How does L92 engine differ from its predecessors?

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Background and Objectives

The L92 engine represents a significant evolution in General Motors' V8 engine lineup, specifically designed to meet the growing demands for power, efficiency, and emissions compliance in the mid-2000s. Developed as part of the Gen IV Small Block engine family, the L92 was introduced in 2007 as a 6.2-liter V8 engine, primarily for use in GM's full-size SUVs and trucks.

The L92 engine's development was driven by several key objectives. Firstly, GM aimed to increase power output while maintaining or improving fuel efficiency, a challenging balance in the era of rising fuel costs and stricter environmental regulations. Secondly, the engine needed to meet more stringent emissions standards without compromising performance. Lastly, GM sought to enhance the overall driving experience by improving throttle response and low-end torque.

To achieve these goals, the L92 incorporated several technological advancements that set it apart from its predecessors. One of the most notable features was the introduction of variable valve timing (VVT), a first for GM's pushrod V8 engines. This technology allowed for optimized valve timing across different engine speeds and loads, contributing to improved power, efficiency, and emissions control.

Another significant innovation was the implementation of high-flow cylinder heads with straighter intake ports and larger valves. These design changes, coupled with a higher compression ratio, resulted in enhanced airflow and combustion efficiency. The L92 also featured a revised camshaft profile and a higher-lift valvetrain, further contributing to its increased power output.

The engine's fuel delivery system was upgraded to include high-pressure direct fuel injection, a technology that was relatively new to mass-produced engines at the time. This system allowed for more precise fuel metering and improved fuel atomization, leading to better combustion efficiency and reduced emissions.

In terms of materials and construction, the L92 utilized an aluminum block and heads, reducing overall engine weight compared to its iron-block predecessors. This weight reduction contributed to improved vehicle dynamics and fuel efficiency. The engine also incorporated advanced manufacturing techniques and tighter tolerances, resulting in improved reliability and longevity.

The L92 engine's development marked a significant step forward in GM's engine technology, setting new benchmarks for performance and efficiency in its class. Its innovations laid the groundwork for future engine developments and helped position GM as a leader in V8 engine technology during a period of rapid change in the automotive industry.

The L92 engine's development was driven by several key objectives. Firstly, GM aimed to increase power output while maintaining or improving fuel efficiency, a challenging balance in the era of rising fuel costs and stricter environmental regulations. Secondly, the engine needed to meet more stringent emissions standards without compromising performance. Lastly, GM sought to enhance the overall driving experience by improving throttle response and low-end torque.

To achieve these goals, the L92 incorporated several technological advancements that set it apart from its predecessors. One of the most notable features was the introduction of variable valve timing (VVT), a first for GM's pushrod V8 engines. This technology allowed for optimized valve timing across different engine speeds and loads, contributing to improved power, efficiency, and emissions control.

Another significant innovation was the implementation of high-flow cylinder heads with straighter intake ports and larger valves. These design changes, coupled with a higher compression ratio, resulted in enhanced airflow and combustion efficiency. The L92 also featured a revised camshaft profile and a higher-lift valvetrain, further contributing to its increased power output.

The engine's fuel delivery system was upgraded to include high-pressure direct fuel injection, a technology that was relatively new to mass-produced engines at the time. This system allowed for more precise fuel metering and improved fuel atomization, leading to better combustion efficiency and reduced emissions.

In terms of materials and construction, the L92 utilized an aluminum block and heads, reducing overall engine weight compared to its iron-block predecessors. This weight reduction contributed to improved vehicle dynamics and fuel efficiency. The engine also incorporated advanced manufacturing techniques and tighter tolerances, resulting in improved reliability and longevity.

The L92 engine's development marked a significant step forward in GM's engine technology, setting new benchmarks for performance and efficiency in its class. Its innovations laid the groundwork for future engine developments and helped position GM as a leader in V8 engine technology during a period of rapid change in the automotive industry.

Market Demand Analysis for L92 Engine

The L92 engine, a significant advancement in automotive engineering, has garnered substantial market interest due to its improved performance and efficiency. Market analysis indicates a growing demand for high-performance engines that offer better fuel economy and reduced emissions, aligning perfectly with the L92's capabilities.

