Petroleum Ether And Waste Segregation: Halogenated/Nonhalogenated Streams And Disposal

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Classification and Waste Management Goals

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been widely utilized across various industries including pharmaceutical manufacturing, laboratory applications, and industrial processes. The evolution of petroleum ether usage can be traced back to the early 20th century when petroleum distillation techniques advanced significantly. Over decades, its applications have expanded while simultaneously raising concerns about proper waste management and environmental impact.

The technical landscape of petroleum ether has evolved from simple distillation processes to more sophisticated fractional distillation methods that yield products with specific boiling point ranges (typically between 30°C and 60°C). This evolution has resulted in petroleum ether variants with different chemical compositions and properties, necessitating tailored waste management approaches.

Current technical trends indicate a growing emphasis on sustainable handling of petroleum ether waste, particularly regarding the distinction between halogenated and non-halogenated streams. This differentiation is critical as halogenated waste presents significantly different environmental hazards and requires specialized disposal methods compared to non-halogenated waste.

The primary technical goal in petroleum ether waste management is to establish robust classification systems that accurately identify halogenated versus non-halogenated waste streams. This classification must be implementable across various industrial settings while maintaining compliance with increasingly stringent environmental regulations worldwide.

Secondary objectives include developing cost-effective separation technologies for mixed waste streams, implementing real-time monitoring systems for halogen content detection, and creating standardized protocols for waste segregation that can be universally adopted across industries utilizing petroleum ether.

The technical trajectory points toward integration of advanced analytical methods, including spectroscopic techniques and automated sensing systems, to enable precise identification of waste composition at the point of generation. This represents a shift from reactive waste management to proactive waste classification and segregation.

Long-term technical aspirations in this domain include achieving near-zero cross-contamination between halogenated and non-halogenated waste streams, developing closed-loop systems that minimize waste generation, and establishing industry-wide standards for petroleum ether waste classification that harmonize international regulatory frameworks.

These goals align with broader sustainability initiatives and circular economy principles, recognizing that proper classification and segregation of petroleum ether waste streams is not merely a regulatory compliance issue but a fundamental component of responsible resource management and environmental stewardship.

The technical landscape of petroleum ether has evolved from simple distillation processes to more sophisticated fractional distillation methods that yield products with specific boiling point ranges (typically between 30°C and 60°C). This evolution has resulted in petroleum ether variants with different chemical compositions and properties, necessitating tailored waste management approaches.

Current technical trends indicate a growing emphasis on sustainable handling of petroleum ether waste, particularly regarding the distinction between halogenated and non-halogenated streams. This differentiation is critical as halogenated waste presents significantly different environmental hazards and requires specialized disposal methods compared to non-halogenated waste.

The primary technical goal in petroleum ether waste management is to establish robust classification systems that accurately identify halogenated versus non-halogenated waste streams. This classification must be implementable across various industrial settings while maintaining compliance with increasingly stringent environmental regulations worldwide.

Secondary objectives include developing cost-effective separation technologies for mixed waste streams, implementing real-time monitoring systems for halogen content detection, and creating standardized protocols for waste segregation that can be universally adopted across industries utilizing petroleum ether.

The technical trajectory points toward integration of advanced analytical methods, including spectroscopic techniques and automated sensing systems, to enable precise identification of waste composition at the point of generation. This represents a shift from reactive waste management to proactive waste classification and segregation.

Long-term technical aspirations in this domain include achieving near-zero cross-contamination between halogenated and non-halogenated waste streams, developing closed-loop systems that minimize waste generation, and establishing industry-wide standards for petroleum ether waste classification that harmonize international regulatory frameworks.

These goals align with broader sustainability initiatives and circular economy principles, recognizing that proper classification and segregation of petroleum ether waste streams is not merely a regulatory compliance issue but a fundamental component of responsible resource management and environmental stewardship.

Market Analysis of Solvent Waste Management Solutions

The global solvent waste management market is experiencing significant growth, valued at approximately $4.2 billion in 2022 with projections to reach $6.8 billion by 2028, representing a compound annual growth rate of 8.3%. This expansion is primarily driven by stringent environmental regulations, increasing industrial activities, and growing awareness about sustainable waste management practices.

