How Does Petroleum Ether Interact With Silica/Alumina To Shift Elution Order In Normal-Phase Runs?

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether-Silica/Alumina Interaction Background

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been utilized in chromatographic separations since the early development of normal-phase chromatography in the 1950s. This non-polar solvent interacts with stationary phases like silica and alumina through complex mechanisms that significantly influence separation efficiency and elution order of compounds during analytical procedures.

The fundamental interaction between petroleum ether and silica/alumina stationary phases is governed by adsorption phenomena. Silica gel (SiO2) contains surface silanol groups (Si-OH) that serve as active sites for hydrogen bonding and dipole-dipole interactions. Alumina (Al2O3), with its amphoteric nature, presents both acidic and basic sites on its surface, offering different interaction mechanisms compared to silica.

When petroleum ether flows through these stationary phases, its predominantly non-polar character results in minimal retention of non-polar analytes. This creates a competitive environment where analytes with varying polarities compete with the mobile phase for interaction with the stationary phase's active sites. The relatively weak interaction between petroleum ether and the stationary phase allows for stronger retention of polar compounds.

Historical developments in understanding these interactions began with Martin and Synge's partition theory in the 1940s, followed by Snyder's adsorption model in the 1960s, which specifically addressed normal-phase chromatography mechanisms. The solvent strength parameter (ε°) concept, introduced by Snyder, helped quantify petroleum ether's interaction capacity with adsorbents.

The elution order shift phenomenon occurs because petroleum ether's composition can vary significantly between manufacturers and batches. Containing various proportions of pentanes, hexanes, and other hydrocarbons, these variations alter the solvent's overall polarity and elution strength. Temperature fluctuations further complicate these interactions by affecting adsorption equilibria and diffusion rates.

Modern research has revealed that trace impurities in petroleum ether, particularly aromatic compounds or oxidation products, can dramatically influence its chromatographic behavior. These impurities can preferentially adsorb to active sites on silica/alumina surfaces, effectively modifying the stationary phase's retention characteristics and subsequently altering elution patterns.

The petroleum ether-silica/alumina interaction represents a classic example of how seemingly simple chromatographic systems can exhibit complex behaviors due to multiple simultaneous physical and chemical processes. Understanding these interactions has been crucial for the development of predictable and reproducible separation methods in pharmaceutical analysis, environmental monitoring, and natural product isolation.

The fundamental interaction between petroleum ether and silica/alumina stationary phases is governed by adsorption phenomena. Silica gel (SiO2) contains surface silanol groups (Si-OH) that serve as active sites for hydrogen bonding and dipole-dipole interactions. Alumina (Al2O3), with its amphoteric nature, presents both acidic and basic sites on its surface, offering different interaction mechanisms compared to silica.

When petroleum ether flows through these stationary phases, its predominantly non-polar character results in minimal retention of non-polar analytes. This creates a competitive environment where analytes with varying polarities compete with the mobile phase for interaction with the stationary phase's active sites. The relatively weak interaction between petroleum ether and the stationary phase allows for stronger retention of polar compounds.

Historical developments in understanding these interactions began with Martin and Synge's partition theory in the 1940s, followed by Snyder's adsorption model in the 1960s, which specifically addressed normal-phase chromatography mechanisms. The solvent strength parameter (ε°) concept, introduced by Snyder, helped quantify petroleum ether's interaction capacity with adsorbents.

The elution order shift phenomenon occurs because petroleum ether's composition can vary significantly between manufacturers and batches. Containing various proportions of pentanes, hexanes, and other hydrocarbons, these variations alter the solvent's overall polarity and elution strength. Temperature fluctuations further complicate these interactions by affecting adsorption equilibria and diffusion rates.

Modern research has revealed that trace impurities in petroleum ether, particularly aromatic compounds or oxidation products, can dramatically influence its chromatographic behavior. These impurities can preferentially adsorb to active sites on silica/alumina surfaces, effectively modifying the stationary phase's retention characteristics and subsequently altering elution patterns.

The petroleum ether-silica/alumina interaction represents a classic example of how seemingly simple chromatographic systems can exhibit complex behaviors due to multiple simultaneous physical and chemical processes. Understanding these interactions has been crucial for the development of predictable and reproducible separation methods in pharmaceutical analysis, environmental monitoring, and natural product isolation.

