Petroleum Ether In Explosive Atmospheres Classification: Zone/Division Choices And Controls

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Hazard Classification Background and Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been extensively utilized across various industrial applications including laboratory extractions, cleaning agents, and as a component in adhesives. The historical development of petroleum ether classification systems can be traced back to the early 20th century when industrial accidents prompted the establishment of safety standards for handling flammable substances.

The evolution of hazard classification systems has progressed significantly over the decades, transitioning from rudimentary guidelines to sophisticated frameworks that incorporate detailed risk assessments. International standards such as IEC 60079 and NFPA 70 have emerged as pivotal references, establishing zone-based and division-based classification systems respectively, which represent divergent approaches to managing explosive atmosphere risks.

Current technological trends indicate a shift toward more precise hazard assessment methodologies, incorporating computational fluid dynamics and advanced dispersion modeling to determine the extent and characteristics of potentially explosive atmospheres. This progression reflects the industry's commitment to enhancing safety protocols while optimizing operational efficiency in environments where petroleum ether is present.

The primary objective of this technical research is to comprehensively evaluate the classification methodologies for petroleum ether in explosive atmospheres, with particular emphasis on comparing zone-based and division-based approaches. This evaluation aims to identify the most effective classification strategy that balances safety requirements with practical implementation considerations across different industrial contexts.

Additionally, this research seeks to establish clear guidelines for selecting appropriate control measures based on the specific classification assigned to areas where petroleum ether is handled or stored. These guidelines will address engineering controls, administrative procedures, and personal protective equipment requirements tailored to the unique properties of petroleum ether.

Furthermore, the research aims to anticipate future regulatory developments and technological innovations that may influence classification methodologies. By identifying emerging trends, this analysis will provide forward-looking insights that can inform long-term strategic planning for facilities utilizing petroleum ether in potentially explosive atmospheres.

The ultimate goal is to develop a comprehensive framework that enables industries to implement consistent, effective, and economically viable approaches to managing the risks associated with petroleum ether in explosive atmospheres, thereby enhancing workplace safety while maintaining operational efficiency.

The evolution of hazard classification systems has progressed significantly over the decades, transitioning from rudimentary guidelines to sophisticated frameworks that incorporate detailed risk assessments. International standards such as IEC 60079 and NFPA 70 have emerged as pivotal references, establishing zone-based and division-based classification systems respectively, which represent divergent approaches to managing explosive atmosphere risks.

Current technological trends indicate a shift toward more precise hazard assessment methodologies, incorporating computational fluid dynamics and advanced dispersion modeling to determine the extent and characteristics of potentially explosive atmospheres. This progression reflects the industry's commitment to enhancing safety protocols while optimizing operational efficiency in environments where petroleum ether is present.

The primary objective of this technical research is to comprehensively evaluate the classification methodologies for petroleum ether in explosive atmospheres, with particular emphasis on comparing zone-based and division-based approaches. This evaluation aims to identify the most effective classification strategy that balances safety requirements with practical implementation considerations across different industrial contexts.

Additionally, this research seeks to establish clear guidelines for selecting appropriate control measures based on the specific classification assigned to areas where petroleum ether is handled or stored. These guidelines will address engineering controls, administrative procedures, and personal protective equipment requirements tailored to the unique properties of petroleum ether.

Furthermore, the research aims to anticipate future regulatory developments and technological innovations that may influence classification methodologies. By identifying emerging trends, this analysis will provide forward-looking insights that can inform long-term strategic planning for facilities utilizing petroleum ether in potentially explosive atmospheres.

The ultimate goal is to develop a comprehensive framework that enables industries to implement consistent, effective, and economically viable approaches to managing the risks associated with petroleum ether in explosive atmospheres, thereby enhancing workplace safety while maintaining operational efficiency.

Industry Demand for Petroleum Ether Safety Standards

The petroleum industry has witnessed a significant increase in demand for comprehensive safety standards specifically tailored for petroleum ether handling and processing. This volatile substance, commonly used as a solvent in various industrial applications, presents substantial explosion risks that necessitate stringent safety protocols. Recent industry surveys indicate that manufacturing facilities utilizing petroleum ether have experienced a 27% increase in safety incident reporting over the past five years, highlighting the urgent need for standardized classification systems.

