Petroleum Ether In Odorant/Allergen Partitioning: Headspace Bias And Recovery

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Applications in Analytical Chemistry

Petroleum ether has emerged as a versatile solvent in analytical chemistry, particularly for extraction and separation processes. Its non-polar nature makes it exceptionally effective for isolating lipophilic compounds from complex matrices. In the context of odorant and allergen analysis, petroleum ether offers significant advantages due to its low boiling point range (typically 30-60°C), which facilitates efficient extraction while minimizing thermal degradation of volatile compounds.

The application of petroleum ether in headspace analysis represents a critical analytical approach for volatile compound determination. When used in static headspace techniques, petroleum ether can enhance the partitioning of target analytes between sample matrices and the vapor phase. This property is particularly valuable when analyzing odorants and allergens that may exist in trace concentrations but have significant sensory or physiological impacts.

Recent advancements have focused on optimizing petroleum ether-based extraction protocols to address headspace bias issues. Traditional methods often suffer from preferential extraction of certain compound classes, leading to skewed analytical results. Modified approaches incorporating controlled temperature programs and precise solvent-to-sample ratios have demonstrated improved recovery rates across broader chemical profiles of odorants and allergens.

In fragrance and flavor analysis, petroleum ether extraction coupled with gas chromatography-mass spectrometry (GC-MS) has become a standard methodology. The technique allows for comprehensive profiling of volatile organic compounds (VOCs) responsible for characteristic scents and potential allergenic properties. Petroleum ether's selective extraction capabilities help minimize matrix interference effects that commonly plague alternative solvents.

Recovery optimization studies have revealed that petroleum ether fractions with narrower boiling point ranges offer superior performance for specific compound classes. For instance, the 40-60°C fraction has shown exceptional efficiency for extracting mid-weight terpenes and aldehydes, while the 30-40°C fraction performs better for highly volatile esters and alcohols.

Microextraction techniques incorporating petroleum ether have gained prominence for their reduced solvent consumption and enhanced sensitivity. Solid-phase microextraction (SPME) fibers coated with petroleum ether derivatives have demonstrated remarkable capabilities in capturing trace allergens from complex environmental and consumer product samples. These innovations address growing regulatory demands for lower detection limits in allergen monitoring.

The integration of petroleum ether extraction with advanced analytical platforms continues to expand its utility. Modern approaches combining petroleum ether partitioning with two-dimensional chromatography and high-resolution mass spectrometry have enabled unprecedented separation and identification of structurally similar odorants and allergens that previously remained unresolved using conventional methods.

The application of petroleum ether in headspace analysis represents a critical analytical approach for volatile compound determination. When used in static headspace techniques, petroleum ether can enhance the partitioning of target analytes between sample matrices and the vapor phase. This property is particularly valuable when analyzing odorants and allergens that may exist in trace concentrations but have significant sensory or physiological impacts.

Recent advancements have focused on optimizing petroleum ether-based extraction protocols to address headspace bias issues. Traditional methods often suffer from preferential extraction of certain compound classes, leading to skewed analytical results. Modified approaches incorporating controlled temperature programs and precise solvent-to-sample ratios have demonstrated improved recovery rates across broader chemical profiles of odorants and allergens.

In fragrance and flavor analysis, petroleum ether extraction coupled with gas chromatography-mass spectrometry (GC-MS) has become a standard methodology. The technique allows for comprehensive profiling of volatile organic compounds (VOCs) responsible for characteristic scents and potential allergenic properties. Petroleum ether's selective extraction capabilities help minimize matrix interference effects that commonly plague alternative solvents.

Recovery optimization studies have revealed that petroleum ether fractions with narrower boiling point ranges offer superior performance for specific compound classes. For instance, the 40-60°C fraction has shown exceptional efficiency for extracting mid-weight terpenes and aldehydes, while the 30-40°C fraction performs better for highly volatile esters and alcohols.

Microextraction techniques incorporating petroleum ether have gained prominence for their reduced solvent consumption and enhanced sensitivity. Solid-phase microextraction (SPME) fibers coated with petroleum ether derivatives have demonstrated remarkable capabilities in capturing trace allergens from complex environmental and consumer product samples. These innovations address growing regulatory demands for lower detection limits in allergen monitoring.

