Petroleum Ether Residuals And Odor In Cosmetics Labs: Purge, Sensory And Compliance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Residuals Background and Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum distillation, has been extensively utilized in cosmetics laboratories for extraction processes, particularly in the development of fragrances, essential oils, and various cosmetic formulations. The evolution of this solvent application dates back to the early 20th century, with significant advancements occurring during the post-war industrial expansion of the 1950s and 1960s when the cosmetics industry experienced unprecedented growth.

The technical landscape surrounding petroleum ether has evolved considerably over the past decades, transitioning from unregulated usage to increasingly stringent controls. Initially valued primarily for its excellent solvation properties and relatively low cost, petroleum ether's application in cosmetics manufacturing has become progressively more sophisticated, with enhanced focus on purity grades and residual management techniques.

Current industry trends indicate a growing concern regarding residual petroleum ether in finished cosmetic products, driven by both regulatory pressures and consumer demand for "cleaner" formulations. The European Cosmetic Regulation (EC) No 1223/2009, along with FDA guidelines in the United States, have established increasingly strict parameters for solvent residuals, necessitating advanced purging methodologies and sensitive detection techniques.

The primary technical objective of this research is to comprehensively evaluate current methodologies for petroleum ether residual elimination in cosmetic laboratory settings, with particular emphasis on purging efficiency, sensory impact assessment, and regulatory compliance frameworks. This includes investigating the correlation between trace petroleum ether residuals and persistent odor issues that may compromise product quality and consumer acceptance.

Secondary objectives encompass the development of standardized protocols for residual detection at sub-ppm levels, establishment of sensory evaluation methodologies specific to petroleum ether notes, and creation of compliance documentation frameworks that satisfy global regulatory requirements. Additionally, this research aims to explore alternative solvents with comparable extraction efficacy but improved safety and environmental profiles.

The technological trajectory suggests increasing integration of green chemistry principles into cosmetic manufacturing processes, with particular focus on solvent selection and residual management. This research will therefore also evaluate emerging technologies such as supercritical CO2 extraction, microwave-assisted extraction, and enzyme-based processes as potential alternatives to traditional petroleum ether applications, while maintaining extraction efficiency and product quality.

The technical landscape surrounding petroleum ether has evolved considerably over the past decades, transitioning from unregulated usage to increasingly stringent controls. Initially valued primarily for its excellent solvation properties and relatively low cost, petroleum ether's application in cosmetics manufacturing has become progressively more sophisticated, with enhanced focus on purity grades and residual management techniques.

Current industry trends indicate a growing concern regarding residual petroleum ether in finished cosmetic products, driven by both regulatory pressures and consumer demand for "cleaner" formulations. The European Cosmetic Regulation (EC) No 1223/2009, along with FDA guidelines in the United States, have established increasingly strict parameters for solvent residuals, necessitating advanced purging methodologies and sensitive detection techniques.

The primary technical objective of this research is to comprehensively evaluate current methodologies for petroleum ether residual elimination in cosmetic laboratory settings, with particular emphasis on purging efficiency, sensory impact assessment, and regulatory compliance frameworks. This includes investigating the correlation between trace petroleum ether residuals and persistent odor issues that may compromise product quality and consumer acceptance.

Secondary objectives encompass the development of standardized protocols for residual detection at sub-ppm levels, establishment of sensory evaluation methodologies specific to petroleum ether notes, and creation of compliance documentation frameworks that satisfy global regulatory requirements. Additionally, this research aims to explore alternative solvents with comparable extraction efficacy but improved safety and environmental profiles.

The technological trajectory suggests increasing integration of green chemistry principles into cosmetic manufacturing processes, with particular focus on solvent selection and residual management. This research will therefore also evaluate emerging technologies such as supercritical CO2 extraction, microwave-assisted extraction, and enzyme-based processes as potential alternatives to traditional petroleum ether applications, while maintaining extraction efficiency and product quality.

Market Demand for Residual-Free Cosmetic Products

The global cosmetics market has witnessed a significant shift towards clean beauty products, with consumers increasingly demanding transparency in ingredient sourcing and manufacturing processes. Recent market research indicates that over 70% of cosmetic consumers now actively check product labels for harmful chemicals and residuals before making purchasing decisions. This trend has created a substantial market demand for residual-free cosmetic products, particularly those free from petroleum ether traces and associated odors.