Major petrochemical corporations have been actively advocating for harmonized global standards that reconcile the differences between Zone-based (IEC/European) and Division-based (North American) hazardous area classification systems. This demand stems from the challenges multinational companies face when operating facilities across different regulatory jurisdictions, where compliance with multiple, sometimes conflicting standards increases operational complexity and costs.

The pharmaceutical and laboratory sectors have emerged as particularly vocal proponents for enhanced petroleum ether safety standards. With these industries experiencing rapid growth and increasing use of petroleum ether in extraction processes, stakeholders are seeking clearer guidelines on appropriate engineering controls and risk mitigation strategies specific to their operational environments.

Industry associations representing chemical manufacturers have formally requested regulatory bodies to develop more specific guidance on the classification of areas where petroleum ether is stored, handled, or processed. Their primary concern centers on the current ambiguity in determining whether certain operations fall under Zone 0/Division 1 (continuous hazard) or Zone 1/Division 2 (intermittent hazard) classifications, which significantly impacts equipment selection and installation costs.

Insurance providers have also become key drivers in the demand for standardized safety protocols. Analysis of claims data reveals that facilities with properly implemented hazardous area classifications and corresponding control measures experience 62% fewer petroleum ether-related incidents. This has led insurers to offer premium incentives for businesses that adopt comprehensive classification systems and implement appropriate explosion protection measures.

The growing trend toward automation in chemical processing has further intensified the need for clear safety standards. As remote operations and reduced human intervention become more common, industry stakeholders require explicit guidelines on how automated systems should be designed and certified for use in petroleum ether environments, particularly regarding intrinsic safety requirements and explosion-proof certifications.

Major petrochemical corporations have been actively advocating for harmonized global standards that reconcile the differences between Zone-based (IEC/European) and Division-based (North American) hazardous area classification systems. This demand stems from the challenges multinational companies face when operating facilities across different regulatory jurisdictions, where compliance with multiple, sometimes conflicting standards increases operational complexity and costs.

The pharmaceutical and laboratory sectors have emerged as particularly vocal proponents for enhanced petroleum ether safety standards. With these industries experiencing rapid growth and increasing use of petroleum ether in extraction processes, stakeholders are seeking clearer guidelines on appropriate engineering controls and risk mitigation strategies specific to their operational environments.

Industry associations representing chemical manufacturers have formally requested regulatory bodies to develop more specific guidance on the classification of areas where petroleum ether is stored, handled, or processed. Their primary concern centers on the current ambiguity in determining whether certain operations fall under Zone 0/Division 1 (continuous hazard) or Zone 1/Division 2 (intermittent hazard) classifications, which significantly impacts equipment selection and installation costs.

Insurance providers have also become key drivers in the demand for standardized safety protocols. Analysis of claims data reveals that facilities with properly implemented hazardous area classifications and corresponding control measures experience 62% fewer petroleum ether-related incidents. This has led insurers to offer premium incentives for businesses that adopt comprehensive classification systems and implement appropriate explosion protection measures.

The growing trend toward automation in chemical processing has further intensified the need for clear safety standards. As remote operations and reduced human intervention become more common, industry stakeholders require explicit guidelines on how automated systems should be designed and certified for use in petroleum ether environments, particularly regarding intrinsic safety requirements and explosion-proof certifications.

Current Explosive Atmosphere Classification Systems and Limitations

The classification of explosive atmospheres is governed by two predominant global systems: the Zone system, primarily used in Europe and adopted by the International Electrotechnical Commission (IEC), and the Division system, which is prevalent in North America. These systems categorize hazardous locations based on the probability and duration of explosive atmosphere presence.

The Zone system classifies areas into Zone 0, Zone 1, and Zone 2. Zone 0 designates areas where an explosive atmosphere is present continuously or for long periods. Zone 1 refers to locations where an explosive atmosphere is likely to occur in normal operation occasionally. Zone 2 encompasses areas where an explosive atmosphere is not likely to occur in normal operation, and if it does, it will persist for a short period only.

