L92 engine's adaptability in extreme weather conditions

AUG 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

L92 Engine Background and Objectives

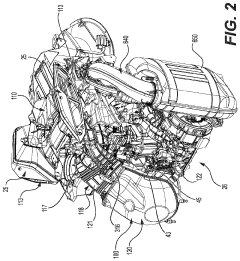

The L92 engine, a marvel of modern automotive engineering, has been at the forefront of powertrain technology since its inception. Developed as a high-performance V8 engine, the L92 has found its place in various General Motors vehicles, particularly in the Chevrolet and GMC lineups. Its design philosophy centers on delivering robust power output while maintaining fuel efficiency, a balance that has become increasingly crucial in the automotive industry.

The evolution of the L92 engine is rooted in GM's pursuit of advanced engine technologies to meet stringent emissions standards and consumer demands for improved performance. This engine represents a significant milestone in the company's small-block V8 engine family, incorporating features such as variable valve timing and active fuel management systems. These innovations have allowed the L92 to adapt to changing market needs and regulatory requirements over time.

As global climate patterns continue to shift, the automotive industry faces new challenges in ensuring vehicle performance across a wider range of environmental conditions. The L92 engine's adaptability to extreme weather conditions has become a focal point for engineers and researchers. This focus aligns with the broader industry trend towards creating more resilient and versatile powertrains capable of maintaining optimal performance in diverse climates.

The primary objective in exploring the L92 engine's adaptability to extreme weather is to enhance its reliability and efficiency across a spectrum of temperature ranges. This includes improving cold-start capabilities in sub-zero temperatures, optimizing performance in scorching heat, and maintaining consistent output in high-altitude environments with reduced air density. Additionally, there is a growing emphasis on developing solutions that address the impact of humidity and atmospheric pressure variations on engine performance.

Another critical goal is to minimize the engine's environmental impact while maximizing its adaptability. This involves refining combustion processes, improving thermal management systems, and developing advanced materials that can withstand extreme temperature fluctuations without compromising performance or longevity. The pursuit of these objectives is driven by both consumer expectations for all-weather reliability and regulatory pressures to reduce emissions across all operating conditions.

In the context of extreme weather adaptability, the L92 engine serves as a platform for testing and implementing cutting-edge technologies. These may include advanced sensor systems for real-time environmental monitoring, adaptive control algorithms that adjust engine parameters based on atmospheric conditions, and innovative cooling solutions that maintain optimal operating temperatures in challenging environments. The insights gained from this research are expected to influence future engine designs and contribute to the broader field of automotive engineering.

The evolution of the L92 engine is rooted in GM's pursuit of advanced engine technologies to meet stringent emissions standards and consumer demands for improved performance. This engine represents a significant milestone in the company's small-block V8 engine family, incorporating features such as variable valve timing and active fuel management systems. These innovations have allowed the L92 to adapt to changing market needs and regulatory requirements over time.

As global climate patterns continue to shift, the automotive industry faces new challenges in ensuring vehicle performance across a wider range of environmental conditions. The L92 engine's adaptability to extreme weather conditions has become a focal point for engineers and researchers. This focus aligns with the broader industry trend towards creating more resilient and versatile powertrains capable of maintaining optimal performance in diverse climates.

The primary objective in exploring the L92 engine's adaptability to extreme weather is to enhance its reliability and efficiency across a spectrum of temperature ranges. This includes improving cold-start capabilities in sub-zero temperatures, optimizing performance in scorching heat, and maintaining consistent output in high-altitude environments with reduced air density. Additionally, there is a growing emphasis on developing solutions that address the impact of humidity and atmospheric pressure variations on engine performance.

Another critical goal is to minimize the engine's environmental impact while maximizing its adaptability. This involves refining combustion processes, improving thermal management systems, and developing advanced materials that can withstand extreme temperature fluctuations without compromising performance or longevity. The pursuit of these objectives is driven by both consumer expectations for all-weather reliability and regulatory pressures to reduce emissions across all operating conditions.

