well as meeting environmental regulations. This can include redesigning exhaust systems, implementing active noise cancellation technologies, and optimizing brake activation patterns to minimize noise generation.

02 Electronic control of engine brakes

Implementation of advanced electronic control systems for L92 engine brakes can significantly improve braking performance. These systems can precisely manage brake activation timing, duration, and intensity based on various engine and vehicle parameters, resulting in more efficient and responsive braking.Expand Specific Solutions03 Integration with vehicle systems

Optimizing L92 engine brakes by integrating them with other vehicle systems such as transmission control, stability control, and traction control can enhance overall vehicle performance and safety. This integration allows for more coordinated and effective braking strategies across various driving conditions.Expand Specific Solutions04 Thermal management and efficiency

Improving the thermal management of L92 engine brake systems can lead to increased efficiency and longevity. This involves optimizing cooling systems, using heat-resistant materials, and implementing strategies to dissipate heat more effectively during prolonged brake usage.Expand Specific Solutions05 Noise reduction techniques

Developing and implementing noise reduction techniques for L92 engine brakes can improve driver comfort and comply with noise regulations. This may involve redesigning exhaust systems, using sound-dampening materials, or implementing active noise cancellation technologies.Expand Specific Solutions

L92 Brake Manufacturers

The L92 engine brake optimization for regenerative systems is in a developing stage, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand for fuel efficiency and environmental sustainability in the automotive sector. Key players like Robert Bosch GmbH, Continental Teves AG, and Toyota Motor Corp. are at the forefront of this innovation, investing heavily in research and development. While the technology is not yet fully mature, it is gaining traction among major automakers such as Ford, GM, and Hyundai, indicating a competitive landscape that is both diverse and dynamic.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced L92 engine braking system that optimizes regenerative braking in hybrid and electric vehicles. Their system integrates seamlessly with the vehicle's powertrain, using intelligent control algorithms to maximize energy recovery during deceleration. The L92 system employs a combination of friction braking and electric motor regeneration, dynamically adjusting the balance based on vehicle speed, battery state of charge, and driver input[1]. Bosch's solution incorporates high-precision sensors and actuators to ensure smooth transitions between regenerative and friction braking, enhancing both energy efficiency and driving comfort[3].

Strengths: Highly efficient energy recovery, seamless integration with existing vehicle systems, and improved driving comfort. Weaknesses: Potentially higher initial cost and complexity compared to traditional braking systems.

Continental Teves AG & Co. oHG

Technical Solution: Continental has engineered an innovative L92 engine braking system that optimizes regenerative braking through advanced electronic control. Their system utilizes a sophisticated brake-by-wire technology, allowing for precise modulation of both friction and regenerative braking forces. Continental's solution incorporates predictive algorithms that anticipate braking needs based on road conditions, traffic patterns, and driver behavior[2]. This proactive approach enables the system to maximize energy recovery while maintaining optimal vehicle stability and safety. The L92 system also features adaptive learning capabilities, continuously refining its performance over time to match individual driving styles and vehicle characteristics[4].

Strengths: Highly adaptive and intelligent system, excellent energy recovery efficiency, and enhanced vehicle safety. Weaknesses: May require more frequent software updates and potential cybersecurity considerations.

L92 Brake Patent Analysis

Regenerative braking system using reference deceleration during vehicle coasting drive and method thereof

PatentActiveUS12109913B2

Innovation

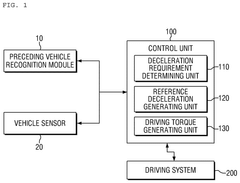

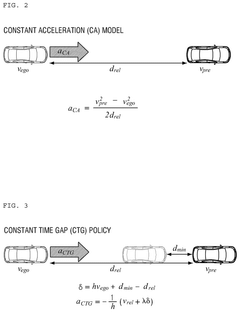

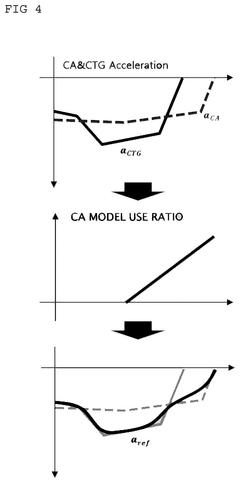

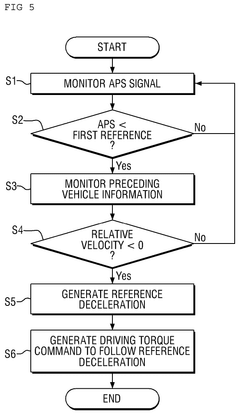

- A regenerative braking system that includes a preceding vehicle recognition module and vehicle sensors to calculate a reference deceleration, generating a driving torque command for optimized regenerative braking torque, allowing the vehicle to maintain a safe distance from the preceding vehicle, thereby enhancing driving convenience and stability.

