How Does Petroleum Ether Permeate PPE Materials And Which Gloves Provide Adequate Protection?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Permeation Mechanisms and Research Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been extensively used in various industrial applications including extraction processes, cleaning operations, and as a solvent in chemical laboratories. The interaction between petroleum ether and personal protective equipment (PPE) materials, particularly gloves, represents a critical area of study due to its implications for worker safety across multiple industries.

The evolution of petroleum ether usage can be traced back to the early 20th century, with significant advancements in petroleum refining technologies leading to more standardized and purified forms. Over the decades, the understanding of its chemical properties and potential hazards has grown substantially, prompting increased attention to protective measures against exposure.

Current technological trends in this field focus on developing advanced materials with enhanced resistance to petroleum ether permeation while maintaining practical usability characteristics such as flexibility, durability, and tactile sensitivity. The molecular structure of petroleum ether, consisting primarily of pentanes and hexanes, presents unique challenges for barrier materials due to its low molecular weight and non-polar nature.

The primary objective of this technical research is to comprehensively analyze the mechanisms through which petroleum ether permeates different PPE materials at the molecular level. This includes investigating factors such as diffusion rates, solubility parameters, material porosity, and chemical interactions between petroleum ether components and various polymer structures used in protective gloves.

Secondary objectives include quantifying breakthrough times for different glove materials under standardized testing conditions, evaluating the impact of temperature and mechanical stress on permeation rates, and identifying potential correlations between material composition and resistance performance. These investigations aim to establish evidence-based guidelines for glove selection in environments where petroleum ether exposure is a concern.

The research also seeks to address existing knowledge gaps regarding the long-term effects of repeated petroleum ether exposure on glove materials, including potential degradation mechanisms and changes in protective properties over time. This longitudinal perspective is essential for developing more accurate risk assessment models and improving PPE replacement protocols in industrial settings.

By establishing a comprehensive understanding of petroleum ether permeation mechanisms, this research ultimately aims to contribute to the development of next-generation protective materials with enhanced resistance properties, thereby reducing occupational exposure risks and improving safety standards across affected industries.

The evolution of petroleum ether usage can be traced back to the early 20th century, with significant advancements in petroleum refining technologies leading to more standardized and purified forms. Over the decades, the understanding of its chemical properties and potential hazards has grown substantially, prompting increased attention to protective measures against exposure.

Current technological trends in this field focus on developing advanced materials with enhanced resistance to petroleum ether permeation while maintaining practical usability characteristics such as flexibility, durability, and tactile sensitivity. The molecular structure of petroleum ether, consisting primarily of pentanes and hexanes, presents unique challenges for barrier materials due to its low molecular weight and non-polar nature.

The primary objective of this technical research is to comprehensively analyze the mechanisms through which petroleum ether permeates different PPE materials at the molecular level. This includes investigating factors such as diffusion rates, solubility parameters, material porosity, and chemical interactions between petroleum ether components and various polymer structures used in protective gloves.

Secondary objectives include quantifying breakthrough times for different glove materials under standardized testing conditions, evaluating the impact of temperature and mechanical stress on permeation rates, and identifying potential correlations between material composition and resistance performance. These investigations aim to establish evidence-based guidelines for glove selection in environments where petroleum ether exposure is a concern.

The research also seeks to address existing knowledge gaps regarding the long-term effects of repeated petroleum ether exposure on glove materials, including potential degradation mechanisms and changes in protective properties over time. This longitudinal perspective is essential for developing more accurate risk assessment models and improving PPE replacement protocols in industrial settings.

By establishing a comprehensive understanding of petroleum ether permeation mechanisms, this research ultimately aims to contribute to the development of next-generation protective materials with enhanced resistance properties, thereby reducing occupational exposure risks and improving safety standards across affected industries.

Market Analysis of Chemical-Resistant PPE Solutions

The global market for chemical-resistant Personal Protective Equipment (PPE) has experienced significant growth, reaching approximately $7.3 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028. This expansion is primarily driven by stringent workplace safety regulations, increasing awareness of occupational hazards, and growing industrial activities in emerging economies. The petroleum industry, chemical manufacturing, and healthcare sectors represent the largest market segments for chemical-resistant PPE solutions.

