How Does Petroleum Ether Usage Impact VOC Compliance Programs And Capture Efficiency Targets?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether VOC Compliance Background & Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been widely utilized across various industrial applications for decades. The evolution of this solvent's usage parallels the development of industrial manufacturing processes, particularly in extraction, cleaning, and as a reaction medium in chemical synthesis. Historical data indicates a significant increase in petroleum ether consumption since the 1950s, coinciding with the rapid expansion of the chemical and pharmaceutical industries.

The regulatory landscape surrounding volatile organic compounds (VOCs) has undergone substantial transformation over the past 30 years. The 1990 Clean Air Act Amendments marked a pivotal shift in VOC regulation, establishing more stringent control requirements for industries utilizing VOC-emitting substances like petroleum ether. This legislative evolution has continued with increasingly strict standards implemented at both federal and state levels, particularly in regions with persistent air quality challenges.

Petroleum ether presents a complex regulatory challenge due to its variable composition, typically consisting of alkanes with carbon chains ranging from C5 to C8. This variability affects its volatility profile and consequently its VOC classification and regulatory treatment. The technical objective of modern compliance programs is to accurately quantify petroleum ether emissions and implement effective capture technologies that meet or exceed regulatory thresholds.

Current VOC compliance programs targeting petroleum ether usage focus on several key metrics, including total emissions volume, capture efficiency percentages, and destruction removal efficiency (DRE) rates. The benchmark for capture efficiency has progressively increased, with many jurisdictions now requiring 85-95% capture rates for industrial processes utilizing significant quantities of petroleum ether and similar solvents.

The technological trajectory in this field is moving toward more sophisticated monitoring systems, including continuous emission monitoring systems (CEMS) and advanced predictive modeling tools that can account for the complex behavior of petroleum ether under various operating conditions. These developments aim to provide more accurate emissions data while facilitating more effective compliance strategies.

The ultimate goal of current research and regulatory efforts is to establish a balance between industrial productivity and environmental protection, developing technical solutions that allow for continued petroleum ether usage where functionally necessary while minimizing atmospheric VOC contributions. This includes exploration of alternative solvents with lower volatility profiles and the development of closed-loop systems that maximize solvent recovery and minimize emissions.

The regulatory landscape surrounding volatile organic compounds (VOCs) has undergone substantial transformation over the past 30 years. The 1990 Clean Air Act Amendments marked a pivotal shift in VOC regulation, establishing more stringent control requirements for industries utilizing VOC-emitting substances like petroleum ether. This legislative evolution has continued with increasingly strict standards implemented at both federal and state levels, particularly in regions with persistent air quality challenges.

Petroleum ether presents a complex regulatory challenge due to its variable composition, typically consisting of alkanes with carbon chains ranging from C5 to C8. This variability affects its volatility profile and consequently its VOC classification and regulatory treatment. The technical objective of modern compliance programs is to accurately quantify petroleum ether emissions and implement effective capture technologies that meet or exceed regulatory thresholds.

Current VOC compliance programs targeting petroleum ether usage focus on several key metrics, including total emissions volume, capture efficiency percentages, and destruction removal efficiency (DRE) rates. The benchmark for capture efficiency has progressively increased, with many jurisdictions now requiring 85-95% capture rates for industrial processes utilizing significant quantities of petroleum ether and similar solvents.

The technological trajectory in this field is moving toward more sophisticated monitoring systems, including continuous emission monitoring systems (CEMS) and advanced predictive modeling tools that can account for the complex behavior of petroleum ether under various operating conditions. These developments aim to provide more accurate emissions data while facilitating more effective compliance strategies.

The ultimate goal of current research and regulatory efforts is to establish a balance between industrial productivity and environmental protection, developing technical solutions that allow for continued petroleum ether usage where functionally necessary while minimizing atmospheric VOC contributions. This includes exploration of alternative solvents with lower volatility profiles and the development of closed-loop systems that maximize solvent recovery and minimize emissions.

