Petroleum Ether–Induced Stress Cracking: Polymer Selection, Exposure And Screening

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Stress Cracking Background and Objectives

Petroleum ether-induced stress cracking represents a significant challenge in polymer applications across various industries. This phenomenon, characterized by the formation of cracks in polymeric materials when exposed to petroleum ether under stress, has been observed since the mid-20th century but has gained increased attention in recent decades due to the expanding use of polymers in critical applications where chemical resistance is paramount.

The evolution of this technical field has followed the broader development of polymer science, with early observations documented in the 1950s when petroleum-based solvents began seeing widespread industrial use. Initially, stress cracking was primarily considered a failure mode rather than a distinct research area. By the 1970s, as polymer applications expanded into more demanding environments, systematic studies emerged to characterize and quantify this phenomenon.

Recent technological advancements have shifted focus toward predictive modeling and accelerated testing methodologies, enabling more efficient polymer selection processes. The current research landscape encompasses both empirical testing approaches and theoretical models that attempt to predict stress cracking behavior based on polymer structure and solvent properties.

The primary objective of this technical investigation is to establish comprehensive guidelines for polymer selection in applications where exposure to petroleum ether is anticipated. This includes developing reliable screening methodologies that can accurately predict long-term performance without requiring extensive real-time testing, which is often impractical in product development timelines.

Secondary objectives include quantifying the relationship between molecular structure and stress cracking resistance, identifying key environmental factors that accelerate or mitigate cracking, and developing standardized testing protocols that can be widely adopted across industries. These objectives align with the broader goal of enhancing product reliability while reducing development cycles.

From a technological perspective, this field intersects with several emerging trends, including computational materials science, high-throughput screening methodologies, and the development of novel polymer composites specifically engineered for enhanced chemical resistance. The integration of machine learning approaches to predict stress cracking behavior represents a particularly promising frontier that could revolutionize polymer selection processes.

Understanding petroleum ether-induced stress cracking has significant implications for industries ranging from automotive and aerospace to medical devices and consumer products, where unexpected material failures can have serious consequences. As regulatory requirements for product safety and reliability continue to increase, the importance of addressing this technical challenge will only grow in the coming years.

The evolution of this technical field has followed the broader development of polymer science, with early observations documented in the 1950s when petroleum-based solvents began seeing widespread industrial use. Initially, stress cracking was primarily considered a failure mode rather than a distinct research area. By the 1970s, as polymer applications expanded into more demanding environments, systematic studies emerged to characterize and quantify this phenomenon.

Recent technological advancements have shifted focus toward predictive modeling and accelerated testing methodologies, enabling more efficient polymer selection processes. The current research landscape encompasses both empirical testing approaches and theoretical models that attempt to predict stress cracking behavior based on polymer structure and solvent properties.

The primary objective of this technical investigation is to establish comprehensive guidelines for polymer selection in applications where exposure to petroleum ether is anticipated. This includes developing reliable screening methodologies that can accurately predict long-term performance without requiring extensive real-time testing, which is often impractical in product development timelines.

Secondary objectives include quantifying the relationship between molecular structure and stress cracking resistance, identifying key environmental factors that accelerate or mitigate cracking, and developing standardized testing protocols that can be widely adopted across industries. These objectives align with the broader goal of enhancing product reliability while reducing development cycles.

From a technological perspective, this field intersects with several emerging trends, including computational materials science, high-throughput screening methodologies, and the development of novel polymer composites specifically engineered for enhanced chemical resistance. The integration of machine learning approaches to predict stress cracking behavior represents a particularly promising frontier that could revolutionize polymer selection processes.

Understanding petroleum ether-induced stress cracking has significant implications for industries ranging from automotive and aerospace to medical devices and consumer products, where unexpected material failures can have serious consequences. As regulatory requirements for product safety and reliability continue to increase, the importance of addressing this technical challenge will only grow in the coming years.

Market Demand for Chemical-Resistant Polymers

The global market for chemical-resistant polymers has experienced significant growth in recent years, driven primarily by expanding applications in industries where exposure to aggressive chemicals is common. The petroleum ether resistance segment specifically has seen increased demand due to the critical nature of preventing stress cracking in components exposed to hydrocarbon solvents. Current market valuations indicate that the chemical-resistant polymer sector represents approximately 18% of the specialty polymers market, with annual growth rates consistently outpacing general polymer markets.