In the context of extreme weather adaptability, the L92 engine serves as a platform for testing and implementing cutting-edge technologies. These may include advanced sensor systems for real-time environmental monitoring, adaptive control algorithms that adjust engine parameters based on atmospheric conditions, and innovative cooling solutions that maintain optimal operating temperatures in challenging environments. The insights gained from this research are expected to influence future engine designs and contribute to the broader field of automotive engineering.

Market Demand Analysis

The market demand for engines capable of adapting to extreme weather conditions has been steadily increasing in recent years. This trend is driven by several factors, including the growing awareness of climate change impacts and the expansion of industrial activities into harsh environments.

In the automotive sector, there is a rising demand for vehicles that can perform reliably in diverse climates. Consumers and fleet operators in regions with extreme temperatures, such as the Arctic or desert areas, require engines that can start and operate efficiently in both extremely cold and hot conditions. This demand extends to commercial vehicles, off-road equipment, and emergency response vehicles that must function reliably in challenging environments.

The aviation industry also presents a significant market for weather-adaptive engines. Aircraft engines must maintain performance and safety standards across a wide range of temperatures and altitudes. As air travel continues to grow globally, including in regions with extreme weather patterns, the need for engines that can withstand these conditions becomes more critical.

In the marine sector, ships operating in polar regions or tropical waters require engines that can handle temperature extremes and varying humidity levels. The increasing focus on Arctic shipping routes and offshore operations in diverse climatic zones further amplifies this demand.

The power generation industry, particularly in remote locations or areas prone to extreme weather events, seeks robust engine solutions. This includes backup power systems for critical infrastructure and portable generators for disaster response, which must function reliably regardless of environmental conditions.

Military applications represent another significant market segment. Armed forces worldwide require vehicles and equipment capable of operating in diverse and often extreme environments, from desert warfare to Arctic operations. The ability of engines to perform consistently in these conditions is crucial for mission success and troop safety.

The industrial sector, including mining, oil and gas, and construction, also contributes to the demand for weather-adaptive engines. These industries often operate in challenging environments where equipment reliability is paramount.

Market analysts project that the global demand for weather-resistant engines will continue to grow. This growth is expected to be particularly strong in emerging markets where infrastructure development is expanding into previously underdeveloped regions with harsh climates.

As environmental regulations become more stringent, there is also an increasing emphasis on engines that can maintain optimal performance and emissions standards across various weather conditions. This regulatory pressure is likely to further drive innovation and demand in the weather-adaptive engine market.

In the automotive sector, there is a rising demand for vehicles that can perform reliably in diverse climates. Consumers and fleet operators in regions with extreme temperatures, such as the Arctic or desert areas, require engines that can start and operate efficiently in both extremely cold and hot conditions. This demand extends to commercial vehicles, off-road equipment, and emergency response vehicles that must function reliably in challenging environments.

The aviation industry also presents a significant market for weather-adaptive engines. Aircraft engines must maintain performance and safety standards across a wide range of temperatures and altitudes. As air travel continues to grow globally, including in regions with extreme weather patterns, the need for engines that can withstand these conditions becomes more critical.

In the marine sector, ships operating in polar regions or tropical waters require engines that can handle temperature extremes and varying humidity levels. The increasing focus on Arctic shipping routes and offshore operations in diverse climatic zones further amplifies this demand.

The power generation industry, particularly in remote locations or areas prone to extreme weather events, seeks robust engine solutions. This includes backup power systems for critical infrastructure and portable generators for disaster response, which must function reliably regardless of environmental conditions.

Military applications represent another significant market segment. Armed forces worldwide require vehicles and equipment capable of operating in diverse and often extreme environments, from desert warfare to Arctic operations. The ability of engines to perform consistently in these conditions is crucial for mission success and troop safety.

The industrial sector, including mining, oil and gas, and construction, also contributes to the demand for weather-adaptive engines. These industries often operate in challenging environments where equipment reliability is paramount.

Market analysts project that the global demand for weather-resistant engines will continue to grow. This growth is expected to be particularly strong in emerging markets where infrastructure development is expanding into previously underdeveloped regions with harsh climates.

