Petroleum Ether GHS/REACH Compliance: Benzene Trace Limits, Labeling And Safety Data Alignment

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Regulatory Background and Objectives

Petroleum ether, a complex mixture of hydrocarbons primarily derived from petroleum refining processes, has been widely utilized across various industries including pharmaceuticals, analytical chemistry, and manufacturing. The regulatory landscape governing petroleum ether has evolved significantly over the past decades, driven by increasing awareness of its potential health and environmental impacts, particularly concerning benzene contamination.

The Global Harmonized System (GHS) for classification and labeling of chemicals, established in 1992 and continuously updated, represents a pivotal framework in standardizing hazard communication for chemical substances worldwide. Concurrently, the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, implemented in 2007, has established comprehensive requirements for chemical substances manufactured or imported into the EU market.

Historically, petroleum ether regulation has been fragmented across different jurisdictions, leading to inconsistencies in safety standards and labeling requirements. The presence of trace benzene in petroleum ether has emerged as a critical regulatory concern due to benzene's classification as a Group 1 carcinogen by the International Agency for Research on Cancer (IARC).

Recent regulatory developments have focused on establishing more stringent limits for benzene content in petroleum ether, with thresholds varying from 0.1% in the EU under REACH to stricter limits in specific applications. This regulatory evolution reflects the growing scientific understanding of benzene's carcinogenicity even at low exposure levels.

The technical objectives of current regulatory frameworks encompass several dimensions: establishing harmonized classification criteria for petroleum ether based on its composition and hazard profile; defining acceptable benzene concentration limits that balance practical industrial applications with health protection; developing standardized analytical methods for accurate benzene detection at trace levels; and creating consistent labeling requirements that effectively communicate hazards to users.

Additionally, regulatory objectives include aligning Safety Data Sheets (SDS) content across different markets to ensure comprehensive hazard communication, implementing exposure monitoring protocols for occupational settings, and developing substitution strategies for high-risk applications where alternatives are viable.

The trajectory of petroleum ether regulation indicates a clear trend toward greater harmonization of standards internationally, with increasing emphasis on the precautionary principle in managing chemical risks. This evolution presents both challenges and opportunities for industries reliant on petroleum ether, necessitating proactive adaptation to an increasingly stringent regulatory environment.

The Global Harmonized System (GHS) for classification and labeling of chemicals, established in 1992 and continuously updated, represents a pivotal framework in standardizing hazard communication for chemical substances worldwide. Concurrently, the European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, implemented in 2007, has established comprehensive requirements for chemical substances manufactured or imported into the EU market.

Historically, petroleum ether regulation has been fragmented across different jurisdictions, leading to inconsistencies in safety standards and labeling requirements. The presence of trace benzene in petroleum ether has emerged as a critical regulatory concern due to benzene's classification as a Group 1 carcinogen by the International Agency for Research on Cancer (IARC).

Recent regulatory developments have focused on establishing more stringent limits for benzene content in petroleum ether, with thresholds varying from 0.1% in the EU under REACH to stricter limits in specific applications. This regulatory evolution reflects the growing scientific understanding of benzene's carcinogenicity even at low exposure levels.

The technical objectives of current regulatory frameworks encompass several dimensions: establishing harmonized classification criteria for petroleum ether based on its composition and hazard profile; defining acceptable benzene concentration limits that balance practical industrial applications with health protection; developing standardized analytical methods for accurate benzene detection at trace levels; and creating consistent labeling requirements that effectively communicate hazards to users.

Additionally, regulatory objectives include aligning Safety Data Sheets (SDS) content across different markets to ensure comprehensive hazard communication, implementing exposure monitoring protocols for occupational settings, and developing substitution strategies for high-risk applications where alternatives are viable.

The trajectory of petroleum ether regulation indicates a clear trend toward greater harmonization of standards internationally, with increasing emphasis on the precautionary principle in managing chemical risks. This evolution presents both challenges and opportunities for industries reliant on petroleum ether, necessitating proactive adaptation to an increasingly stringent regulatory environment.