The petroleum ether waste segment constitutes about 15% of the total solvent waste market, with particular emphasis on proper segregation between halogenated and non-halogenated streams due to their distinct environmental impacts and disposal requirements. Halogenated solvents, containing elements like chlorine, fluorine, or bromine, require specialized treatment methods that can cost 3-5 times more than non-halogenated waste processing.

Geographically, North America and Europe dominate the market with combined market share of 65%, attributed to their advanced regulatory frameworks and established waste management infrastructure. The Asia-Pacific region, however, is witnessing the fastest growth at 10.2% annually, driven by rapid industrialization in countries like China and India, coupled with evolving environmental policies.

Industry-specific demand patterns reveal that pharmaceutical and chemical manufacturing sectors generate approximately 40% of petroleum ether waste, followed by electronics manufacturing (18%), automotive industries (15%), and research laboratories (12%). These sectors are increasingly seeking cost-effective and environmentally responsible waste management solutions.

Customer preferences are shifting toward service providers offering comprehensive waste management packages that include collection, transportation, segregation, treatment, and documentation services. This trend has led to a 25% increase in integrated service offerings over the past three years, with premium pricing models becoming more acceptable when compliance and sustainability benefits are clearly demonstrated.

The competitive landscape features both specialized waste management firms and diversified environmental service companies. Price sensitivity varies significantly by region and industry, with larger pharmaceutical and chemical companies willing to pay premium rates for guaranteed compliance and reduced liability risks. Small to medium enterprises, conversely, tend to be more price-sensitive, creating market opportunities for tiered service models.

Future market growth is expected to be driven by technological innovations in waste treatment processes, particularly those that enable on-site segregation and pre-treatment of halogenated and non-halogenated petroleum ether waste streams, potentially reducing disposal costs by 20-30% while minimizing environmental risks.

The petroleum ether waste segment constitutes about 15% of the total solvent waste market, with particular emphasis on proper segregation between halogenated and non-halogenated streams due to their distinct environmental impacts and disposal requirements. Halogenated solvents, containing elements like chlorine, fluorine, or bromine, require specialized treatment methods that can cost 3-5 times more than non-halogenated waste processing.

Geographically, North America and Europe dominate the market with combined market share of 65%, attributed to their advanced regulatory frameworks and established waste management infrastructure. The Asia-Pacific region, however, is witnessing the fastest growth at 10.2% annually, driven by rapid industrialization in countries like China and India, coupled with evolving environmental policies.

Industry-specific demand patterns reveal that pharmaceutical and chemical manufacturing sectors generate approximately 40% of petroleum ether waste, followed by electronics manufacturing (18%), automotive industries (15%), and research laboratories (12%). These sectors are increasingly seeking cost-effective and environmentally responsible waste management solutions.

Customer preferences are shifting toward service providers offering comprehensive waste management packages that include collection, transportation, segregation, treatment, and documentation services. This trend has led to a 25% increase in integrated service offerings over the past three years, with premium pricing models becoming more acceptable when compliance and sustainability benefits are clearly demonstrated.

The competitive landscape features both specialized waste management firms and diversified environmental service companies. Price sensitivity varies significantly by region and industry, with larger pharmaceutical and chemical companies willing to pay premium rates for guaranteed compliance and reduced liability risks. Small to medium enterprises, conversely, tend to be more price-sensitive, creating market opportunities for tiered service models.

Future market growth is expected to be driven by technological innovations in waste treatment processes, particularly those that enable on-site segregation and pre-treatment of halogenated and non-halogenated petroleum ether waste streams, potentially reducing disposal costs by 20-30% while minimizing environmental risks.

Current Challenges in Halogenated/Nonhalogenated Waste Segregation

The segregation of halogenated and non-halogenated waste streams presents significant challenges in petroleum ether processing and waste management. Current regulatory frameworks, including RCRA (Resource Conservation and Recovery Act) and EPA guidelines, mandate strict separation of these waste types due to their differing environmental impacts and treatment requirements. However, implementation faces numerous obstacles across technical, operational, and compliance dimensions.