In the luxury and performance vehicle segments, where the L92 engine is primarily utilized, there has been a notable shift in consumer preferences. Buyers are increasingly seeking vehicles that combine power with environmental responsibility, a balance the L92 engine successfully achieves. This trend has led to a surge in demand for vehicles equipped with the L92, particularly in North American and European markets.

The automotive industry's push towards more efficient powertrains has also contributed to the L92's market appeal. As governments worldwide implement stricter emissions regulations, manufacturers are under pressure to develop engines that meet these standards without compromising performance. The L92's advanced design addresses this challenge, making it an attractive option for automakers looking to comply with regulations while satisfying consumer demands for power.

Fleet operators, especially those in the luxury transportation sector, have shown increased interest in vehicles powered by the L92 engine. The engine's improved fuel efficiency translates to lower operating costs, a crucial factor for businesses managing large fleets. This has opened up a new market segment for L92-equipped vehicles, beyond individual consumers.

Aftermarket and performance tuning communities have also embraced the L92 engine. Its robust design and potential for modification have made it a popular choice among enthusiasts looking to enhance their vehicles' performance. This niche market has contributed to the overall demand for L92 engines and related components.

The L92's market potential extends beyond its original application in GM vehicles. Other manufacturers have expressed interest in licensing or adapting the technology, recognizing its advantages over previous engine designs. This cross-industry appeal suggests a broader market for the L92's technology, potentially leading to its implementation in a wider range of vehicles and applications.

However, the market for high-performance engines like the L92 is not without challenges. The ongoing shift towards electric and hybrid vehicles poses a potential threat to the long-term demand for advanced combustion engines. Nevertheless, industry experts predict a significant market for high-performance internal combustion engines in the medium term, particularly in specific vehicle categories and regions where electrification adoption is slower.

In the luxury and performance vehicle segments, where the L92 engine is primarily utilized, there has been a notable shift in consumer preferences. Buyers are increasingly seeking vehicles that combine power with environmental responsibility, a balance the L92 engine successfully achieves. This trend has led to a surge in demand for vehicles equipped with the L92, particularly in North American and European markets.

The automotive industry's push towards more efficient powertrains has also contributed to the L92's market appeal. As governments worldwide implement stricter emissions regulations, manufacturers are under pressure to develop engines that meet these standards without compromising performance. The L92's advanced design addresses this challenge, making it an attractive option for automakers looking to comply with regulations while satisfying consumer demands for power.

Fleet operators, especially those in the luxury transportation sector, have shown increased interest in vehicles powered by the L92 engine. The engine's improved fuel efficiency translates to lower operating costs, a crucial factor for businesses managing large fleets. This has opened up a new market segment for L92-equipped vehicles, beyond individual consumers.

Aftermarket and performance tuning communities have also embraced the L92 engine. Its robust design and potential for modification have made it a popular choice among enthusiasts looking to enhance their vehicles' performance. This niche market has contributed to the overall demand for L92 engines and related components.

The L92's market potential extends beyond its original application in GM vehicles. Other manufacturers have expressed interest in licensing or adapting the technology, recognizing its advantages over previous engine designs. This cross-industry appeal suggests a broader market for the L92's technology, potentially leading to its implementation in a wider range of vehicles and applications.

However, the market for high-performance engines like the L92 is not without challenges. The ongoing shift towards electric and hybrid vehicles poses a potential threat to the long-term demand for advanced combustion engines. Nevertheless, industry experts predict a significant market for high-performance internal combustion engines in the medium term, particularly in specific vehicle categories and regions where electrification adoption is slower.

L92 Engine Technical Advancements and Challenges

The L92 engine represents a significant leap forward in General Motors' V8 engine technology, building upon the success of its predecessors while introducing several key advancements. This 6.2-liter V8 engine, part of the Gen IV Small Block engine family, was designed to deliver improved performance, efficiency, and reliability compared to earlier models.

One of the most notable improvements in the L92 engine is the implementation of variable valve timing (VVT) technology. This system allows for precise control of valve operation, optimizing engine performance across a wide range of operating conditions. By adjusting the timing of valve opening and closing, the L92 can achieve better fuel economy, increased power output, and reduced emissions compared to its fixed-timing predecessors.