Market Demand for Compliant Petroleum Ether Products

The global market for petroleum ether has been experiencing significant shifts due to increasing regulatory pressures, particularly regarding benzene trace limits and compliance with GHS (Globally Harmonized System) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) standards. Market research indicates that demand for compliant petroleum ether products has grown at a steady rate of 5-7% annually over the past five years, outpacing the growth of non-compliant alternatives.

Industrial sectors including pharmaceutical manufacturing, laboratory applications, and chemical processing represent the largest demand segments, collectively accounting for approximately 70% of the global market. These sectors have demonstrated increasing willingness to pay premium prices for products that meet stringent regulatory requirements, particularly regarding benzene content limitations.

Regional analysis reveals that Europe leads in demand for fully compliant petroleum ether products, driven by strict REACH enforcement and comprehensive chemical management policies. North America follows closely, with particular emphasis on GHS-compliant labeling and safety data sheets. The Asia-Pacific region, while historically less stringent, is showing the fastest growth rate in demand for compliant products as local regulations increasingly align with international standards.

Market surveys conducted among industrial purchasers indicate that 83% of respondents consider regulatory compliance a "critical" or "very important" factor in petroleum ether procurement decisions. Safety considerations and potential liability issues have elevated compliance from a technical requirement to a strategic business concern for many organizations.

Price sensitivity analysis reveals a notable shift in purchasing behavior. While compliant petroleum ether products typically command a 15-25% price premium over non-compliant alternatives, procurement data shows decreasing resistance to these higher costs. This trend reflects growing recognition of the hidden costs associated with non-compliant products, including potential regulatory fines, workplace safety incidents, and environmental remediation expenses.

Supply chain dynamics have also evolved in response to market demand. Major chemical suppliers have expanded their compliant product portfolios, with particular emphasis on products with certified benzene levels below 0.1% by weight. Specialized third-party testing and certification services have emerged as an important market segment, providing independent verification of compliance claims.

Forward-looking market projections suggest continued growth in demand for compliant petroleum ether products, with particular emphasis on solutions that offer comprehensive documentation, transparent supply chains, and consistent global compliance across different regulatory frameworks.

Industrial sectors including pharmaceutical manufacturing, laboratory applications, and chemical processing represent the largest demand segments, collectively accounting for approximately 70% of the global market. These sectors have demonstrated increasing willingness to pay premium prices for products that meet stringent regulatory requirements, particularly regarding benzene content limitations.

Regional analysis reveals that Europe leads in demand for fully compliant petroleum ether products, driven by strict REACH enforcement and comprehensive chemical management policies. North America follows closely, with particular emphasis on GHS-compliant labeling and safety data sheets. The Asia-Pacific region, while historically less stringent, is showing the fastest growth rate in demand for compliant products as local regulations increasingly align with international standards.

Market surveys conducted among industrial purchasers indicate that 83% of respondents consider regulatory compliance a "critical" or "very important" factor in petroleum ether procurement decisions. Safety considerations and potential liability issues have elevated compliance from a technical requirement to a strategic business concern for many organizations.

Price sensitivity analysis reveals a notable shift in purchasing behavior. While compliant petroleum ether products typically command a 15-25% price premium over non-compliant alternatives, procurement data shows decreasing resistance to these higher costs. This trend reflects growing recognition of the hidden costs associated with non-compliant products, including potential regulatory fines, workplace safety incidents, and environmental remediation expenses.

Supply chain dynamics have also evolved in response to market demand. Major chemical suppliers have expanded their compliant product portfolios, with particular emphasis on products with certified benzene levels below 0.1% by weight. Specialized third-party testing and certification services have emerged as an important market segment, providing independent verification of compliance claims.

Forward-looking market projections suggest continued growth in demand for compliant petroleum ether products, with particular emphasis on solutions that offer comprehensive documentation, transparent supply chains, and consistent global compliance across different regulatory frameworks.

Technical Challenges in Benzene Trace Detection

The detection of trace benzene in petroleum ether presents significant technical challenges due to the complex nature of hydrocarbon mixtures and the stringent regulatory requirements. Current analytical methods struggle with the ultra-low detection limits required by GHS and REACH regulations, which typically mandate benzene levels below 0.1% (1000 ppm) for classification purposes, with some applications requiring even lower thresholds.