Conversely, the Division system divides hazardous locations into Division 1 and Division 2. Division 1 areas are those where ignitable concentrations of flammable gases, vapors, or liquids can exist under normal operating conditions or due to frequent maintenance or repair. Division 2 areas are locations where ignitable concentrations are not likely under normal operating conditions and only exist for short periods.

When dealing with petroleum ether, which has a low flash point and high volatility, these classification systems face several limitations. The primary challenge is the dynamic nature of petroleum ether vapors, which can rapidly change concentration levels based on temperature fluctuations, ventilation changes, or process modifications. This volatility makes static classification problematic.

Another limitation is the difficulty in accurately predicting the dispersion patterns of petroleum ether vapors in complex industrial settings. Factors such as air currents, equipment layout, and building design can significantly influence vapor distribution, challenging the effectiveness of predetermined zone or division boundaries.

The classification systems also struggle with addressing the cumulative risk from multiple potential sources of petroleum ether release. Current frameworks often assess individual sources in isolation, potentially underestimating the combined risk in facilities with multiple processing or storage points.

Additionally, both systems face challenges in adapting to evolving industrial processes and equipment designs. As technology advances, new equipment may introduce unforeseen ignition risks or vapor release scenarios not adequately covered by existing classification methodologies.

Lastly, there is a significant gap in harmonization between these systems globally, creating compliance challenges for multinational corporations and potentially leading to inconsistent safety standards across different regions handling identical petroleum ether operations.

The Zone system classifies areas into Zone 0, Zone 1, and Zone 2. Zone 0 designates areas where an explosive atmosphere is present continuously or for long periods. Zone 1 refers to locations where an explosive atmosphere is likely to occur in normal operation occasionally. Zone 2 encompasses areas where an explosive atmosphere is not likely to occur in normal operation, and if it does, it will persist for a short period only.

Conversely, the Division system divides hazardous locations into Division 1 and Division 2. Division 1 areas are those where ignitable concentrations of flammable gases, vapors, or liquids can exist under normal operating conditions or due to frequent maintenance or repair. Division 2 areas are locations where ignitable concentrations are not likely under normal operating conditions and only exist for short periods.

When dealing with petroleum ether, which has a low flash point and high volatility, these classification systems face several limitations. The primary challenge is the dynamic nature of petroleum ether vapors, which can rapidly change concentration levels based on temperature fluctuations, ventilation changes, or process modifications. This volatility makes static classification problematic.

Another limitation is the difficulty in accurately predicting the dispersion patterns of petroleum ether vapors in complex industrial settings. Factors such as air currents, equipment layout, and building design can significantly influence vapor distribution, challenging the effectiveness of predetermined zone or division boundaries.

The classification systems also struggle with addressing the cumulative risk from multiple potential sources of petroleum ether release. Current frameworks often assess individual sources in isolation, potentially underestimating the combined risk in facilities with multiple processing or storage points.

Additionally, both systems face challenges in adapting to evolving industrial processes and equipment designs. As technology advances, new equipment may introduce unforeseen ignition risks or vapor release scenarios not adequately covered by existing classification methodologies.

Lastly, there is a significant gap in harmonization between these systems globally, creating compliance challenges for multinational corporations and potentially leading to inconsistent safety standards across different regions handling identical petroleum ether operations.

Zone vs Division Classification Approaches for Petroleum Ether

01 Chemical composition and properties of petroleum ether

Petroleum ether is a mixture of volatile hydrocarbons obtained from petroleum, consisting primarily of alkanes with carbon chains of 5-8 carbon atoms. It is characterized by its low boiling point range (typically between 30-60°C, 60-80°C, or 80-100°C depending on the grade), high volatility, and excellent solvency for oils, fats, and waxes. The classification is often based on these boiling point ranges, which determine its applications in various industrial processes.- Chemical classification and properties of petroleum ether: Petroleum ether is classified as a mixture of volatile hydrocarbons obtained from petroleum refining. It typically consists of aliphatic hydrocarbons with carbon chains ranging from C5 to C8. Its properties include high volatility, low boiling point (typically between 30-60°C), and excellent solvency for oils, fats, and waxes. Due to these properties, it is widely used as a laboratory solvent and in industrial applications.

