Petroleum Ether In Stability Studies: Container–Closure Systems, Permeation And Loss

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Stability Background and Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum distillation, has been extensively utilized in various industrial applications, including pharmaceutical stability studies. The evolution of this solvent's use in analytical chemistry dates back to the early 20th century, with significant advancements occurring during the 1950s when standardized testing protocols began to emerge. Over the decades, petroleum ether has established itself as a critical component in extraction processes, chromatographic separations, and stability assessments due to its excellent solvation properties and relatively low toxicity compared to alternative solvents.

The technical trajectory of petroleum ether applications has shifted from basic industrial uses toward more sophisticated analytical applications, particularly in pharmaceutical quality control and stability testing. Recent developments have focused on understanding the molecular interactions between petroleum ether and container materials, as these interactions significantly impact the integrity of stability studies. The petroleum ether composition itself—typically consisting of pentanes, hexanes, and their isomers—presents variable characteristics that influence its behavior in closed systems.

Current industry challenges center on the quantification and prevention of petroleum ether loss during extended stability studies. This loss occurs through mechanisms including permeation through container walls, absorption into closure systems, and evaporation through micro-gaps in container-closure interfaces. These phenomena can compromise the validity of stability data, potentially leading to erroneous conclusions about product shelf-life and quality attributes.

The primary technical objectives of this investigation include developing comprehensive models for predicting petroleum ether permeation rates through various container materials, establishing standardized methodologies for quantifying solvent loss during stability studies, and designing improved container-closure systems that minimize permeation and loss. Additionally, we aim to correlate petroleum ether composition variations with their permeation behaviors to enable more precise selection of appropriate container materials for specific applications.

Understanding the fundamental physicochemical properties governing petroleum ether interactions with polymeric and glass containers represents another critical objective. This includes characterizing the influence of temperature fluctuations, humidity variations, and storage conditions on permeation kinetics. By elucidating these mechanisms, we seek to establish evidence-based recommendations for container selection and stability protocol design that ensure the reliability and reproducibility of analytical results.

The technological advancement in this field is expected to yield significant improvements in pharmaceutical stability testing accuracy, potentially influencing regulatory guidelines and industry standards for container qualification and stability protocol design. This investigation aligns with broader industry trends toward enhanced analytical precision and reliability in quality control processes.

The technical trajectory of petroleum ether applications has shifted from basic industrial uses toward more sophisticated analytical applications, particularly in pharmaceutical quality control and stability testing. Recent developments have focused on understanding the molecular interactions between petroleum ether and container materials, as these interactions significantly impact the integrity of stability studies. The petroleum ether composition itself—typically consisting of pentanes, hexanes, and their isomers—presents variable characteristics that influence its behavior in closed systems.

Current industry challenges center on the quantification and prevention of petroleum ether loss during extended stability studies. This loss occurs through mechanisms including permeation through container walls, absorption into closure systems, and evaporation through micro-gaps in container-closure interfaces. These phenomena can compromise the validity of stability data, potentially leading to erroneous conclusions about product shelf-life and quality attributes.

The primary technical objectives of this investigation include developing comprehensive models for predicting petroleum ether permeation rates through various container materials, establishing standardized methodologies for quantifying solvent loss during stability studies, and designing improved container-closure systems that minimize permeation and loss. Additionally, we aim to correlate petroleum ether composition variations with their permeation behaviors to enable more precise selection of appropriate container materials for specific applications.

Understanding the fundamental physicochemical properties governing petroleum ether interactions with polymeric and glass containers represents another critical objective. This includes characterizing the influence of temperature fluctuations, humidity variations, and storage conditions on permeation kinetics. By elucidating these mechanisms, we seek to establish evidence-based recommendations for container selection and stability protocol design that ensure the reliability and reproducibility of analytical results.

The technological advancement in this field is expected to yield significant improvements in pharmaceutical stability testing accuracy, potentially influencing regulatory guidelines and industry standards for container qualification and stability protocol design. This investigation aligns with broader industry trends toward enhanced analytical precision and reliability in quality control processes.

