How Does Petroleum Ether Affect Barrier Film Testing And What Conditioning Avoids Artefacts?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Impact on Barrier Film Testing

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum, plays a significant role in barrier film testing methodologies across various industries. This solvent, characterized by its low boiling point range (typically 30-60°C), has become an essential component in evaluating the performance and integrity of barrier films used in packaging, electronics, and medical applications. The interaction between petroleum ether and barrier films represents a critical area of study due to its implications for product safety, shelf life, and functional performance.

When petroleum ether comes into contact with barrier films, it can trigger several physical and chemical reactions that potentially alter the film's structural integrity. The low molecular weight hydrocarbons in petroleum ether can penetrate polymer matrices, causing swelling, plasticization, or even partial dissolution of certain film components. This interaction may lead to increased permeability, reduced mechanical strength, and compromised barrier properties - effects that can significantly distort test results if not properly accounted for.

The testing protocols involving petroleum ether typically aim to evaluate solvent resistance, chemical compatibility, or permeation rates through barrier films. Standard methodologies include gravimetric analysis, permeation cells, and spectroscopic techniques that measure the rate and extent of petroleum ether transmission through the barrier material. However, these tests face challenges related to the volatile nature of petroleum ether, which can evaporate rapidly during testing, potentially leading to inaccurate measurements and inconsistent results.

Temperature fluctuations during testing further complicate the interaction between petroleum ether and barrier films. At elevated temperatures, the solvent's penetration rate increases substantially, while at lower temperatures, its viscosity changes may affect diffusion kinetics. These temperature-dependent behaviors necessitate strict environmental control during testing to ensure reproducible results.

The concentration gradient of petroleum ether across the barrier film represents another critical factor influencing test outcomes. Higher concentration gradients accelerate permeation rates, potentially overwhelming the barrier properties that would function adequately under normal service conditions. This phenomenon can create misleading test results that fail to reflect real-world performance scenarios.

Film composition significantly determines how petroleum ether affects barrier properties. While some polymers like EVOH (ethylene vinyl alcohol) and PVDC (polyvinylidene chloride) demonstrate excellent resistance to petroleum ether, others such as polyethylene may experience significant swelling and increased permeability. Multi-layer films often exhibit complex behaviors as different layers respond uniquely to petroleum ether exposure, sometimes leading to delamination or interface weakening that compromises overall barrier integrity.

When petroleum ether comes into contact with barrier films, it can trigger several physical and chemical reactions that potentially alter the film's structural integrity. The low molecular weight hydrocarbons in petroleum ether can penetrate polymer matrices, causing swelling, plasticization, or even partial dissolution of certain film components. This interaction may lead to increased permeability, reduced mechanical strength, and compromised barrier properties - effects that can significantly distort test results if not properly accounted for.

The testing protocols involving petroleum ether typically aim to evaluate solvent resistance, chemical compatibility, or permeation rates through barrier films. Standard methodologies include gravimetric analysis, permeation cells, and spectroscopic techniques that measure the rate and extent of petroleum ether transmission through the barrier material. However, these tests face challenges related to the volatile nature of petroleum ether, which can evaporate rapidly during testing, potentially leading to inaccurate measurements and inconsistent results.

Temperature fluctuations during testing further complicate the interaction between petroleum ether and barrier films. At elevated temperatures, the solvent's penetration rate increases substantially, while at lower temperatures, its viscosity changes may affect diffusion kinetics. These temperature-dependent behaviors necessitate strict environmental control during testing to ensure reproducible results.

The concentration gradient of petroleum ether across the barrier film represents another critical factor influencing test outcomes. Higher concentration gradients accelerate permeation rates, potentially overwhelming the barrier properties that would function adequately under normal service conditions. This phenomenon can create misleading test results that fail to reflect real-world performance scenarios.

Film composition significantly determines how petroleum ether affects barrier properties. While some polymers like EVOH (ethylene vinyl alcohol) and PVDC (polyvinylidene chloride) demonstrate excellent resistance to petroleum ether, others such as polyethylene may experience significant swelling and increased permeability. Multi-layer films often exhibit complex behaviors as different layers respond uniquely to petroleum ether exposure, sometimes leading to delamination or interface weakening that compromises overall barrier integrity.