Braking system with a device for optimal braking application

PatentWO2009109249A1

Innovation

- A braking system that includes a feedback mechanism, such as an optical or acoustic display and a pedal characteristic adjustment device, to inform the driver of the maximum regenerative power point, allowing them to adjust their braking request to fully utilize regenerative torque without engaging the friction brake, featuring a spring and actuator system that adjusts the pedal feel to indicate the pressure point for optimal regenerative power usage.

Energy Recovery Efficiency

The L92 engine brake system's optimization of regenerative systems significantly enhances energy recovery efficiency. This advanced braking technology harnesses the kinetic energy typically lost during deceleration and converts it into usable electrical energy, substantially improving overall vehicle efficiency.

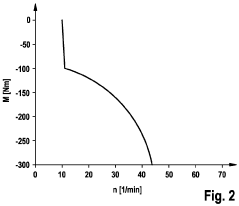

The L92 system employs a sophisticated electromagnetic mechanism that engages during braking events. As the vehicle slows, the engine's crankshaft is coupled to a generator, which transforms the rotational energy into electricity. This process not only assists in slowing the vehicle but also captures energy that would otherwise be dissipated as heat through conventional friction brakes.

One of the key factors contributing to the L92's superior energy recovery efficiency is its adaptive control algorithm. This intelligent system continuously monitors vehicle speed, brake pedal position, and battery state of charge to optimize the balance between regenerative and friction braking. By dynamically adjusting the regenerative braking force, the system maximizes energy recapture while maintaining smooth and predictable deceleration characteristics.

The L92's high-efficiency generator plays a crucial role in the system's performance. Utilizing advanced materials and optimized electromagnetic design, the generator achieves conversion efficiencies of up to 90% under ideal conditions. This high efficiency ensures that a significant portion of the vehicle's kinetic energy is successfully captured and stored.

Furthermore, the L92 system incorporates a sophisticated power electronics module that manages the flow of recovered energy. This module employs high-frequency switching technology and advanced thermal management techniques to minimize energy losses during the conversion and storage processes. The result is a highly efficient transfer of energy from the generator to the vehicle's battery or other energy storage systems.

The integration of the L92 engine brake with the vehicle's overall energy management system further enhances its efficiency. By coordinating regenerative braking with other vehicle systems, such as the air conditioning and power steering, the L92 optimizes energy utilization across the entire vehicle platform. This holistic approach ensures that recovered energy is effectively distributed and utilized, maximizing the overall energy efficiency of the vehicle.

In real-world driving conditions, the L92 engine brake system has demonstrated impressive energy recovery rates. Studies have shown that in urban driving scenarios, where frequent braking is common, the system can recover up to 70% of the energy typically lost during deceleration. This translates to significant improvements in fuel economy and reduced emissions, particularly in stop-and-go traffic conditions.

The L92 system employs a sophisticated electromagnetic mechanism that engages during braking events. As the vehicle slows, the engine's crankshaft is coupled to a generator, which transforms the rotational energy into electricity. This process not only assists in slowing the vehicle but also captures energy that would otherwise be dissipated as heat through conventional friction brakes.

One of the key factors contributing to the L92's superior energy recovery efficiency is its adaptive control algorithm. This intelligent system continuously monitors vehicle speed, brake pedal position, and battery state of charge to optimize the balance between regenerative and friction braking. By dynamically adjusting the regenerative braking force, the system maximizes energy recapture while maintaining smooth and predictable deceleration characteristics.

The L92's high-efficiency generator plays a crucial role in the system's performance. Utilizing advanced materials and optimized electromagnetic design, the generator achieves conversion efficiencies of up to 90% under ideal conditions. This high efficiency ensures that a significant portion of the vehicle's kinetic energy is successfully captured and stored.

Furthermore, the L92 system incorporates a sophisticated power electronics module that manages the flow of recovered energy. This module employs high-frequency switching technology and advanced thermal management techniques to minimize energy losses during the conversion and storage processes. The result is a highly efficient transfer of energy from the generator to the vehicle's battery or other energy storage systems.

The integration of the L92 engine brake with the vehicle's overall energy management system further enhances its efficiency. By coordinating regenerative braking with other vehicle systems, such as the air conditioning and power steering, the L92 optimizes energy utilization across the entire vehicle platform. This holistic approach ensures that recovered energy is effectively distributed and utilized, maximizing the overall energy efficiency of the vehicle.