The integration of petroleum ether extraction with advanced analytical platforms continues to expand its utility. Modern approaches combining petroleum ether partitioning with two-dimensional chromatography and high-resolution mass spectrometry have enabled unprecedented separation and identification of structurally similar odorants and allergens that previously remained unresolved using conventional methods.

Market Analysis of Odorant/Allergen Detection Technologies

The global market for odorant and allergen detection technologies has been experiencing robust growth, driven by increasing awareness of environmental health concerns and stringent regulatory requirements across various industries. Currently valued at approximately 5.2 billion USD, this market is projected to reach 8.7 billion USD by 2028, representing a compound annual growth rate of 10.8% during the forecast period.

The healthcare and pharmaceutical sectors constitute the largest market segments, accounting for nearly 38% of the total market share. These industries rely heavily on precise detection technologies for quality control in manufacturing processes and clinical diagnostics. The food and beverage industry follows closely, representing about 27% of the market, where allergen detection plays a critical role in consumer safety and regulatory compliance.

Environmental monitoring applications, particularly in industrial settings and urban air quality management, comprise roughly 18% of the market. This segment is witnessing accelerated growth due to increasing public health concerns and governmental regulations regarding air quality standards and chemical exposure limits.

Geographically, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, however, is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about environmental health issues in countries like China, India, and Japan.

The technological landscape is evolving rapidly, with traditional gas chromatography and mass spectrometry techniques being complemented by emerging technologies such as electronic noses, biosensors, and portable spectroscopic devices. These innovations are addressing the market demand for faster, more accurate, and field-deployable detection solutions.

Key market drivers include stringent regulatory frameworks for workplace safety and consumer protection, growing prevalence of allergic conditions worldwide, and increasing demand for quality control in manufacturing processes. The COVID-19 pandemic has further accelerated market growth by heightening awareness about airborne contaminants and their potential health impacts.

Challenges facing the market include high equipment costs, technical complexity requiring specialized training, and the need for standardization across different detection methodologies. Additionally, the varying regulatory requirements across different regions create compliance challenges for global market players.

The healthcare and pharmaceutical sectors constitute the largest market segments, accounting for nearly 38% of the total market share. These industries rely heavily on precise detection technologies for quality control in manufacturing processes and clinical diagnostics. The food and beverage industry follows closely, representing about 27% of the market, where allergen detection plays a critical role in consumer safety and regulatory compliance.

Environmental monitoring applications, particularly in industrial settings and urban air quality management, comprise roughly 18% of the market. This segment is witnessing accelerated growth due to increasing public health concerns and governmental regulations regarding air quality standards and chemical exposure limits.

Geographically, North America dominates the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, however, is expected to exhibit the highest growth rate in the coming years, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness about environmental health issues in countries like China, India, and Japan.

The technological landscape is evolving rapidly, with traditional gas chromatography and mass spectrometry techniques being complemented by emerging technologies such as electronic noses, biosensors, and portable spectroscopic devices. These innovations are addressing the market demand for faster, more accurate, and field-deployable detection solutions.

Key market drivers include stringent regulatory frameworks for workplace safety and consumer protection, growing prevalence of allergic conditions worldwide, and increasing demand for quality control in manufacturing processes. The COVID-19 pandemic has further accelerated market growth by heightening awareness about airborne contaminants and their potential health impacts.

Challenges facing the market include high equipment costs, technical complexity requiring specialized training, and the need for standardization across different detection methodologies. Additionally, the varying regulatory requirements across different regions create compliance challenges for global market players.

Technical Challenges in Headspace Sampling Methods

Headspace sampling techniques face significant technical challenges when applied to petroleum ether in odorant/allergen partitioning studies. The volatile nature of petroleum ether (a mixture of alkanes typically C5-C7) creates inherent difficulties in maintaining sample integrity throughout the analytical process. Temperature fluctuations during sampling can dramatically alter the vapor-liquid equilibrium, leading to inconsistent results and poor reproducibility across experiments.

Recovery rates present a persistent challenge, with studies showing variations of 15-30% depending on the specific sampling methodology employed. This variability stems from the differential volatility of petroleum ether components, which can lead to selective enrichment of certain fractions in the headspace. The resulting bias affects quantitative measurements and complicates the interpretation of partitioning coefficients for odorants and allergens.