As environmental regulations become more stringent, there is also an increasing emphasis on engines that can maintain optimal performance and emissions standards across various weather conditions. This regulatory pressure is likely to further drive innovation and demand in the weather-adaptive engine market.

Technical Challenges in Extreme Weather

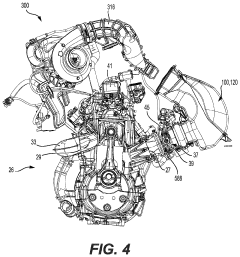

The L92 engine faces significant challenges when operating in extreme weather conditions, particularly in terms of performance, reliability, and efficiency. One of the primary concerns is the engine's ability to maintain optimal combustion temperatures across a wide range of ambient conditions. In extremely cold environments, fuel atomization becomes problematic, leading to incomplete combustion and increased emissions. Conversely, in hot climates, the engine may struggle with adequate cooling, potentially causing overheating and reduced power output.

Material selection plays a crucial role in addressing these challenges. Components must withstand thermal expansion and contraction without compromising structural integrity or sealing properties. This is particularly critical for gaskets, seals, and bearings, which are susceptible to degradation under extreme temperature fluctuations. Additionally, lubricants must maintain their viscosity and protective properties across a broad temperature range to ensure proper engine lubrication and wear prevention.

The engine's electronic control systems also face significant hurdles in extreme weather. Sensors and control units must operate reliably in both sub-zero temperatures and scorching heat. Moisture ingress and condensation in cold climates can lead to electrical malfunctions, while high temperatures may cause electronic components to fail prematurely. Developing robust, weather-resistant housings and connectors for these systems is essential for maintaining engine performance and diagnostics capabilities.

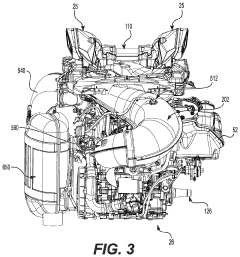

Air intake systems present another area of concern, particularly in dusty or humid environments. In cold weather, ice formation in the air intake can restrict airflow, while hot and humid conditions may reduce the density of incoming air, affecting the engine's power output. Designing adaptive intake systems that can preheat or precool incoming air, as well as effectively filter out contaminants, is crucial for maintaining engine efficiency across diverse climates.

Fuel system components, including injectors and fuel lines, must also be engineered to withstand extreme temperatures. In cold weather, fuel can thicken or even freeze, leading to poor flow and potential system blockages. Conversely, high temperatures can cause fuel vaporization issues, potentially leading to vapor lock. Implementing heated fuel lines and advanced injector designs can help mitigate these issues, ensuring consistent fuel delivery under all conditions.

Addressing these technical challenges requires a multifaceted approach, combining advanced materials science, sophisticated electronic control systems, and innovative mechanical designs. Engineers must consider not only the individual components but also their interactions within the engine system as a whole. Rigorous testing under simulated extreme conditions is essential to validate the effectiveness of proposed solutions and ensure the L92 engine's reliability and performance across a wide range of environmental conditions.

Material selection plays a crucial role in addressing these challenges. Components must withstand thermal expansion and contraction without compromising structural integrity or sealing properties. This is particularly critical for gaskets, seals, and bearings, which are susceptible to degradation under extreme temperature fluctuations. Additionally, lubricants must maintain their viscosity and protective properties across a broad temperature range to ensure proper engine lubrication and wear prevention.

The engine's electronic control systems also face significant hurdles in extreme weather. Sensors and control units must operate reliably in both sub-zero temperatures and scorching heat. Moisture ingress and condensation in cold climates can lead to electrical malfunctions, while high temperatures may cause electronic components to fail prematurely. Developing robust, weather-resistant housings and connectors for these systems is essential for maintaining engine performance and diagnostics capabilities.