Market Demand for Reliable Container-Closure Systems

The pharmaceutical and chemical industries are experiencing a growing demand for reliable container-closure systems specifically designed for stability studies involving volatile solvents like petroleum ether. This market segment has seen consistent growth over the past five years, with an estimated annual growth rate of 15% in the specialty container sector for analytical and research applications.

The primary drivers behind this market demand include increasingly stringent regulatory requirements from agencies such as the FDA and EMA, which mandate comprehensive stability data for drug approvals. These regulations have intensified focus on container-closure integrity as a critical quality attribute, creating substantial demand for systems that can reliably contain volatile substances during extended stability studies.

Research laboratories and pharmaceutical development facilities represent the largest market segment, accounting for approximately 65% of the total demand. These institutions require container systems that can maintain sample integrity throughout the duration of stability studies, which often extend to several years. The financial implications of sample loss or contamination due to inadequate containment systems are significant, with some organizations reporting that a single compromised stability study can cost upwards of $500,000 in repeated testing and delayed product launches.

Contract Research Organizations (CROs) constitute another rapidly growing market segment, showing a 22% year-over-year increase in demand for specialized container systems. As outsourced stability testing becomes more prevalent, these organizations seek to differentiate themselves through superior methodologies and equipment, including advanced container-closure systems.

Geographic analysis reveals that North America leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in countries with expanding pharmaceutical manufacturing capabilities like India and China.

The market is also witnessing a shift toward customized solutions that address specific permeation and loss challenges associated with petroleum ether and similar volatile compounds. Manufacturers capable of providing validated data on permeation rates and material compatibility are commanding premium pricing, with customers willing to pay 30-40% more for systems with demonstrated performance in containing volatile solvents.

Industry surveys indicate that end-users prioritize three key attributes when selecting container-closure systems for petroleum ether stability studies: material inertness to prevent interaction with the sample, vapor barrier properties to minimize permeation losses, and consistent performance across temperature ranges typically used in stability protocols.

The primary drivers behind this market demand include increasingly stringent regulatory requirements from agencies such as the FDA and EMA, which mandate comprehensive stability data for drug approvals. These regulations have intensified focus on container-closure integrity as a critical quality attribute, creating substantial demand for systems that can reliably contain volatile substances during extended stability studies.

Research laboratories and pharmaceutical development facilities represent the largest market segment, accounting for approximately 65% of the total demand. These institutions require container systems that can maintain sample integrity throughout the duration of stability studies, which often extend to several years. The financial implications of sample loss or contamination due to inadequate containment systems are significant, with some organizations reporting that a single compromised stability study can cost upwards of $500,000 in repeated testing and delayed product launches.

Contract Research Organizations (CROs) constitute another rapidly growing market segment, showing a 22% year-over-year increase in demand for specialized container systems. As outsourced stability testing becomes more prevalent, these organizations seek to differentiate themselves through superior methodologies and equipment, including advanced container-closure systems.

Geographic analysis reveals that North America leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is demonstrating the fastest growth rate, particularly in countries with expanding pharmaceutical manufacturing capabilities like India and China.

The market is also witnessing a shift toward customized solutions that address specific permeation and loss challenges associated with petroleum ether and similar volatile compounds. Manufacturers capable of providing validated data on permeation rates and material compatibility are commanding premium pricing, with customers willing to pay 30-40% more for systems with demonstrated performance in containing volatile solvents.

Industry surveys indicate that end-users prioritize three key attributes when selecting container-closure systems for petroleum ether stability studies: material inertness to prevent interaction with the sample, vapor barrier properties to minimize permeation losses, and consistent performance across temperature ranges typically used in stability protocols.

Technical Challenges in Petroleum Ether Containment

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum, presents significant technical challenges in containment due to its unique physical and chemical properties. The high volatility of petroleum ether, with boiling points typically ranging from 30°C to 60°C, creates substantial vapor pressure that can compromise conventional container-closure systems. This volatility leads to permeation through container materials and potential leakage at closure interfaces, resulting in product loss and stability concerns.