The L92 also features a revised cylinder head design with straighter intake ports and a higher compression ratio. These changes contribute to improved airflow and combustion efficiency, resulting in enhanced power output and fuel economy. The engine's intake manifold has been redesigned to complement these improvements, featuring longer runners and a larger plenum volume to optimize air distribution across the cylinders.

Another significant advancement in the L92 is the incorporation of Active Fuel Management (AFM) technology. This system allows the engine to operate on four cylinders under light load conditions, effectively improving fuel efficiency without sacrificing performance when full power is needed. The seamless transition between eight-cylinder and four-cylinder operation represents a major step forward in engine management capabilities.

The L92 engine also benefits from improved materials and manufacturing processes. The use of high-strength aluminum alloys for the engine block and heads contributes to a lighter overall weight while maintaining structural integrity. Advanced casting techniques and precision machining processes ensure tighter tolerances and improved reliability compared to earlier engine generations.

Challenges faced during the development of the L92 engine included balancing the demands for increased power output with stringent emissions regulations and fuel economy targets. Engineers had to optimize the combustion process, refine the engine control systems, and implement advanced technologies like VVT and AFM without compromising the engine's durability or drivability.

In conclusion, the L92 engine differs from its predecessors through a combination of advanced technologies, improved design features, and refined manufacturing processes. These advancements collectively result in an engine that offers superior performance, efficiency, and reliability, setting a new standard for V8 engines in General Motors' lineup.

One of the most notable improvements in the L92 engine is the implementation of variable valve timing (VVT) technology. This system allows for precise control of valve operation, optimizing engine performance across a wide range of operating conditions. By adjusting the timing of valve opening and closing, the L92 can achieve better fuel economy, increased power output, and reduced emissions compared to its fixed-timing predecessors.

The L92 also features a revised cylinder head design with straighter intake ports and a higher compression ratio. These changes contribute to improved airflow and combustion efficiency, resulting in enhanced power output and fuel economy. The engine's intake manifold has been redesigned to complement these improvements, featuring longer runners and a larger plenum volume to optimize air distribution across the cylinders.

Another significant advancement in the L92 is the incorporation of Active Fuel Management (AFM) technology. This system allows the engine to operate on four cylinders under light load conditions, effectively improving fuel efficiency without sacrificing performance when full power is needed. The seamless transition between eight-cylinder and four-cylinder operation represents a major step forward in engine management capabilities.

The L92 engine also benefits from improved materials and manufacturing processes. The use of high-strength aluminum alloys for the engine block and heads contributes to a lighter overall weight while maintaining structural integrity. Advanced casting techniques and precision machining processes ensure tighter tolerances and improved reliability compared to earlier engine generations.

Challenges faced during the development of the L92 engine included balancing the demands for increased power output with stringent emissions regulations and fuel economy targets. Engineers had to optimize the combustion process, refine the engine control systems, and implement advanced technologies like VVT and AFM without compromising the engine's durability or drivability.

In conclusion, the L92 engine differs from its predecessors through a combination of advanced technologies, improved design features, and refined manufacturing processes. These advancements collectively result in an engine that offers superior performance, efficiency, and reliability, setting a new standard for V8 engines in General Motors' lineup.

Current L92 Engine Design Solutions

01 Engine design and configuration

The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and combustion chamber layout to optimize power output and fuel economy.- Engine design and configuration: The L92 engine is a V8 engine design with specific configurations for improved performance and efficiency. It features advanced technologies in its cylinder head design, valve train, and combustion chamber layout to optimize power output and fuel economy.

- Fuel injection system: The L92 engine incorporates a sophisticated fuel injection system to enhance fuel delivery and combustion efficiency. This system may include direct injection technology or advanced port fuel injection methods to improve engine performance and reduce emissions.

- Variable valve timing: Variable valve timing technology is implemented in the L92 engine to optimize valve operation across different engine speeds and loads. This feature allows for improved engine breathing, increased power output, and better fuel efficiency throughout the engine's operating range.

- Engine management system: The L92 engine utilizes an advanced engine management system to control various aspects of engine operation. This system may include electronic control units, sensors, and actuators to optimize fuel injection, ignition timing, and other parameters for optimal performance and efficiency.