Industries such as automotive, aerospace, medical devices, and chemical processing are the primary consumers of petroleum ether-resistant polymers. The automotive sector alone accounts for nearly 30% of market demand, particularly for fuel system components where exposure to petroleum-based solvents is inevitable. The aerospace industry follows closely, with stringent requirements for materials that maintain structural integrity under extreme chemical exposure conditions.

Market research indicates a growing preference for high-performance polymers that offer comprehensive resistance profiles rather than single-chemical resistance. This trend reflects the industrial reality where components are frequently exposed to multiple chemical stressors simultaneously. Fluoropolymers, polyamides, and certain grades of polyethylene have consequently gained market share due to their broad chemical resistance profiles.

Regional analysis reveals that North America and Europe currently dominate the market for chemical-resistant polymers, though Asia-Pacific represents the fastest-growing region with compound annual growth rates exceeding those of established markets. This growth is attributed to rapid industrialization, increasing automotive production, and stricter regulatory frameworks regarding material safety and performance.

End-user feedback indicates willingness to pay premium prices for polymers with proven resistance to petroleum ether-induced stress cracking, particularly when such materials can extend component lifespans and reduce maintenance costs. This price elasticity has encouraged material manufacturers to invest in research and development of next-generation resistant polymers.

Market forecasts suggest continued strong demand growth, with particular emphasis on polymers that combine petroleum ether resistance with other desirable properties such as thermal stability, processability, and recyclability. The sustainability aspect is increasingly influencing purchasing decisions, with buyers showing preference for materials that meet environmental standards while maintaining chemical resistance properties.

The testing and certification market for chemical resistance has grown in parallel, with specialized services for petroleum ether stress crack resistance testing becoming standard requirements in supply chains across multiple industries. This trend underscores the critical importance of reliable material selection in applications where exposure to petroleum ether and similar solvents is unavoidable.

Industries such as automotive, aerospace, medical devices, and chemical processing are the primary consumers of petroleum ether-resistant polymers. The automotive sector alone accounts for nearly 30% of market demand, particularly for fuel system components where exposure to petroleum-based solvents is inevitable. The aerospace industry follows closely, with stringent requirements for materials that maintain structural integrity under extreme chemical exposure conditions.

Market research indicates a growing preference for high-performance polymers that offer comprehensive resistance profiles rather than single-chemical resistance. This trend reflects the industrial reality where components are frequently exposed to multiple chemical stressors simultaneously. Fluoropolymers, polyamides, and certain grades of polyethylene have consequently gained market share due to their broad chemical resistance profiles.

Regional analysis reveals that North America and Europe currently dominate the market for chemical-resistant polymers, though Asia-Pacific represents the fastest-growing region with compound annual growth rates exceeding those of established markets. This growth is attributed to rapid industrialization, increasing automotive production, and stricter regulatory frameworks regarding material safety and performance.

End-user feedback indicates willingness to pay premium prices for polymers with proven resistance to petroleum ether-induced stress cracking, particularly when such materials can extend component lifespans and reduce maintenance costs. This price elasticity has encouraged material manufacturers to invest in research and development of next-generation resistant polymers.

Market forecasts suggest continued strong demand growth, with particular emphasis on polymers that combine petroleum ether resistance with other desirable properties such as thermal stability, processability, and recyclability. The sustainability aspect is increasingly influencing purchasing decisions, with buyers showing preference for materials that meet environmental standards while maintaining chemical resistance properties.

The testing and certification market for chemical resistance has grown in parallel, with specialized services for petroleum ether stress crack resistance testing becoming standard requirements in supply chains across multiple industries. This trend underscores the critical importance of reliable material selection in applications where exposure to petroleum ether and similar solvents is unavoidable.

Current Challenges in Polymer Stress Cracking Resistance

Polymer stress cracking resistance (SCR) faces significant challenges when exposed to petroleum ether environments, creating complex material selection problems for engineers and researchers. The petroleum industry particularly struggles with this issue as components frequently contact various hydrocarbon solvents under mechanical stress. Current testing methodologies often fail to accurately predict real-world performance, leading to premature material failures and costly maintenance cycles.