Market Demand for Accurate Barrier Film Evaluation

The barrier film market has experienced significant growth in recent years, driven primarily by increasing demand in food packaging, pharmaceutical packaging, and electronics industries. The global barrier film market was valued at approximately 30 billion USD in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030, highlighting the economic importance of accurate testing methodologies.

Accurate barrier film evaluation has become critical as end-users demand packaging solutions with precise and reliable barrier properties. Food and beverage companies require films that can extend shelf life while maintaining product quality, creating a substantial market segment that depends on accurate permeation testing. Any testing artifacts that might lead to incorrect permeation measurements could result in product spoilage, consumer safety issues, and significant financial losses.

Pharmaceutical companies represent another major market driver, as they require barrier films with exceptional oxygen, moisture, and chemical resistance properties. With the global pharmaceutical packaging market expected to reach 158 billion USD by 2028, the demand for precise barrier testing methodologies has never been higher. Testing artifacts caused by conditioning agents like petroleum ether can lead to regulatory non-compliance and compromised drug efficacy.

The electronics industry has similarly stringent requirements for barrier films used in flexible displays, photovoltaics, and other sensitive components. As this sector continues its rapid growth, manufacturers are willing to pay premium prices for films with verified barrier properties, creating a high-value market segment for testing services and equipment.

Market research indicates that companies are increasingly investing in advanced testing equipment and methodologies to ensure accurate barrier property measurements. The global packaging testing equipment market is growing at approximately 10.2% annually, with barrier property testing devices representing a significant portion of this growth.

Consumer trends toward sustainable packaging solutions have further intensified the need for accurate barrier testing. As manufacturers develop new bio-based and recyclable barrier materials, precise evaluation becomes essential to ensure these environmentally friendly alternatives meet performance standards. Testing artifacts that might overstate or understate barrier properties could significantly impede the adoption of sustainable packaging solutions.

Regulatory bodies worldwide have also increased scrutiny of packaging materials, particularly those in contact with food and pharmaceuticals. This regulatory pressure has created additional market demand for standardized, artifact-free testing methodologies that can provide consistent and reliable barrier property measurements across different laboratories and testing conditions.

Accurate barrier film evaluation has become critical as end-users demand packaging solutions with precise and reliable barrier properties. Food and beverage companies require films that can extend shelf life while maintaining product quality, creating a substantial market segment that depends on accurate permeation testing. Any testing artifacts that might lead to incorrect permeation measurements could result in product spoilage, consumer safety issues, and significant financial losses.

Pharmaceutical companies represent another major market driver, as they require barrier films with exceptional oxygen, moisture, and chemical resistance properties. With the global pharmaceutical packaging market expected to reach 158 billion USD by 2028, the demand for precise barrier testing methodologies has never been higher. Testing artifacts caused by conditioning agents like petroleum ether can lead to regulatory non-compliance and compromised drug efficacy.

The electronics industry has similarly stringent requirements for barrier films used in flexible displays, photovoltaics, and other sensitive components. As this sector continues its rapid growth, manufacturers are willing to pay premium prices for films with verified barrier properties, creating a high-value market segment for testing services and equipment.

Market research indicates that companies are increasingly investing in advanced testing equipment and methodologies to ensure accurate barrier property measurements. The global packaging testing equipment market is growing at approximately 10.2% annually, with barrier property testing devices representing a significant portion of this growth.

Consumer trends toward sustainable packaging solutions have further intensified the need for accurate barrier testing. As manufacturers develop new bio-based and recyclable barrier materials, precise evaluation becomes essential to ensure these environmentally friendly alternatives meet performance standards. Testing artifacts that might overstate or understate barrier properties could significantly impede the adoption of sustainable packaging solutions.