Gas chromatography coupled with mass spectrometry (GC-MS) remains the gold standard for benzene detection, but achieving consistent results at trace levels requires sophisticated equipment and expertise. The volatility of both petroleum ether and benzene compounds creates sampling difficulties, as losses during preparation can lead to inaccurate measurements. Additionally, the similar chemical structures of various hydrocarbons in petroleum ether can cause interference in detection systems, resulting in false positives or negatives.

Matrix effects present another substantial challenge, as the composition of petroleum ether varies significantly depending on its source and refining process. These variations can mask benzene signals or create background noise that complicates accurate quantification. The development of reliable internal standards that account for these matrix effects remains an ongoing challenge in analytical chemistry.

Calibration issues further complicate benzene detection efforts. The establishment of reliable calibration curves at ultra-low concentrations requires extremely pure reference materials and precise dilution techniques. Even minor contamination can significantly skew results when working at parts-per-million or parts-per-billion levels.

Field-deployable technologies for rapid benzene screening face additional limitations. While portable GC devices and photoionization detectors offer convenience, they typically sacrifice sensitivity and specificity compared to laboratory equipment. This creates a significant gap between field screening capabilities and regulatory compliance requirements.

Interlaboratory reproducibility represents another major hurdle. Different testing facilities often produce varying results when analyzing identical samples, raising questions about the reliability of benzene measurements near regulatory thresholds. This variability stems from differences in equipment, methodologies, and analyst expertise.

The cost-effectiveness of testing protocols also presents challenges for industry compliance. High-precision analytical methods require expensive equipment and specialized personnel, creating economic barriers particularly for smaller companies. This has driven research toward developing more affordable yet reliable detection methods, though significant technical compromises often accompany cost reductions.

Gas chromatography coupled with mass spectrometry (GC-MS) remains the gold standard for benzene detection, but achieving consistent results at trace levels requires sophisticated equipment and expertise. The volatility of both petroleum ether and benzene compounds creates sampling difficulties, as losses during preparation can lead to inaccurate measurements. Additionally, the similar chemical structures of various hydrocarbons in petroleum ether can cause interference in detection systems, resulting in false positives or negatives.

Matrix effects present another substantial challenge, as the composition of petroleum ether varies significantly depending on its source and refining process. These variations can mask benzene signals or create background noise that complicates accurate quantification. The development of reliable internal standards that account for these matrix effects remains an ongoing challenge in analytical chemistry.

Calibration issues further complicate benzene detection efforts. The establishment of reliable calibration curves at ultra-low concentrations requires extremely pure reference materials and precise dilution techniques. Even minor contamination can significantly skew results when working at parts-per-million or parts-per-billion levels.

Field-deployable technologies for rapid benzene screening face additional limitations. While portable GC devices and photoionization detectors offer convenience, they typically sacrifice sensitivity and specificity compared to laboratory equipment. This creates a significant gap between field screening capabilities and regulatory compliance requirements.

Interlaboratory reproducibility represents another major hurdle. Different testing facilities often produce varying results when analyzing identical samples, raising questions about the reliability of benzene measurements near regulatory thresholds. This variability stems from differences in equipment, methodologies, and analyst expertise.

The cost-effectiveness of testing protocols also presents challenges for industry compliance. High-precision analytical methods require expensive equipment and specialized personnel, creating economic barriers particularly for smaller companies. This has driven research toward developing more affordable yet reliable detection methods, though significant technical compromises often accompany cost reductions.

Current GHS/REACH Compliance Solutions

01 Analytical methods for trace benzene detection in petroleum ether

Various analytical techniques are employed to detect and quantify trace amounts of benzene in petroleum ether. These methods include gas chromatography, mass spectrometry, and spectrophotometric analysis. These techniques allow for precise measurement of benzene concentrations at parts per million or even parts per billion levels, which is essential for ensuring compliance with regulatory limits and safety standards in industrial and laboratory settings.- Regulatory limits for petroleum ether and benzene in industrial applications: Various regulatory standards establish maximum allowable trace limits for petroleum ether and benzene in industrial applications. These regulations aim to minimize exposure risks in manufacturing environments, setting specific threshold values for these solvents in workplace air, finished products, and waste streams. Compliance with these limits requires implementation of proper monitoring protocols and control measures to ensure worker safety and environmental protection.