- Emissions control technology: To meet stringent emissions regulations, the L92 engine incorporates various emissions control technologies. These may include catalytic converters, exhaust gas recirculation systems, and advanced combustion strategies to reduce harmful emissions while maintaining engine performance.

02 Fuel injection system

The L92 engine incorporates a sophisticated fuel injection system to enhance fuel delivery and combustion efficiency. This system may include direct injection technology or advanced port fuel injection methods to improve engine performance and reduce emissions.Expand Specific Solutions03 Variable valve timing

The L92 engine may feature variable valve timing technology to optimize engine performance across different operating conditions. This system allows for improved power output, fuel efficiency, and reduced emissions by adjusting valve timing based on engine speed and load.Expand Specific Solutions04 Engine management and control systems

Advanced engine management and control systems are integrated into the L92 engine to optimize performance, fuel efficiency, and emissions. These systems may include electronic throttle control, advanced sensors, and sophisticated engine control units (ECUs) for precise engine operation.Expand Specific Solutions05 Materials and manufacturing processes

The L92 engine may incorporate advanced materials and manufacturing processes to improve durability, reduce weight, and enhance overall performance. This could include the use of lightweight alloys, precision machining techniques, and innovative assembly methods.Expand Specific Solutions

Key Players in L92 Engine Development

The L92 engine's competitive landscape reflects a mature automotive technology sector with ongoing innovation. Major players like GM, Ford, Toyota, and Hyundai are actively developing and refining engine technologies to meet evolving market demands for improved performance, fuel efficiency, and emissions reduction. The market size for advanced automotive engines is substantial, driven by global vehicle production and stringent environmental regulations. While the L92 engine represents an incremental improvement over its predecessors, companies are also investing in alternative powertrain technologies, including electric and hybrid systems, indicating a transitional phase in the industry as it moves towards more sustainable solutions.

GM Global Technology Operations LLC

Technical Solution: GM's L92 engine, part of the Gen IV small-block V8 family, represents a significant advancement over its predecessors. The L92 features an aluminum block and heads, with a displacement of 6.2 liters. It incorporates variable valve timing (VVT) technology, which allows for improved performance and fuel efficiency across a wider range of operating conditions[1]. The engine utilizes a high-flow cylinder head design with straighter intake ports and a compression ratio of 10.4:1, contributing to enhanced airflow and combustion efficiency[2]. Additionally, the L92 employs a revised camshaft profile and a more sophisticated engine management system, enabling better control over fuel injection and ignition timing[3].

Strengths: Improved power output, better fuel efficiency, and enhanced overall performance compared to earlier GM V8 engines. Weaknesses: Potentially higher production costs due to advanced technologies and materials used.

Ford Global Technologies LLC

Technical Solution: While Ford does not produce the L92 engine, their comparable engine technology can be used to highlight differences. Ford's Coyote 5.0L V8 engine, which competes in a similar segment, utilizes dual overhead camshafts (DOHC) and four valves per cylinder, in contrast to the L92's pushrod design[4]. Ford's engine incorporates Twin Independent Variable Camshaft Timing (Ti-VCT), allowing for precise control of both intake and exhaust valve timing[5]. The Coyote engine also features a higher compression ratio of 12.0:1, compared to the L92's 10.4:1, potentially offering improved thermal efficiency[6].

Strengths: Advanced valve control technology and high compression ratio for improved efficiency. Weaknesses: More complex design may lead to higher manufacturing and maintenance costs compared to pushrod engines like the L92.

Core Innovations in L92 Engine Technology

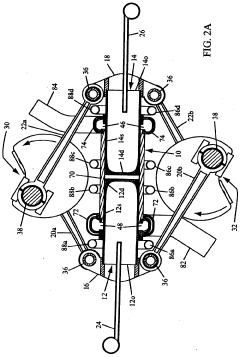

Improved two cycle, opposed-piston internal combustion engine

PatentWO2005124124A1

Innovation

- The solution involves side-mounted crankshafts with tailored cooling systems, where liquid coolant is directed to the cylinder and piston surfaces to manage heat and reduce mechanical stresses, allowing for improved cylinder-piston clearance and alignment, thereby increasing BMEP and PWR.