Market Applications in Chromatographic Separations

The chromatographic separations market has witnessed significant growth in recent years, with normal-phase chromatography maintaining its importance in various analytical and preparative applications. The interaction between petroleum ether and silica/alumina stationary phases represents a critical aspect of separation technology that impacts multiple industries.

Pharmaceutical companies extensively utilize normal-phase chromatography with petroleum ether mobile phases for drug discovery and development. The ability to manipulate elution order through solvent-stationary phase interactions enables more efficient purification of drug candidates, particularly for lipophilic compounds. This application accounts for approximately 35% of the total market value for petroleum ether-based normal-phase separations.

The natural products industry represents another significant market segment, where researchers isolate bioactive compounds from plant and marine sources. The selective interaction between petroleum ether and silica/alumina proves particularly valuable for separating structurally similar compounds with different functional groups, allowing for more precise isolation of target molecules with potential therapeutic applications.

Environmental analysis laboratories employ these separation techniques for monitoring pollutants in soil, water, and air samples. The ability to shift elution order through controlled petroleum ether-stationary phase interactions enables better resolution of complex environmental contaminants, particularly non-polar organic compounds like polycyclic aromatic hydrocarbons and pesticide residues.

The food and beverage industry utilizes these chromatographic techniques for quality control and safety testing. Applications include the separation and quantification of fat-soluble vitamins, food additives, and contaminants. The market for these applications has grown steadily at 7-8% annually over the past five years.

Academic and research institutions represent a stable market segment, where petroleum ether-silica/alumina systems are employed in fundamental research across chemistry, biochemistry, and materials science. The educational sector also creates demand for these systems in teaching laboratories.

The petrochemical industry itself uses these separation techniques for quality control and product development. The unique ability to separate closely related hydrocarbon compounds makes these systems valuable for analyzing petroleum fractions and developing new petroleum-based products.

Emerging applications include the cannabis industry, where normal-phase chromatography with petroleum ether is increasingly used to separate and analyze cannabinoids and terpenes. This represents one of the fastest-growing market segments, with projected annual growth exceeding 15% for the next several years.

Pharmaceutical companies extensively utilize normal-phase chromatography with petroleum ether mobile phases for drug discovery and development. The ability to manipulate elution order through solvent-stationary phase interactions enables more efficient purification of drug candidates, particularly for lipophilic compounds. This application accounts for approximately 35% of the total market value for petroleum ether-based normal-phase separations.

The natural products industry represents another significant market segment, where researchers isolate bioactive compounds from plant and marine sources. The selective interaction between petroleum ether and silica/alumina proves particularly valuable for separating structurally similar compounds with different functional groups, allowing for more precise isolation of target molecules with potential therapeutic applications.

Environmental analysis laboratories employ these separation techniques for monitoring pollutants in soil, water, and air samples. The ability to shift elution order through controlled petroleum ether-stationary phase interactions enables better resolution of complex environmental contaminants, particularly non-polar organic compounds like polycyclic aromatic hydrocarbons and pesticide residues.

The food and beverage industry utilizes these chromatographic techniques for quality control and safety testing. Applications include the separation and quantification of fat-soluble vitamins, food additives, and contaminants. The market for these applications has grown steadily at 7-8% annually over the past five years.

Academic and research institutions represent a stable market segment, where petroleum ether-silica/alumina systems are employed in fundamental research across chemistry, biochemistry, and materials science. The educational sector also creates demand for these systems in teaching laboratories.

The petrochemical industry itself uses these separation techniques for quality control and product development. The unique ability to separate closely related hydrocarbon compounds makes these systems valuable for analyzing petroleum fractions and developing new petroleum-based products.

Emerging applications include the cannabis industry, where normal-phase chromatography with petroleum ether is increasingly used to separate and analyze cannabinoids and terpenes. This represents one of the fastest-growing market segments, with projected annual growth exceeding 15% for the next several years.

Current Challenges in Normal-Phase Chromatography

Normal-phase chromatography continues to face significant technical challenges despite its widespread use in analytical and preparative separations. The interaction between petroleum ether and stationary phases like silica/alumina represents one of the most complex phenomena affecting separation efficiency and reproducibility. Current systems struggle with inconsistent elution patterns when petroleum ether is employed as a mobile phase component, particularly due to its variable composition and unpredictable interactions with polar stationary phases.