Regulatory bodies worldwide have also increased scrutiny of packaging materials, particularly those in contact with food and pharmaceuticals. This regulatory pressure has created additional market demand for standardized, artifact-free testing methodologies that can provide consistent and reliable barrier property measurements across different laboratories and testing conditions.

Current Challenges in Petroleum Ether-Based Testing

Petroleum ether, a widely used solvent in barrier film testing, presents significant challenges that impact test accuracy and reliability. The volatile nature of petroleum ether creates inconsistent testing environments, as its rapid evaporation rate varies with ambient temperature and humidity conditions. This variability introduces unpredictable changes in sample properties during testing, making standardization difficult across different laboratory settings.

Material compatibility issues represent another major challenge. Petroleum ether can interact with certain polymer films, causing swelling, plasticization, or partial dissolution of film components. These interactions alter the fundamental properties of the barrier materials being tested, potentially leading to artificially degraded barrier performance measurements that don't reflect real-world performance.

The health and safety concerns associated with petroleum ether cannot be overlooked. Its high flammability presents fire hazards in laboratory environments, while its volatile organic compound (VOC) emissions pose respiratory risks to laboratory personnel. These safety considerations often necessitate specialized ventilation systems and handling protocols that increase testing complexity and cost.

Regulatory compliance presents an evolving challenge as environmental regulations increasingly restrict the use of petroleum-based solvents. Many jurisdictions have implemented stricter controls on VOC emissions, forcing laboratories to reconsider their testing methodologies or implement costly containment measures to continue using petroleum ether in testing procedures.

Reproducibility issues plague petroleum ether-based testing methods. The solvent's batch-to-batch variability in composition affects its interaction with barrier films, leading to inconsistent test results even when following identical protocols. This variability undermines the reliability of comparative studies and quality control processes that depend on consistent testing conditions.

Conditioning artifacts represent perhaps the most insidious challenge. Pre-conditioning and post-conditioning of samples with petroleum ether can introduce microscopic changes to film structure that aren't representative of actual use conditions. These artifacts may include micro-crack formation, surface roughness alterations, or changes in crystallinity that artificially influence barrier properties, leading to misleading conclusions about material performance.

The lack of standardized protocols for petroleum ether application and sample conditioning further complicates the testing landscape. Different laboratories employ varying conditioning times, temperatures, and application methods, making cross-laboratory comparisons problematic and hindering the development of industry-wide quality standards for barrier films.

Material compatibility issues represent another major challenge. Petroleum ether can interact with certain polymer films, causing swelling, plasticization, or partial dissolution of film components. These interactions alter the fundamental properties of the barrier materials being tested, potentially leading to artificially degraded barrier performance measurements that don't reflect real-world performance.

The health and safety concerns associated with petroleum ether cannot be overlooked. Its high flammability presents fire hazards in laboratory environments, while its volatile organic compound (VOC) emissions pose respiratory risks to laboratory personnel. These safety considerations often necessitate specialized ventilation systems and handling protocols that increase testing complexity and cost.

Regulatory compliance presents an evolving challenge as environmental regulations increasingly restrict the use of petroleum-based solvents. Many jurisdictions have implemented stricter controls on VOC emissions, forcing laboratories to reconsider their testing methodologies or implement costly containment measures to continue using petroleum ether in testing procedures.

Reproducibility issues plague petroleum ether-based testing methods. The solvent's batch-to-batch variability in composition affects its interaction with barrier films, leading to inconsistent test results even when following identical protocols. This variability undermines the reliability of comparative studies and quality control processes that depend on consistent testing conditions.

Conditioning artifacts represent perhaps the most insidious challenge. Pre-conditioning and post-conditioning of samples with petroleum ether can introduce microscopic changes to film structure that aren't representative of actual use conditions. These artifacts may include micro-crack formation, surface roughness alterations, or changes in crystallinity that artificially influence barrier properties, leading to misleading conclusions about material performance.

The lack of standardized protocols for petroleum ether application and sample conditioning further complicates the testing landscape. Different laboratories employ varying conditioning times, temperatures, and application methods, making cross-laboratory comparisons problematic and hindering the development of industry-wide quality standards for barrier films.