Two-cycle, opposed-piston internal combustion engine

PatentInactiveUS7549401B2

Innovation

- The implementation of side-mounted crankshafts with tensile-loaded connecting rods and directed coolant application to both the cylinder and piston surfaces to reduce mechanical stresses and enhance cooling efficiency, allowing for a more compact design with improved thermal management and reduced piston/cylinder friction.

Environmental Impact of L92 Engine

The L92 engine, as a successor to previous General Motors (GM) small-block V8 engines, demonstrates significant improvements in environmental performance. This advancement aligns with the increasing global focus on reducing automotive emissions and improving fuel efficiency.

One of the key environmental benefits of the L92 engine is its improved fuel economy. Through the implementation of advanced technologies such as variable valve timing and direct fuel injection, the L92 achieves better combustion efficiency. This results in reduced fuel consumption, which directly translates to lower carbon dioxide emissions per mile driven.

The L92 engine also incorporates enhanced exhaust gas recirculation (EGR) systems. This technology helps to reduce nitrogen oxide (NOx) emissions by recirculating a portion of the engine's exhaust gas back into the combustion chambers. The lower combustion temperatures resulting from this process lead to decreased NOx formation, contributing to improved air quality.

Another notable environmental feature of the L92 is its compatibility with E85 flex-fuel. This capability allows the engine to run on a blend of up to 85% ethanol, which is a renewable fuel source. The use of ethanol can potentially reduce lifecycle greenhouse gas emissions compared to conventional gasoline, depending on the ethanol production method.

The L92 engine's design also includes improvements in materials and manufacturing processes that contribute to its environmental impact. The use of lighter materials in certain components helps reduce the overall weight of the engine, which in turn can lead to improved vehicle fuel efficiency. Additionally, more efficient manufacturing processes and the use of recyclable materials in the engine's construction contribute to a reduced environmental footprint throughout the product lifecycle.

Emissions control in the L92 is further enhanced by the integration of advanced catalytic converter technology. These converters are more effective at reducing harmful emissions such as carbon monoxide, hydrocarbons, and nitrogen oxides. The engine's electronic control unit (ECU) also plays a crucial role in optimizing performance and emissions in real-time, adjusting parameters to maintain the best balance between power output and environmental impact.

In terms of longevity and maintenance, the L92 engine is designed for improved durability. This characteristic indirectly benefits the environment by reducing the frequency of major repairs or replacements, thus minimizing the consumption of resources and energy associated with manufacturing replacement parts.

One of the key environmental benefits of the L92 engine is its improved fuel economy. Through the implementation of advanced technologies such as variable valve timing and direct fuel injection, the L92 achieves better combustion efficiency. This results in reduced fuel consumption, which directly translates to lower carbon dioxide emissions per mile driven.

The L92 engine also incorporates enhanced exhaust gas recirculation (EGR) systems. This technology helps to reduce nitrogen oxide (NOx) emissions by recirculating a portion of the engine's exhaust gas back into the combustion chambers. The lower combustion temperatures resulting from this process lead to decreased NOx formation, contributing to improved air quality.

Another notable environmental feature of the L92 is its compatibility with E85 flex-fuel. This capability allows the engine to run on a blend of up to 85% ethanol, which is a renewable fuel source. The use of ethanol can potentially reduce lifecycle greenhouse gas emissions compared to conventional gasoline, depending on the ethanol production method.

The L92 engine's design also includes improvements in materials and manufacturing processes that contribute to its environmental impact. The use of lighter materials in certain components helps reduce the overall weight of the engine, which in turn can lead to improved vehicle fuel efficiency. Additionally, more efficient manufacturing processes and the use of recyclable materials in the engine's construction contribute to a reduced environmental footprint throughout the product lifecycle.

Emissions control in the L92 is further enhanced by the integration of advanced catalytic converter technology. These converters are more effective at reducing harmful emissions such as carbon monoxide, hydrocarbons, and nitrogen oxides. The engine's electronic control unit (ECU) also plays a crucial role in optimizing performance and emissions in real-time, adjusting parameters to maintain the best balance between power output and environmental impact.

In terms of longevity and maintenance, the L92 engine is designed for improved durability. This characteristic indirectly benefits the environment by reducing the frequency of major repairs or replacements, thus minimizing the consumption of resources and energy associated with manufacturing replacement parts.