A primary challenge lies in understanding the molecular mechanisms of petroleum ether-induced stress cracking. Unlike water or other polar solvents, petroleum ether penetrates polymer matrices through different pathways, creating unique degradation patterns that remain inadequately characterized. The interaction between mechanical stress and chemical exposure creates synergistic effects that accelerate failure beyond what individual factors would suggest.

Material selection presents another significant hurdle. While some polymers like fluoropolymers and certain grades of polyethylene demonstrate superior resistance, their implementation often involves trade-offs in cost, processability, and mechanical properties. Engineers frequently lack comprehensive comparative data across diverse polymer families under standardized petroleum ether exposure conditions, forcing reliance on trial-and-error approaches rather than science-based selection.

Testing protocols themselves present substantial challenges. Current ASTM and ISO standards for stress cracking resistance were largely developed for aqueous environments, with limited guidance for hydrocarbon exposures. The variability in petroleum ether composition—containing mixtures of pentanes, hexanes, and other light hydrocarbons—further complicates standardization efforts. This leads to inconsistent test results across laboratories and poor correlation with field performance.

Time-dependent effects create additional complexity. Polymers may exhibit acceptable short-term resistance while developing catastrophic failures after prolonged exposure. Accelerated testing methods often fail to capture these long-term degradation mechanisms, creating a disconnect between laboratory qualification and actual service lifetimes.

Environmental factors such as temperature fluctuations, UV exposure, and mechanical cycling dramatically influence stress cracking behavior but remain poorly integrated into current testing frameworks. The combined effect of these variables creates failure modes that single-factor testing cannot predict.

Finally, the industry faces significant knowledge gaps regarding additive packages and stabilization strategies specifically designed for petroleum ether environments. While antioxidants and UV stabilizers have been extensively studied for general applications, their effectiveness against stress cracking in hydrocarbon environments remains underexplored, limiting mitigation options for vulnerable polymer systems.

A primary challenge lies in understanding the molecular mechanisms of petroleum ether-induced stress cracking. Unlike water or other polar solvents, petroleum ether penetrates polymer matrices through different pathways, creating unique degradation patterns that remain inadequately characterized. The interaction between mechanical stress and chemical exposure creates synergistic effects that accelerate failure beyond what individual factors would suggest.

Material selection presents another significant hurdle. While some polymers like fluoropolymers and certain grades of polyethylene demonstrate superior resistance, their implementation often involves trade-offs in cost, processability, and mechanical properties. Engineers frequently lack comprehensive comparative data across diverse polymer families under standardized petroleum ether exposure conditions, forcing reliance on trial-and-error approaches rather than science-based selection.

Testing protocols themselves present substantial challenges. Current ASTM and ISO standards for stress cracking resistance were largely developed for aqueous environments, with limited guidance for hydrocarbon exposures. The variability in petroleum ether composition—containing mixtures of pentanes, hexanes, and other light hydrocarbons—further complicates standardization efforts. This leads to inconsistent test results across laboratories and poor correlation with field performance.

Time-dependent effects create additional complexity. Polymers may exhibit acceptable short-term resistance while developing catastrophic failures after prolonged exposure. Accelerated testing methods often fail to capture these long-term degradation mechanisms, creating a disconnect between laboratory qualification and actual service lifetimes.

Environmental factors such as temperature fluctuations, UV exposure, and mechanical cycling dramatically influence stress cracking behavior but remain poorly integrated into current testing frameworks. The combined effect of these variables creates failure modes that single-factor testing cannot predict.

Finally, the industry faces significant knowledge gaps regarding additive packages and stabilization strategies specifically designed for petroleum ether environments. While antioxidants and UV stabilizers have been extensively studied for general applications, their effectiveness against stress cracking in hydrocarbon environments remains underexplored, limiting mitigation options for vulnerable polymer systems.