Air intake systems present another area of concern, particularly in dusty or humid environments. In cold weather, ice formation in the air intake can restrict airflow, while hot and humid conditions may reduce the density of incoming air, affecting the engine's power output. Designing adaptive intake systems that can preheat or precool incoming air, as well as effectively filter out contaminants, is crucial for maintaining engine efficiency across diverse climates.

Fuel system components, including injectors and fuel lines, must also be engineered to withstand extreme temperatures. In cold weather, fuel can thicken or even freeze, leading to poor flow and potential system blockages. Conversely, high temperatures can cause fuel vaporization issues, potentially leading to vapor lock. Implementing heated fuel lines and advanced injector designs can help mitigate these issues, ensuring consistent fuel delivery under all conditions.

Addressing these technical challenges requires a multifaceted approach, combining advanced materials science, sophisticated electronic control systems, and innovative mechanical designs. Engineers must consider not only the individual components but also their interactions within the engine system as a whole. Rigorous testing under simulated extreme conditions is essential to validate the effectiveness of proposed solutions and ensure the L92 engine's reliability and performance across a wide range of environmental conditions.

Current Adaptability Solutions

01 Engine control system adaptability

The L92 engine's adaptability is enhanced through advanced control systems that can adjust to various operating conditions. These systems optimize performance, fuel efficiency, and emissions by continuously monitoring and adapting to factors such as temperature, altitude, and driving style. The adaptive control algorithms allow for real-time adjustments to ignition timing, fuel injection, and valve timing, ensuring optimal engine performance across a wide range of scenarios.- Engine control system adaptability: The L92 engine's adaptability is enhanced through advanced control systems that can adjust to various operating conditions. These systems optimize performance, fuel efficiency, and emissions by continuously monitoring and adapting to factors such as temperature, altitude, and driving style.

- Fuel system flexibility: The L92 engine demonstrates adaptability in its fuel system, allowing for compatibility with different fuel types or blends. This flexibility enables the engine to maintain performance and efficiency across various fuel compositions, enhancing its versatility in different markets or applications.

- Thermal management adaptability: Adaptability in thermal management is a key feature of the L92 engine, incorporating advanced cooling systems and heat dissipation techniques. These systems adjust to varying operating temperatures and conditions, ensuring optimal engine performance and longevity across different environments.

- Emissions control adaptability: The L92 engine incorporates adaptive emissions control systems that can adjust to meet varying regulatory requirements. These systems utilize advanced sensors and control algorithms to optimize the engine's operation for reduced emissions while maintaining performance across different operating conditions.

- Integration with hybrid and electric systems: Adaptability of the L92 engine extends to its potential integration with hybrid and electric powertrain systems. This flexibility allows for the development of more efficient and environmentally friendly vehicle configurations, adapting to the evolving automotive landscape and energy transition requirements.

02 Fuel system flexibility

The L92 engine demonstrates adaptability in its fuel system design, allowing for compatibility with different fuel types and blends. This flexibility enables the engine to operate efficiently on various octane ratings and even alternative fuels, enhancing its versatility for different markets and environmental regulations. The fuel system incorporates advanced sensors and injectors that can adjust fuel delivery based on the specific characteristics of the fuel being used.Expand Specific Solutions03 Thermal management adaptability

Adaptability in thermal management is a key feature of the L92 engine, allowing it to maintain optimal operating temperatures across various climates and load conditions. The engine incorporates advanced cooling systems with variable speed pumps and thermostats that can adjust coolant flow and temperature based on real-time needs. This adaptive thermal management contributes to improved efficiency, reduced emissions, and enhanced durability of engine components.Expand Specific Solutions04 Variable valve timing and lift

The L92 engine's adaptability is further enhanced by its variable valve timing and lift systems. These systems allow for dynamic adjustment of valve operation based on engine speed, load, and other factors. By optimizing valve timing and lift for different operating conditions, the engine can achieve improved power output, fuel efficiency, and emissions performance across a wide range of driving scenarios.Expand Specific Solutions05 Modular design for easy modification