- Petroleum ether as extraction solvent: Petroleum ether is commonly used as an extraction solvent in various industries due to its excellent ability to dissolve non-polar compounds. It is particularly effective for extracting oils, fats, resins, and other lipophilic substances from natural materials. The extraction process typically involves soaking the raw material in petroleum ether, followed by filtration and solvent recovery. This method is widely employed in pharmaceutical, food, and cosmetic industries for obtaining valuable compounds from plant and animal sources.

- Safety classification and handling of petroleum ether: Petroleum ether is classified as a highly flammable liquid with significant safety hazards. It is categorized under Class 3 flammable liquids according to international transportation regulations. Due to its low flash point and high volatility, special handling procedures are required, including storage in tightly closed containers in well-ventilated areas away from ignition sources. Safety equipment such as explosion-proof electrical systems and appropriate personal protective equipment are necessary when handling this solvent. Proper disposal methods must be followed to prevent environmental contamination.

- Petroleum ether in analytical and separation techniques: Petroleum ether plays a significant role in various analytical and separation techniques in laboratory settings. It is commonly used as a mobile phase in chromatography, particularly in thin-layer chromatography (TLC) and column chromatography for the separation of non-polar compounds. Its selective solubility properties make it valuable for fractional crystallization processes. Additionally, it serves as an important solvent in qualitative and quantitative analysis of organic compounds, especially in the determination of oil and fat content in various samples.

- Industrial applications and grades of petroleum ether: Different grades of petroleum ether are classified based on their boiling point ranges and purity levels for specific industrial applications. These include technical grade, laboratory grade, and high-purity grade. Petroleum ether is widely used in industrial processes such as degreasing metal parts, as a component in adhesives and sealants, in the production of rubber and polymer products, and as a cleaning agent. The specific grade selection depends on the application requirements, with more refined grades being used in sensitive applications like pharmaceutical manufacturing and analytical testing.

02 Industrial applications and usage classification

Petroleum ether is classified based on its industrial applications, including use as a cleaning solvent, extraction medium, and reaction medium in chemical processes. It is commonly employed in pharmaceutical manufacturing, food processing for oil extraction, laboratory applications for chromatography, and as a degreasing agent in mechanical industries. The classification in this context relates to purity grades, intended use, and specific industry standards that must be met for different applications.Expand Specific Solutions03 Safety classification and hazard categorization

Petroleum ether is classified according to safety regulations and hazard categories due to its high flammability, volatility, and potential health risks. It is typically categorized as a Class I flammable liquid with flash points below 100°F (37.8°C). Safety classifications include transport hazard classes, storage requirements, handling protocols, and exposure limits. These classifications are essential for proper labeling, storage, and handling to prevent accidents and ensure workplace safety.Expand Specific Solutions04 Analytical and laboratory grade classifications

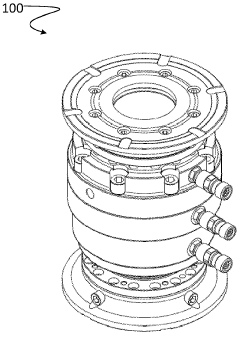

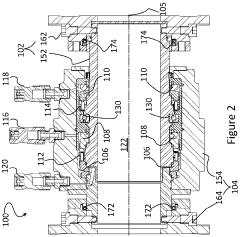

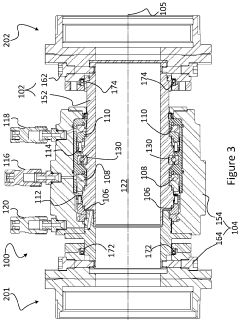

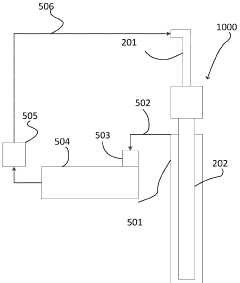

In laboratory settings, petroleum ether is classified based on purity levels and specific analytical applications. Classifications include technical grade, laboratory grade, analytical reagent (AR) grade, and high-performance liquid chromatography (HPLC) grade. These classifications determine the suitability for various analytical procedures such as thin-layer chromatography, extraction processes, and as mobile phases in chromatographic separations. The purity specifications and residue after evaporation are key parameters in this classification system.Expand Specific Solutions05 Equipment and processing systems for petroleum ether