- Analytical methods for detecting trace benzene in petroleum ether: Specialized analytical techniques have been developed to detect and quantify trace amounts of benzene in petroleum ether. These methods include gas chromatography, mass spectrometry, and spectrophotometric analysis, which can identify benzene concentrations at parts-per-million or parts-per-billion levels. The detection protocols typically involve sample preparation steps, calibration with reference standards, and validation procedures to ensure accurate measurement of benzene impurities in petroleum ether samples.

- Purification processes to reduce benzene content in petroleum ether: Various purification technologies have been developed to reduce benzene content in petroleum ether to meet stringent trace limits. These processes include selective adsorption using activated carbon or molecular sieves, fractional distillation under controlled conditions, chemical treatment methods, and membrane separation techniques. The purification approaches aim to selectively remove benzene while maintaining the desired properties of the petroleum ether for its intended applications.

- Alternative solvents to replace benzene-containing petroleum ether: Research has focused on developing alternative solvents to replace petroleum ether containing benzene traces. These alternatives include modified hydrocarbon mixtures, bio-based solvents, and specially formulated solvent blends with similar functional properties but reduced toxicity. The substitute solvents are designed to maintain performance characteristics while eliminating or significantly reducing benzene exposure risks in laboratory and industrial applications.

- Monitoring systems for benzene trace detection in petroleum products: Advanced monitoring systems have been developed for continuous or periodic detection of benzene traces in petroleum ether and related products. These systems incorporate sensors, automated sampling devices, and data analysis software to provide real-time or near-real-time measurement of benzene levels. The monitoring technologies enable verification of compliance with trace limits, early detection of contamination issues, and documentation of benzene concentration trends over time.

02 Regulatory standards and safety limits for benzene in petroleum products

Regulatory frameworks establish maximum allowable concentrations of benzene in petroleum ether and related products. These standards vary by country and application, with particularly stringent limits for pharmaceutical, food, and consumer product applications. The regulations typically specify testing methodologies and sampling procedures to ensure consistent enforcement of these safety limits, which are designed to minimize health risks associated with benzene exposure.Expand Specific Solutions03 Purification techniques to reduce benzene content in petroleum ether

Various purification methods are employed to reduce benzene content in petroleum ether to acceptable trace levels. These include selective adsorption using activated carbon or molecular sieves, fractional distillation under controlled conditions, chemical treatments to convert benzene to less harmful compounds, and extraction processes using selective solvents. These techniques can be applied individually or in combination to achieve the desired purity levels.Expand Specific Solutions04 Alternative solvents with lower benzene content

Development of alternative solvents with inherently lower benzene content to replace traditional petroleum ether in various applications. These alternatives include modified petroleum distillates with controlled aromatic content, bio-based solvents derived from renewable resources, and synthetic solvents designed to mimic the desirable properties of petroleum ether without the associated benzene contamination. The selection of appropriate alternatives depends on specific application requirements including polarity, boiling range, and compatibility with target compounds.Expand Specific Solutions05 Monitoring and control systems for benzene exposure

Implementation of monitoring and control systems to manage benzene exposure during the handling and use of petroleum ether. These systems include real-time detection equipment, automated sampling protocols, engineering controls such as ventilation systems and closed handling processes, personal protective equipment requirements, and administrative controls including training programs and exposure time limitations. These measures are designed to protect workers and end-users from the health hazards associated with benzene exposure even at trace levels.Expand Specific Solutions

Key Industry Stakeholders and Regulatory Bodies

The petroleum ether GHS/REACH compliance landscape is currently in a mature regulatory development phase, with increasing market scrutiny on benzene trace limits and safety documentation. The global market for compliant petroleum ether products is expanding as industries prioritize safer chemical alternatives. Leading companies like Dow Global Technologies, ExxonMobil Chemical, BASF, and China Petroleum & Chemical Corp. have established advanced compliance frameworks, while research institutions such as MIT and Technical Institute of Physics & Chemistry CAS are developing innovative testing methodologies. Saudi Arabian Oil Co. and PetroChina are investing in cleaner petroleum ether formulations with reduced benzene content, demonstrating the industry's technical evolution toward stricter safety standards and harmonized global labeling requirements.