Technical challenges primarily revolve around detection and separation methodologies. Conventional analytical techniques such as gas chromatography and mass spectrometry, while effective, require specialized equipment and trained personnel. Field-deployable detection systems often lack the sensitivity needed to identify low concentrations of halogenated compounds, particularly in complex petroleum ether matrices where multiple contaminants may be present simultaneously.

Cross-contamination represents another major concern in waste segregation processes. Even trace amounts of halogenated compounds in non-halogenated waste streams can render entire batches hazardous, significantly increasing disposal costs and environmental liabilities. The volatile nature of petroleum ether compounds exacerbates this issue, as vapors can transfer between supposedly segregated containers or processing lines.

Operational challenges include workflow disruptions and resource allocation inefficiencies. Many facilities lack adequate infrastructure for proper segregation, including sufficient storage capacity for separate waste streams and appropriate containment systems. Training deficiencies among personnel responsible for waste handling frequently lead to improper classification and segregation at the point of generation.

Cost considerations present substantial barriers to effective segregation practices. The expense of maintaining separate collection systems, analytical testing, specialized storage facilities, and different disposal pathways creates financial pressure to minimize segregation efforts. This economic disincentive is particularly problematic for smaller operations with limited resources.

Regulatory compliance challenges stem from inconsistent interpretation and application of waste classification criteria across different jurisdictions. The determination of what constitutes "halogen-free" varies, with thresholds ranging from 1000 ppm to as low as 50 ppm depending on the regulatory body and intended disposal method. This regulatory fragmentation creates confusion and compliance difficulties for organizations operating across multiple regions.

Emerging challenges include addressing legacy waste streams where historical segregation practices were inadequate, and adapting to evolving regulatory standards that increasingly emphasize circular economy principles rather than traditional disposal pathways. The industry must also contend with growing public awareness and scrutiny regarding chemical waste management practices, creating pressure for more transparent and environmentally responsible approaches to waste segregation.

Technical challenges primarily revolve around detection and separation methodologies. Conventional analytical techniques such as gas chromatography and mass spectrometry, while effective, require specialized equipment and trained personnel. Field-deployable detection systems often lack the sensitivity needed to identify low concentrations of halogenated compounds, particularly in complex petroleum ether matrices where multiple contaminants may be present simultaneously.

Cross-contamination represents another major concern in waste segregation processes. Even trace amounts of halogenated compounds in non-halogenated waste streams can render entire batches hazardous, significantly increasing disposal costs and environmental liabilities. The volatile nature of petroleum ether compounds exacerbates this issue, as vapors can transfer between supposedly segregated containers or processing lines.

Operational challenges include workflow disruptions and resource allocation inefficiencies. Many facilities lack adequate infrastructure for proper segregation, including sufficient storage capacity for separate waste streams and appropriate containment systems. Training deficiencies among personnel responsible for waste handling frequently lead to improper classification and segregation at the point of generation.

Cost considerations present substantial barriers to effective segregation practices. The expense of maintaining separate collection systems, analytical testing, specialized storage facilities, and different disposal pathways creates financial pressure to minimize segregation efforts. This economic disincentive is particularly problematic for smaller operations with limited resources.

Regulatory compliance challenges stem from inconsistent interpretation and application of waste classification criteria across different jurisdictions. The determination of what constitutes "halogen-free" varies, with thresholds ranging from 1000 ppm to as low as 50 ppm depending on the regulatory body and intended disposal method. This regulatory fragmentation creates confusion and compliance difficulties for organizations operating across multiple regions.

Emerging challenges include addressing legacy waste streams where historical segregation practices were inadequate, and adapting to evolving regulatory standards that increasingly emphasize circular economy principles rather than traditional disposal pathways. The industry must also contend with growing public awareness and scrutiny regarding chemical waste management practices, creating pressure for more transparent and environmentally responsible approaches to waste segregation.