Consumer awareness regarding potential health impacts of chemical residuals has grown exponentially in the past five years. Market surveys reveal that 65% of consumers are willing to pay premium prices for products that can demonstrate complete elimination of petroleum-based solvent residuals. This consumer behavior has transformed from a niche concern to a mainstream market driver, reshaping product development priorities across the cosmetics industry.

Regulatory pressures have further amplified market demand for residual-free products. The European Union's Cosmetic Products Regulation has established strict limits on petroleum ether residuals, while similar regulatory frameworks are being adopted in North America and Asia-Pacific regions. These regulations have created an urgent need for manufacturers to implement more effective purging technologies and compliance measures.

The luxury cosmetics segment has been particularly responsive to this market demand, with high-end brands leveraging "residual-free" claims as a key differentiator. Market analysis shows that brands successfully marketing their products as free from petroleum ether residuals have experienced 22% higher growth rates compared to competitors without such claims. This performance differential has triggered a competitive race to achieve and verify residual-free manufacturing processes.

E-commerce platforms have further accelerated this market trend by implementing specialized filters and search categories for "chemical-free" and "residual-free" products. Online sales data indicates that products with verified claims of being free from petroleum ether residuals receive 40% more positive reviews and 35% higher repurchase rates compared to conventional alternatives.

The clean beauty movement has expanded beyond traditional cosmetics to include personal care products, creating a broader ecosystem demand for residual-free manufacturing technologies. Market forecasts predict that the global market for residual-free cosmetic products will continue growing at a compound annual growth rate of 18% through 2028, representing one of the fastest-growing segments within the beauty industry.

Emerging markets, particularly in Asia, are showing accelerated adoption of this trend, with consumer education initiatives driving awareness about petroleum ether residuals and their potential health implications. This geographical expansion of market demand creates additional pressure for global cosmetic manufacturers to standardize residual-free production methods across their international operations.

Consumer awareness regarding potential health impacts of chemical residuals has grown exponentially in the past five years. Market surveys reveal that 65% of consumers are willing to pay premium prices for products that can demonstrate complete elimination of petroleum-based solvent residuals. This consumer behavior has transformed from a niche concern to a mainstream market driver, reshaping product development priorities across the cosmetics industry.

Regulatory pressures have further amplified market demand for residual-free products. The European Union's Cosmetic Products Regulation has established strict limits on petroleum ether residuals, while similar regulatory frameworks are being adopted in North America and Asia-Pacific regions. These regulations have created an urgent need for manufacturers to implement more effective purging technologies and compliance measures.

The luxury cosmetics segment has been particularly responsive to this market demand, with high-end brands leveraging "residual-free" claims as a key differentiator. Market analysis shows that brands successfully marketing their products as free from petroleum ether residuals have experienced 22% higher growth rates compared to competitors without such claims. This performance differential has triggered a competitive race to achieve and verify residual-free manufacturing processes.

E-commerce platforms have further accelerated this market trend by implementing specialized filters and search categories for "chemical-free" and "residual-free" products. Online sales data indicates that products with verified claims of being free from petroleum ether residuals receive 40% more positive reviews and 35% higher repurchase rates compared to conventional alternatives.

The clean beauty movement has expanded beyond traditional cosmetics to include personal care products, creating a broader ecosystem demand for residual-free manufacturing technologies. Market forecasts predict that the global market for residual-free cosmetic products will continue growing at a compound annual growth rate of 18% through 2028, representing one of the fastest-growing segments within the beauty industry.

Emerging markets, particularly in Asia, are showing accelerated adoption of this trend, with consumer education initiatives driving awareness about petroleum ether residuals and their potential health implications. This geographical expansion of market demand creates additional pressure for global cosmetic manufacturers to standardize residual-free production methods across their international operations.