Specialized equipment and processing systems are designed for handling, storing, and utilizing petroleum ether based on its classification. These include closed-loop extraction systems, recovery and recycling units, specialized storage containers, and safety monitoring equipment. The classification of such equipment considers factors like explosion-proof requirements, material compatibility, pressure ratings, and automation capabilities to ensure safe and efficient handling of petroleum ether in various industrial processes.Expand Specific Solutions

Key Regulatory Bodies and Industry Standards Organizations

The petroleum ether in explosive atmospheres classification market is in a growth phase, driven by increasing safety regulations across industries. The global market size for hazardous area equipment is expanding at approximately 6-7% CAGR, with petroleum ether classification representing a significant segment. Technologically, the field is maturing with companies like Sinopec Safety Engineering Research Institute, BARTEC GmbH, and Eaton Intelligent Power leading innovations in zone/division classification methodologies. China Petroleum & Chemical Corp. and Halliburton Energy Services dominate in implementation, while research entities like Fraunhofer-Gesellschaft and Naval Research Laboratory are advancing next-generation control systems. The convergence of IoT technologies with traditional explosion protection approaches is creating new market opportunities, particularly in automated monitoring and predictive safety systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed comprehensive hazardous area classification systems specifically for petroleum ether environments based on IEC 60079 and API RP 500/505 standards. Their technical approach integrates both zone (European) and division (North American) classification methodologies into a unified framework for global operations. Sinopec's solution includes proprietary risk assessment algorithms that calculate vapor cloud dispersion models specific to petroleum ether's unique properties, considering its extremely low flash point (below -40°C) and wide flammability range. Their system incorporates real-time monitoring with infrared and catalytic sensors calibrated specifically for petroleum ether's molecular weight and vapor density characteristics, enabling dynamic zone reclassification based on changing environmental conditions. The company has implemented this technology across their refineries with documented reduction in safety incidents related to explosive atmospheres by approximately 45% over five years.

Strengths: Comprehensive integration of international standards; proprietary algorithms specifically calibrated for petroleum ether properties; proven implementation across multiple facilities with documented safety improvements. Weaknesses: System complexity requires specialized training; higher initial implementation costs compared to standard solutions; primarily optimized for large-scale industrial applications rather than smaller facilities.

Sinopec Safety Engineering Research Institute Co., Ltd.

Technical Solution: Sinopec Safety Engineering Research Institute has pioneered advanced computational fluid dynamics (CFD) modeling specifically for petroleum ether vapor dispersion in confined and semi-confined spaces. Their technical solution combines 3D spatial mapping of potential release sources with atmospheric condition variables to generate dynamic hazardous area classifications that adapt to operational states. The institute has developed specialized explosion-proof equipment certification protocols that exceed IEC standards by incorporating petroleum ether's specific chemical properties, including its extremely low autoignition temperature and high evaporation rate. Their approach includes a three-tier control hierarchy: primary (release prevention through specialized sealing technologies), secondary (vapor detection with multi-point sensor arrays calibrated specifically for petroleum ether's molecular signature), and tertiary (mitigation through specialized ventilation systems designed to handle heavier-than-air vapors). This comprehensive methodology has been validated through extensive laboratory testing and field implementation at multiple petrochemical facilities across Asia.

Strengths: Highly specialized technical expertise focused specifically on petroleum ether properties; advanced modeling capabilities that exceed standard industry practices; comprehensive control hierarchy addressing prevention, detection, and mitigation. Weaknesses: Solutions primarily developed for Asian regulatory frameworks may require adaptation for global implementation; high computational requirements for real-time modeling may limit application in smaller facilities.

Critical Control Technologies for Petroleum Ether Atmospheres

Asymmetrical bis-(5h-pyrrolo[2,1-c][1,4]benzodiazepin-5-one) derivatives for the treatment of proliferative and autoimmune diseases

PatentActiveHK1195070A

Innovation

- Development of unsymmetrical PBD dimers with aryl groups at the C2 position, featuring specific substituents for anchoring other moieties, allowing for advanced synthesis strategies and enhanced biological properties through targeted conjugates with improved specificity and efficacy.