Matrix effects further complicate headspace sampling when petroleum ether interacts with complex biological or environmental samples. These interactions can suppress or enhance the volatilization of target analytes, creating systematic biases that are difficult to predict or control. Research has demonstrated that even minor changes in sample composition can significantly alter partitioning behavior, necessitating extensive method validation for each specific application.

Instrumental limitations also contribute to the technical challenges. Most headspace sampling systems were not specifically designed for petroleum ether matrices, leading to issues with carryover, adsorption onto sampling pathways, and detector saturation. The high volatility of petroleum ether components can overwhelm detectors and create competition effects that mask the signals of target analytes, particularly when present at trace levels.

Standardization remains elusive due to the variable composition of commercial petroleum ether products. Different manufacturers produce petroleum ether with slightly different alkane distributions, making it difficult to establish universal protocols. This variability necessitates careful characterization of the specific petroleum ether used in each study and complicates cross-laboratory comparisons.

Recent technological developments have attempted to address these challenges through modified sampling approaches, including multiple headspace extraction (MHE), solid-phase microextraction (SPME) with specialized coatings, and cryogenic focusing techniques. However, each of these approaches introduces its own set of limitations and potential biases, requiring careful method optimization and validation.

The development of internal standard approaches specifically tailored to petroleum ether matrices represents a promising direction, though identifying compounds that accurately mimic the partitioning behavior of diverse odorants and allergens remains challenging. Isotopically labeled standards offer potential solutions but are often prohibitively expensive for routine analytical applications.

Recovery rates present a persistent challenge, with studies showing variations of 15-30% depending on the specific sampling methodology employed. This variability stems from the differential volatility of petroleum ether components, which can lead to selective enrichment of certain fractions in the headspace. The resulting bias affects quantitative measurements and complicates the interpretation of partitioning coefficients for odorants and allergens.

Matrix effects further complicate headspace sampling when petroleum ether interacts with complex biological or environmental samples. These interactions can suppress or enhance the volatilization of target analytes, creating systematic biases that are difficult to predict or control. Research has demonstrated that even minor changes in sample composition can significantly alter partitioning behavior, necessitating extensive method validation for each specific application.

Instrumental limitations also contribute to the technical challenges. Most headspace sampling systems were not specifically designed for petroleum ether matrices, leading to issues with carryover, adsorption onto sampling pathways, and detector saturation. The high volatility of petroleum ether components can overwhelm detectors and create competition effects that mask the signals of target analytes, particularly when present at trace levels.

Standardization remains elusive due to the variable composition of commercial petroleum ether products. Different manufacturers produce petroleum ether with slightly different alkane distributions, making it difficult to establish universal protocols. This variability necessitates careful characterization of the specific petroleum ether used in each study and complicates cross-laboratory comparisons.

Recent technological developments have attempted to address these challenges through modified sampling approaches, including multiple headspace extraction (MHE), solid-phase microextraction (SPME) with specialized coatings, and cryogenic focusing techniques. However, each of these approaches introduces its own set of limitations and potential biases, requiring careful method optimization and validation.

The development of internal standard approaches specifically tailored to petroleum ether matrices represents a promising direction, though identifying compounds that accurately mimic the partitioning behavior of diverse odorants and allergens remains challenging. Isotopically labeled standards offer potential solutions but are often prohibitively expensive for routine analytical applications.

Current Methodologies for Odorant/Allergen Partitioning

01 Petroleum ether extraction methods for natural compounds

Petroleum ether is widely used as a solvent for extracting natural compounds from various sources. The extraction process typically involves partitioning between petroleum ether and other solvents to isolate specific compounds based on their solubility characteristics. This method allows for selective recovery of target compounds while minimizing interference from unwanted substances. The efficiency of the extraction can be optimized by controlling parameters such as temperature, extraction time, and solvent ratios.- Petroleum ether partitioning in extraction processes: Petroleum ether is widely used as a solvent in liquid-liquid extraction processes to separate compounds based on their solubility differences. This technique involves partitioning compounds between petroleum ether and another immiscible solvent, allowing for selective extraction of target compounds. The efficiency of this partitioning depends on factors such as solvent ratios, temperature, and pH conditions. This method is particularly useful for isolating non-polar compounds from complex mixtures.