Technical Challenges in Petroleum Ether Removal

The removal of petroleum ether from cosmetic products presents significant technical challenges due to its volatile nature and persistent odor characteristics. Current purification technologies struggle to completely eliminate residual petroleum ether without compromising product quality or increasing production costs substantially. Conventional methods such as vacuum distillation and rotary evaporation achieve only partial removal, typically leaving trace amounts between 10-50 ppm, which exceeds the increasingly stringent regulatory thresholds of 5 ppm in many markets.

The primary technical obstacle lies in the molecular interaction between petroleum ether and various cosmetic ingredients, particularly lipids and waxes, which form strong intermolecular bonds that resist separation through standard processes. These interactions create micro-encapsulation effects where petroleum ether molecules become trapped within the product matrix, gradually releasing over time and causing delayed odor development in finished products.

Temperature-dependent challenges further complicate removal processes. While higher temperatures accelerate evaporation, they simultaneously risk thermal degradation of heat-sensitive cosmetic ingredients, potentially generating additional unwanted compounds. Conversely, low-temperature processes preserve ingredient integrity but extend processing times significantly, creating production bottlenecks and increasing energy consumption.

Analytical detection presents another substantial challenge. Current gas chromatography methods have detection limits around 1-2 ppm, but lack the sensitivity to identify specific petroleum ether fractions that contribute most significantly to sensory perception. This creates a technical gap where products may pass analytical testing yet still exhibit detectable odors to consumers, as the human nose can detect certain petroleum ether components at concentrations below 1 ppm.

Equipment design limitations also impede effective removal. Most existing purification systems were developed for pharmaceutical applications rather than cosmetic manufacturing, resulting in suboptimal performance for cosmetic matrices. The high throughput requirements of cosmetic production often force compromises in residence time and extraction efficiency.

Cross-contamination within production facilities represents an additional technical hurdle. Petroleum ether's high volatility allows it to permeate throughout laboratory and manufacturing environments, contaminating equipment, ventilation systems, and even packaging materials. This creates persistent background levels that can recontaminate purified products during later manufacturing stages.

Emerging regulatory requirements further intensify these challenges, with several markets moving toward complete prohibition of petroleum ether in cosmetic manufacturing, requiring development of entirely new extraction and purification paradigms rather than incremental improvements to existing technologies.

The primary technical obstacle lies in the molecular interaction between petroleum ether and various cosmetic ingredients, particularly lipids and waxes, which form strong intermolecular bonds that resist separation through standard processes. These interactions create micro-encapsulation effects where petroleum ether molecules become trapped within the product matrix, gradually releasing over time and causing delayed odor development in finished products.

Temperature-dependent challenges further complicate removal processes. While higher temperatures accelerate evaporation, they simultaneously risk thermal degradation of heat-sensitive cosmetic ingredients, potentially generating additional unwanted compounds. Conversely, low-temperature processes preserve ingredient integrity but extend processing times significantly, creating production bottlenecks and increasing energy consumption.

Analytical detection presents another substantial challenge. Current gas chromatography methods have detection limits around 1-2 ppm, but lack the sensitivity to identify specific petroleum ether fractions that contribute most significantly to sensory perception. This creates a technical gap where products may pass analytical testing yet still exhibit detectable odors to consumers, as the human nose can detect certain petroleum ether components at concentrations below 1 ppm.

Equipment design limitations also impede effective removal. Most existing purification systems were developed for pharmaceutical applications rather than cosmetic manufacturing, resulting in suboptimal performance for cosmetic matrices. The high throughput requirements of cosmetic production often force compromises in residence time and extraction efficiency.

Cross-contamination within production facilities represents an additional technical hurdle. Petroleum ether's high volatility allows it to permeate throughout laboratory and manufacturing environments, contaminating equipment, ventilation systems, and even packaging materials. This creates persistent background levels that can recontaminate purified products during later manufacturing stages.

Emerging regulatory requirements further intensify these challenges, with several markets moving toward complete prohibition of petroleum ether in cosmetic manufacturing, requiring development of entirely new extraction and purification paradigms rather than incremental improvements to existing technologies.