Market Demand Analysis for VOC-Compliant Solvents

The global market for VOC-compliant solvents has experienced significant growth in recent years, driven primarily by increasingly stringent environmental regulations across major industrial economies. Current market valuations place the VOC-compliant solvent sector at approximately 7.2 billion USD in 2023, with projections indicating a compound annual growth rate of 5.8% through 2030.

Industries most actively seeking alternatives to petroleum ether include coatings and adhesives (representing 34% of market demand), industrial cleaning (22%), pharmaceuticals (18%), and electronics manufacturing (12%). The remaining 14% encompasses various applications including laboratory research, consumer products, and specialty manufacturing processes.

Regional analysis reveals that North America and Europe currently lead market demand due to their mature regulatory frameworks, with the EU's Industrial Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) serving as primary drivers. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China, India, and South Korea implementing progressively stricter VOC regulations to address urban air quality concerns.

Customer surveys indicate that manufacturing facilities are willing to pay a premium of 15-20% for VOC-compliant alternatives that maintain performance characteristics comparable to petroleum ether. Key performance metrics sought by end-users include evaporation rate, solvency power, purity, and compatibility with existing manufacturing processes.

Market segmentation analysis reveals three distinct customer profiles: regulatory-driven adopters (58%) who prioritize compliance above all other factors; performance-balanced adopters (32%) who require both compliance and specific technical properties; and innovation leaders (10%) who seek sustainable solutions that exceed current regulatory requirements.

The competitive landscape for VOC-compliant solvents shows increasing consolidation, with major chemical manufacturers expanding their environmentally friendly product portfolios through both R&D investment and strategic acquisitions. Notably, bio-based and recycled solvents represent the fastest-growing segment, achieving 12.3% annual growth compared to 4.5% for traditional synthetic alternatives.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing for certain VOC-compliant alternatives, particularly those derived from specialized agricultural feedstocks or requiring advanced processing technologies. This has created market opportunities for vertically integrated suppliers who can guarantee consistent quality and availability.

Industries most actively seeking alternatives to petroleum ether include coatings and adhesives (representing 34% of market demand), industrial cleaning (22%), pharmaceuticals (18%), and electronics manufacturing (12%). The remaining 14% encompasses various applications including laboratory research, consumer products, and specialty manufacturing processes.

Regional analysis reveals that North America and Europe currently lead market demand due to their mature regulatory frameworks, with the EU's Industrial Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) serving as primary drivers. However, the Asia-Pacific region demonstrates the fastest growth trajectory, with China, India, and South Korea implementing progressively stricter VOC regulations to address urban air quality concerns.

Customer surveys indicate that manufacturing facilities are willing to pay a premium of 15-20% for VOC-compliant alternatives that maintain performance characteristics comparable to petroleum ether. Key performance metrics sought by end-users include evaporation rate, solvency power, purity, and compatibility with existing manufacturing processes.

Market segmentation analysis reveals three distinct customer profiles: regulatory-driven adopters (58%) who prioritize compliance above all other factors; performance-balanced adopters (32%) who require both compliance and specific technical properties; and innovation leaders (10%) who seek sustainable solutions that exceed current regulatory requirements.

The competitive landscape for VOC-compliant solvents shows increasing consolidation, with major chemical manufacturers expanding their environmentally friendly product portfolios through both R&D investment and strategic acquisitions. Notably, bio-based and recycled solvents represent the fastest-growing segment, achieving 12.3% annual growth compared to 4.5% for traditional synthetic alternatives.

Supply chain analysis indicates potential vulnerabilities in raw material sourcing for certain VOC-compliant alternatives, particularly those derived from specialized agricultural feedstocks or requiring advanced processing technologies. This has created market opportunities for vertically integrated suppliers who can guarantee consistent quality and availability.

Technical Challenges in Petroleum Ether VOC Compliance

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, presents significant challenges for VOC compliance programs across industries. The compound's high volatility contributes substantially to atmospheric emissions, with evaporation rates exceeding many other industrial solvents. This characteristic makes petroleum ether particularly problematic for facilities attempting to meet increasingly stringent regulatory standards for volatile organic compounds.