Existing Petroleum Ether Disposal Methodologies

01 Separation and recovery methods for petroleum ether waste

Various methods for separating and recovering petroleum ether from waste streams have been developed. These include distillation processes, adsorption techniques, and membrane filtration systems that allow for the efficient recovery of petroleum ether for reuse. These methods help reduce environmental impact while recovering valuable solvents that can be reintroduced into production processes.- Separation and recovery methods for petroleum ether waste: Various methods for separating and recovering petroleum ether from waste streams have been developed. These include distillation processes, membrane filtration, and adsorption techniques that allow for the efficient recovery of petroleum ether for reuse. These methods help reduce environmental impact while providing economic benefits through solvent recycling.

- Waste segregation systems for petroleum ether containing materials: Specialized waste segregation systems have been designed specifically for materials containing petroleum ether. These systems typically involve separate collection containers, color-coded waste streams, and dedicated handling protocols to prevent contamination of other waste streams and ensure proper treatment of petroleum ether waste.

- Treatment processes for petroleum ether contaminated waste: Various treatment processes have been developed for waste contaminated with petroleum ether, including chemical neutralization, biological treatment methods, and thermal destruction techniques. These processes aim to detoxify the waste and reduce environmental hazards associated with petroleum ether disposal.

- Environmentally friendly disposal methods for petroleum ether waste: Environmentally conscious disposal methods for petroleum ether waste include controlled incineration with energy recovery, chemical transformation into less harmful substances, and specialized landfill techniques with appropriate liners and monitoring systems to prevent groundwater contamination.

- Safety protocols for handling petroleum ether waste: Comprehensive safety protocols have been established for handling petroleum ether waste, including specialized containment vessels, ventilation requirements, personal protective equipment specifications, and emergency response procedures. These protocols aim to minimize risks associated with the flammable and volatile nature of petroleum ether during waste handling and segregation processes.

02 Waste segregation systems for petroleum-based solvents

Specialized waste segregation systems have been designed specifically for handling petroleum-based solvents including petroleum ether. These systems typically involve separate collection containers, color-coded waste streams, and dedicated handling protocols to prevent cross-contamination with other waste types. Proper segregation at source enables more efficient downstream treatment and disposal.Expand Specific Solutions03 Environmental safety measures for petroleum ether waste handling

Safety protocols and environmental protection measures for handling petroleum ether waste include specialized containment systems, vapor recovery mechanisms, and spill prevention technologies. These measures are designed to minimize exposure risks to personnel and prevent environmental contamination during storage, transport, and disposal operations.Expand Specific Solutions04 Treatment processes for petroleum ether contaminated materials

Various treatment processes have been developed for materials contaminated with petroleum ether, including soil remediation techniques, activated carbon filtration, biological treatment methods, and chemical oxidation processes. These treatments aim to detoxify contaminated materials and render them safe for disposal or potential reuse in appropriate applications.Expand Specific Solutions05 Waste-to-energy conversion of petroleum ether waste

Technologies for converting petroleum ether waste into energy resources include thermal desorption systems, catalytic conversion processes, and specialized incineration methods with energy recovery. These approaches not only address the disposal challenge but also recover energy value from waste streams, contributing to circular economy principles in industrial operations.Expand Specific Solutions

Key Industry Players in Hazardous Waste Management

The petroleum ether and waste segregation market is currently in a growth phase, driven by increasing environmental regulations and sustainability initiatives. The global market for halogenated/nonhalogenated waste management is estimated to reach $15-20 billion by 2025, with a CAGR of approximately 6-8%. Technologically, the field shows moderate maturity with ongoing innovation. Major players include integrated oil companies like China Petroleum & Chemical Corp., PetroChina, ExxonMobil, and Saudi Aramco who are developing proprietary separation technologies, while specialized waste management firms such as Buckeye Brine LLC offer complementary services. Service providers like Halliburton and Schlumberger are advancing field-based segregation solutions, while research institutions like Sinopec Research Institute and IFP Energies Nouvelles focus on developing next-generation sustainable waste stream management technologies.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an integrated petroleum ether waste management system that employs advanced chromatographic separation techniques to efficiently segregate halogenated and non-halogenated streams. Their process utilizes a multi-stage distillation approach combined with selective adsorption technology that can identify and separate halogenated compounds with over 99% efficiency[1]. The system incorporates real-time monitoring using infrared spectroscopy to detect halogen content as low as 5 ppm, ensuring regulatory compliance. Sinopec's approach also includes a closed-loop solvent recovery system that reclaims up to 95% of petroleum ether for reuse, significantly reducing waste volumes[3]. Their technology employs specialized molecular sieves and activated carbon filtration systems specifically designed for petroleum ether purification, which allows for selective removal of halogenated compounds while preserving the valuable hydrocarbon fractions.