Existing Conditioning Solutions for Artifact Prevention

01 Testing methods for barrier film properties

Various testing methods are employed to evaluate the barrier properties of films, including permeability tests, transmission rate measurements, and resistance to environmental factors. These tests help identify potential artefacts that may affect the performance of barrier films in real-world applications. Standardized testing protocols ensure consistent evaluation of barrier properties across different film compositions and manufacturing processes.- Testing methods for barrier film properties: Various testing methods are employed to evaluate the barrier properties of films, including permeability tests, transmission rate measurements, and resistance to environmental factors. These methods help identify potential artefacts in testing that could affect the accuracy of results. Standardized testing protocols ensure consistent evaluation of barrier performance against oxygen, moisture, and other substances, which is critical for quality control and product development.

- Identification and mitigation of testing artefacts: Testing artefacts can arise from sample preparation, environmental conditions, or equipment limitations. These artefacts may include edge effects, surface contamination, or inconsistent film thickness that can skew test results. Techniques to identify and mitigate these artefacts include specialized sample holders, controlled testing environments, and statistical analysis methods to distinguish between true barrier properties and testing anomalies.

- Advanced barrier film composition and structure analysis: Analysis of barrier film composition and structure is essential for understanding how material properties affect testing outcomes. Techniques such as electron microscopy, spectroscopy, and thermal analysis help characterize film morphology, layer adhesion, and defect distribution. These analyses can reveal how structural features might create artefacts during barrier property testing, allowing for more accurate interpretation of test results.

- Environmental factors affecting barrier film testing: Environmental conditions such as temperature, humidity, and pressure can significantly impact barrier film testing results and create artefacts. Controlling these variables is crucial for obtaining reliable and reproducible test data. Testing protocols often include specific environmental conditioning steps and monitoring systems to account for these factors and minimize their influence on the measured barrier properties.

- Innovative barrier film testing technologies: New technologies are being developed to improve the accuracy and efficiency of barrier film testing while reducing artefacts. These include automated testing systems, non-destructive evaluation methods, and real-time monitoring techniques. Advanced computational models and machine learning algorithms are also being employed to predict barrier performance and identify potential testing artefacts before they affect results.

02 Identification and mitigation of testing artefacts

Testing artefacts can significantly impact the accuracy of barrier film evaluation. These artefacts may arise from sample preparation, testing conditions, or measurement techniques. Methods to identify and mitigate these artefacts include calibration procedures, control samples, and statistical analysis of test results. By addressing these artefacts, more reliable data on barrier film performance can be obtained.Expand Specific Solutions03 Advanced materials for reducing testing artefacts

Innovative materials and compositions are being developed to minimize testing artefacts in barrier films. These include specialized coatings, composite structures, and novel polymers that provide more consistent barrier properties under various testing conditions. The incorporation of these advanced materials helps to reduce variability in test results and provides more accurate assessment of barrier performance.Expand Specific Solutions04 Environmental factors affecting barrier film testing

Environmental conditions such as temperature, humidity, and exposure to UV radiation can introduce artefacts in barrier film testing. Controlling these factors during testing is crucial for obtaining reliable results. Specialized testing chambers and equipment are used to simulate various environmental conditions and evaluate their impact on barrier properties, helping to identify potential artefacts that may occur in real-world applications.Expand Specific Solutions05 Optical and surface characterization techniques

Optical and surface characterization techniques play a vital role in identifying testing artefacts in barrier films. Methods such as microscopy, spectroscopy, and surface profilometry can detect imperfections, contamination, or structural anomalies that may affect barrier properties. These techniques provide valuable insights into the physical and chemical characteristics of barrier films, helping to distinguish between genuine material properties and testing artefacts.Expand Specific Solutions

Key Industry Players in Barrier Film Testing

The petroleum ether barrier film testing market is in a growth phase, driven by increasing demand for high-performance packaging materials across food, pharmaceutical, and electronics industries. The market size is expanding as regulations on packaging safety become more stringent globally. Technologically, the field is moderately mature but evolving, with companies like China National Petroleum Corp. and China Petroleum & Chemical Corp. leading in petroleum-based testing materials, while OrganoClick AB and Henkel AG are advancing eco-friendly alternatives. Specialized testing expertise comes from Carestream Health and Dai Nippon Printing, who are developing standardized conditioning protocols to prevent testing artifacts. BASF, Evonik, and Kuraray Europe are focusing on innovative barrier materials that maintain integrity during petroleum ether exposure.