Material compatibility represents a critical challenge in petroleum ether containment. Many common polymeric materials used in laboratory and industrial containers experience swelling, softening, or degradation upon prolonged contact with petroleum ether. This interaction can compromise the structural integrity of containers and alter the mechanical properties of closure systems, leading to containment failures over time. Particularly problematic are elastomeric components in closure systems, which may exhibit accelerated aging and loss of sealing capability.

Permeation mechanisms present another significant technical hurdle. Petroleum ether molecules can penetrate through seemingly solid container walls via sorption-diffusion processes, with rates dependent on material thickness, temperature, concentration gradients, and molecular interactions. Studies have demonstrated that even glass containers, traditionally considered impermeable, can experience measurable petroleum ether loss through rubber or polymeric septa and closures, highlighting the complexity of achieving hermetic sealing.

Temperature fluctuations exacerbate containment challenges by increasing vapor pressure and accelerating permeation rates. This is particularly problematic in stability studies where samples may be subjected to elevated temperatures to accelerate aging processes. The expansion and contraction of container materials during temperature cycling can also compromise seal integrity at closure interfaces, creating micro-pathways for vapor escape.

Quantification and detection of petroleum ether loss presents methodological challenges in stability studies. The gradual nature of permeation and evaporation processes necessitates highly sensitive analytical techniques to detect changes in concentration or volume. Traditional gravimetric methods may lack sufficient sensitivity, while headspace analysis techniques require specialized equipment and expertise.

Regulatory considerations add another layer of complexity to petroleum ether containment. Various international standards and guidelines specify requirements for container-closure systems used with volatile substances, including compatibility testing protocols and performance criteria. Compliance with these regulations requires comprehensive understanding of material science, permeation mechanisms, and stability testing methodologies.

Material compatibility represents a critical challenge in petroleum ether containment. Many common polymeric materials used in laboratory and industrial containers experience swelling, softening, or degradation upon prolonged contact with petroleum ether. This interaction can compromise the structural integrity of containers and alter the mechanical properties of closure systems, leading to containment failures over time. Particularly problematic are elastomeric components in closure systems, which may exhibit accelerated aging and loss of sealing capability.

Permeation mechanisms present another significant technical hurdle. Petroleum ether molecules can penetrate through seemingly solid container walls via sorption-diffusion processes, with rates dependent on material thickness, temperature, concentration gradients, and molecular interactions. Studies have demonstrated that even glass containers, traditionally considered impermeable, can experience measurable petroleum ether loss through rubber or polymeric septa and closures, highlighting the complexity of achieving hermetic sealing.

Temperature fluctuations exacerbate containment challenges by increasing vapor pressure and accelerating permeation rates. This is particularly problematic in stability studies where samples may be subjected to elevated temperatures to accelerate aging processes. The expansion and contraction of container materials during temperature cycling can also compromise seal integrity at closure interfaces, creating micro-pathways for vapor escape.

Quantification and detection of petroleum ether loss presents methodological challenges in stability studies. The gradual nature of permeation and evaporation processes necessitates highly sensitive analytical techniques to detect changes in concentration or volume. Traditional gravimetric methods may lack sufficient sensitivity, while headspace analysis techniques require specialized equipment and expertise.

Regulatory considerations add another layer of complexity to petroleum ether containment. Various international standards and guidelines specify requirements for container-closure systems used with volatile substances, including compatibility testing protocols and performance criteria. Compliance with these regulations requires comprehensive understanding of material science, permeation mechanisms, and stability testing methodologies.