Within this market, gloves specifically designed to resist petroleum ether permeation constitute a specialized but critical segment. The demand for such protective solutions has intensified following several high-profile workplace exposure incidents and subsequent regulatory responses. North America currently dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%, with the latter showing the fastest growth trajectory.

The competitive landscape features both established industrial safety equipment manufacturers and specialized chemical protection innovators. Key market players include Ansell Limited, Honeywell International, 3M Company, Kimberly-Clark Corporation, and DuPont, collectively controlling approximately 65% of the global market share. These companies have been investing heavily in research and development to create advanced materials with superior resistance to petroleum ether and similar solvents.

Recent market trends indicate a shift toward more specialized, application-specific PPE solutions rather than general-purpose protective equipment. End-users are increasingly demanding gloves and other PPE that provide optimal protection against specific chemicals like petroleum ether while maintaining dexterity, comfort, and durability. This trend has spurred innovation in material science, with manufacturers developing multi-layer composites and novel polymer formulations.

Price sensitivity varies significantly across market segments. While high-end research laboratories and pharmaceutical companies prioritize performance over cost, industrial users often seek a balance between protection levels and economic considerations. The average price point for premium chemical-resistant gloves has increased by 12% over the past three years, reflecting both rising material costs and enhanced protective capabilities.

Distribution channels are evolving, with e-commerce platforms gaining significant traction, particularly following supply chain disruptions during the COVID-19 pandemic. However, specialized industrial suppliers remain the dominant channel, accounting for approximately 58% of sales volume, as they provide valuable technical guidance on appropriate PPE selection for specific chemical hazards like petroleum ether exposure.

Within this market, gloves specifically designed to resist petroleum ether permeation constitute a specialized but critical segment. The demand for such protective solutions has intensified following several high-profile workplace exposure incidents and subsequent regulatory responses. North America currently dominates the market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%, with the latter showing the fastest growth trajectory.

The competitive landscape features both established industrial safety equipment manufacturers and specialized chemical protection innovators. Key market players include Ansell Limited, Honeywell International, 3M Company, Kimberly-Clark Corporation, and DuPont, collectively controlling approximately 65% of the global market share. These companies have been investing heavily in research and development to create advanced materials with superior resistance to petroleum ether and similar solvents.

Recent market trends indicate a shift toward more specialized, application-specific PPE solutions rather than general-purpose protective equipment. End-users are increasingly demanding gloves and other PPE that provide optimal protection against specific chemicals like petroleum ether while maintaining dexterity, comfort, and durability. This trend has spurred innovation in material science, with manufacturers developing multi-layer composites and novel polymer formulations.

Price sensitivity varies significantly across market segments. While high-end research laboratories and pharmaceutical companies prioritize performance over cost, industrial users often seek a balance between protection levels and economic considerations. The average price point for premium chemical-resistant gloves has increased by 12% over the past three years, reflecting both rising material costs and enhanced protective capabilities.

Distribution channels are evolving, with e-commerce platforms gaining significant traction, particularly following supply chain disruptions during the COVID-19 pandemic. However, specialized industrial suppliers remain the dominant channel, accounting for approximately 58% of sales volume, as they provide valuable technical guidance on appropriate PPE selection for specific chemical hazards like petroleum ether exposure.

Current Challenges in Petroleum Ether Protection Technologies

The protection against petroleum ether permeation presents significant challenges in occupational safety environments. Current glove materials exhibit varying degrees of effectiveness when exposed to this highly volatile hydrocarbon mixture. Nitrile gloves, commonly used in laboratory settings, demonstrate limited resistance to petroleum ether, with breakthrough times often less than 30 minutes under continuous exposure. This creates a critical vulnerability for workers in chemical processing, pharmaceutical manufacturing, and analytical laboratories where extended contact is common.

Material degradation mechanisms remain incompletely understood, particularly the molecular interactions between petroleum ether's alkane components and polymer matrices in protective materials. Research indicates that petroleum ether primarily penetrates through polymer chain displacement and micro-channel formation, but quantitative models predicting permeation rates across different material compositions are still underdeveloped.