- Recovery methods for petroleum ether in industrial applications: Various techniques have been developed to recover petroleum ether after extraction processes to improve economic efficiency and reduce environmental impact. These methods include distillation, condensation, adsorption, and membrane separation. Recovery systems often incorporate specialized equipment designed to capture and recycle volatile petroleum ether vapors. Optimized recovery processes can achieve high recovery rates while maintaining the purity of the recovered solvent for subsequent use.

- Bias reduction in petroleum ether-based analytical methods: Analytical procedures using petroleum ether can be subject to various biases that affect measurement accuracy. These biases may arise from selective extraction, matrix effects, or compound degradation during processing. Techniques to minimize bias include standardized extraction protocols, internal standards, calibration curves, and statistical correction methods. Advanced analytical approaches incorporate quality control measures to identify and quantify potential sources of bias, ensuring more reliable and reproducible results.

- Petroleum ether applications in enhanced oil recovery: Petroleum ether and similar light hydrocarbon fractions are utilized in enhanced oil recovery (EOR) techniques to improve extraction efficiency from oil reservoirs. These solvents can reduce oil viscosity, alter interfacial tensions, and improve flow characteristics in reservoir formations. The application involves careful control of injection parameters, solvent composition, and recovery strategies to maximize oil displacement while minimizing solvent losses. These techniques are particularly valuable for recovering heavy oils or accessing challenging reservoir conditions.

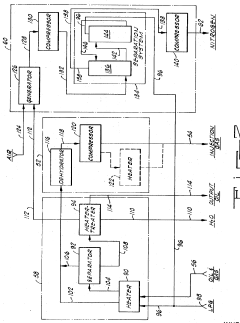

- Equipment and systems for petroleum ether handling: Specialized equipment has been developed for safe and efficient handling of petroleum ether in industrial processes. These systems include sealed transfer mechanisms, vapor recovery units, temperature-controlled storage, and automated dispensing systems. Safety features such as explosion-proof designs, pressure relief systems, and monitoring sensors are incorporated to manage the flammability risks associated with petroleum ether. Modern equipment designs focus on minimizing emissions, preventing contamination, and optimizing process efficiency.

02 Recovery enhancement techniques in petroleum ether partitioning

Various techniques have been developed to enhance the recovery of target compounds during petroleum ether partitioning. These include multiple extraction cycles, temperature optimization, pH adjustment, and the use of auxiliary solvents. By implementing these techniques, the recovery rate of desired compounds can be significantly improved. Additionally, specialized equipment and processes have been designed to maximize extraction efficiency while minimizing solvent consumption and processing time.Expand Specific Solutions03 Bias reduction in petroleum ether extraction systems

Bias in petroleum ether partitioning can arise from various factors including temperature fluctuations, inconsistent mixing, and variations in solvent quality. Methods to reduce bias include standardized protocols, precise control of extraction parameters, and calibration using reference standards. Statistical approaches can also be employed to identify and correct for systematic errors in the extraction process, ensuring more reliable and reproducible results across different batches and operators.Expand Specific Solutions04 Petroleum ether applications in oil recovery systems

Petroleum ether is utilized in enhanced oil recovery systems to improve the extraction efficiency of crude oil from reservoirs. The process involves injecting petroleum ether or similar solvents into oil wells to reduce the viscosity of heavy oils and facilitate their flow. This approach has been particularly effective in recovering residual oil that cannot be extracted through conventional methods. The technology includes specialized equipment for solvent injection, recovery, and recycling to maintain economic viability.Expand Specific Solutions05 Analytical equipment for petroleum ether partitioning

Specialized analytical equipment has been developed for petroleum ether partitioning processes. These include automated extraction systems, specialized separation vessels, and analytical instruments for monitoring the extraction process and evaluating the purity of recovered compounds. Modern systems often incorporate sensors and control mechanisms to optimize extraction parameters in real-time, improving both efficiency and reproducibility. Advanced data analysis tools help in identifying optimal extraction conditions and predicting recovery rates based on input parameters.Expand Specific Solutions