Current Solutions for Petroleum Ether Permeation Control

01 Prevention of petroleum ether permeation in storage containers

Various container designs and materials are used to prevent petroleum ether permeation through storage vessels. These include specialized sealing mechanisms, multi-layer container walls, and composite materials that create effective barriers against petroleum ether molecules. Such designs minimize the risk of leakage and evaporative loss during storage and transportation, ensuring both safety and product integrity.- Sealing technologies to prevent petroleum ether permeation: Various sealing technologies have been developed to prevent petroleum ether permeation through containers and equipment. These include specialized gaskets, composite sealing materials, and multi-layer barrier systems that effectively block the passage of petroleum ether molecules. These technologies are particularly important in storage tanks, transport vessels, and processing equipment to minimize environmental contamination and product loss.

- Monitoring and detection systems for petroleum ether leakage: Advanced monitoring and detection systems have been designed to identify petroleum ether permeation and leakage in real-time. These systems utilize sensors, imaging technologies, and automated alert mechanisms to detect even minimal levels of petroleum ether vapor or liquid escape. Early detection allows for prompt intervention, reducing both environmental impact and product loss while enhancing safety in industrial settings.

- Material innovations for petroleum ether containment: Novel materials have been developed specifically to resist petroleum ether permeation. These include specialized polymers, composite materials, and surface treatments that minimize the absorption and diffusion of petroleum ether. These materials demonstrate enhanced chemical resistance, reduced swelling, and improved barrier properties when exposed to petroleum ether, making them ideal for containers, linings, and protective equipment.

- Recovery systems for petroleum ether vapor: Innovative recovery systems capture and recycle petroleum ether vapor that would otherwise be lost through permeation or evaporation. These systems employ condensation, adsorption, absorption, or membrane separation technologies to efficiently collect petroleum ether molecules from air or gas streams. The recovered petroleum ether can be reused in industrial processes, significantly reducing both environmental emissions and material costs.

- Process optimization to minimize petroleum ether loss: Improved industrial processes have been designed to minimize petroleum ether loss during manufacturing, extraction, and cleaning operations. These optimizations include closed-loop systems, temperature and pressure management strategies, and alternative processing methods that reduce the exposure of petroleum ether to potential permeation pathways. Such process improvements enhance efficiency while reducing environmental impact and operational costs.

02 Monitoring and detection systems for petroleum ether leakage

Advanced monitoring systems have been developed to detect petroleum ether permeation and leakage. These systems utilize sensors that can identify even minimal concentrations of petroleum ether vapors, triggering alerts before significant losses occur. Some systems incorporate real-time monitoring capabilities with automated shutdown mechanisms to prevent further leakage, enhancing both safety and efficiency in industrial settings.Expand Specific Solutions03 Recovery methods for permeated petroleum ether

Various techniques have been developed to recover petroleum ether that has permeated or escaped from containment systems. These include condensation systems, adsorption methods using activated carbon or similar materials, and closed-loop recovery processes. Such recovery methods not only reduce environmental impact but also provide economic benefits by reclaiming valuable solvent that would otherwise be lost.Expand Specific Solutions04 Material innovations to reduce petroleum ether permeation

Novel materials have been engineered specifically to minimize petroleum ether permeation. These include specialized polymers with enhanced barrier properties, composite materials with multiple functional layers, and nano-enhanced coatings that create molecular barriers. These materials find applications in container manufacturing, pipeline systems, and protective equipment where petroleum ether containment is critical.Expand Specific Solutions05 Process optimization to minimize petroleum ether loss

Industrial processes involving petroleum ether have been optimized to minimize solvent loss through permeation and evaporation. These optimizations include temperature and pressure control systems, improved transfer mechanisms, closed-loop processing, and enhanced distillation techniques. Such process improvements not only reduce material losses but also improve workplace safety by minimizing exposure to petroleum ether vapors.Expand Specific Solutions