Current Polymer Selection Methodologies for Petroleum Ether Exposure

01 Polymer compositions resistant to stress cracking

Specific polymer compositions can be formulated to resist environmental stress cracking. These compositions often include modified polyethylene or polypropylene with additives that enhance their resistance to cracking under stress. The formulations may incorporate cross-linking agents, stabilizers, or specific co-polymers that improve the mechanical properties and durability of the polymer when exposed to stressors such as chemicals, temperature variations, or mechanical loads.- Stress cracking resistance in polyethylene compositions: Polyethylene compositions can be modified to improve resistance to environmental stress cracking. This involves incorporating specific additives or modifying the polymer structure through copolymerization with alpha-olefins. The resulting compositions show enhanced durability under stress conditions while maintaining other desirable mechanical properties. These improvements are particularly valuable for applications exposed to harsh environments or chemicals that typically accelerate stress cracking.

- Testing methods for polymer stress cracking: Various testing methodologies have been developed to evaluate and predict stress cracking behavior in polymers. These include accelerated testing under controlled environmental conditions, mechanical stress application techniques, and specialized equipment for measuring crack initiation and propagation. These testing methods help manufacturers assess material performance and durability before deployment in real-world applications, allowing for better material selection and design optimization.

- Protective coatings to prevent stress cracking: Specialized coatings can be applied to polymer surfaces to create a protective barrier against environmental factors that cause stress cracking. These coatings typically contain compounds that neutralize aggressive chemicals, block UV radiation, or provide a physical barrier against environmental stressors. The application techniques and coating formulations are designed to ensure strong adhesion to the polymer substrate while maintaining flexibility under mechanical stress.

- Polymer blends and composites for enhanced stress crack resistance: Creating blends of different polymers or incorporating reinforcing materials can significantly improve stress cracking resistance. These composite materials distribute mechanical stress more effectively and create physical barriers to crack propagation. The synergistic effects between different polymer types or between polymers and reinforcing agents result in materials with superior performance in high-stress environments compared to homogeneous polymers.

- Electronic and electrical applications requiring stress crack resistant polymers: Electronic and electrical components often require polymers with exceptional stress cracking resistance due to their operating conditions. These applications expose materials to thermal cycling, electrical fields, and sometimes harsh chemicals. Specialized polymer formulations have been developed that maintain structural integrity and electrical insulation properties even under these challenging conditions, ensuring long-term reliability of electronic devices and electrical infrastructure.

02 Testing methods for polymer stress cracking

Various testing methodologies have been developed to evaluate and predict the stress cracking behavior of polymers. These include accelerated aging tests, constant strain tests, and specialized equipment designed to simulate environmental conditions that may induce stress cracking. These testing methods help manufacturers assess the durability and performance of polymer materials before they are used in commercial applications, ensuring they meet required standards for resistance to environmental stress cracking.Expand Specific Solutions03 Protective coatings to prevent stress cracking

Applying protective coatings to polymer surfaces can significantly reduce the risk of stress cracking. These coatings create a barrier that shields the polymer from environmental factors that might induce cracking, such as chemicals, UV radiation, or moisture. The coatings may be composed of various materials including silicones, fluoropolymers, or specialized polymer blends that adhere well to the base polymer while providing enhanced protection against stress-inducing factors.Expand Specific Solutions04 Stress crack prevention in electronic and electrical applications

Polymers used in electronic and electrical applications require special formulations to prevent stress cracking due to thermal cycling, electrical stress, and mechanical vibrations. These formulations often incorporate flame retardants, thermal stabilizers, and reinforcing fillers that enhance the polymer's resistance to cracking under the unique stresses encountered in electronic environments. The design of polymer components in these applications also considers stress distribution to minimize the risk of cracking at critical points.Expand Specific Solutions05 Advanced polymer blends for enhanced stress crack resistance

Research has led to the development of advanced polymer blends that exhibit superior resistance to stress cracking. These blends combine different types of polymers, each contributing specific properties that enhance overall performance. The synergistic effect of these blends results in materials that maintain structural integrity under conditions that would cause conventional polymers to fail. These advanced formulations often incorporate nanomaterials, specialty additives, or phase-separated structures that effectively dissipate stress and prevent crack initiation and propagation.Expand Specific Solutions