Dai Nippon Printing Co., Ltd.

Technical Solution: Dai Nippon Printing has developed specialized barrier film testing protocols that account for petroleum ether effects through a multi-stage conditioning process. Their approach involves pre-treatment of barrier films with controlled exposure to petroleum ether under standardized temperature and humidity conditions (23°C, 50% RH) for 24-48 hours before testing. This allows for stabilization of film properties affected by petroleum ether's solvent properties. DNP's methodology includes a proprietary vapor transmission rate measurement system that compensates for petroleum ether-induced swelling in polymer layers. Their research demonstrates that petroleum ether can increase oxygen transmission rates by 15-30% in certain barrier films due to microscopic pathway formation, but this effect can be mitigated through their patented post-conditioning technique involving gradual solvent removal under vacuum at temperatures below the film's glass transition point.

Strengths: Highly standardized testing protocol with excellent reproducibility; comprehensive understanding of solvent-polymer interactions specific to petroleum ether. Weaknesses: Conditioning process extends overall testing time significantly; requires specialized equipment not widely available in standard testing laboratories.

Kuraray Europe GmbH

Technical Solution: Kuraray Europe has developed a comprehensive approach to barrier film testing that addresses petroleum ether effects through their "Controlled Solvent Interaction Protocol" (CSIP). This methodology recognizes that petroleum ether, being a mixture of volatile hydrocarbons, can significantly alter barrier film properties through selective absorption and swelling of polymer matrices. Kuraray's research demonstrates that petroleum ether primarily affects the amorphous regions of semi-crystalline polymers used in barrier films, creating temporary pathways for gas permeation. Their testing protocol incorporates a three-stage conditioning process: initial equilibration at standard conditions (23°C, 50% RH), controlled petroleum ether exposure in vapor phase at precisely regulated partial pressure, and a stabilization period allowing for redistribution of the solvent within the film structure. Kuraray's data indicates that petroleum ether can increase oxygen transmission rates by 20-40% in EVOH-based barrier films, but these effects can be accurately quantified and accounted for using their proprietary mathematical models that incorporate diffusion coefficients specific to petroleum ether-polymer interactions.

Strengths: Precise control of petroleum ether exposure conditions; excellent reproducibility across different film compositions; comprehensive mathematical modeling of solvent effects. Weaknesses: Time-intensive conditioning protocol (typically 72+ hours); requires specialized equipment for vapor phase control of petroleum ether.

Critical Technical Innovations in Test Standardization

Gas barrier film and method for manufacturing gas barrier film

PatentPendingUS20250109266A1

Innovation

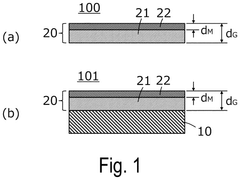

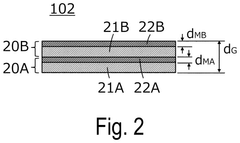

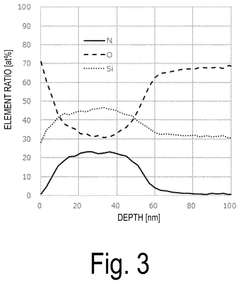

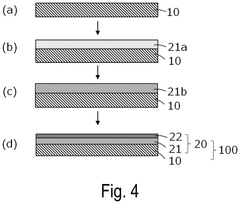

- A gas barrier film with a region containing silicon, oxygen, and nitrogen, with a nitrogen element ratio of 5% or greater and a thickness of 30 nm or greater, formed through specific plasma irradiation conditions, particularly using helium gas, to enhance the gas barrier layer.