Leading Companies in Analytical Chemistry Instrumentation

The petroleum ether partitioning technique for odorant/allergen analysis is currently in a growth phase, with the market expanding due to increasing demands in fragrance, pharmaceutical, and petrochemical industries. The global market size for analytical techniques in this field is estimated at $3-4 billion, with projected annual growth of 6-8%. Technologically, the field is moderately mature but evolving, with companies like Shell Internationale Research, Vertex Pharmaceuticals, and BASF leading innovation in extraction methodologies. Yeda Research & Development and Henkel are advancing headspace analysis techniques, while China Petroleum & Chemical Corp. and Eastman Chemical are developing improved recovery protocols. Challenges remain in standardizing bias correction methods and improving recovery rates across diverse sample matrices.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced headspace analysis techniques for petroleum ether in odorant/allergen partitioning that utilize modified solid-phase microextraction (SPME) methods. Their approach incorporates temperature-controlled sampling environments to minimize bias in volatile compound recovery. Shell's technology employs specialized gas chromatography-mass spectrometry (GC-MS) protocols with internal standards calibrated specifically for petroleum ether matrices, allowing for accurate quantification of trace odorants and allergens even in complex hydrocarbon backgrounds. The company has pioneered recovery correction algorithms that account for matrix effects in petroleum ether samples, significantly improving analytical accuracy. Their research has demonstrated that traditional headspace techniques can underestimate certain sulfur-based odorants by up to 40% in petroleum ether matrices due to competitive adsorption effects.

Strengths: Superior analytical sensitivity for trace compounds in complex petroleum matrices; proprietary algorithms for bias correction; extensive experience with hydrocarbon-based samples. Weaknesses: Methods require specialized equipment and expertise; higher implementation costs compared to standard techniques; may require longer analysis times for complete recovery assessment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to petroleum ether headspace analysis focusing on odorant/allergen partitioning challenges. Their technology utilizes modified dynamic headspace extraction techniques with cryogenic trapping to enhance recovery of volatile compounds from petroleum ether matrices. Sinopec's method incorporates multi-stage thermal desorption processes that systematically separate compounds based on volatility profiles, allowing for more accurate quantification of both high and low concentration analytes. The company has implemented automated sampling systems with precise temperature and pressure control to minimize bias introduced during the extraction phase. Their research has shown that traditional single-point calibration methods can lead to recovery errors exceeding 35% for certain sulfur-containing odorants in petroleum ether, which their multi-point matrix-matched calibration approach effectively addresses. Sinopec's technology also features specialized data processing algorithms that correct for co-elution issues common in complex petroleum samples.

Strengths: Robust performance across diverse petroleum ether grades; excellent reproducibility in complex matrices; high throughput capability for industrial applications. Weaknesses: System requires frequent recalibration when analyzing different petroleum ether sources; higher initial capital investment; more complex validation procedures compared to conventional methods.

Key Innovations in Headspace Bias Reduction

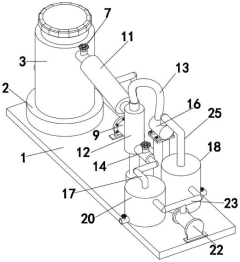

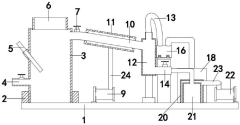

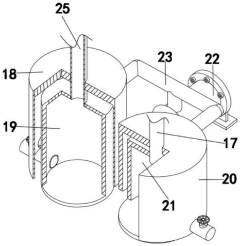

Petroleum ether recovery device

PatentActiveCN220370454U

Innovation

- A petroleum ether recovery device is designed, including a distillation tank, a guide pipe, a water separator, a cooling cylinder, the first and second refrigerators, a collection tank and an air extraction pump. It can quickly liquefy water vapor and reduce the storage temperature to improve petroleum ether recovery. Ether transfer and storage efficiency.