Key Industry Players in Chemical-Resistant Polymer Development

The petroleum ether-induced stress cracking technology landscape is currently in a growth phase, with an estimated market size of $3-5 billion annually. The competitive field is dominated by major petrochemical corporations including ExxonMobil Chemical, BASF, Sinopec, and Dow Global Technologies, who possess advanced polymer screening methodologies. Technical maturity varies significantly across applications, with China Petroleum & Chemical Corp. and Braskem SA leading in stress-resistant polymer development, while academic institutions like Zhejiang University and Shandong Normal University contribute fundamental research. The industry is witnessing increased collaboration between chemical manufacturers and end-users, particularly in automotive, packaging, and electronics sectors, as companies seek to develop polymers with enhanced resistance to petroleum ether exposure under various environmental conditions.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to petroleum ether-induced stress cracking through their multi-phase polymer selection methodology. Their technical solution involves specialized polyolefin blends with controlled crystallinity and molecular weight distribution to enhance resistance against petroleum ether exposure. Sinopec's research has demonstrated that incorporating 2-5% of specially functionalized elastomers into polyethylene matrices significantly improves stress crack resistance while maintaining mechanical properties. Their proprietary testing protocol evaluates polymers under various petroleum ether concentrations and exposure times, simulating real-world conditions with standardized notched specimen testing under constant strain. This approach has led to the development of specialized grades for fuel-contact applications with documented resistance improvements of up to 300% compared to conventional materials.

Strengths: Extensive petroleum industry expertise allows for realistic testing conditions; vertically integrated operations enable rapid implementation of research findings into commercial products. Weaknesses: Solutions may be optimized primarily for petroleum industry applications rather than broader consumer or medical applications; proprietary nature of some technologies limits wider adoption.

Sinopec Research Institute of Petroleum Processing

Technical Solution: Sinopec Research Institute of Petroleum Processing has pioneered advanced polymer screening methodologies specifically targeting petroleum ether-induced stress cracking. Their technical approach centers on a three-tier evaluation system that first assesses base polymer compatibility through accelerated exposure testing, then evaluates modified formulations with antioxidant packages, and finally conducts long-term validation under simulated field conditions. Their research has identified that controlling the tie-molecule concentration in semi-crystalline polymers is critical for stress crack resistance when exposed to petroleum ether. The institute has developed specialized fluoropolymer-modified polyethylene compounds that demonstrate exceptional resistance to petroleum ether exposure, with some formulations showing no detectable cracking after 1000+ hours of exposure under constant strain conditions. Their methodology includes proprietary stress-strain analysis techniques that can predict long-term performance based on short-term exposure data, significantly reducing development cycles for new materials.

Strengths: Highly specialized knowledge in petroleum-polymer interactions; extensive laboratory facilities for comprehensive testing protocols. Weaknesses: Research focus may be narrower than commercial polymer producers; solutions may prioritize performance over cost-effectiveness for general market applications.

Critical Analysis of Stress Cracking Screening Techniques

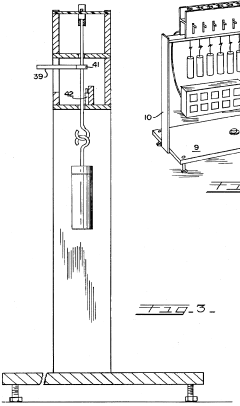

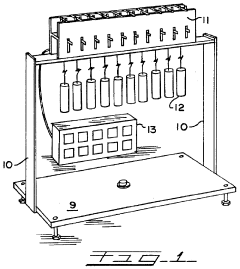

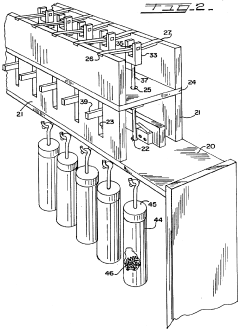

Method for determining the environmental stress cracking resistance of plastic articles

PatentInactiveUS4829839A

Innovation

- A method and device where a weight is applied below the horizontal plane of the plastic article to apply uniform stress, with a hanger assembly and timer to record the time to failure, minimizing components and allowing for reproducible and automated testing.