The L92 engine features a modular design that enhances its adaptability for different applications and markets. This design approach allows for easy modification and customization of various engine components, such as intake and exhaust systems, turbochargers, and auxiliary systems. The modular architecture facilitates quick adaptation to different vehicle platforms, power requirements, and regulatory standards, making the engine versatile for a wide range of automotive applications.Expand Specific Solutions

Key Players in Engine Manufacturing

The L92 engine's adaptability in extreme weather conditions represents a mature technology in the automotive industry, with significant market potential due to increasing demand for reliable vehicles in diverse climates. The competitive landscape is dominated by established players like Weichai Power, Continental Automotive, and Robert Bosch, who have extensive experience in engine technology. These companies are investing heavily in research and development to enhance engine performance and efficiency across various weather conditions. The market is characterized by ongoing innovation, with a focus on integrating advanced materials and smart technologies to improve engine resilience and adaptability.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced thermal management systems for the L92 engine to enhance its adaptability in extreme weather conditions. Their solution includes an intelligent coolant flow control system that optimizes engine temperature across a wide range of ambient conditions. This system utilizes advanced sensors and algorithms to precisely regulate coolant flow, ensuring optimal engine performance and efficiency in both extremely cold and hot environments[1]. Additionally, Bosch has implemented a sophisticated oil heating and cooling system that maintains ideal oil viscosity regardless of external temperatures, contributing to improved engine longevity and performance consistency[2].

Strengths: Precise temperature control, improved engine efficiency, and enhanced durability in extreme conditions. Weaknesses: Potentially higher system complexity and cost compared to traditional cooling systems.

AUDI AG

Technical Solution: Audi has implemented innovative solutions to enhance the L92 engine's adaptability to extreme weather conditions. Their approach includes a multi-stage intake heating system that ensures optimal air temperature entering the engine, regardless of ambient conditions. This system utilizes waste heat from the engine and electrical heating elements to pre-warm intake air in cold weather, improving combustion efficiency and reducing emissions[3]. For hot weather operation, Audi has developed an advanced intercooling system with variable coolant flow, allowing for rapid temperature adjustments to maintain optimal charge air density[4]. Furthermore, Audi's engine management system incorporates predictive algorithms that adjust engine parameters based on real-time weather data and forecasts, ensuring optimal performance across diverse climate conditions[5].

Strengths: Comprehensive approach addressing both cold and hot weather challenges, integration with vehicle's data systems for predictive adjustments. Weaknesses: Potential for increased system complexity and higher production costs.

Core Innovations for L92 Engine

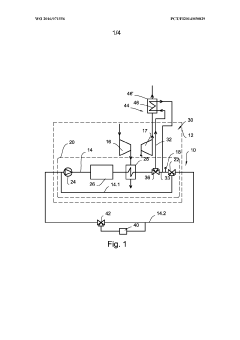

Internal combustion piston engine and method of operating an internal combustion piston engine

PatentWO2016071556A1

Innovation

- A heat transfer system with a closed circuit and a heat exchanger that transfers heat from exhaust gases to a cooling fluid, allowing for effective temperature control of the engine, reducing the need for additional heating and maintaining optimal operating temperatures even in low ambient temperatures.

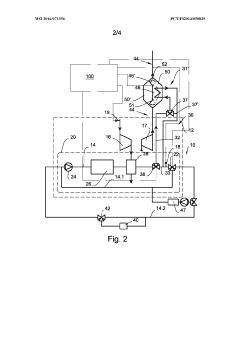

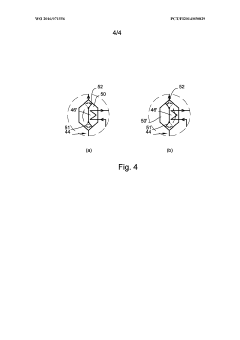

Engine assembly and method for controlling an engine

PatentActiveUS11905905B2

Innovation

- An engine assembly and method that includes a turbocharger with a temperature sensor and controller to adjust boost target pressure based on exhaust gas temperature and throttle position, using a bypass conduit and valve to divert exhaust gas, ensuring optimal power output by compensating for temperature and pressure variations.