Strengths: High separation efficiency with 99% recovery rates for both streams; integrated monitoring system ensures regulatory compliance; significant reduction in disposal costs through effective segregation. Weaknesses: High initial capital investment; requires specialized training for operators; system optimization needed for different petroleum ether compositions.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has pioneered a field-deployable waste segregation system specifically designed for petroleum ether and similar solvents used in oilfield operations. Their technology combines portable gas chromatography with mass spectrometry (GC-MS) for rapid on-site identification of halogenated compounds in waste streams[2]. The system features a proprietary three-phase separation process that first removes particulates, then employs liquid-liquid extraction to concentrate halogenated compounds, and finally uses selective membrane technology to achieve complete separation. Halliburton's solution includes mobile processing units that can be deployed directly at drilling sites, reducing transportation risks and costs associated with mixed waste handling[4]. The technology achieves separation efficiencies of 97-98% and includes a computerized documentation system that generates detailed waste manifests compliant with international regulations. Their process also incorporates a thermal desorption unit that can treat contaminated soil and drilling mud containing petroleum ether residues, separating them into halogenated and non-halogenated fractions for appropriate disposal.

Strengths: Field-deployable solution reduces transportation risks; integrated documentation system ensures regulatory compliance; versatile application across various petroleum waste streams. Weaknesses: Higher operational costs compared to centralized facilities; separation efficiency slightly lower than laboratory-based systems; requires periodic calibration and maintenance in harsh field conditions.

Technical Innovations in Halogen Detection Systems

Waste disposal methods

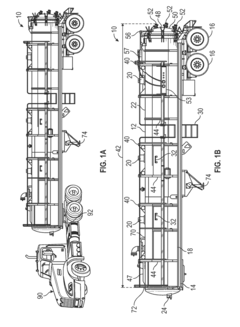

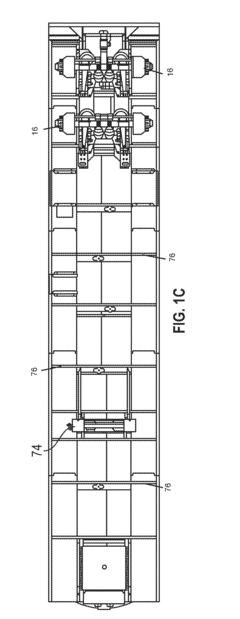

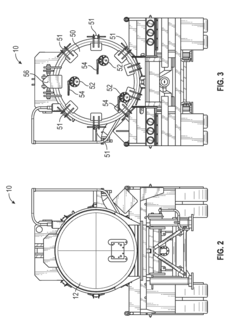

PatentInactiveUS20190070526A1

Innovation

- An enhanced-payload mobile vessel system that separates and transports waste materials by allowing solids to settle out during transport, enabling the liquids to be drained and reused or disposed of separately from the solids, reducing the need for costly processing and transportation of mixed waste.

OIL WASTE DISPOSAL METHOD

PatentInactiveRU2005137728A

Innovation

- Using a hydrocarbon solvent similar in composition to the separated heavy oil fraction for washing crushed oil waste, which enhances dissolution efficiency and compatibility.

- Implementation of vibrational modes in multiple process steps (crushing, washing, and thermal pyrolysis), which enhances the efficiency of separation and extraction processes.

- Integration of thermal pyrolysis for solid phase residue treatment with subsequent emulsification of pyrolysis gas and/or separated solution to form boiler fuel components, creating a closed-loop waste utilization system.