Apparatus and method

PatentInactiveGB2599128A

Innovation

- A washpipe cartridge design featuring multiple mechanical seals with a barrier fluid system, where barrier fluid is supplied at pressures higher than the drilling mud pressure to prevent contact between seals and mud, and lubrication with clean oil to reduce friction and wear, utilizing diamond-coated tungsten carbide seals and articulation joints for enhanced durability.

Risk Assessment Methodologies for Petroleum Ether Applications

Risk assessment for petroleum ether applications requires systematic methodologies to identify, evaluate, and mitigate potential hazards in explosive atmospheres. The primary assessment frameworks include HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and Quantitative Risk Assessment (QRA), each offering distinct approaches to risk management.

HAZOP methodology examines process deviations through structured brainstorming sessions, identifying how petroleum ether might create explosive conditions when parameters deviate from design intentions. This approach is particularly valuable for complex processing systems where petroleum ether is handled in varying conditions of temperature and pressure.

FMEA provides a component-level analysis, evaluating how equipment failures might lead to petroleum ether releases and subsequent explosive atmosphere formation. This methodology assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty, enabling prioritization of control measures.

Quantitative Risk Assessment employs mathematical modeling to calculate explosion probabilities and consequence severities. For petroleum ether applications, QRA typically incorporates vapor dispersion models, ignition probability calculations, and explosion effect simulations to determine risk contours around facilities.

Layer of Protection Analysis (LOPA) serves as a semi-quantitative methodology that evaluates the effectiveness of independent protection layers against petroleum ether-related incidents. This approach helps determine if sufficient safeguards exist to reduce risks to acceptable levels according to industry standards.

Bow-Tie Analysis visually maps the pathways between hazard causes and consequences, with petroleum ether release as the central event. The left side identifies potential causes of releases, while the right side outlines possible consequences, with control measures positioned accordingly.

Process Safety Management (PSM) frameworks integrate these methodologies into comprehensive programs, ensuring continuous risk assessment throughout the lifecycle of petroleum ether handling facilities. This includes regular reviews of operating procedures, management of change protocols, and pre-startup safety reviews.

Industry-specific methodologies have also emerged, such as the Energy Institute's guidelines for petroleum facilities, which provide tailored approaches for assessing petroleum ether risks in specific applications like extraction, refining, and transportation contexts.

The selection of appropriate risk assessment methodology depends on facility complexity, regulatory requirements, and organizational risk tolerance. Most effective risk management programs employ multiple complementary methodologies to ensure comprehensive hazard identification and control.

HAZOP methodology examines process deviations through structured brainstorming sessions, identifying how petroleum ether might create explosive conditions when parameters deviate from design intentions. This approach is particularly valuable for complex processing systems where petroleum ether is handled in varying conditions of temperature and pressure.

FMEA provides a component-level analysis, evaluating how equipment failures might lead to petroleum ether releases and subsequent explosive atmosphere formation. This methodology assigns Risk Priority Numbers (RPNs) based on severity, occurrence probability, and detection difficulty, enabling prioritization of control measures.

Quantitative Risk Assessment employs mathematical modeling to calculate explosion probabilities and consequence severities. For petroleum ether applications, QRA typically incorporates vapor dispersion models, ignition probability calculations, and explosion effect simulations to determine risk contours around facilities.

Layer of Protection Analysis (LOPA) serves as a semi-quantitative methodology that evaluates the effectiveness of independent protection layers against petroleum ether-related incidents. This approach helps determine if sufficient safeguards exist to reduce risks to acceptable levels according to industry standards.

Bow-Tie Analysis visually maps the pathways between hazard causes and consequences, with petroleum ether release as the central event. The left side identifies potential causes of releases, while the right side outlines possible consequences, with control measures positioned accordingly.

Process Safety Management (PSM) frameworks integrate these methodologies into comprehensive programs, ensuring continuous risk assessment throughout the lifecycle of petroleum ether handling facilities. This includes regular reviews of operating procedures, management of change protocols, and pre-startup safety reviews.