Temperature dependency presents another significant challenge, as petroleum ether's permeation rate increases exponentially at higher temperatures. Most existing permeation data is collected at standard laboratory conditions (20-25°C), creating potential safety gaps when protective equipment is used in industrial environments with elevated temperatures or in outdoor settings with temperature fluctuations.

The standardization of testing protocols represents a persistent issue in the field. Current ASTM and EN standards for chemical permeation testing do not adequately address the unique properties of petroleum ether, particularly its rapid evaporation rate and the resulting concentration gradients that develop during testing. This leads to inconsistent performance data across manufacturers and testing laboratories.

Cost-effectiveness remains a barrier to implementing optimal protection solutions. While specialized fluoroelastomer and multi-layer composite gloves offer superior resistance to petroleum ether, their significantly higher cost (5-10 times that of standard nitrile gloves) limits widespread adoption, particularly in small-scale operations and educational institutions.

The balance between protection and functionality creates additional complications. Glove materials with excellent chemical resistance often compromise dexterity and tactile sensitivity, forcing users to choose between adequate protection and work performance. This trade-off frequently results in the selection of less protective options that allow greater manual precision, increasing exposure risk.

Environmental and sustainability concerns add another dimension to the challenge. Many highly resistant glove materials contain fluoropolymers or other compounds with significant environmental persistence, creating tension between worker protection goals and environmental responsibility objectives in organizational purchasing decisions.

Material degradation mechanisms remain incompletely understood, particularly the molecular interactions between petroleum ether's alkane components and polymer matrices in protective materials. Research indicates that petroleum ether primarily penetrates through polymer chain displacement and micro-channel formation, but quantitative models predicting permeation rates across different material compositions are still underdeveloped.

Temperature dependency presents another significant challenge, as petroleum ether's permeation rate increases exponentially at higher temperatures. Most existing permeation data is collected at standard laboratory conditions (20-25°C), creating potential safety gaps when protective equipment is used in industrial environments with elevated temperatures or in outdoor settings with temperature fluctuations.

The standardization of testing protocols represents a persistent issue in the field. Current ASTM and EN standards for chemical permeation testing do not adequately address the unique properties of petroleum ether, particularly its rapid evaporation rate and the resulting concentration gradients that develop during testing. This leads to inconsistent performance data across manufacturers and testing laboratories.

Cost-effectiveness remains a barrier to implementing optimal protection solutions. While specialized fluoroelastomer and multi-layer composite gloves offer superior resistance to petroleum ether, their significantly higher cost (5-10 times that of standard nitrile gloves) limits widespread adoption, particularly in small-scale operations and educational institutions.

The balance between protection and functionality creates additional complications. Glove materials with excellent chemical resistance often compromise dexterity and tactile sensitivity, forcing users to choose between adequate protection and work performance. This trade-off frequently results in the selection of less protective options that allow greater manual precision, increasing exposure risk.

Environmental and sustainability concerns add another dimension to the challenge. Many highly resistant glove materials contain fluoropolymers or other compounds with significant environmental persistence, creating tension between worker protection goals and environmental responsibility objectives in organizational purchasing decisions.

Comparative Analysis of Existing Glove Protection Solutions

01 Testing methods for measuring permeation rates through PPE materials

Various testing methods are used to measure the permeation rate of petroleum ether through personal protective equipment (PPE) materials. These methods involve specialized equipment and procedures to determine how quickly petroleum ether can penetrate through protective materials. The tests typically measure breakthrough time, permeation rate, and cumulative permeation to evaluate the effectiveness of PPE against petroleum ether exposure.- Testing methods for measuring permeation rates through PPE materials: Various testing methods and apparatus are used to measure the permeation rate of petroleum ether through personal protective equipment (PPE) materials. These methods typically involve exposing the material to petroleum ether under controlled conditions and measuring the rate at which the chemical passes through the material. Advanced analytical techniques such as gas chromatography may be used to quantify the permeation rate accurately. These testing protocols help in evaluating the effectiveness of PPE materials against petroleum ether exposure.