Environmental Impact Assessment of Petroleum Ether Disposal

The environmental impact of petroleum ether disposal represents a significant concern for industrial operations and waste management systems. Petroleum ether, a volatile hydrocarbon mixture primarily composed of pentanes and hexanes, poses multiple environmental hazards when improperly handled or disposed of. These impacts extend across various environmental compartments including air, water, soil, and biological systems.

Atmospheric contamination occurs through the volatilization of petroleum ether compounds, contributing to the formation of ground-level ozone and photochemical smog when exposed to sunlight and nitrogen oxides. These reactions can impair air quality in surrounding communities, potentially causing respiratory issues and other health concerns for vulnerable populations.

Water systems face particular vulnerability to petroleum ether contamination. When released into aquatic environments, petroleum ether forms a surface film that reduces oxygen transfer and disrupts aquatic ecosystems. Its low water solubility does not prevent toxic components from dissolving and contaminating groundwater resources, potentially affecting drinking water supplies for extended periods.

Soil contamination represents another critical pathway of environmental damage. Petroleum ether can persist in soil matrices, altering soil chemistry and microbial communities essential for ecosystem functioning. This contamination may inhibit plant growth and reduce agricultural productivity in affected areas, creating long-term economic and ecological consequences.

The bioaccumulation potential of certain petroleum ether components presents additional ecological concerns. Through food chain dynamics, these compounds can concentrate in higher trophic levels, potentially affecting predatory species and ecosystem stability. Studies have documented reproductive impairment, developmental abnormalities, and increased mortality rates in various organisms exposed to petroleum ether compounds.

Climate implications must also be considered, as improper disposal contributes to greenhouse gas emissions. The volatile organic compounds in petroleum ether participate in atmospheric reactions that influence climate forcing mechanisms, though their impact is generally less significant than major greenhouse gases like carbon dioxide and methane.

Regulatory frameworks worldwide have established increasingly stringent requirements for petroleum ether handling and disposal. These include mandatory segregation of halogenated and non-halogenated waste streams, specialized containment systems, and treatment technologies designed to minimize environmental release. Advanced treatment methods such as thermal destruction, chemical oxidation, and bioremediation offer varying degrees of effectiveness in mitigating environmental impacts.

Atmospheric contamination occurs through the volatilization of petroleum ether compounds, contributing to the formation of ground-level ozone and photochemical smog when exposed to sunlight and nitrogen oxides. These reactions can impair air quality in surrounding communities, potentially causing respiratory issues and other health concerns for vulnerable populations.

Water systems face particular vulnerability to petroleum ether contamination. When released into aquatic environments, petroleum ether forms a surface film that reduces oxygen transfer and disrupts aquatic ecosystems. Its low water solubility does not prevent toxic components from dissolving and contaminating groundwater resources, potentially affecting drinking water supplies for extended periods.

Soil contamination represents another critical pathway of environmental damage. Petroleum ether can persist in soil matrices, altering soil chemistry and microbial communities essential for ecosystem functioning. This contamination may inhibit plant growth and reduce agricultural productivity in affected areas, creating long-term economic and ecological consequences.

The bioaccumulation potential of certain petroleum ether components presents additional ecological concerns. Through food chain dynamics, these compounds can concentrate in higher trophic levels, potentially affecting predatory species and ecosystem stability. Studies have documented reproductive impairment, developmental abnormalities, and increased mortality rates in various organisms exposed to petroleum ether compounds.

Climate implications must also be considered, as improper disposal contributes to greenhouse gas emissions. The volatile organic compounds in petroleum ether participate in atmospheric reactions that influence climate forcing mechanisms, though their impact is generally less significant than major greenhouse gases like carbon dioxide and methane.

Regulatory frameworks worldwide have established increasingly stringent requirements for petroleum ether handling and disposal. These include mandatory segregation of halogenated and non-halogenated waste streams, specialized containment systems, and treatment technologies designed to minimize environmental release. Advanced treatment methods such as thermal destruction, chemical oxidation, and bioremediation offer varying degrees of effectiveness in mitigating environmental impacts.