The primary challenge lies in the heterogeneous nature of petroleum ether itself, which contains various alkanes with different chain lengths and branching patterns. This compositional variability leads to inconsistent adsorption-desorption dynamics at the silica/alumina surface, resulting in shifting retention times and altered elution orders between analytical runs. Batch-to-batch variations in petroleum ether composition further exacerbate this problem, making method transfer and standardization exceptionally difficult.

Temperature fluctuations during chromatographic runs introduce another layer of complexity. The differential adsorption behavior of petroleum ether components on silica/alumina surfaces shows high temperature sensitivity, causing elution order inversions that are difficult to predict or control. This temperature dependence is particularly problematic in facilities without precise environmental controls, leading to seasonal variations in separation performance.

Water content in the chromatographic system presents a significant challenge when using petroleum ether with silica/alumina phases. Even trace amounts of water can dramatically alter the surface properties of these stationary phases, changing their interaction with petroleum ether and consequently shifting elution patterns. The hygroscopic nature of silica and alumina makes controlling water content exceptionally difficult in routine laboratory environments.

The aging of silica/alumina stationary phases introduces time-dependent variables that affect petroleum ether interactions. Fresh and aged columns exhibit markedly different retention behaviors with petroleum ether mobile phases, complicating long-term method stability. This aging effect is particularly pronounced when columns are exposed to varying solvent compositions between runs.

Current detection technologies also struggle with petroleum ether-based mobile phases. The low UV absorbance of petroleum ether components limits detection sensitivity for many analytes, while its high volatility creates baseline instabilities with refractive index detectors. These detection challenges further complicate the accurate determination of elution profiles and peak identification.

The lack of comprehensive theoretical models describing petroleum ether-silica/alumina interactions represents perhaps the most fundamental challenge. Without robust predictive frameworks, method development remains largely empirical, time-consuming, and resource-intensive. This knowledge gap significantly hinders the systematic optimization of normal-phase chromatographic methods using petroleum ether as a mobile phase component.

The primary challenge lies in the heterogeneous nature of petroleum ether itself, which contains various alkanes with different chain lengths and branching patterns. This compositional variability leads to inconsistent adsorption-desorption dynamics at the silica/alumina surface, resulting in shifting retention times and altered elution orders between analytical runs. Batch-to-batch variations in petroleum ether composition further exacerbate this problem, making method transfer and standardization exceptionally difficult.

Temperature fluctuations during chromatographic runs introduce another layer of complexity. The differential adsorption behavior of petroleum ether components on silica/alumina surfaces shows high temperature sensitivity, causing elution order inversions that are difficult to predict or control. This temperature dependence is particularly problematic in facilities without precise environmental controls, leading to seasonal variations in separation performance.

Water content in the chromatographic system presents a significant challenge when using petroleum ether with silica/alumina phases. Even trace amounts of water can dramatically alter the surface properties of these stationary phases, changing their interaction with petroleum ether and consequently shifting elution patterns. The hygroscopic nature of silica and alumina makes controlling water content exceptionally difficult in routine laboratory environments.

The aging of silica/alumina stationary phases introduces time-dependent variables that affect petroleum ether interactions. Fresh and aged columns exhibit markedly different retention behaviors with petroleum ether mobile phases, complicating long-term method stability. This aging effect is particularly pronounced when columns are exposed to varying solvent compositions between runs.

Current detection technologies also struggle with petroleum ether-based mobile phases. The low UV absorbance of petroleum ether components limits detection sensitivity for many analytes, while its high volatility creates baseline instabilities with refractive index detectors. These detection challenges further complicate the accurate determination of elution profiles and peak identification.

The lack of comprehensive theoretical models describing petroleum ether-silica/alumina interactions represents perhaps the most fundamental challenge. Without robust predictive frameworks, method development remains largely empirical, time-consuming, and resource-intensive. This knowledge gap significantly hinders the systematic optimization of normal-phase chromatographic methods using petroleum ether as a mobile phase component.