- Barrier materials for protection against petroleum ether permeation: Specialized barrier materials are developed to provide protection against petroleum ether permeation in PPE. These materials often incorporate multiple layers or specialized polymers that resist chemical penetration. Some materials feature selective permeability that allows moisture vapor to escape while blocking petroleum ether molecules. The effectiveness of these barrier materials is determined by their chemical composition, thickness, and structural integrity, which collectively influence the permeation rate of petroleum ether through the protective equipment.

- Real-time monitoring systems for petroleum ether permeation: Advanced monitoring systems have been developed to detect and measure petroleum ether permeation through PPE materials in real-time. These systems utilize sensors that can immediately alert users when permeation occurs or reaches dangerous levels. Some monitoring technologies incorporate wireless communication capabilities to transmit permeation data to safety monitoring stations. Real-time monitoring allows for immediate response to potential exposure risks and provides valuable data for improving PPE design and material selection.

- Factors affecting petroleum ether permeation rates through PPE: Multiple factors influence the permeation rate of petroleum ether through PPE materials. Temperature plays a significant role, with higher temperatures generally increasing permeation rates. Material thickness, exposure duration, and petroleum ether concentration also affect permeation behavior. Physical stress on the material, such as stretching or flexing, can compromise barrier integrity and accelerate permeation. Understanding these factors is crucial for designing effective protective equipment and establishing appropriate wear-time limitations for PPE exposed to petroleum ether.

- Innovative PPE designs to minimize petroleum ether permeation: Novel PPE designs incorporate innovative features specifically aimed at minimizing petroleum ether permeation. These designs may include specialized sealing mechanisms at material junctions, reinforced areas in high-exposure zones, or multi-layer composite structures. Some designs incorporate active countermeasures such as absorbent layers that trap petroleum ether molecules before they can fully permeate the material. These innovations focus not only on reducing permeation rates but also on maintaining user comfort and mobility while providing adequate protection.

02 Barrier materials and their resistance to petroleum ether permeation

Different barrier materials used in PPE show varying levels of resistance to petroleum ether permeation. Materials such as specific polymers, multi-layer composites, and specially treated fabrics are designed to minimize the permeation rate of petroleum ether. The effectiveness of these materials depends on their chemical composition, thickness, and structural properties, which influence their ability to prevent petroleum ether molecules from passing through.Expand Specific Solutions03 Detection systems for monitoring petroleum ether permeation

Advanced detection systems are used to monitor the permeation of petroleum ether through PPE materials in real-time. These systems employ various sensors and analytical techniques to detect even trace amounts of petroleum ether that may penetrate protective barriers. The detection technologies include spectroscopic methods, chemical sensors, and electronic monitoring devices that provide alerts when permeation exceeds safe thresholds.Expand Specific Solutions04 Factors affecting petroleum ether permeation rates

Multiple factors influence the permeation rate of petroleum ether through PPE materials. These include temperature, pressure, concentration gradient, material thickness, exposure duration, and physical stress on the material. Environmental conditions and the presence of other chemicals can also affect how quickly petroleum ether penetrates protective barriers. Understanding these factors is crucial for designing effective protective equipment and establishing safety protocols.Expand Specific Solutions05 Innovative PPE designs to minimize petroleum ether permeation

Innovative designs and technologies are being developed to minimize petroleum ether permeation through PPE materials. These include multi-layer protective systems, self-healing materials, active barrier technologies, and specialized coatings that repel petroleum ether. Some designs incorporate indicators that change color when petroleum ether begins to penetrate, providing visual warnings to users. These advancements aim to enhance safety for workers exposed to petroleum ether in various industries.Expand Specific Solutions

Leading Manufacturers in Chemical-Resistant PPE Industry

The petroleum ether permeation through PPE materials represents a mature technical challenge in the chemical protection industry, currently valued at approximately $8-10 billion globally. The market is in a consolidation phase, with established players like Ansell Ltd., Dipped Products Plc, and O&M Halyard dominating the specialized glove segment. Technical maturity varies across materials, with nitrile and neoprene solutions from Ansell and Asahi Kasei showing superior resistance to petroleum ether permeation compared to standard latex options. Research institutions including China Institute of Radiation Protection and Johns Hopkins University continue collaborating with manufacturers to develop next-generation barrier materials, while companies like Wacker Chemie and Global Graphene Group are exploring advanced polymer composites that could significantly improve permeation resistance in future PPE applications.