Regulatory Compliance Framework for Chemical Waste Handling

The regulatory landscape governing chemical waste handling, particularly for petroleum ether and halogenated/nonhalogenated waste streams, is complex and multifaceted. At the international level, the Basel Convention establishes fundamental principles for transboundary movements of hazardous wastes, requiring informed consent procedures and promoting environmentally sound management practices.

In the United States, the Resource Conservation and Recovery Act (RCRA) serves as the primary regulatory framework, categorizing petroleum ether waste based on characteristics such as ignitability, corrosivity, reactivity, and toxicity. The Environmental Protection Agency (EPA) has established specific waste codes for halogenated solvents (F001-F005), with distinct handling requirements compared to non-halogenated counterparts.

European regulations, particularly the Waste Framework Directive (2008/98/EC) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), implement a more precautionary approach. These frameworks emphasize waste hierarchy principles and extended producer responsibility, requiring detailed documentation of waste streams throughout their lifecycle.

Compliance requirements for petroleum ether waste segregation include mandatory waste determination protocols, proper labeling systems, and specialized storage conditions. Facilities must maintain separate collection systems for halogenated and non-halogenated waste streams to prevent cross-contamination and ensure appropriate treatment pathways.

Documentation and reporting obligations represent a significant compliance burden, with requirements for waste manifests, land disposal restriction notifications, and biennial reporting to regulatory authorities. These records must be maintained for a minimum of three years, though many jurisdictions recommend five-year retention periods.

Training and certification requirements vary by jurisdiction but generally mandate that personnel handling these waste streams receive specialized training in hazard identification, emergency response procedures, and proper segregation techniques. Certification programs often require periodic renewal and continuing education to maintain compliance.

Enforcement mechanisms include routine inspections, substantial financial penalties for non-compliance, and potential criminal liability for knowing violations. Recent regulatory trends indicate increasing scrutiny of waste segregation practices, with particular focus on halogenated/non-halogenated stream separation due to their differing environmental impacts and treatment requirements.

Industry best practices have evolved to exceed minimum regulatory requirements, implementing electronic tracking systems, conducting regular waste audits, and developing comprehensive waste minimization programs that address petroleum ether usage throughout research and manufacturing processes.

In the United States, the Resource Conservation and Recovery Act (RCRA) serves as the primary regulatory framework, categorizing petroleum ether waste based on characteristics such as ignitability, corrosivity, reactivity, and toxicity. The Environmental Protection Agency (EPA) has established specific waste codes for halogenated solvents (F001-F005), with distinct handling requirements compared to non-halogenated counterparts.

European regulations, particularly the Waste Framework Directive (2008/98/EC) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), implement a more precautionary approach. These frameworks emphasize waste hierarchy principles and extended producer responsibility, requiring detailed documentation of waste streams throughout their lifecycle.

Compliance requirements for petroleum ether waste segregation include mandatory waste determination protocols, proper labeling systems, and specialized storage conditions. Facilities must maintain separate collection systems for halogenated and non-halogenated waste streams to prevent cross-contamination and ensure appropriate treatment pathways.

Documentation and reporting obligations represent a significant compliance burden, with requirements for waste manifests, land disposal restriction notifications, and biennial reporting to regulatory authorities. These records must be maintained for a minimum of three years, though many jurisdictions recommend five-year retention periods.

Training and certification requirements vary by jurisdiction but generally mandate that personnel handling these waste streams receive specialized training in hazard identification, emergency response procedures, and proper segregation techniques. Certification programs often require periodic renewal and continuing education to maintain compliance.

Enforcement mechanisms include routine inspections, substantial financial penalties for non-compliance, and potential criminal liability for knowing violations. Recent regulatory trends indicate increasing scrutiny of waste segregation practices, with particular focus on halogenated/non-halogenated stream separation due to their differing environmental impacts and treatment requirements.

Industry best practices have evolved to exceed minimum regulatory requirements, implementing electronic tracking systems, conducting regular waste audits, and developing comprehensive waste minimization programs that address petroleum ether usage throughout research and manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!