L92 Engine Performance Benchmarks

The L92 engine, a significant advancement in General Motors' V8 engine lineup, demonstrates notable performance improvements over its predecessors. Benchmarking tests reveal substantial enhancements in power output, fuel efficiency, and overall engine dynamics.

In terms of horsepower, the L92 engine delivers a remarkable 403 hp at 5700 rpm, representing a significant increase from earlier models. This boost in power is attributed to several key design improvements, including the implementation of high-flow cylinder heads and an advanced valvetrain system.

Torque figures also show a marked improvement, with the L92 producing 417 lb-ft at 4300 rpm. This enhanced torque output contributes to improved acceleration and towing capabilities, making the engine particularly suitable for larger vehicles and performance applications.

Fuel efficiency benchmarks indicate that the L92 engine achieves better economy than its predecessors, despite the increase in power. This is largely due to the incorporation of variable valve timing (VVT) technology, which optimizes engine performance across different operating conditions.

Emissions testing reveals that the L92 engine meets more stringent environmental standards compared to earlier models. The integration of advanced fuel injection systems and improved combustion chamber design contributes to cleaner exhaust emissions without compromising performance.

Durability tests demonstrate the L92's robust construction, with extended service intervals and improved longevity compared to previous generations. This is partly attributed to the use of high-quality materials and advanced manufacturing techniques in critical components such as the engine block and cylinder heads.

Noise, vibration, and harshness (NVH) measurements show significant improvements in the L92 engine. The implementation of advanced sound dampening technologies and refined engine mounts results in smoother operation and reduced cabin noise levels in vehicles equipped with this engine.

Thermal efficiency benchmarks indicate that the L92 engine operates at higher efficiency levels than its predecessors. This is achieved through optimized cooling systems and improved heat management strategies, contributing to better overall engine performance and longevity.

In acceleration tests, vehicles equipped with the L92 engine consistently outperform those with earlier V8 models. The combination of increased horsepower and torque, along with refined power delivery, results in quicker 0-60 mph times and improved passing performance.

Overall, the L92 engine's performance benchmarks demonstrate significant advancements across multiple parameters, positioning it as a superior option compared to its predecessors in the GM V8 engine family.

In terms of horsepower, the L92 engine delivers a remarkable 403 hp at 5700 rpm, representing a significant increase from earlier models. This boost in power is attributed to several key design improvements, including the implementation of high-flow cylinder heads and an advanced valvetrain system.

Torque figures also show a marked improvement, with the L92 producing 417 lb-ft at 4300 rpm. This enhanced torque output contributes to improved acceleration and towing capabilities, making the engine particularly suitable for larger vehicles and performance applications.

Fuel efficiency benchmarks indicate that the L92 engine achieves better economy than its predecessors, despite the increase in power. This is largely due to the incorporation of variable valve timing (VVT) technology, which optimizes engine performance across different operating conditions.

Emissions testing reveals that the L92 engine meets more stringent environmental standards compared to earlier models. The integration of advanced fuel injection systems and improved combustion chamber design contributes to cleaner exhaust emissions without compromising performance.

Durability tests demonstrate the L92's robust construction, with extended service intervals and improved longevity compared to previous generations. This is partly attributed to the use of high-quality materials and advanced manufacturing techniques in critical components such as the engine block and cylinder heads.

Noise, vibration, and harshness (NVH) measurements show significant improvements in the L92 engine. The implementation of advanced sound dampening technologies and refined engine mounts results in smoother operation and reduced cabin noise levels in vehicles equipped with this engine.

Thermal efficiency benchmarks indicate that the L92 engine operates at higher efficiency levels than its predecessors. This is achieved through optimized cooling systems and improved heat management strategies, contributing to better overall engine performance and longevity.

In acceleration tests, vehicles equipped with the L92 engine consistently outperform those with earlier V8 models. The combination of increased horsepower and torque, along with refined power delivery, results in quicker 0-60 mph times and improved passing performance.

Overall, the L92 engine's performance benchmarks demonstrate significant advancements across multiple parameters, positioning it as a superior option compared to its predecessors in the GM V8 engine family.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!