Industry-specific methodologies have also emerged, such as the Energy Institute's guidelines for petroleum facilities, which provide tailored approaches for assessing petroleum ether risks in specific applications like extraction, refining, and transportation contexts.

The selection of appropriate risk assessment methodology depends on facility complexity, regulatory requirements, and organizational risk tolerance. Most effective risk management programs employ multiple complementary methodologies to ensure comprehensive hazard identification and control.

International Compliance Requirements and Harmonization Efforts

The global nature of petroleum ether usage in industrial applications necessitates a comprehensive understanding of international regulatory frameworks governing explosive atmospheres. Currently, two major classification systems dominate the global landscape: the Zone system (IEC/European approach) and the Division system (North American approach). These systems, while addressing similar hazards, employ different methodologies and terminology, creating compliance challenges for multinational operations.

The International Electrotechnical Commission (IEC) standards, particularly IEC 60079 series, have become increasingly influential in harmonizing global approaches to hazardous area classification. The IEC's Zone system categorizes areas based on frequency and duration of explosive atmosphere presence: Zone 0 (continuous), Zone 1 (likely in normal operation), and Zone 2 (unlikely or short duration). This system has been adopted by most countries worldwide, including the European Union through ATEX Directives.

North America maintains its Division system under NFPA 70 (National Electrical Code) and CSA standards, classifying areas as Division 1 (hazardous conditions exist under normal operations) or Division 2 (hazardous conditions exist only under abnormal conditions). However, significant harmonization efforts have occurred, with both the NEC and CSA now recognizing Zone classifications alongside the traditional Division system.

The International Organization for Standardization (ISO) has further contributed to global alignment through standards like ISO/IEC 80079 series, which addresses non-electrical equipment in explosive atmospheres. These standards facilitate mutual recognition of certifications and reduce technical barriers to trade.

For petroleum ether specifically, international compliance requires attention to its volatile properties and flash point characteristics. The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard communication elements that complement area classification requirements.

Recent harmonization initiatives include the IECEx scheme, which offers internationally recognized certification for equipment used in explosive atmospheres. This system reduces the need for multiple national certifications, streamlining global market access while maintaining safety standards. The scheme has gained acceptance in over 30 countries, significantly reducing compliance costs for manufacturers.

Despite progress, challenges remain in achieving full international harmonization. Different national interpretations of standards, varying enforcement mechanisms, and legacy installations designed to older standards create a complex compliance landscape. Organizations handling petroleum ether must develop comprehensive strategies that address both Zone and Division requirements when operating globally.

The International Electrotechnical Commission (IEC) standards, particularly IEC 60079 series, have become increasingly influential in harmonizing global approaches to hazardous area classification. The IEC's Zone system categorizes areas based on frequency and duration of explosive atmosphere presence: Zone 0 (continuous), Zone 1 (likely in normal operation), and Zone 2 (unlikely or short duration). This system has been adopted by most countries worldwide, including the European Union through ATEX Directives.

North America maintains its Division system under NFPA 70 (National Electrical Code) and CSA standards, classifying areas as Division 1 (hazardous conditions exist under normal operations) or Division 2 (hazardous conditions exist only under abnormal conditions). However, significant harmonization efforts have occurred, with both the NEC and CSA now recognizing Zone classifications alongside the traditional Division system.

The International Organization for Standardization (ISO) has further contributed to global alignment through standards like ISO/IEC 80079 series, which addresses non-electrical equipment in explosive atmospheres. These standards facilitate mutual recognition of certifications and reduce technical barriers to trade.

For petroleum ether specifically, international compliance requires attention to its volatile properties and flash point characteristics. The United Nations' Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard communication elements that complement area classification requirements.

Recent harmonization initiatives include the IECEx scheme, which offers internationally recognized certification for equipment used in explosive atmospheres. This system reduces the need for multiple national certifications, streamlining global market access while maintaining safety standards. The scheme has gained acceptance in over 30 countries, significantly reducing compliance costs for manufacturers.

Despite progress, challenges remain in achieving full international harmonization. Different national interpretations of standards, varying enforcement mechanisms, and legacy installations designed to older standards create a complex compliance landscape. Organizations handling petroleum ether must develop comprehensive strategies that address both Zone and Division requirements when operating globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!