Ansell Microgard Ltd.

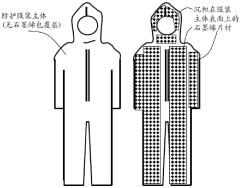

Technical Solution: Ansell Microgard, a specialized division of Ansell focused on chemical protective clothing, has developed comprehensive solutions for petroleum ether protection beyond just hand protection. Their research has demonstrated that petroleum ether permeates different PPE materials through various mechanisms depending on material composition, with polymeric materials being particularly vulnerable to swelling and subsequent increased permeation rates. The company's MICROGARD® 2000 series incorporates a multi-layer barrier with microporous film technology that effectively blocks petroleum ether molecules while maintaining breathability. Their testing protocols examine both steady-state permeation and the often overlooked initial breakthrough dynamics, providing more comprehensive protection data. Ansell Microgard has pioneered the development of seam sealing technologies that address a critical weakness in many protective garments, as their research identified that up to 60% of chemical exposures occur through seams rather than through the base material. Their integrated approach considers the entire protective ensemble, recognizing that glove-sleeve interfaces and other connection points represent significant vulnerability to petroleum ether exposure.

Strengths: Holistic approach addressing full-body protection beyond just gloves; specialized expertise in seam and interface protection where many exposures occur; comprehensive testing protocols that consider real-world usage scenarios. Weaknesses: Full protective ensembles represent significant cost compared to basic PPE; integrated systems may have compatibility issues with equipment from other manufacturers; higher protection levels often come with reduced comfort and increased heat stress for workers.

Dipped Products Plc

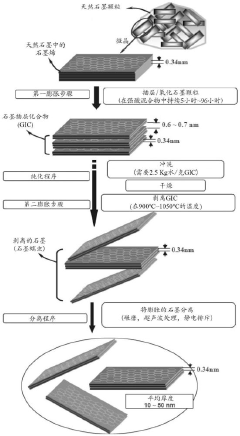

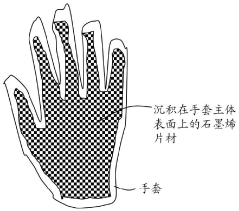

Technical Solution: Dipped Products has developed innovative glove manufacturing techniques specifically addressing petroleum ether permeation challenges. Their proprietary DPL BarrierTech™ process creates multi-layer nitrile gloves with graduated density profiles - higher density outer layers resist initial chemical contact while more flexible inner layers maintain comfort and dexterity. The company's research has identified that petroleum ether, with its low molecular weight hydrocarbons, penetrates conventional glove materials through polymer chain spacing, which their manufacturing process specifically addresses by optimizing cross-linking density. Their gloves undergo specialized permeation testing that simulates real-world conditions including mechanical stress and temperature variations, factors that significantly affect breakthrough times in practical applications. Dipped Products has also pioneered the incorporation of graphene nanoparticles into their premium industrial gloves, creating a tortuous path that significantly extends petroleum ether breakthrough times while maintaining flexibility. Their manufacturing facilities utilize advanced quality control systems with inline spectroscopic analysis to ensure consistent barrier properties throughout production runs.

Strengths: Specialized manufacturing processes create consistent barrier properties throughout the glove; practical testing protocols that include mechanical stress provide realistic protection assessments; cost-effective solutions suitable for industrial-scale deployment. Weaknesses: Less extensive research capabilities compared to larger corporations; limited presence in North American and European markets affects availability; focus on industrial applications may result in bulkier designs less suitable for precision work.

Breakthrough Technologies in Chemical Barrier Materials

Chemical barrier fabric

PatentActiveUS20140141210A1

Innovation

- A laminated chemical barrier fabric with chemical barrier layers that are intermittently point-bonded, creating a majority un-bonded area and a minority point-bonded area, allowing for improved chemical barrier properties while maintaining flexibility and comfort by reducing intimate contact between layers.