Polymeric additive for improving polymer environmental stress cracking resistance properties

PatentActiveUS11161945B2

Innovation

- A crosslinked polymeric additive composition is introduced, comprising a polyolefin matrix with selectively crosslinked polar polymer particles, which improves environmental stress cracking resistance and balances mechanical properties when blended with secondary polymer compositions.

Regulatory Standards for Chemical Compatibility Testing

Chemical compatibility testing for petroleum ether exposure is governed by several international and regional regulatory frameworks that establish standardized testing protocols and safety requirements. The International Organization for Standardization (ISO) has developed ISO 175, which specifically addresses the determination of the effects of liquid chemicals on polymeric materials. This standard provides methodologies for evaluating resistance to environmental stress cracking when polymers are exposed to aggressive chemicals like petroleum ether.

In the United States, ASTM International offers multiple relevant standards, including ASTM D543 for evaluating the resistance of plastics to chemical reagents and ASTM F2096 which focuses on detecting gross leaks in packaging. The FDA's 21 CFR 177 regulations are particularly important for food-contact applications, establishing requirements for polymer materials that might encounter petroleum-based solvents while in contact with food products.

The European Union's regulatory framework includes the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which mandates comprehensive chemical compatibility testing for materials exposed to various substances. Additionally, the EU's Directive 2002/72/EC specifically addresses plastic materials intended to come into contact with foodstuffs, requiring rigorous testing for materials potentially exposed to petroleum derivatives.

For industrial applications, the German Institute for Standardization (DIN) has established DIN 53521, which outlines procedures for testing the resistance of elastomers to liquids and vapors. This standard is widely referenced in European industrial contexts when evaluating petroleum ether compatibility with polymer materials.

Regulatory bodies also specify different exposure conditions for testing. Short-term exposure tests typically range from 24 to 72 hours, while long-term compatibility testing may extend to several months. Temperature conditions are standardized at specific points (typically 23°C, 40°C, and 70°C) to evaluate temperature-dependent degradation mechanisms.

Safety standards such as those from the Occupational Safety and Health Administration (OSHA) in the US and similar agencies worldwide establish permissible exposure limits for workers handling petroleum ether during manufacturing and testing processes. These standards necessitate appropriate ventilation, personal protective equipment, and handling protocols during compatibility testing procedures.

Industry-specific standards also exist, such as those from the Society of Automotive Engineers (SAE) for automotive applications, and NACE International standards for petroleum industry applications, each providing specialized testing protocols for evaluating stress cracking in their respective domains.

In the United States, ASTM International offers multiple relevant standards, including ASTM D543 for evaluating the resistance of plastics to chemical reagents and ASTM F2096 which focuses on detecting gross leaks in packaging. The FDA's 21 CFR 177 regulations are particularly important for food-contact applications, establishing requirements for polymer materials that might encounter petroleum-based solvents while in contact with food products.

The European Union's regulatory framework includes the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which mandates comprehensive chemical compatibility testing for materials exposed to various substances. Additionally, the EU's Directive 2002/72/EC specifically addresses plastic materials intended to come into contact with foodstuffs, requiring rigorous testing for materials potentially exposed to petroleum derivatives.

For industrial applications, the German Institute for Standardization (DIN) has established DIN 53521, which outlines procedures for testing the resistance of elastomers to liquids and vapors. This standard is widely referenced in European industrial contexts when evaluating petroleum ether compatibility with polymer materials.

Regulatory bodies also specify different exposure conditions for testing. Short-term exposure tests typically range from 24 to 72 hours, while long-term compatibility testing may extend to several months. Temperature conditions are standardized at specific points (typically 23°C, 40°C, and 70°C) to evaluate temperature-dependent degradation mechanisms.

Safety standards such as those from the Occupational Safety and Health Administration (OSHA) in the US and similar agencies worldwide establish permissible exposure limits for workers handling petroleum ether during manufacturing and testing processes. These standards necessitate appropriate ventilation, personal protective equipment, and handling protocols during compatibility testing procedures.

Industry-specific standards also exist, such as those from the Society of Automotive Engineers (SAE) for automotive applications, and NACE International standards for petroleum industry applications, each providing specialized testing protocols for evaluating stress cracking in their respective domains.