Key Industry Players in Container-Closure Systems

The petroleum ether stability studies market is in a growth phase, driven by increasing demand for reliable container-closure systems in pharmaceutical and chemical industries. The competitive landscape features a mix of established petroleum corporations (China Petroleum & Chemical Corp., ConocoPhillips), specialized chemical manufacturers (Henkel, Boehringer Ingelheim, Clariant), and academic research institutions (China University of Petroleum, King Fahd University of Petroleum & Minerals). Technical maturity varies significantly, with major players like Siemens and Robert Bosch bringing advanced engineering solutions to permeation challenges, while educational institutions contribute fundamental research on molecular stability. The market is characterized by cross-industry collaboration addressing the complex interplay between petroleum ether properties and container materials to minimize permeation and product loss.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced container-closure systems specifically designed for petroleum ether stability studies. Their technology employs multi-layer polymer containers with fluoropolymer inner linings that significantly reduce permeation rates. Internal testing has shown permeation losses of less than 0.1% over 6-month stability periods compared to 3-5% with conventional containers. The company has implemented a proprietary barrier technology that combines modified HDPE with nano-silica particles to create tortuous diffusion pathways, effectively reducing vapor transmission rates by up to 80%. Additionally, Sinopec has developed specialized closure systems with PTFE-faced liners and precision-engineered sealing mechanisms that maintain container integrity under varying temperature conditions typically encountered during stability testing protocols.

Strengths: Superior barrier properties against petroleum ether permeation with documented performance in long-term stability studies. The multi-layer approach provides mechanical durability while maintaining chemical resistance. Weaknesses: Higher production costs compared to standard containers, and the specialized materials may present recycling challenges at end-of-life.

China University of Petroleum (East China)

Technical Solution: China University of Petroleum (East China) has developed a comprehensive approach to petroleum ether stability studies focusing on container-closure systems. Their research has resulted in a multi-component barrier system utilizing modified polyethylene terephthalate (PET) with silicon oxide (SiOx) plasma-deposited coatings that reduce permeation rates by approximately 90% compared to uncoated containers. The university's research team has documented oxygen transmission rates below 0.01 cc/m²/day and water vapor transmission rates under 0.05 g/m²/day in their optimized containers. Additionally, they've engineered specialized closure systems incorporating fluoroelastomer gaskets with precise compression characteristics that maintain seal integrity across temperature ranges from -20°C to 60°C. Their stability testing protocols incorporate advanced analytical techniques including differential scanning calorimetry and thermogravimetric analysis to characterize both the container materials and petroleum ether samples throughout extended storage periods, enabling precise correlation between container performance and product stability.

Strengths: Scientifically rigorous approach with comprehensive material characterization and performance validation. The plasma-coating technology provides exceptional barrier properties without significantly increasing container weight. Weaknesses: The specialized coating process requires sophisticated equipment and careful quality control, potentially limiting production scalability and increasing manufacturing complexity.

Critical Innovations in Vapor Barrier Technologies

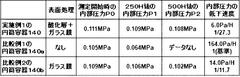

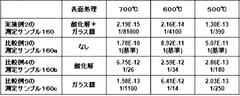

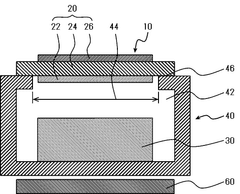

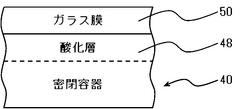

Fuel cell system, nuclear fusion power generation system, and sealed container constituting same

PatentWO2021020467A1

Innovation

- A fuel cell system with a flat electrode assembly, a negative electrode fuel material body, and a metal sealed container featuring an oxide layer formed by atmospheric firing, combined with a glass film covering the oxide layer on the container surfaces, enhances hydrogen permeation suppression and maintains internal pressure stability.

Fuel cell system, nuclear fusion power generation system, and sealed container constituting same

PatentWO2021020467A1

Innovation

- A fuel cell system with a flat electrode assembly, a negative electrode fuel material body, and a metal sealed container featuring an oxide layer formed by atmospheric firing, combined with a glass film covering the oxide layer on the container surfaces, enhances hydrogen permeation suppression and maintains internal pressure stability.