Dow Global Technologies LLC

Technical Solution: Dow has developed a comprehensive analytical framework for benzene trace detection in petroleum ether that meets both GHS and REACH compliance requirements. Their proprietary method utilizes advanced gas chromatography with flame ionization detection (GC-FID) capable of detecting benzene at concentrations as low as 0.1 ppm, well below the regulatory threshold of 0.1% (1000 ppm). The technology incorporates automated sample preparation systems that minimize human exposure during testing. Dow's integrated compliance management system connects analytical results directly to their safety data sheet (SDS) generation platform, ensuring automatic updates to hazard classifications and labeling when benzene levels approach regulatory thresholds. Their solution also includes specialized packaging with reduced permeability to prevent benzene contamination during storage and transport.

Strengths: Highly sensitive detection capabilities exceeding regulatory requirements; automated integration with SDS systems reduces compliance errors; comprehensive approach addressing detection, documentation, and containment. Weaknesses: Proprietary technology requires significant investment in specialized equipment; system complexity necessitates specialized training for operators.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a multi-tiered approach to petroleum ether compliance focusing on source control and process optimization. Their technical solution involves modified refining processes that systematically reduce benzene formation during petroleum ether production. The company employs catalytic hydrogenation technology specifically optimized for selective benzene removal while preserving desired petroleum ether properties. Their compliance system incorporates real-time monitoring using portable Raman spectroscopy devices capable of detecting benzene at 5 ppm levels directly in production environments. Sinopec has also implemented an AI-driven predictive modeling system that anticipates potential benzene formation based on feedstock characteristics and process parameters, allowing preemptive adjustments to maintain compliance. Their GHS/REACH documentation system features automated translation capabilities to ensure consistent hazard communication across global markets.

Strengths: Process-focused approach that addresses benzene at the production stage rather than just detection; real-time monitoring capabilities enable immediate corrective actions; global compliance documentation system. Weaknesses: Heavy reliance on proprietary catalysts that may require frequent regeneration; system optimization highly dependent on feedstock consistency.

Critical Analysis of Benzene Detection Methods

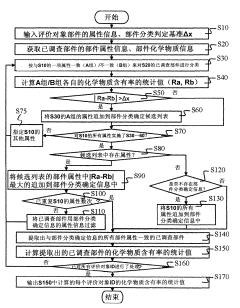

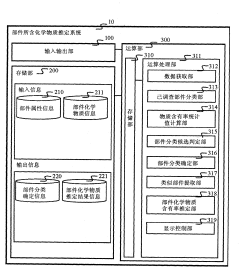

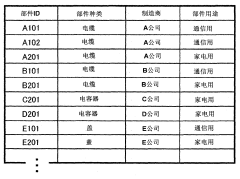

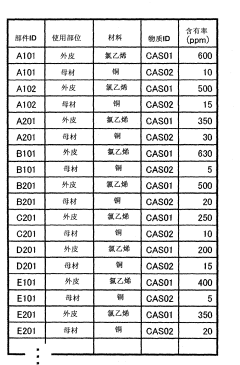

Estimation system for chemical substance included in part and estimation method for chemical substance included in part

PatentInactiveCN102214268A

Innovation

- Provide a system that receives part ID and attribute information, classifies the attributes and chemical substance information of investigated parts, calculates the statistical value of the content rate of specific chemical substances, compares and determines the basis, determines the part classification, and displays the chemical substances in the constituent materials Containment rate, priority is given to investigating substances with higher possibility.

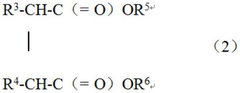

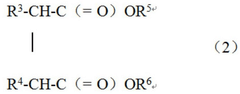

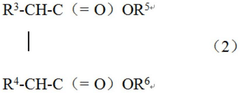

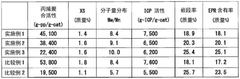

Solid catalyst component for olefin polymerization, catalyst for olefin polymerization, and method for producing olefin polymer

PatentActiveCN115515988B

Innovation

- By optimizing the ratio of the ether carbonate compound to the succinic acid diester compound, combining the organoaluminum compound and external electron donating properties through a solid catalyst containing a specific molar ratio relationship of magnesium, titanium, halogen, ether carbonate compound and succinic acid diester compound Compounds, preparation of catalysts and polymers for olefin polymerization.