Environmental Impact Assessment

The environmental impact of the L92 engine's adaptability in extreme weather conditions is a crucial aspect to consider in its development and deployment. This assessment focuses on the engine's performance and emissions across various climatic scenarios, from arctic cold to tropical heat.

In extreme cold conditions, the L92 engine's adaptability mechanisms may require additional energy consumption for pre-heating and maintaining optimal operating temperatures. This could lead to increased fuel consumption and, consequently, higher emissions during the initial phases of operation. However, once the engine reaches its optimal temperature, its efficiency in cold climates could potentially reduce overall emissions compared to less adaptable engines.

Conversely, in extremely hot conditions, the engine's cooling systems play a vital role. The enhanced adaptability features of the L92 engine may necessitate more sophisticated cooling mechanisms, which could impact the engine's overall energy efficiency. While this might result in a slight increase in fuel consumption, it could also lead to more stable emissions across a wider temperature range, potentially reducing harmful pollutants that are typically exacerbated by extreme heat.

The engine's adaptability also influences its longevity and maintenance requirements. By maintaining optimal performance across diverse weather conditions, the L92 engine may experience less wear and tear, potentially extending its operational lifespan. This could have positive environmental implications by reducing the frequency of engine replacements and the associated manufacturing and disposal impacts.

Furthermore, the L92 engine's weather adaptability may contribute to more consistent emissions profiles across different geographical regions and seasons. This consistency could facilitate more accurate emissions modeling and regulatory compliance, potentially leading to better air quality management strategies in areas with extreme weather patterns.

However, it's important to consider the potential environmental trade-offs. The additional components or systems required for extreme weather adaptability may increase the engine's overall complexity and material requirements. This could result in a larger environmental footprint during the manufacturing process and potentially complicate end-of-life recycling efforts.

In conclusion, while the L92 engine's adaptability to extreme weather conditions presents several potential environmental benefits, particularly in terms of emissions consistency and engine longevity, it also introduces new considerations regarding resource use and manufacturing impacts. A comprehensive life cycle assessment would be necessary to fully quantify the net environmental impact of these adaptability features.

In extreme cold conditions, the L92 engine's adaptability mechanisms may require additional energy consumption for pre-heating and maintaining optimal operating temperatures. This could lead to increased fuel consumption and, consequently, higher emissions during the initial phases of operation. However, once the engine reaches its optimal temperature, its efficiency in cold climates could potentially reduce overall emissions compared to less adaptable engines.

Conversely, in extremely hot conditions, the engine's cooling systems play a vital role. The enhanced adaptability features of the L92 engine may necessitate more sophisticated cooling mechanisms, which could impact the engine's overall energy efficiency. While this might result in a slight increase in fuel consumption, it could also lead to more stable emissions across a wider temperature range, potentially reducing harmful pollutants that are typically exacerbated by extreme heat.

The engine's adaptability also influences its longevity and maintenance requirements. By maintaining optimal performance across diverse weather conditions, the L92 engine may experience less wear and tear, potentially extending its operational lifespan. This could have positive environmental implications by reducing the frequency of engine replacements and the associated manufacturing and disposal impacts.

Furthermore, the L92 engine's weather adaptability may contribute to more consistent emissions profiles across different geographical regions and seasons. This consistency could facilitate more accurate emissions modeling and regulatory compliance, potentially leading to better air quality management strategies in areas with extreme weather patterns.

However, it's important to consider the potential environmental trade-offs. The additional components or systems required for extreme weather adaptability may increase the engine's overall complexity and material requirements. This could result in a larger environmental footprint during the manufacturing process and potentially complicate end-of-life recycling efforts.

In conclusion, while the L92 engine's adaptability to extreme weather conditions presents several potential environmental benefits, particularly in terms of emissions consistency and engine longevity, it also introduces new considerations regarding resource use and manufacturing impacts. A comprehensive life cycle assessment would be necessary to fully quantify the net environmental impact of these adaptability features.