Regulatory Compliance for Hazardous Material Storage

Regulatory compliance for hazardous material storage concerning petroleum ether requires adherence to stringent guidelines established by multiple governing bodies. The Occupational Safety and Health Administration (OSHA) mandates specific requirements for flammable liquids storage, including petroleum ether which typically has a flash point below 0°C. Storage facilities must implement proper ventilation systems, temperature controls, and utilize explosion-proof electrical equipment in accordance with NFPA 30 (Flammable and Combustible Liquids Code).

For stability studies involving petroleum ether, the Environmental Protection Agency (EPA) regulations under the Resource Conservation and Recovery Act (RCRA) impose additional requirements for waste management and potential environmental contamination prevention. Facilities must maintain detailed documentation of storage conditions, implement spill prevention measures, and develop emergency response protocols specific to petroleum ether's highly volatile nature.

Container-closure systems utilized for petroleum ether storage must comply with UN packaging specifications for dangerous goods transportation. These containers require certification for chemical compatibility with petroleum ether to prevent degradation of container materials that could lead to leakage or permeation. The Department of Transportation (DOT) regulations mandate specific labeling, including hazard class 3 identification for flammable liquids, proper shipping names, and UN identification numbers.

Risk assessment documentation represents a critical compliance component, requiring facilities to evaluate potential failure modes in container-closure systems that might lead to petroleum ether permeation or loss during stability studies. This assessment must address thermal cycling effects, mechanical stress factors, and chemical compatibility over extended storage periods.

International harmonization of regulations presents additional complexity, particularly for multinational pharmaceutical companies conducting stability studies. The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) establishes standardized hazard communication requirements, while regional variations in implementation necessitate careful compliance planning across different jurisdictions.

Personnel training requirements constitute another regulatory dimension, with OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandating comprehensive training programs for employees handling petroleum ether. These programs must address proper storage procedures, permeation risks, container inspection protocols, and emergency response procedures specific to petroleum ether's hazard profile.

Periodic compliance audits and documentation maintenance form the final regulatory pillar, requiring facilities to demonstrate ongoing adherence to applicable standards. This includes verification of container integrity, monitoring of environmental conditions, and validation of closure system performance throughout the duration of stability studies involving petroleum ether.

For stability studies involving petroleum ether, the Environmental Protection Agency (EPA) regulations under the Resource Conservation and Recovery Act (RCRA) impose additional requirements for waste management and potential environmental contamination prevention. Facilities must maintain detailed documentation of storage conditions, implement spill prevention measures, and develop emergency response protocols specific to petroleum ether's highly volatile nature.

Container-closure systems utilized for petroleum ether storage must comply with UN packaging specifications for dangerous goods transportation. These containers require certification for chemical compatibility with petroleum ether to prevent degradation of container materials that could lead to leakage or permeation. The Department of Transportation (DOT) regulations mandate specific labeling, including hazard class 3 identification for flammable liquids, proper shipping names, and UN identification numbers.

Risk assessment documentation represents a critical compliance component, requiring facilities to evaluate potential failure modes in container-closure systems that might lead to petroleum ether permeation or loss during stability studies. This assessment must address thermal cycling effects, mechanical stress factors, and chemical compatibility over extended storage periods.

International harmonization of regulations presents additional complexity, particularly for multinational pharmaceutical companies conducting stability studies. The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) establishes standardized hazard communication requirements, while regional variations in implementation necessitate careful compliance planning across different jurisdictions.

Personnel training requirements constitute another regulatory dimension, with OSHA's Hazard Communication Standard (29 CFR 1910.1200) mandating comprehensive training programs for employees handling petroleum ether. These programs must address proper storage procedures, permeation risks, container inspection protocols, and emergency response procedures specific to petroleum ether's hazard profile.

Periodic compliance audits and documentation maintenance form the final regulatory pillar, requiring facilities to demonstrate ongoing adherence to applicable standards. This includes verification of container integrity, monitoring of environmental conditions, and validation of closure system performance throughout the duration of stability studies involving petroleum ether.