Current VOC compliance frameworks struggle to effectively account for petroleum ether's unique properties. The compound's variable composition—typically consisting of pentanes, hexanes, and heptanes in differing proportions—creates inconsistencies in emission factor calculations. This variability complicates the accurate measurement and reporting required by environmental protection agencies, potentially leading to compliance violations despite good-faith efforts by industrial operators.

Capture efficiency technologies face substantial technical limitations when dealing with petroleum ether. Conventional carbon adsorption systems demonstrate reduced effectiveness due to the compound's low molecular weight and high vapor pressure. These properties result in premature breakthrough and reduced adsorption capacity, requiring more frequent regeneration cycles and increasing operational costs. Similarly, thermal oxidizers must operate at higher temperatures to achieve complete destruction of petroleum ether, resulting in increased energy consumption and associated carbon emissions.

Monitoring challenges further complicate compliance efforts. Many continuous emission monitoring systems (CEMS) were not specifically calibrated for petroleum ether's unique spectral characteristics, potentially leading to measurement inaccuracies. The compound's rapid dispersion patterns also make traditional fence-line monitoring less effective at detecting fugitive emissions, creating blind spots in environmental protection protocols.

Material compatibility issues represent another significant technical hurdle. Petroleum ether's aggressive solvent properties accelerate the degradation of gaskets, seals, and other containment components in processing equipment. This degradation increases the likelihood of fugitive emissions through equipment leaks, further compromising VOC capture efficiency targets and compliance status.

The economic feasibility of achieving high capture efficiencies presents perhaps the most formidable challenge. As regulatory standards tighten, the marginal cost of capturing each additional percentage of petroleum ether emissions increases exponentially. This cost curve creates difficult decision points for industries balancing environmental compliance with economic sustainability, particularly in sectors with narrow profit margins operating in competitive global markets.

Interdepartmental coordination challenges within organizations further complicate compliance efforts. Engineering teams focused on production efficiency may implement process changes that inadvertently impact emission profiles, while environmental compliance departments often lack real-time visibility into these operational modifications. This communication gap can result in unexpected compliance violations despite substantial investments in control technologies.

Current VOC compliance frameworks struggle to effectively account for petroleum ether's unique properties. The compound's variable composition—typically consisting of pentanes, hexanes, and heptanes in differing proportions—creates inconsistencies in emission factor calculations. This variability complicates the accurate measurement and reporting required by environmental protection agencies, potentially leading to compliance violations despite good-faith efforts by industrial operators.

Capture efficiency technologies face substantial technical limitations when dealing with petroleum ether. Conventional carbon adsorption systems demonstrate reduced effectiveness due to the compound's low molecular weight and high vapor pressure. These properties result in premature breakthrough and reduced adsorption capacity, requiring more frequent regeneration cycles and increasing operational costs. Similarly, thermal oxidizers must operate at higher temperatures to achieve complete destruction of petroleum ether, resulting in increased energy consumption and associated carbon emissions.

Monitoring challenges further complicate compliance efforts. Many continuous emission monitoring systems (CEMS) were not specifically calibrated for petroleum ether's unique spectral characteristics, potentially leading to measurement inaccuracies. The compound's rapid dispersion patterns also make traditional fence-line monitoring less effective at detecting fugitive emissions, creating blind spots in environmental protection protocols.

Material compatibility issues represent another significant technical hurdle. Petroleum ether's aggressive solvent properties accelerate the degradation of gaskets, seals, and other containment components in processing equipment. This degradation increases the likelihood of fugitive emissions through equipment leaks, further compromising VOC capture efficiency targets and compliance status.

The economic feasibility of achieving high capture efficiencies presents perhaps the most formidable challenge. As regulatory standards tighten, the marginal cost of capturing each additional percentage of petroleum ether emissions increases exponentially. This cost curve creates difficult decision points for industries balancing environmental compliance with economic sustainability, particularly in sectors with narrow profit margins operating in competitive global markets.

Interdepartmental coordination challenges within organizations further complicate compliance efforts. Engineering teams focused on production efficiency may implement process changes that inadvertently impact emission profiles, while environmental compliance departments often lack real-time visibility into these operational modifications. This communication gap can result in unexpected compliance violations despite substantial investments in control technologies.