Antiviral element and personal protective equipment comprising same

PatentPendingCN117460871A

Innovation

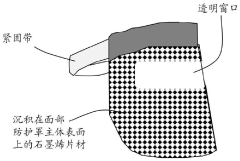

- Graphene sheets are used as the core material of personal protective equipment by depositing graphene sheets on the surface of or embedded in fabrics, clothing, face shields or gloves, and combining them with antimicrobial compounds to enhance their filtration and protective properties. Graphene sheets include multi-layer structures, such as graphene oxide, fluorinated graphene, etc., and can be combined with anti-viral or anti-bacterial nanoparticles, nanowires or nano-coatings to improve their ability to kill pathogens.

Safety Standards and Compliance Requirements for Chemical PPE

The regulatory landscape for chemical Personal Protective Equipment (PPE) is governed by multiple international and regional standards that establish minimum performance requirements for protective gear. OSHA 29 CFR 1910.138 in the United States mandates employers to select appropriate hand protection when employees' hands are exposed to hazards such as skin absorption of harmful substances. This regulation specifically addresses petroleum ether, categorizing it as a chemical requiring specialized protective measures.

The European standard EN 374 provides a comprehensive framework for chemical-resistant gloves, classifying them based on permeation resistance against specific chemicals. For petroleum ether protection, gloves must achieve at least Class 2 performance (breakthrough time >30 minutes) under this standard. The more stringent EN 16523-1:2015 has replaced EN 374-3 for permeation testing methodologies, introducing more precise measurement techniques for volatile hydrocarbons like petroleum ether.

ISO 16602:2007 establishes international requirements for chemical protective clothing, including gloves, with specific provisions for testing resistance against permeation by hazardous chemicals. The standard employs a six-level classification system based on normalized breakthrough times, where petroleum ether typically requires Level 4 protection (breakthrough time >120 minutes).

ASTM F739 in North America details the standard test method for permeation of liquids and gases through protective clothing materials under conditions of continuous contact. This test method is particularly relevant for assessing petroleum ether permeation through different glove materials, measuring both breakthrough time and permeation rate.

Compliance with these standards requires manufacturers to conduct rigorous testing and provide detailed chemical compatibility charts. These charts typically indicate performance levels against specific chemicals, including petroleum ether, using a color-coded or numerical system to represent protection levels.

For workplace implementation, NIOSH recommends a hierarchical approach to chemical hazard control, with PPE selection being the final protective measure after engineering and administrative controls. Their guidelines specify that for petroleum ether exposure, gloves should be selected based on manufacturer permeation data rather than general material recommendations.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) further influences PPE requirements by standardizing hazard communication, ensuring that safety data sheets contain specific information about appropriate protective equipment for handling petroleum ether and similar substances.

The European standard EN 374 provides a comprehensive framework for chemical-resistant gloves, classifying them based on permeation resistance against specific chemicals. For petroleum ether protection, gloves must achieve at least Class 2 performance (breakthrough time >30 minutes) under this standard. The more stringent EN 16523-1:2015 has replaced EN 374-3 for permeation testing methodologies, introducing more precise measurement techniques for volatile hydrocarbons like petroleum ether.

ISO 16602:2007 establishes international requirements for chemical protective clothing, including gloves, with specific provisions for testing resistance against permeation by hazardous chemicals. The standard employs a six-level classification system based on normalized breakthrough times, where petroleum ether typically requires Level 4 protection (breakthrough time >120 minutes).

ASTM F739 in North America details the standard test method for permeation of liquids and gases through protective clothing materials under conditions of continuous contact. This test method is particularly relevant for assessing petroleum ether permeation through different glove materials, measuring both breakthrough time and permeation rate.

Compliance with these standards requires manufacturers to conduct rigorous testing and provide detailed chemical compatibility charts. These charts typically indicate performance levels against specific chemicals, including petroleum ether, using a color-coded or numerical system to represent protection levels.