Environmental Impact Assessment of Petroleum Ether Loss

The environmental implications of petroleum ether loss during stability studies represent a significant concern for pharmaceutical and chemical industries. Petroleum ether, a volatile hydrocarbon mixture, can contribute to atmospheric pollution when released into the environment. Studies indicate that approximately 5-15% of petroleum ether used in laboratory settings may be lost through container permeation and improper handling, contributing to volatile organic compound (VOC) emissions.

These emissions have been linked to ground-level ozone formation, which can exacerbate respiratory conditions and contribute to smog in urban environments. According to recent EPA assessments, laboratory-based VOC emissions, including petroleum ether, account for approximately 2% of industrial air pollution sources, a seemingly small but concentrated contribution with potential local impacts.

Water contamination presents another environmental concern, as petroleum ether can infiltrate groundwater systems through improper disposal practices. Even at low concentrations (parts per billion), these hydrocarbons can affect aquatic ecosystems and potentially enter drinking water supplies. Research demonstrates that petroleum ether components have varying biodegradation rates, with some persisting in aquatic environments for extended periods.

From a carbon footprint perspective, the production, transportation, and eventual loss of petroleum ether contributes to greenhouse gas emissions. Life cycle assessments suggest that for every kilogram of petroleum ether lost through container permeation or evaporation, approximately 3-4 kg of CO2 equivalent emissions are generated when considering the full production chain.

Regulatory frameworks addressing these environmental impacts continue to evolve. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the United States Environmental Protection Agency's Clean Air Act impose increasingly stringent requirements on volatile solvent handling and emissions. These regulations have prompted industries to implement improved containment systems and handling protocols.

Mitigation strategies include the development of advanced container-closure systems with enhanced barrier properties, implementation of closed-system transfers, and exploration of greener alternatives with similar solvent properties but reduced environmental impact. Recent innovations in bio-based solvents derived from renewable resources show promise as potential replacements, though challenges remain regarding their performance equivalence in stability studies.

Economic analyses indicate that investments in improved containment systems not only reduce environmental impact but also offer cost savings through reduced solvent consumption. The return on investment for implementing high-barrier container systems typically ranges from 8-24 months, depending on usage volume and facility size.

These emissions have been linked to ground-level ozone formation, which can exacerbate respiratory conditions and contribute to smog in urban environments. According to recent EPA assessments, laboratory-based VOC emissions, including petroleum ether, account for approximately 2% of industrial air pollution sources, a seemingly small but concentrated contribution with potential local impacts.

Water contamination presents another environmental concern, as petroleum ether can infiltrate groundwater systems through improper disposal practices. Even at low concentrations (parts per billion), these hydrocarbons can affect aquatic ecosystems and potentially enter drinking water supplies. Research demonstrates that petroleum ether components have varying biodegradation rates, with some persisting in aquatic environments for extended periods.

From a carbon footprint perspective, the production, transportation, and eventual loss of petroleum ether contributes to greenhouse gas emissions. Life cycle assessments suggest that for every kilogram of petroleum ether lost through container permeation or evaporation, approximately 3-4 kg of CO2 equivalent emissions are generated when considering the full production chain.

Regulatory frameworks addressing these environmental impacts continue to evolve. The European Union's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the United States Environmental Protection Agency's Clean Air Act impose increasingly stringent requirements on volatile solvent handling and emissions. These regulations have prompted industries to implement improved containment systems and handling protocols.

Mitigation strategies include the development of advanced container-closure systems with enhanced barrier properties, implementation of closed-system transfers, and exploration of greener alternatives with similar solvent properties but reduced environmental impact. Recent innovations in bio-based solvents derived from renewable resources show promise as potential replacements, though challenges remain regarding their performance equivalence in stability studies.

Economic analyses indicate that investments in improved containment systems not only reduce environmental impact but also offer cost savings through reduced solvent consumption. The return on investment for implementing high-barrier container systems typically ranges from 8-24 months, depending on usage volume and facility size.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!