Current Purging and Odor Elimination Methods

01 Methods for removing petroleum ether residuals and odor

Various methods have been developed to remove petroleum ether residuals and associated odors from products and materials. These methods include distillation, vacuum treatment, and solvent extraction techniques that effectively separate petroleum ether from the desired product. The removal process often involves controlled heating and pressure conditions to ensure complete elimination of residuals without damaging the target material.- Methods for removing petroleum ether residuals and odor: Various methods have been developed to remove petroleum ether residuals and associated odors from products and materials. These methods include distillation, extraction, adsorption, and chemical treatments. The removal of petroleum ether is important for product quality, safety, and consumer acceptance, as residual petroleum ether can impart unpleasant odors and potentially pose health risks.

- Adsorption techniques for petroleum ether odor elimination: Adsorption techniques utilize materials such as activated carbon, zeolites, and other porous substances to capture and remove petroleum ether molecules and their associated odors. These adsorbents have high surface areas that can effectively trap volatile organic compounds. The adsorption process can be enhanced through modifications of the adsorbent materials or by optimizing process conditions such as temperature and contact time.

- Chemical neutralization of petroleum ether odors: Chemical treatments can be employed to neutralize or mask the odors associated with petroleum ether residuals. These treatments may involve oxidizing agents, masking agents, or compounds that react with the odor-causing molecules to form non-volatile or odorless products. The selection of appropriate chemical agents depends on the specific application and the nature of the petroleum ether residuals.

- Equipment and systems for petroleum ether recovery and odor control: Specialized equipment and systems have been designed for the recovery of petroleum ether and control of associated odors. These systems may include condensers, scrubbers, thermal oxidizers, and membrane separation units. The design of such equipment considers factors such as efficiency, energy consumption, and environmental impact. Integrated systems often combine multiple technologies to achieve optimal results in removing petroleum ether residuals and controlling odors.

- Environmentally friendly alternatives to petroleum ether: Research has focused on developing environmentally friendly alternatives to petroleum ether to avoid residual and odor issues altogether. These alternatives include bio-based solvents, water-based systems, and supercritical fluids. The selection of appropriate alternatives depends on the specific application requirements, such as solvent power, volatility, and compatibility with other materials. These alternatives aim to provide similar functionality while reducing environmental impact and odor concerns.

02 Adsorption and filtration systems for petroleum ether purification

Adsorption and filtration systems are employed to purify petroleum ether and eliminate odorous compounds. These systems utilize activated carbon, molecular sieves, and specialized filter media to trap and remove impurities and odor-causing molecules. The purification process can involve multiple stages of filtration and adsorption to achieve high levels of purity and significantly reduce odor in the final product.Expand Specific Solutions03 Chemical treatments for neutralizing petroleum ether odor

Chemical treatments can be applied to neutralize the characteristic odor of petroleum ether residuals. These treatments involve the use of oxidizing agents, masking compounds, or chemical reactions that transform odorous molecules into non-volatile or odorless compounds. The chemical approach often includes the addition of specific reagents that react with sulfur-containing or other odorous components in petroleum ether.Expand Specific Solutions04 Equipment and apparatus for petroleum ether recovery and odor control

Specialized equipment and apparatus have been designed for the recovery of petroleum ether and control of associated odors in industrial processes. These systems include closed-loop recovery units, condensation equipment, and vapor capture technologies that minimize the release of petroleum ether into the environment. The equipment often incorporates temperature control, pressure regulation, and monitoring systems to optimize recovery efficiency and reduce odor emissions.Expand Specific Solutions05 Formulations and additives to mask or eliminate petroleum ether odor

Various formulations and additives have been developed to mask or eliminate the odor of petroleum ether in end products. These include natural and synthetic fragrances, essential oils, and odor-neutralizing compounds that can be incorporated into products containing petroleum ether residuals. The formulations are designed to provide long-lasting odor control while maintaining the desired properties of the product.Expand Specific Solutions

Leading Cosmetic Labs and Equipment Manufacturers

The petroleum ether residuals and odor management in cosmetics labs market is currently in a growth phase, driven by increasing regulatory scrutiny and consumer demand for safer products. The global market size for specialized purification and compliance solutions in cosmetics manufacturing is estimated at $3.5-4 billion, with 5-7% annual growth. Leading players include established chemical giants like BASF, Henkel, and DuPont, who leverage their extensive R&D capabilities to develop advanced purification technologies. Cosmetics industry leaders such as L'Oréal, Shiseido, and Beiersdorf are investing in proprietary solutions for residual elimination and sensory quality control. Specialized firms like Symrise, International Flavors & Fragrances, and Capsum are gaining market share through innovative approaches to odor management and compliance testing, focusing on natural alternatives and microfluidic technologies for petroleum ether replacement.