Environmental and Safety Considerations

The use of petroleum ether in barrier film testing necessitates careful consideration of environmental and safety factors due to its volatile and hazardous nature. Petroleum ether is classified as a highly flammable liquid with a flash point below 0°C, presenting significant fire and explosion risks when handled improperly. Laboratory environments must maintain adequate ventilation systems with a minimum of 6-12 air changes per hour to prevent the accumulation of vapors that could reach explosive concentrations.

Storage protocols for petroleum ether require specialized flammable storage cabinets that comply with NFPA 30 standards, situated away from ignition sources and oxidizing agents. Testing facilities should implement comprehensive emergency response plans specifically addressing petroleum ether spills and fires, including appropriate fire suppression equipment and evacuation procedures.

Environmental concerns extend beyond immediate safety risks. Petroleum ether contains volatile organic compounds (VOCs) that contribute to air pollution and potential ground-level ozone formation when released. Waste management protocols must adhere to local and national regulations for hazardous waste disposal, with proper documentation through Material Safety Data Sheets (MSDS) and waste manifests.

Personal protective equipment requirements for handling petroleum ether include chemical-resistant gloves (preferably nitrile or neoprene), safety goggles, lab coats, and in some cases, respiratory protection with organic vapor cartridges. Exposure limits established by occupational safety organizations must be strictly observed, with the ACGIH threshold limit value (TLV) for petroleum ether typically set at 300 ppm for an 8-hour time-weighted average.

Alternative testing solvents with lower environmental and safety impacts are increasingly being explored. These include water-based systems, bio-derived solvents like d-limonene, and newer engineered fluids with reduced VOC content. Regulatory compliance frameworks such as REACH in Europe and various EPA regulations in the United States are progressively restricting the use of petroleum ether, driving the industry toward these safer alternatives.

Implementing engineering controls such as fume hoods, closed handling systems, and automated dispensing equipment can significantly reduce exposure risks while maintaining testing accuracy. Regular environmental monitoring through air sampling and employee health surveillance programs provides additional safeguards against chronic exposure effects, which may include neurological symptoms, respiratory irritation, and dermatitis from repeated contact.

Storage protocols for petroleum ether require specialized flammable storage cabinets that comply with NFPA 30 standards, situated away from ignition sources and oxidizing agents. Testing facilities should implement comprehensive emergency response plans specifically addressing petroleum ether spills and fires, including appropriate fire suppression equipment and evacuation procedures.

Environmental concerns extend beyond immediate safety risks. Petroleum ether contains volatile organic compounds (VOCs) that contribute to air pollution and potential ground-level ozone formation when released. Waste management protocols must adhere to local and national regulations for hazardous waste disposal, with proper documentation through Material Safety Data Sheets (MSDS) and waste manifests.

Personal protective equipment requirements for handling petroleum ether include chemical-resistant gloves (preferably nitrile or neoprene), safety goggles, lab coats, and in some cases, respiratory protection with organic vapor cartridges. Exposure limits established by occupational safety organizations must be strictly observed, with the ACGIH threshold limit value (TLV) for petroleum ether typically set at 300 ppm for an 8-hour time-weighted average.

Alternative testing solvents with lower environmental and safety impacts are increasingly being explored. These include water-based systems, bio-derived solvents like d-limonene, and newer engineered fluids with reduced VOC content. Regulatory compliance frameworks such as REACH in Europe and various EPA regulations in the United States are progressively restricting the use of petroleum ether, driving the industry toward these safer alternatives.

Implementing engineering controls such as fume hoods, closed handling systems, and automated dispensing equipment can significantly reduce exposure risks while maintaining testing accuracy. Regular environmental monitoring through air sampling and employee health surveillance programs provides additional safeguards against chronic exposure effects, which may include neurological symptoms, respiratory irritation, and dermatitis from repeated contact.