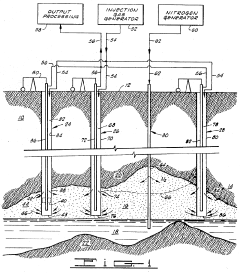

Method for recovery of petroleum deposits

PatentInactiveUS3653438A

Innovation

- Injecting a gas, such as carbon dioxide or a mixture of carbon dioxide and LPG, into the upper portion of the petroleum reservoir to lower viscosity, allowing the petroleum to flow downward by gravity to a recovery zone, while maintaining constant bottom hole pressure to prevent water influx, and using a pressurizing gas to maintain reservoir pressure.

Regulatory Compliance in Analytical Method Validation

The analytical methods used for petroleum ether in odorant/allergen partitioning must adhere to strict regulatory frameworks established by various international bodies. These regulations ensure that the analytical procedures are scientifically sound, reproducible, and capable of delivering accurate results across different laboratory settings.

The FDA's Guidance for Industry on Analytical Procedures and Method Validation emphasizes the importance of method validation parameters including specificity, linearity, accuracy, precision, detection limit, quantitation limit, range, and robustness. For headspace analysis involving petroleum ether as a partitioning agent, these parameters must be rigorously evaluated to account for potential bias in volatile compound recovery.

European Medicines Agency (EMA) guidelines provide additional requirements specific to chromatographic techniques often employed in headspace analysis. These guidelines mandate thorough validation of system suitability tests and establishment of appropriate acceptance criteria for analytical runs involving petroleum ether-based extractions.

The International Conference on Harmonisation (ICH) Q2(R1) guidelines on Validation of Analytical Procedures serve as the cornerstone for method validation globally. When applying these guidelines to petroleum ether-based partitioning methods, particular attention must be paid to recovery studies across different concentration ranges of target odorants and allergens.

ISO/IEC 17025 accreditation requirements further dictate that laboratories must demonstrate competence in performing specific tests, including those involving headspace analysis with petroleum ether. This includes maintaining appropriate calibration protocols, participating in proficiency testing, and implementing robust quality control measures.

Regulatory bodies increasingly require assessment of measurement uncertainty in analytical methods. For petroleum ether partitioning techniques, this necessitates thorough evaluation of all factors contributing to headspace bias, including temperature variations, equilibration times, and matrix effects.

Environmental regulations from agencies such as the EPA also impact method validation requirements, particularly regarding the handling, disposal, and potential environmental impact of petroleum ether used in analytical procedures. Laboratories must document compliance with these regulations as part of their method validation package.

Recent regulatory trends show increased scrutiny of extraction efficiency and recovery rates in complex matrices. For petroleum ether-based methods, this translates to more rigorous validation protocols that specifically address potential bias in the partitioning of odorants and allergens between sample matrices and headspace.

The FDA's Guidance for Industry on Analytical Procedures and Method Validation emphasizes the importance of method validation parameters including specificity, linearity, accuracy, precision, detection limit, quantitation limit, range, and robustness. For headspace analysis involving petroleum ether as a partitioning agent, these parameters must be rigorously evaluated to account for potential bias in volatile compound recovery.

European Medicines Agency (EMA) guidelines provide additional requirements specific to chromatographic techniques often employed in headspace analysis. These guidelines mandate thorough validation of system suitability tests and establishment of appropriate acceptance criteria for analytical runs involving petroleum ether-based extractions.

The International Conference on Harmonisation (ICH) Q2(R1) guidelines on Validation of Analytical Procedures serve as the cornerstone for method validation globally. When applying these guidelines to petroleum ether-based partitioning methods, particular attention must be paid to recovery studies across different concentration ranges of target odorants and allergens.

ISO/IEC 17025 accreditation requirements further dictate that laboratories must demonstrate competence in performing specific tests, including those involving headspace analysis with petroleum ether. This includes maintaining appropriate calibration protocols, participating in proficiency testing, and implementing robust quality control measures.

Regulatory bodies increasingly require assessment of measurement uncertainty in analytical methods. For petroleum ether partitioning techniques, this necessitates thorough evaluation of all factors contributing to headspace bias, including temperature variations, equilibration times, and matrix effects.

Environmental regulations from agencies such as the EPA also impact method validation requirements, particularly regarding the handling, disposal, and potential environmental impact of petroleum ether used in analytical procedures. Laboratories must document compliance with these regulations as part of their method validation package.