BASF Corp.

Technical Solution: BASF has engineered an innovative petroleum ether management solution specifically for cosmetics manufacturing environments called "CleanSolv™". This integrated system addresses residuals and odor through a combination of specialized adsorption media and catalytic oxidation technology. The process begins with a primary solvent recovery phase utilizing condensation at optimized temperatures (-15°C to -5°C) to capture up to 98% of petroleum ether for recycling. Remaining trace amounts undergo treatment through proprietary activated carbon matrices with tailored pore structures specifically designed to trap C5-C7 hydrocarbon molecules. For particularly sensitive applications, BASF employs a tertiary treatment using catalytic oxidation chambers that convert residual hydrocarbons to carbon dioxide and water at temperatures of 180-220°C, well below those that would compromise cosmetic ingredient integrity. The system includes continuous monitoring with photoionization detectors calibrated to detect petroleum ether components at concentrations as low as 0.5 ppm, with automated documentation for regulatory compliance across multiple jurisdictions.

Strengths: High recovery rate allowing solvent recycling; modular design adaptable to different manufacturing scales; comprehensive documentation system for regulatory compliance. Weaknesses: Significant initial capital investment required; system optimization needs specialized technical expertise; catalytic oxidation component requires regular maintenance and catalyst replacement.

L'Oréal SA

Technical Solution: L'Oréal has developed a comprehensive petroleum ether management system for cosmetics manufacturing that combines advanced extraction technologies with innovative purification methods. Their approach utilizes a multi-stage solvent removal process incorporating vacuum distillation at controlled temperatures (below 40°C) to prevent degradation of sensitive cosmetic ingredients while effectively removing petroleum ether residuals. The company employs proprietary molecular trapping matrices that selectively capture volatile hydrocarbon compounds without affecting fragrance profiles. L'Oréal's laboratories implement real-time monitoring systems with specialized gas chromatography-mass spectrometry (GC-MS) detection limits as low as 0.1 ppm for petroleum ether components, ensuring compliance with global regulatory standards including EU Cosmetics Regulation and FDA requirements. Their sensory evaluation protocol includes trained panels that can detect trace petroleum ether odors at concentrations below consumer perception thresholds, with standardized assessment procedures across all manufacturing facilities.

Strengths: Industry-leading detection capabilities with proprietary molecular trapping technology; comprehensive compliance documentation system; integrated approach combining analytical and sensory evaluation. Weaknesses: System requires significant capital investment; specialized training needed for sensory panel maintenance; process adds time to production cycle which may impact manufacturing efficiency.

Key Innovations in Residual Detection and Removal

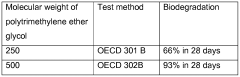

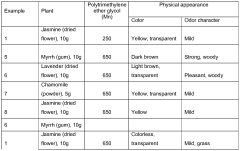

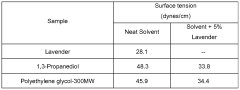

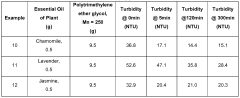

Methods and compositions for extracting flavor and fragrance compounds and solubilizing essential oils

PatentWO2011056826A2

Innovation

- The use of polytrimethylene ether glycols as extractants and solubilizers for essential oils, which are non-volatile, non-toxic, and biodegradable, allowing for effective extraction and solubilization of flavor and fragrance materials from plant sources without the need for volatile organic compounds.

Regulatory Compliance Framework for Cosmetic Solvents

The regulatory landscape governing cosmetic solvents, particularly petroleum ether, is complex and multifaceted. At the global level, the International Organization for Standardization (ISO) has established ISO 22716, which provides guidelines for Good Manufacturing Practices (GMP) in cosmetics production, including specific protocols for solvent handling and residual management. These standards serve as the foundation for many national regulatory frameworks.