Quality Assurance Protocols for Test Reliability

To ensure the reliability and validity of barrier film testing when petroleum ether is involved, comprehensive quality assurance protocols must be established and rigorously followed. These protocols should address the specific challenges posed by petroleum ether's volatile nature and its potential to create artifacts in test results.

Standardized sample preparation procedures represent the foundation of reliable testing. Samples must be cut to precise dimensions with clean edges to prevent edge leakage effects. A minimum of five replicates per test condition is recommended to account for material variability and enable statistical validation of results. Additionally, all samples should undergo a controlled conditioning period of 24-48 hours at 23°C ± 1°C and 50% ± 2% relative humidity before testing.

Equipment calibration schedules must be more frequent when petroleum ether is used as a test medium. Gas chromatography systems should be calibrated weekly using certified reference standards, while permeation cells require verification of seal integrity before each test series. Temperature and humidity monitoring systems must maintain ±0.5°C and ±1% RH precision respectively, with calibration verification monthly.

Blank controls and reference materials play a crucial role in identifying potential artifacts. Each test batch should include untreated control samples and industry-standard reference films with known permeation properties. When petroleum ether is used, additional controls using alternative solvents (such as n-hexane) can help distinguish between genuine barrier properties and solvent-specific artifacts.

Data validation procedures must incorporate statistical analysis techniques appropriate for permeation testing. Results exhibiting coefficients of variation exceeding 10% should trigger automatic retesting. Outlier detection using Grubbs' test at a 95% confidence level helps identify anomalous results potentially caused by petroleum ether-induced artifacts. Time-series analysis of permeation rates can further reveal non-linear behaviors indicative of material degradation or testing anomalies.

Documentation requirements extend beyond standard test parameters to include detailed records of petroleum ether specifications (purity grade, supplier, lot number), exposure conditions (temperature profiles, contact duration), and any observed physical changes in test specimens. Photographic documentation before and after testing provides valuable visual evidence of potential material interactions.

Inter-laboratory validation studies are particularly important when petroleum ether is involved in testing protocols. Participation in round-robin testing with at least three independent laboratories using identical materials and methods helps establish reproducibility limits and identify facility-specific artifacts that may otherwise go undetected.

Standardized sample preparation procedures represent the foundation of reliable testing. Samples must be cut to precise dimensions with clean edges to prevent edge leakage effects. A minimum of five replicates per test condition is recommended to account for material variability and enable statistical validation of results. Additionally, all samples should undergo a controlled conditioning period of 24-48 hours at 23°C ± 1°C and 50% ± 2% relative humidity before testing.

Equipment calibration schedules must be more frequent when petroleum ether is used as a test medium. Gas chromatography systems should be calibrated weekly using certified reference standards, while permeation cells require verification of seal integrity before each test series. Temperature and humidity monitoring systems must maintain ±0.5°C and ±1% RH precision respectively, with calibration verification monthly.

Blank controls and reference materials play a crucial role in identifying potential artifacts. Each test batch should include untreated control samples and industry-standard reference films with known permeation properties. When petroleum ether is used, additional controls using alternative solvents (such as n-hexane) can help distinguish between genuine barrier properties and solvent-specific artifacts.

Data validation procedures must incorporate statistical analysis techniques appropriate for permeation testing. Results exhibiting coefficients of variation exceeding 10% should trigger automatic retesting. Outlier detection using Grubbs' test at a 95% confidence level helps identify anomalous results potentially caused by petroleum ether-induced artifacts. Time-series analysis of permeation rates can further reveal non-linear behaviors indicative of material degradation or testing anomalies.

Documentation requirements extend beyond standard test parameters to include detailed records of petroleum ether specifications (purity grade, supplier, lot number), exposure conditions (temperature profiles, contact duration), and any observed physical changes in test specimens. Photographic documentation before and after testing provides valuable visual evidence of potential material interactions.

Inter-laboratory validation studies are particularly important when petroleum ether is involved in testing protocols. Participation in round-robin testing with at least three independent laboratories using identical materials and methods helps establish reproducibility limits and identify facility-specific artifacts that may otherwise go undetected.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!