For workplace implementation, NIOSH recommends a hierarchical approach to chemical hazard control, with PPE selection being the final protective measure after engineering and administrative controls. Their guidelines specify that for petroleum ether exposure, gloves should be selected based on manufacturer permeation data rather than general material recommendations.

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) further influences PPE requirements by standardizing hazard communication, ensuring that safety data sheets contain specific information about appropriate protective equipment for handling petroleum ether and similar substances.

Environmental Impact of Chemical-Resistant Glove Materials

The environmental impact of chemical-resistant glove materials used for protection against petroleum ether presents significant sustainability challenges. Traditional chemical-resistant gloves, particularly those made from nitrile, neoprene, and PVC, require petroleum-based manufacturing processes that contribute to carbon emissions and resource depletion. The production of these materials involves energy-intensive processes and the release of volatile organic compounds (VOCs) that can harm air quality.

When considering the lifecycle assessment of chemical-resistant gloves, disposal issues become particularly concerning. Most synthetic polymer-based gloves are not biodegradable and can persist in landfills for decades or even centuries. Petroleum ether resistance often correlates with materials that have poor environmental degradation profiles, creating a tension between protection requirements and ecological responsibility.

Water pollution represents another critical environmental concern. The manufacturing processes for high-performance chemical-resistant gloves often involve water-intensive steps and can release harmful chemicals into waterways if proper treatment systems are not in place. Additionally, microplastic shedding from worn gloves can contribute to aquatic ecosystem contamination.

Recent innovations have begun addressing these environmental challenges through the development of bio-based alternatives. Some manufacturers are exploring plant-derived polymers that maintain resistance to petroleum ether while offering improved biodegradability. These materials, though promising, currently face limitations in performance consistency and cost-effectiveness compared to traditional options.

Recycling programs for chemical-resistant gloves remain underdeveloped due to contamination concerns and the complex material compositions required for petroleum ether resistance. The presence of chemical residues on used gloves further complicates recycling efforts, often necessitating specialized handling procedures that increase processing costs.

Energy consumption during manufacturing varies significantly across different glove materials. Butyl rubber gloves, which offer excellent protection against petroleum ether, typically require more energy to produce than nitrile alternatives, though they may offer longer service lives that partially offset their initial environmental impact.

The environmental footprint of chemical-resistant gloves extends to transportation impacts, as many specialized materials are manufactured in limited global locations and must be shipped worldwide. This distribution network adds carbon emissions to the overall environmental cost of providing adequate protection against petroleum ether exposure.

When considering the lifecycle assessment of chemical-resistant gloves, disposal issues become particularly concerning. Most synthetic polymer-based gloves are not biodegradable and can persist in landfills for decades or even centuries. Petroleum ether resistance often correlates with materials that have poor environmental degradation profiles, creating a tension between protection requirements and ecological responsibility.

Water pollution represents another critical environmental concern. The manufacturing processes for high-performance chemical-resistant gloves often involve water-intensive steps and can release harmful chemicals into waterways if proper treatment systems are not in place. Additionally, microplastic shedding from worn gloves can contribute to aquatic ecosystem contamination.

Recent innovations have begun addressing these environmental challenges through the development of bio-based alternatives. Some manufacturers are exploring plant-derived polymers that maintain resistance to petroleum ether while offering improved biodegradability. These materials, though promising, currently face limitations in performance consistency and cost-effectiveness compared to traditional options.

Recycling programs for chemical-resistant gloves remain underdeveloped due to contamination concerns and the complex material compositions required for petroleum ether resistance. The presence of chemical residues on used gloves further complicates recycling efforts, often necessitating specialized handling procedures that increase processing costs.

Energy consumption during manufacturing varies significantly across different glove materials. Butyl rubber gloves, which offer excellent protection against petroleum ether, typically require more energy to produce than nitrile alternatives, though they may offer longer service lives that partially offset their initial environmental impact.

The environmental footprint of chemical-resistant gloves extends to transportation impacts, as many specialized materials are manufactured in limited global locations and must be shipped worldwide. This distribution network adds carbon emissions to the overall environmental cost of providing adequate protection against petroleum ether exposure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!