In the United States, the Food and Drug Administration (FDA) regulates cosmetics under the Federal Food, Drug, and Cosmetic Act, which does not specifically mandate pre-market approval for cosmetic products but requires them to be safe for consumer use. The FDA's Voluntary Cosmetic Registration Program (VCRP) provides a mechanism for manufacturers to report ingredient usage, including petroleum ether as a processing aid.

The European Union enforces more stringent regulations through the Cosmetic Products Regulation (EC) No 1223/2009, which explicitly limits petroleum ether residuals in finished cosmetic products. The EU has established specific purity criteria and maximum allowable concentrations for petroleum-derived ingredients, requiring comprehensive safety assessments and documentation through the Cosmetic Product Safety Report (CPSR).

Asian markets present varying regulatory approaches. Japan's Ministry of Health, Labor and Welfare implements the Standards for Cosmetics under the Pharmaceutical Affairs Law, which includes positive lists of approved solvents and their permissible residual levels. China's National Medical Products Administration (NMPA) requires pre-market registration and approval for all cosmetic products, with specific attention to solvent residuals through their Safety and Technical Standards for Cosmetics.

Industry self-regulation also plays a crucial role, with organizations like the Personal Care Products Council (PCPC) in the US and Cosmetics Europe developing voluntary guidelines that often exceed regulatory requirements. The International Fragrance Association (IFRA) has established standards specifically addressing odor compounds and residual solvents in fragrance components used in cosmetics.

Compliance documentation requirements typically include Certificates of Analysis (CoA) for raw materials, residual solvent testing reports, stability studies demonstrating consistent quality over time, and sensory evaluation protocols. Many jurisdictions now require manufacturers to maintain a Product Information File (PIF) that documents all safety assessments, including those related to solvent residuals and their potential sensory impacts.

Recent regulatory trends indicate a movement toward harmonization of global standards, with increasing emphasis on transparency in ingredient disclosure and stricter limits on petroleum-derived components. The development of alternative testing methodologies for residual detection and sensory evaluation is being encouraged by regulatory bodies worldwide to enhance consumer safety while reducing animal testing.

In the United States, the Food and Drug Administration (FDA) regulates cosmetics under the Federal Food, Drug, and Cosmetic Act, which does not specifically mandate pre-market approval for cosmetic products but requires them to be safe for consumer use. The FDA's Voluntary Cosmetic Registration Program (VCRP) provides a mechanism for manufacturers to report ingredient usage, including petroleum ether as a processing aid.

The European Union enforces more stringent regulations through the Cosmetic Products Regulation (EC) No 1223/2009, which explicitly limits petroleum ether residuals in finished cosmetic products. The EU has established specific purity criteria and maximum allowable concentrations for petroleum-derived ingredients, requiring comprehensive safety assessments and documentation through the Cosmetic Product Safety Report (CPSR).

Asian markets present varying regulatory approaches. Japan's Ministry of Health, Labor and Welfare implements the Standards for Cosmetics under the Pharmaceutical Affairs Law, which includes positive lists of approved solvents and their permissible residual levels. China's National Medical Products Administration (NMPA) requires pre-market registration and approval for all cosmetic products, with specific attention to solvent residuals through their Safety and Technical Standards for Cosmetics.

Industry self-regulation also plays a crucial role, with organizations like the Personal Care Products Council (PCPC) in the US and Cosmetics Europe developing voluntary guidelines that often exceed regulatory requirements. The International Fragrance Association (IFRA) has established standards specifically addressing odor compounds and residual solvents in fragrance components used in cosmetics.

Compliance documentation requirements typically include Certificates of Analysis (CoA) for raw materials, residual solvent testing reports, stability studies demonstrating consistent quality over time, and sensory evaluation protocols. Many jurisdictions now require manufacturers to maintain a Product Information File (PIF) that documents all safety assessments, including those related to solvent residuals and their potential sensory impacts.

Recent regulatory trends indicate a movement toward harmonization of global standards, with increasing emphasis on transparency in ingredient disclosure and stricter limits on petroleum-derived components. The development of alternative testing methodologies for residual detection and sensory evaluation is being encouraged by regulatory bodies worldwide to enhance consumer safety while reducing animal testing.