Environmental Impact of Petroleum Ether-Polymer Interactions

The environmental implications of petroleum ether-polymer interactions extend far beyond the immediate concerns of material degradation. When petroleum ether induces stress cracking in polymers, it creates pathways for chemical leaching into surrounding ecosystems. Studies indicate that degraded polymer fragments can persist in soil and water systems for decades, with microplastic particles being particularly problematic due to their ability to adsorb other environmental contaminants.

Petroleum ether itself, composed primarily of volatile hydrocarbons, presents significant environmental hazards when released. Its high volatility contributes to air pollution through VOC emissions, while any groundwater contamination can persist for extended periods due to its limited water solubility and tendency to form separate phases in aquatic environments.

The polymer degradation process triggered by petroleum ether exposure often releases additional chemical compounds, including plasticizers, stabilizers, and other additives incorporated during manufacturing. These compounds, such as phthalates and bisphenol derivatives, have been linked to endocrine disruption in aquatic organisms and potential bioaccumulation through food chains.

Risk assessment models examining petroleum ether-polymer interactions have identified particularly high environmental concerns in industrial settings where both substances are routinely handled. Waste management facilities, chemical processing plants, and transportation hubs represent hotspots where preventative measures are most critical. Recent environmental monitoring has detected elevated levels of polymer degradation products in soil samples collected near industrial facilities handling petroleum-based solvents.

Regulatory frameworks addressing these interactions vary significantly across regions, with the European Union's REACH regulations providing the most comprehensive approach to managing chemical-polymer compatibility from an environmental perspective. In contrast, regulations in developing economies often lack specific provisions for addressing the environmental impacts of solvent-induced polymer degradation.

Mitigation strategies focus on containment systems, proper disposal protocols, and the development of environmentally benign alternatives to petroleum ether in applications where polymer contact is unavoidable. Emerging green chemistry approaches have yielded promising bio-based solvents with similar functional properties but reduced environmental persistence and toxicity profiles.

Life cycle assessment studies comparing traditional petroleum ether applications versus newer alternatives demonstrate significant potential for environmental impact reduction, particularly regarding aquatic toxicity and greenhouse gas emissions. These findings underscore the importance of considering environmental factors alongside performance criteria when selecting materials for applications where petroleum ether exposure may occur.

Petroleum ether itself, composed primarily of volatile hydrocarbons, presents significant environmental hazards when released. Its high volatility contributes to air pollution through VOC emissions, while any groundwater contamination can persist for extended periods due to its limited water solubility and tendency to form separate phases in aquatic environments.

The polymer degradation process triggered by petroleum ether exposure often releases additional chemical compounds, including plasticizers, stabilizers, and other additives incorporated during manufacturing. These compounds, such as phthalates and bisphenol derivatives, have been linked to endocrine disruption in aquatic organisms and potential bioaccumulation through food chains.

Risk assessment models examining petroleum ether-polymer interactions have identified particularly high environmental concerns in industrial settings where both substances are routinely handled. Waste management facilities, chemical processing plants, and transportation hubs represent hotspots where preventative measures are most critical. Recent environmental monitoring has detected elevated levels of polymer degradation products in soil samples collected near industrial facilities handling petroleum-based solvents.

Regulatory frameworks addressing these interactions vary significantly across regions, with the European Union's REACH regulations providing the most comprehensive approach to managing chemical-polymer compatibility from an environmental perspective. In contrast, regulations in developing economies often lack specific provisions for addressing the environmental impacts of solvent-induced polymer degradation.

Mitigation strategies focus on containment systems, proper disposal protocols, and the development of environmentally benign alternatives to petroleum ether in applications where polymer contact is unavoidable. Emerging green chemistry approaches have yielded promising bio-based solvents with similar functional properties but reduced environmental persistence and toxicity profiles.

Life cycle assessment studies comparing traditional petroleum ether applications versus newer alternatives demonstrate significant potential for environmental impact reduction, particularly regarding aquatic toxicity and greenhouse gas emissions. These findings underscore the importance of considering environmental factors alongside performance criteria when selecting materials for applications where petroleum ether exposure may occur.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!