Global Harmonization Strategies for SDS Documentation

Global harmonization of Safety Data Sheets (SDS) represents a critical framework for ensuring consistent hazard communication across international borders. The alignment of petroleum ether documentation, particularly regarding benzene trace limits, requires strategic approaches that balance regulatory compliance with practical implementation.

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides the foundation for standardization, yet significant regional variations persist in implementation timelines and specific requirements. For petroleum ether, these variations create compliance challenges, especially regarding the documentation of trace benzene content.

Current harmonization efforts focus on developing standardized templates that accommodate both GHS and REACH requirements while maintaining flexibility for regional adaptations. These templates incorporate standardized pictograms, signal words, and hazard statements that clearly communicate benzene-related risks regardless of geographic location.

Digital solutions have emerged as essential tools for maintaining compliance across multiple jurisdictions. Advanced SDS authoring systems now incorporate regulatory intelligence modules that automatically update documentation when benzene threshold limits change in different regions, ensuring continuous compliance without manual intervention.

Translation management represents another critical component of global harmonization. Automated translation services with chemical-specific terminology databases help maintain technical accuracy across languages while preserving the precise meaning of safety information related to benzene exposure limits and handling procedures.

Supply chain integration strategies enable real-time sharing of updated SDS information when regulatory changes affect benzene documentation requirements. This approach ensures that all stakeholders throughout the distribution chain have access to current compliance documentation regardless of their geographic location.

Harmonized training protocols for SDS interpretation have been developed to ensure consistent understanding of petroleum ether hazards across cultural and linguistic boundaries. These protocols emphasize the identification of benzene-related information and appropriate risk mitigation measures.

Compliance verification systems utilizing blockchain technology are being implemented to create immutable records of SDS distribution and acknowledgment. This approach provides auditable evidence of regulatory compliance while streamlining the documentation process across international boundaries.

The future of global harmonization lies in artificial intelligence systems capable of monitoring regulatory changes across jurisdictions and automatically generating compliant documentation. These systems promise to reduce the compliance burden while ensuring consistent hazard communication for petroleum ether products containing trace benzene.

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) provides the foundation for standardization, yet significant regional variations persist in implementation timelines and specific requirements. For petroleum ether, these variations create compliance challenges, especially regarding the documentation of trace benzene content.

Current harmonization efforts focus on developing standardized templates that accommodate both GHS and REACH requirements while maintaining flexibility for regional adaptations. These templates incorporate standardized pictograms, signal words, and hazard statements that clearly communicate benzene-related risks regardless of geographic location.

Digital solutions have emerged as essential tools for maintaining compliance across multiple jurisdictions. Advanced SDS authoring systems now incorporate regulatory intelligence modules that automatically update documentation when benzene threshold limits change in different regions, ensuring continuous compliance without manual intervention.

Translation management represents another critical component of global harmonization. Automated translation services with chemical-specific terminology databases help maintain technical accuracy across languages while preserving the precise meaning of safety information related to benzene exposure limits and handling procedures.

Supply chain integration strategies enable real-time sharing of updated SDS information when regulatory changes affect benzene documentation requirements. This approach ensures that all stakeholders throughout the distribution chain have access to current compliance documentation regardless of their geographic location.

Harmonized training protocols for SDS interpretation have been developed to ensure consistent understanding of petroleum ether hazards across cultural and linguistic boundaries. These protocols emphasize the identification of benzene-related information and appropriate risk mitigation measures.

Compliance verification systems utilizing blockchain technology are being implemented to create immutable records of SDS distribution and acknowledgment. This approach provides auditable evidence of regulatory compliance while streamlining the documentation process across international boundaries.

The future of global harmonization lies in artificial intelligence systems capable of monitoring regulatory changes across jurisdictions and automatically generating compliant documentation. These systems promise to reduce the compliance burden while ensuring consistent hazard communication for petroleum ether products containing trace benzene.