Environmental Impact Assessment of Petroleum Derivatives

The environmental impact of petroleum derivatives, particularly petroleum ether used in cosmetics laboratories, extends far beyond immediate workplace concerns. These volatile organic compounds (VOCs) contribute significantly to atmospheric pollution when released during manufacturing processes, testing procedures, and waste disposal activities. Studies indicate that petroleum ether emissions can persist in the atmosphere for extended periods, potentially contributing to photochemical smog formation in urban areas where cosmetics manufacturing facilities are concentrated.

Water systems face considerable risk from improper disposal of petroleum ether residuals. Even trace amounts can contaminate large volumes of water, creating toxic conditions for aquatic ecosystems. Research has documented bioaccumulation of petroleum hydrocarbons in aquatic organisms, with potential to enter the food chain and affect higher trophic levels. Cosmetics laboratories utilizing petroleum ether as an extraction solvent must implement rigorous wastewater treatment protocols to prevent environmental contamination.

Soil contamination represents another significant environmental concern. Spills or improper disposal of petroleum ether can lead to persistent soil pollution, affecting microbial communities essential for soil health and fertility. The remediation of petroleum-contaminated soils typically requires extensive and costly interventions, including bioremediation techniques or physical removal of affected soil layers.

From a lifecycle perspective, petroleum ether production contributes to environmental degradation through fossil fuel extraction, refining processes, and transportation emissions. The carbon footprint associated with petroleum derivatives extends throughout their entire supply chain, contributing to global climate change concerns. Recent sustainability assessments indicate that a typical cosmetics laboratory utilizing petroleum-based solvents may indirectly contribute several tons of carbon dioxide equivalent emissions annually.

Regulatory frameworks worldwide are increasingly addressing these environmental impacts. The European Union's REACH regulations, California's Proposition 65, and various international environmental protection standards now impose strict requirements on the handling, use, and disposal of petroleum derivatives in laboratory settings. Compliance necessitates comprehensive environmental management systems that track petroleum ether from procurement through disposal.

Alternative technologies and green chemistry approaches offer promising pathways to reduce environmental impacts. Bio-based solvents derived from renewable resources, supercritical CO2 extraction methods, and solvent-free analytical techniques represent emerging solutions that cosmetics laboratories are increasingly adopting to minimize their environmental footprint while maintaining analytical precision and product quality.

Water systems face considerable risk from improper disposal of petroleum ether residuals. Even trace amounts can contaminate large volumes of water, creating toxic conditions for aquatic ecosystems. Research has documented bioaccumulation of petroleum hydrocarbons in aquatic organisms, with potential to enter the food chain and affect higher trophic levels. Cosmetics laboratories utilizing petroleum ether as an extraction solvent must implement rigorous wastewater treatment protocols to prevent environmental contamination.

Soil contamination represents another significant environmental concern. Spills or improper disposal of petroleum ether can lead to persistent soil pollution, affecting microbial communities essential for soil health and fertility. The remediation of petroleum-contaminated soils typically requires extensive and costly interventions, including bioremediation techniques or physical removal of affected soil layers.

From a lifecycle perspective, petroleum ether production contributes to environmental degradation through fossil fuel extraction, refining processes, and transportation emissions. The carbon footprint associated with petroleum derivatives extends throughout their entire supply chain, contributing to global climate change concerns. Recent sustainability assessments indicate that a typical cosmetics laboratory utilizing petroleum-based solvents may indirectly contribute several tons of carbon dioxide equivalent emissions annually.

Regulatory frameworks worldwide are increasingly addressing these environmental impacts. The European Union's REACH regulations, California's Proposition 65, and various international environmental protection standards now impose strict requirements on the handling, use, and disposal of petroleum derivatives in laboratory settings. Compliance necessitates comprehensive environmental management systems that track petroleum ether from procurement through disposal.

Alternative technologies and green chemistry approaches offer promising pathways to reduce environmental impacts. Bio-based solvents derived from renewable resources, supercritical CO2 extraction methods, and solvent-free analytical techniques represent emerging solutions that cosmetics laboratories are increasingly adopting to minimize their environmental footprint while maintaining analytical precision and product quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!