Regulatory Compliance Overview

The regulatory landscape for engine performance and emissions in extreme weather conditions is complex and evolving. Manufacturers of the L92 engine must navigate a web of international, national, and local regulations to ensure compliance across various markets.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established regulations for vehicle emissions and performance, including those related to cold-start emissions and engine operation in extreme temperatures. These regulations are adopted by many countries worldwide and serve as a baseline for national standards.

In the United States, the Environmental Protection Agency (EPA) sets stringent standards for engine emissions and fuel efficiency. The EPA's Cold Temperature CO Emissions Standards require vehicles to meet specific carbon monoxide emission limits at low ambient temperatures, directly impacting the L92 engine's design and performance in cold weather.

The European Union's Euro 6 emissions standards also include provisions for cold-start emissions and require engines to maintain performance and emissions compliance across a wide range of temperatures. These standards are particularly relevant for the L92 engine's adaptability in both cold and hot climates.

China, another significant market, has implemented the China 6 emissions standards, which include requirements for emissions control in various environmental conditions. These standards are considered some of the most stringent globally and pose a significant challenge for engine manufacturers.

Specific to extreme weather conditions, many jurisdictions have implemented regulations addressing cold-start emissions, evaporative emissions in high temperatures, and overall engine performance in challenging climates. For instance, Canada has additional requirements for vehicle operation in extremely cold conditions, given its harsh winter climate.

The California Air Resources Board (CARB) often sets standards that exceed federal requirements, particularly in areas of cold-start emissions and overall engine efficiency. CARB's regulations often influence standards in other states and countries, making compliance with their requirements crucial for global market access.

Manufacturers must also consider future regulatory trends, such as the increasing focus on real-world driving emissions (RDE) tests, which evaluate engine performance under various real-world conditions, including extreme temperatures. This shift towards RDE testing is likely to further challenge the L92 engine's adaptability to extreme weather conditions.

As regulations continue to tighten globally, the L92 engine's design and performance must evolve to meet these standards while maintaining efficiency and reliability across diverse climatic conditions. This regulatory landscape necessitates ongoing investment in research and development to ensure the engine remains compliant and competitive in the global market.

At the international level, the United Nations Economic Commission for Europe (UNECE) has established regulations for vehicle emissions and performance, including those related to cold-start emissions and engine operation in extreme temperatures. These regulations are adopted by many countries worldwide and serve as a baseline for national standards.

In the United States, the Environmental Protection Agency (EPA) sets stringent standards for engine emissions and fuel efficiency. The EPA's Cold Temperature CO Emissions Standards require vehicles to meet specific carbon monoxide emission limits at low ambient temperatures, directly impacting the L92 engine's design and performance in cold weather.

The European Union's Euro 6 emissions standards also include provisions for cold-start emissions and require engines to maintain performance and emissions compliance across a wide range of temperatures. These standards are particularly relevant for the L92 engine's adaptability in both cold and hot climates.

China, another significant market, has implemented the China 6 emissions standards, which include requirements for emissions control in various environmental conditions. These standards are considered some of the most stringent globally and pose a significant challenge for engine manufacturers.

Specific to extreme weather conditions, many jurisdictions have implemented regulations addressing cold-start emissions, evaporative emissions in high temperatures, and overall engine performance in challenging climates. For instance, Canada has additional requirements for vehicle operation in extremely cold conditions, given its harsh winter climate.

The California Air Resources Board (CARB) often sets standards that exceed federal requirements, particularly in areas of cold-start emissions and overall engine efficiency. CARB's regulations often influence standards in other states and countries, making compliance with their requirements crucial for global market access.

Manufacturers must also consider future regulatory trends, such as the increasing focus on real-world driving emissions (RDE) tests, which evaluate engine performance under various real-world conditions, including extreme temperatures. This shift towards RDE testing is likely to further challenge the L92 engine's adaptability to extreme weather conditions.

As regulations continue to tighten globally, the L92 engine's design and performance must evolve to meet these standards while maintaining efficiency and reliability across diverse climatic conditions. This regulatory landscape necessitates ongoing investment in research and development to ensure the engine remains compliant and competitive in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!