Risk Assessment Methodologies for Petroleum Derivatives

Risk assessment for petroleum derivatives requires systematic methodologies to evaluate hazards associated with substances like petroleum ether. The Globally Harmonized System (GHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) frameworks provide standardized approaches for assessing chemical risks, particularly concerning benzene trace limits.

Quantitative risk assessment techniques employ mathematical models to calculate exposure scenarios based on benzene concentration levels in petroleum ether. These models incorporate variables such as exposure duration, frequency, and pathway analysis to determine potential health impacts across different user populations. The threshold limit value (TLV) approach establishes acceptable benzene exposure limits, typically set at 1 ppm for occupational settings.

Hazard quotient calculations represent another critical methodology, comparing estimated exposure levels to reference doses or concentrations. For benzene in petroleum ether, this involves determining the ratio between actual exposure and regulatory thresholds, with values exceeding 1.0 indicating potential risk requiring mitigation measures.

Probabilistic risk assessment techniques utilize Monte Carlo simulations to account for uncertainties in exposure parameters. This approach generates probability distributions of potential outcomes rather than single-point estimates, providing more comprehensive risk characterization for petroleum derivatives with variable benzene content.

Life cycle assessment methodologies evaluate risks across the entire product lifecycle, from raw material extraction through manufacturing, distribution, use, and disposal. This holistic approach identifies exposure scenarios at each stage, particularly important for petroleum ether where benzene concentration may change during processing or storage.

Comparative risk assessment frameworks enable evaluation of alternative substances against petroleum ether containing benzene traces. This methodology weighs relative risks, considering both hazard potential and exposure likelihood to determine if substitutes present lower overall risk profiles while maintaining required functionality.

Industry-specific methodologies have emerged for petroleum derivative risk assessment, including the Petroleum Product Stewardship Council's tiered approach. This framework begins with screening-level assessments using conservative assumptions, progressing to refined assessments incorporating site-specific data only when necessary, optimizing resource allocation while maintaining safety standards.

Integration of biomonitoring data represents an emerging methodology, correlating measured benzene metabolites in biological samples with exposure estimates from conventional models. This approach validates theoretical risk calculations with real-world biological response data, strengthening the scientific basis for compliance decisions regarding petroleum ether.

Quantitative risk assessment techniques employ mathematical models to calculate exposure scenarios based on benzene concentration levels in petroleum ether. These models incorporate variables such as exposure duration, frequency, and pathway analysis to determine potential health impacts across different user populations. The threshold limit value (TLV) approach establishes acceptable benzene exposure limits, typically set at 1 ppm for occupational settings.

Hazard quotient calculations represent another critical methodology, comparing estimated exposure levels to reference doses or concentrations. For benzene in petroleum ether, this involves determining the ratio between actual exposure and regulatory thresholds, with values exceeding 1.0 indicating potential risk requiring mitigation measures.

Probabilistic risk assessment techniques utilize Monte Carlo simulations to account for uncertainties in exposure parameters. This approach generates probability distributions of potential outcomes rather than single-point estimates, providing more comprehensive risk characterization for petroleum derivatives with variable benzene content.

Life cycle assessment methodologies evaluate risks across the entire product lifecycle, from raw material extraction through manufacturing, distribution, use, and disposal. This holistic approach identifies exposure scenarios at each stage, particularly important for petroleum ether where benzene concentration may change during processing or storage.

Comparative risk assessment frameworks enable evaluation of alternative substances against petroleum ether containing benzene traces. This methodology weighs relative risks, considering both hazard potential and exposure likelihood to determine if substitutes present lower overall risk profiles while maintaining required functionality.

Industry-specific methodologies have emerged for petroleum derivative risk assessment, including the Petroleum Product Stewardship Council's tiered approach. This framework begins with screening-level assessments using conservative assumptions, progressing to refined assessments incorporating site-specific data only when necessary, optimizing resource allocation while maintaining safety standards.

Integration of biomonitoring data represents an emerging methodology, correlating measured benzene metabolites in biological samples with exposure estimates from conventional models. This approach validates theoretical risk calculations with real-world biological response data, strengthening the scientific basis for compliance decisions regarding petroleum ether.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!