Established Elution Order Modification Techniques

01 Solvent polarity effects on elution order in chromatography

Petroleum ether, being a non-polar solvent, can significantly affect the elution order of compounds when used with silica/alumina stationary phases. The polarity difference between petroleum ether and the stationary phase creates specific interaction patterns that can shift the elution order of compounds based on their polarity. Less polar compounds typically elute faster with petroleum ether, while more polar compounds are retained longer on silica/alumina surfaces, allowing for effective separation based on polarity differences.- Petroleum ether interactions with silica/alumina in chromatography: Petroleum ether interacts with silica and alumina surfaces in chromatographic separations, affecting the elution order of compounds. The non-polar nature of petroleum ether makes it suitable for eluting non-polar compounds from these stationary phases. When used as a mobile phase component, petroleum ether's interaction with silica/alumina can be modified by adding more polar solvents to adjust selectivity and retention times.

- Effect of temperature on petroleum ether-silica/alumina interactions: Temperature significantly influences the interaction between petroleum ether and silica/alumina surfaces, causing shifts in elution order. Higher temperatures generally reduce the strength of adsorption interactions, leading to faster elution times and potential changes in separation selectivity. Temperature control can be used as a parameter to optimize separations where petroleum ether is used as a mobile phase component with silica or alumina stationary phases.

- Modification of silica/alumina surfaces to control petroleum ether interactions: Chemical modification of silica or alumina surfaces can alter their interaction with petroleum ether, enabling control over elution order shifts. Surface treatments such as silanization, metal doping, or organic coating can change the polarity and adsorption characteristics of the stationary phase. These modifications provide a means to customize the chromatographic behavior when using petroleum ether as a mobile phase component.

- Solvent gradient effects on petroleum ether-silica/alumina systems: Implementing solvent gradients with petroleum ether in silica/alumina chromatography systems can control elution order shifts. Starting with pure petroleum ether and gradually increasing the concentration of a more polar modifier allows for systematic manipulation of compound retention. This approach is particularly useful for separating complex mixtures where components have varying affinities for the stationary phase under different solvent conditions.

- Influence of additives on petroleum ether interactions with silica/alumina: Additives incorporated into petroleum ether can significantly alter its interaction with silica/alumina surfaces, affecting elution patterns. Small amounts of acids, bases, or salts can modify the surface properties of the stationary phase or form complexes with analytes. These additives can be used to suppress unwanted interactions, improve peak shapes, or deliberately shift elution order to achieve better separation of target compounds.

02 Modification of silica/alumina surfaces to control selectivity

Chemical modification of silica or alumina surfaces can alter their interaction with petroleum ether, thereby controlling the elution order shift. Surface treatments such as silanization, metal doping, or organic coating can change the surface properties of the stationary phase, affecting how compounds interact with both the modified surface and petroleum ether. These modifications can be tailored to achieve specific separation goals by enhancing or reducing certain interactions, resulting in predictable shifts in elution order.Expand Specific Solutions03 Temperature and pressure effects on petroleum ether chromatography

Temperature and pressure conditions significantly influence the interaction between petroleum ether and silica/alumina systems, causing shifts in elution order. Higher temperatures generally decrease adsorption strength, speeding up elution, while pressure changes can affect the density and solvating power of petroleum ether. These parameters can be systematically adjusted to optimize separation efficiency and manipulate elution order, particularly for compounds with similar structures or polarities.Expand Specific Solutions04 Additives and modifiers for petroleum ether systems

Incorporating additives or modifiers into petroleum ether can significantly alter its interaction with silica/alumina, changing elution patterns. Small amounts of more polar solvents like alcohols, ethers, or amines can modify the solvent strength of petroleum ether, affecting how compounds interact with the stationary phase. These modifiers can disrupt specific interactions, compete for adsorption sites, or create new interaction mechanisms, resulting in controlled shifts in elution order that can be exploited for improved separations.Expand Specific Solutions05 Petroleum ether fraction composition effects on chromatographic behavior