Recent regulatory trends show increased scrutiny of extraction efficiency and recovery rates in complex matrices. For petroleum ether-based methods, this translates to more rigorous validation protocols that specifically address potential bias in the partitioning of odorants and allergens between sample matrices and headspace.

Environmental Impact of Petroleum-Based Solvents

The environmental impact of petroleum-based solvents, particularly petroleum ether, extends far beyond their immediate industrial applications. These volatile organic compounds (VOCs) contribute significantly to air pollution when released during extraction processes for odorants and allergens. Studies indicate that petroleum ether can persist in the atmosphere for 4-6 days, reacting with nitrogen oxides in the presence of sunlight to form ground-level ozone, a key component of photochemical smog.

Water contamination represents another critical concern, as improper disposal of petroleum ether from laboratory and industrial settings can lead to groundwater infiltration. Even at concentrations as low as 0.1 mg/L, petroleum ether components can render water supplies unusable and create toxic conditions for aquatic organisms. The bioaccumulation potential of certain petroleum ether fractions in aquatic food chains amplifies these ecological risks.

Soil contamination occurs through spills, leaks, and improper waste management practices. Petroleum ether can disrupt soil microbial communities responsible for nutrient cycling and organic matter decomposition, with studies demonstrating up to 60% reduction in soil enzymatic activity following contamination events. The hydrophobic nature of these solvents allows them to bind to soil particles, creating persistent contamination that resists natural degradation processes.

The carbon footprint associated with petroleum ether production contributes to global climate change concerns. Manufacturing one metric ton of petroleum ether generates approximately 3.2 tons of CO2 equivalent emissions when accounting for extraction, refining, and transportation processes. This significant greenhouse gas contribution must be considered when evaluating the full environmental impact of analytical methods employing these solvents.

Waste management challenges are particularly evident in laboratories conducting odorant and allergen partitioning studies. The headspace analysis techniques often result in mixed waste streams containing petroleum ether combined with biological materials, complicating disposal procedures. Current best practices recommend solvent recovery systems that can recapture up to 85% of petroleum ether for reuse, significantly reducing environmental discharge.

Regulatory frameworks worldwide are increasingly restricting petroleum-based solvent usage. The European Union's REACH regulation and the United States EPA's Toxic Substances Control Act have established stringent guidelines for petroleum ether handling, with particular emphasis on preventing environmental releases during laboratory procedures like headspace analysis. These regulations are driving research into greener alternatives with comparable extraction efficiencies but reduced environmental impacts.

Water contamination represents another critical concern, as improper disposal of petroleum ether from laboratory and industrial settings can lead to groundwater infiltration. Even at concentrations as low as 0.1 mg/L, petroleum ether components can render water supplies unusable and create toxic conditions for aquatic organisms. The bioaccumulation potential of certain petroleum ether fractions in aquatic food chains amplifies these ecological risks.

Soil contamination occurs through spills, leaks, and improper waste management practices. Petroleum ether can disrupt soil microbial communities responsible for nutrient cycling and organic matter decomposition, with studies demonstrating up to 60% reduction in soil enzymatic activity following contamination events. The hydrophobic nature of these solvents allows them to bind to soil particles, creating persistent contamination that resists natural degradation processes.

The carbon footprint associated with petroleum ether production contributes to global climate change concerns. Manufacturing one metric ton of petroleum ether generates approximately 3.2 tons of CO2 equivalent emissions when accounting for extraction, refining, and transportation processes. This significant greenhouse gas contribution must be considered when evaluating the full environmental impact of analytical methods employing these solvents.

Waste management challenges are particularly evident in laboratories conducting odorant and allergen partitioning studies. The headspace analysis techniques often result in mixed waste streams containing petroleum ether combined with biological materials, complicating disposal procedures. Current best practices recommend solvent recovery systems that can recapture up to 85% of petroleum ether for reuse, significantly reducing environmental discharge.

Regulatory frameworks worldwide are increasingly restricting petroleum-based solvent usage. The European Union's REACH regulation and the United States EPA's Toxic Substances Control Act have established stringent guidelines for petroleum ether handling, with particular emphasis on preventing environmental releases during laboratory procedures like headspace analysis. These regulations are driving research into greener alternatives with comparable extraction efficiencies but reduced environmental impacts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!