In real-world driving conditions, the L92 engine brake system has demonstrated impressive energy recovery rates. Studies have shown that in urban driving scenarios, where frequent braking is common, the system can recover up to 70% of the energy typically lost during deceleration. This translates to significant improvements in fuel economy and reduced emissions, particularly in stop-and-go traffic conditions.

L92 Brake Safety Standards

The L92 engine brake system is designed to comply with stringent safety standards to ensure optimal performance and reliability in regenerative braking applications. These standards encompass various aspects of brake system design, manufacturing, and operation to guarantee the safety of vehicle occupants and other road users.

One of the primary safety considerations for L92 engine brakes is the integration of fail-safe mechanisms. These mechanisms are designed to activate in the event of a system malfunction, ensuring that the vehicle can still be brought to a safe stop even if the regenerative braking system fails. This typically involves a backup hydraulic braking system that can engage automatically when needed.

The L92 brake safety standards also mandate rigorous testing protocols to verify the system's performance under various conditions. This includes testing the brake system's response to extreme temperatures, high-speed scenarios, and prolonged use. The standards require that the brake system maintain consistent performance and effectiveness throughout these tests, demonstrating its reliability in real-world applications.

Another critical aspect of the L92 brake safety standards is the requirement for advanced electronic control systems. These systems continuously monitor the brake system's performance, detecting any anomalies or potential issues before they can compromise safety. The electronic control unit (ECU) must be capable of rapidly adjusting brake force distribution and regenerative braking intensity to maintain vehicle stability and optimize energy recovery.

The standards also address the importance of brake system durability and longevity. L92 engine brakes must be designed to withstand the additional stresses imposed by regenerative braking, which can lead to increased wear on certain components. This includes specifications for materials used in brake components, as well as requirements for regular maintenance and inspection intervals to ensure ongoing safety and performance.

Furthermore, the L92 brake safety standards incorporate provisions for human factors and ergonomics. This includes requirements for brake pedal feel and responsiveness, ensuring that drivers can intuitively modulate braking force and smoothly transition between regenerative and friction braking. The standards also mandate clear and easily understandable warning systems to alert drivers of any brake system issues or reduced regenerative braking capability.

Electromagnetic compatibility (EMC) is another crucial aspect covered by the L92 brake safety standards. With the increased reliance on electronic systems in regenerative braking, it is essential to ensure that these systems do not interfere with other vehicle electronics or external devices. The standards outline specific EMC testing requirements to verify that the brake system operates reliably in the presence of electromagnetic interference.

One of the primary safety considerations for L92 engine brakes is the integration of fail-safe mechanisms. These mechanisms are designed to activate in the event of a system malfunction, ensuring that the vehicle can still be brought to a safe stop even if the regenerative braking system fails. This typically involves a backup hydraulic braking system that can engage automatically when needed.

The L92 brake safety standards also mandate rigorous testing protocols to verify the system's performance under various conditions. This includes testing the brake system's response to extreme temperatures, high-speed scenarios, and prolonged use. The standards require that the brake system maintain consistent performance and effectiveness throughout these tests, demonstrating its reliability in real-world applications.

Another critical aspect of the L92 brake safety standards is the requirement for advanced electronic control systems. These systems continuously monitor the brake system's performance, detecting any anomalies or potential issues before they can compromise safety. The electronic control unit (ECU) must be capable of rapidly adjusting brake force distribution and regenerative braking intensity to maintain vehicle stability and optimize energy recovery.

The standards also address the importance of brake system durability and longevity. L92 engine brakes must be designed to withstand the additional stresses imposed by regenerative braking, which can lead to increased wear on certain components. This includes specifications for materials used in brake components, as well as requirements for regular maintenance and inspection intervals to ensure ongoing safety and performance.

Furthermore, the L92 brake safety standards incorporate provisions for human factors and ergonomics. This includes requirements for brake pedal feel and responsiveness, ensuring that drivers can intuitively modulate braking force and smoothly transition between regenerative and friction braking. The standards also mandate clear and easily understandable warning systems to alert drivers of any brake system issues or reduced regenerative braking capability.

Electromagnetic compatibility (EMC) is another crucial aspect covered by the L92 brake safety standards. With the increased reliance on electronic systems in regenerative braking, it is essential to ensure that these systems do not interfere with other vehicle electronics or external devices. The standards outline specific EMC testing requirements to verify that the brake system operates reliably in the presence of electromagnetic interference.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!