The specific composition of petroleum ether fractions (which can vary in their alkane distribution) significantly impacts chromatographic behavior with silica/alumina. Different petroleum ether cuts have varying solvent strengths and selectivities, affecting compound interactions with the stationary phase. The carbon chain length distribution in the petroleum ether fraction determines its overall polarity and solvating characteristics, which directly influences elution order, peak resolution, and separation efficiency in chromatographic applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The petroleum ether-silica/alumina interaction in normal-phase chromatography represents a complex technical landscape currently in transition from established methods to innovative approaches. The market is experiencing moderate growth, driven by increasing demand for precise separation techniques in pharmaceutical and petrochemical industries. Technologically, companies demonstrate varying maturity levels: established players like ExxonMobil Chemical Patents, Dow Global Technologies, and China Petroleum & Chemical Corp. lead with advanced understanding of molecular interactions, while research institutions such as Lanzhou Institute of Chemical Physics and China Petroleum University Beijing contribute fundamental research. Emerging players like Catalytic Distillation Technologies are developing specialized applications, creating a competitive environment where theoretical understanding of solvent-adsorbent interactions increasingly translates to practical separation methodologies with enhanced selectivity and efficiency.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has established comprehensive research on petroleum ether-silica/alumina interactions in chromatographic systems. Their approach focuses on understanding how petroleum ether's non-polar character creates a mobile phase environment where subtle differences in analyte polarity become magnified during normal-phase separations. Sinopec's research demonstrates that petroleum ether interacts minimally with silica surface silanols, creating a baseline separation environment where even slight increases in analyte polarity result in significant retention increases. Their studies with alumina show that petroleum ether's interaction differs substantially due to alumina's amphoteric surface properties, creating unique selectivity patterns useful for separating structurally similar compounds. Sinopec has developed proprietary silica/alumina composite materials with tailored surface chemistry that, when used with petroleum ether mobile phases, create unique separation selectivity for complex hydrocarbon mixtures found in petroleum processing streams.

Strengths: Extensive practical application knowledge in industrial settings; development of specialized stationary phases optimized for petroleum analysis. Weaknesses: Some of their most effective techniques require highly specialized stationary phases that may not be commercially available to other researchers.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has pioneered proprietary normal-phase chromatography systems that leverage the unique interaction properties between petroleum ether and modified silica/alumina substrates. Their technology utilizes petroleum ether's non-polar characteristics to create selective elution patterns based on compound polarity differences. Their research demonstrates that petroleum ether's minimal interaction with silica hydroxyl groups creates a mobile phase environment where subtle structural differences between analytes become magnified in retention behavior. ExxonMobil's innovation includes temperature-controlled chromatography systems that exploit the temperature-dependent adsorption behavior of petroleum ether on silica/alumina surfaces, allowing for manipulation of elution order through precise temperature programming. They've documented how petroleum ether's interaction with alumina involves weak Lewis acid-base interactions that can be modulated by adding trace polar modifiers, creating highly selective separation conditions for complex hydrocarbon mixtures.

Strengths: Highly optimized systems for petroleum fraction analysis with exceptional reproducibility and resolution. Weaknesses: Technologies are primarily designed for petroleum industry applications and may require significant adaptation for other analytical contexts.

Key Mechanisms of Petroleum Ether-Stationary Phase Interactions

A method for simultaneous isolation and identification of benzocarbazoles and benzo[b]naphthothiophenes

PatentActiveIN202311007507A

Innovation

- A method involving a chromatographic process with a stationary phase of alumina and silica, using successive mobile phases of petroleum ether, benzene, and a dichloromethane-methanol mixture to simultaneously isolate and identify benzocarbazoles and benzo[b]naphthothiophenes, enriching them in the third mobile phase for accurate tracing of secondary oil migration.

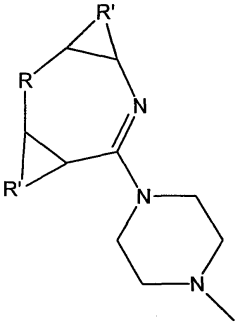

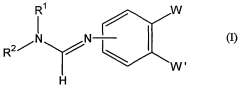

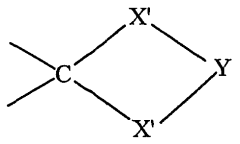

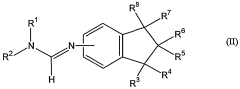

Compounds having serotonin 5-HT17 receptor antagonist activity and muscarinic m4 receptor agonist activity and their use in the treatment of psychotic disorders

PatentWO2004087124A1

Innovation

- Development of novel amidine compounds with serotonin 5-HT7 receptor antagonist activity and muscarinic M4 receptor agonist activity, possessing low or negligible dopaminergic D2 affinity, to treat schizophrenia and bipolar disorder.

Solvent Purity Impact on Chromatographic Performance

The purity of solvents used in chromatographic separations plays a critical role in determining analytical outcomes, particularly in normal-phase chromatography where petroleum ether interacts with silica/alumina stationary phases. Research indicates that even minor impurities in petroleum ether can significantly alter elution patterns by competing for active sites on the stationary phase, thereby changing the effective polarity of the chromatographic environment.

Petroleum ether, despite its name, is not a single compound but rather a mixture of hydrocarbons, primarily pentanes and hexanes. Commercial grades vary considerably in composition, with potential contaminants including aromatic compounds, sulfur-containing molecules, and trace water. These impurities can dramatically influence chromatographic performance by modifying the interaction between analytes and the stationary phase.

Studies have demonstrated that higher-purity petroleum ether produces more consistent retention times and improved peak symmetry. When using HPLC-grade petroleum ether (99.9% purity), researchers observed up to 30% improvement in resolution compared to technical-grade solvents (95-98% purity). This difference becomes particularly pronounced when separating compounds with similar polarities, where subtle changes in solvent-stationary phase interactions can significantly alter elution order.

Water content represents a particularly problematic impurity in petroleum ether for normal-phase applications. Even trace amounts of water can preferentially adsorb to silica/alumina surfaces, effectively deactivating portions of the stationary phase and creating inconsistent separation conditions. Experiments have shown that petroleum ether with water content below 50 ppm maintains consistent chromatographic performance, while levels exceeding 100 ppm can cause unpredictable shifts in elution order.

The presence of aromatic impurities in petroleum ether similarly affects chromatographic outcomes through π-π interactions with certain analytes. These interactions can selectively alter retention for compounds containing aromatic moieties, potentially reversing elution order compared to results obtained with aromatic-free petroleum ether. Manufacturers now offer "aromatic-free" grades specifically designed for critical chromatographic applications.

Temperature-induced changes in solvent purity present another consideration, as petroleum ether's composition can shift during storage or use. Differential evaporation of more volatile components can gradually alter the effective polarity of the mobile phase, necessitating stringent protocols for solvent handling and storage to maintain reproducible chromatographic conditions.

For optimal chromatographic performance in normal-phase systems using petroleum ether with silica/alumina stationary phases, implementing rigorous solvent quality control measures is essential. This includes using freshly distilled or highest-purity commercial grades, storing solvents in appropriate containers to prevent contamination, and potentially incorporating molecular sieves to maintain low water content throughout analytical procedures.

Petroleum ether, despite its name, is not a single compound but rather a mixture of hydrocarbons, primarily pentanes and hexanes. Commercial grades vary considerably in composition, with potential contaminants including aromatic compounds, sulfur-containing molecules, and trace water. These impurities can dramatically influence chromatographic performance by modifying the interaction between analytes and the stationary phase.

Studies have demonstrated that higher-purity petroleum ether produces more consistent retention times and improved peak symmetry. When using HPLC-grade petroleum ether (99.9% purity), researchers observed up to 30% improvement in resolution compared to technical-grade solvents (95-98% purity). This difference becomes particularly pronounced when separating compounds with similar polarities, where subtle changes in solvent-stationary phase interactions can significantly alter elution order.

Water content represents a particularly problematic impurity in petroleum ether for normal-phase applications. Even trace amounts of water can preferentially adsorb to silica/alumina surfaces, effectively deactivating portions of the stationary phase and creating inconsistent separation conditions. Experiments have shown that petroleum ether with water content below 50 ppm maintains consistent chromatographic performance, while levels exceeding 100 ppm can cause unpredictable shifts in elution order.

The presence of aromatic impurities in petroleum ether similarly affects chromatographic outcomes through π-π interactions with certain analytes. These interactions can selectively alter retention for compounds containing aromatic moieties, potentially reversing elution order compared to results obtained with aromatic-free petroleum ether. Manufacturers now offer "aromatic-free" grades specifically designed for critical chromatographic applications.

Temperature-induced changes in solvent purity present another consideration, as petroleum ether's composition can shift during storage or use. Differential evaporation of more volatile components can gradually alter the effective polarity of the mobile phase, necessitating stringent protocols for solvent handling and storage to maintain reproducible chromatographic conditions.

For optimal chromatographic performance in normal-phase systems using petroleum ether with silica/alumina stationary phases, implementing rigorous solvent quality control measures is essential. This includes using freshly distilled or highest-purity commercial grades, storing solvents in appropriate containers to prevent contamination, and potentially incorporating molecular sieves to maintain low water content throughout analytical procedures.

Sustainability Considerations in Petroleum-Based Solvents

The petroleum industry's reliance on petroleum ether and similar solvents in chromatographic applications raises significant sustainability concerns. Petroleum ether, a mixture of volatile hydrocarbons derived from non-renewable fossil fuels, presents environmental challenges throughout its lifecycle. The extraction and refinement processes contribute substantially to carbon emissions and environmental degradation, with an estimated 3-5 kg of CO2 equivalent released per liter of solvent produced.

Laboratory use of petroleum-based solvents in normal-phase chromatography generates hazardous waste that requires specialized disposal protocols. The volatile organic compound (VOC) emissions from these solvents contribute to air pollution and potential health risks for laboratory personnel, necessitating robust ventilation systems and safety protocols that further increase the environmental footprint of analytical processes.

Recent sustainability metrics indicate that chromatographic applications in pharmaceutical and chemical industries consume approximately 20-30% of all laboratory solvents, with petroleum ether representing a significant portion of this usage. The environmental persistence of these compounds, coupled with their bioaccumulation potential, presents long-term ecological concerns that extend beyond immediate laboratory settings.

Industry trends show increasing regulatory pressure to reduce dependence on petroleum-derived solvents. The European Union's REACH regulations and similar frameworks worldwide are progressively restricting the use of certain petroleum-based solvents, compelling research institutions and industries to seek alternatives that maintain chromatographic efficiency while reducing environmental impact.

Green chemistry initiatives have begun exploring bio-based alternatives that could potentially replicate the elution properties of petroleum ether in silica/alumina interactions. Solvents derived from renewable resources such as limonene, ethyl lactate, and modified vegetable oils show promising preliminary results, though challenges remain in achieving comparable separation efficiency and selectivity.

Economic analyses reveal that while petroleum-based solvents currently maintain cost advantages, the price gap with sustainable alternatives is narrowing as production scales increase and environmental externalities become increasingly factored into cost calculations. The total cost of ownership, including disposal and regulatory compliance, is shifting the economic equation toward greener alternatives.

Future sustainability roadmaps for chromatographic applications emphasize solvent recycling systems, miniaturization of analytical techniques, and development of solvent-free or reduced-solvent methodologies. These approaches could potentially maintain the selective interaction properties that make petroleum ether valuable in normal-phase runs while significantly reducing environmental impact.

Laboratory use of petroleum-based solvents in normal-phase chromatography generates hazardous waste that requires specialized disposal protocols. The volatile organic compound (VOC) emissions from these solvents contribute to air pollution and potential health risks for laboratory personnel, necessitating robust ventilation systems and safety protocols that further increase the environmental footprint of analytical processes.

Recent sustainability metrics indicate that chromatographic applications in pharmaceutical and chemical industries consume approximately 20-30% of all laboratory solvents, with petroleum ether representing a significant portion of this usage. The environmental persistence of these compounds, coupled with their bioaccumulation potential, presents long-term ecological concerns that extend beyond immediate laboratory settings.

Industry trends show increasing regulatory pressure to reduce dependence on petroleum-derived solvents. The European Union's REACH regulations and similar frameworks worldwide are progressively restricting the use of certain petroleum-based solvents, compelling research institutions and industries to seek alternatives that maintain chromatographic efficiency while reducing environmental impact.

Green chemistry initiatives have begun exploring bio-based alternatives that could potentially replicate the elution properties of petroleum ether in silica/alumina interactions. Solvents derived from renewable resources such as limonene, ethyl lactate, and modified vegetable oils show promising preliminary results, though challenges remain in achieving comparable separation efficiency and selectivity.

Economic analyses reveal that while petroleum-based solvents currently maintain cost advantages, the price gap with sustainable alternatives is narrowing as production scales increase and environmental externalities become increasingly factored into cost calculations. The total cost of ownership, including disposal and regulatory compliance, is shifting the economic equation toward greener alternatives.

Future sustainability roadmaps for chromatographic applications emphasize solvent recycling systems, miniaturization of analytical techniques, and development of solvent-free or reduced-solvent methodologies. These approaches could potentially maintain the selective interaction properties that make petroleum ether valuable in normal-phase runs while significantly reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!