Current VOC Capture and Control Methodologies

01 VOC capture and recovery systems for petroleum ether

Various systems have been developed to capture and recover volatile organic compounds (VOCs) from petroleum ether emissions. These systems typically employ adsorption technologies, condensation methods, or membrane separation to efficiently capture VOCs before they are released into the atmosphere. The captured petroleum ether can then be recovered and reused in industrial processes, reducing both environmental impact and material costs. These systems are designed to meet increasingly stringent regulatory requirements for VOC emissions.- VOC capture and recovery systems for petroleum ether: Various systems have been developed for capturing and recovering volatile organic compounds (VOCs) from petroleum ether emissions. These systems typically employ adsorption technologies, condensation methods, or membrane separation to efficiently capture VOCs before they are released into the atmosphere. The captured petroleum ether can then be recovered and reused in industrial processes, reducing both environmental impact and material costs.

- Regulatory compliance monitoring for petroleum ether emissions: Systems and methods for monitoring and ensuring compliance with VOC regulations specific to petroleum ether usage. These include automated monitoring equipment, software solutions for tracking emissions data, and reporting tools that help facilities demonstrate compliance with local, national, and international VOC regulations. Such systems often incorporate real-time monitoring capabilities to detect potential compliance issues before they become violations.

- Enhanced efficiency extraction processes with reduced VOC emissions: Innovative extraction processes that utilize petroleum ether while minimizing VOC emissions. These technologies include closed-loop extraction systems, low-temperature processing methods, and solvent recovery mechanisms that significantly reduce the amount of petroleum ether released during industrial operations. By improving process efficiency, these innovations help maintain productivity while meeting increasingly stringent environmental regulations.

- Alternative solvents and formulations to replace high-VOC petroleum ether: Development of alternative solvents and formulations that can replace traditional petroleum ether in various applications while producing lower VOC emissions. These alternatives include modified petroleum ether formulations with lower volatility, bio-based solvents derived from renewable resources, and novel solvent systems that maintain similar performance characteristics while reducing environmental impact and improving regulatory compliance.

- Integrated VOC management systems for industrial facilities: Comprehensive VOC management systems designed specifically for facilities that use petroleum ether in their operations. These integrated solutions combine capture technologies, monitoring systems, and process optimizations to create a holistic approach to VOC compliance. Such systems often incorporate advanced analytics to identify emission reduction opportunities, automated control mechanisms to maintain compliance during varying operating conditions, and documentation tools for regulatory reporting.

02 Monitoring and compliance verification methods

Advanced monitoring systems and methodologies have been developed to verify compliance with VOC regulations for petroleum ether. These include real-time emission monitoring equipment, predictive analytics software, and automated reporting systems that track VOC levels and capture efficiency. Such systems enable facilities to demonstrate regulatory compliance while optimizing their VOC control processes. The monitoring approaches incorporate sensors, data analytics, and reporting mechanisms to provide comprehensive oversight of petroleum ether emissions.Expand Specific Solutions03 Low-VOC petroleum ether formulations

Innovative formulations of petroleum ether with reduced VOC content have been developed to meet environmental regulations while maintaining performance characteristics. These formulations may involve modified distillation processes, alternative solvent blends, or chemical modifications that reduce volatility while preserving the desired solvent properties. Such reformulated products help industries comply with VOC limitations without requiring significant changes to existing processes or equipment.Expand Specific Solutions04 Process optimization for VOC reduction

Methods for optimizing industrial processes to minimize petroleum ether VOC emissions have been developed. These approaches include modified operating parameters, improved sealing technologies, enhanced maintenance protocols, and process redesigns that reduce solvent exposure to air. By optimizing process conditions such as temperature, pressure, and flow rates, facilities can significantly improve capture efficiency and reduce overall VOC emissions while maintaining production efficiency.Expand Specific Solutions05 Regulatory compliance management systems

Comprehensive management systems have been developed to navigate the complex regulatory landscape surrounding petroleum ether VOC emissions. These systems integrate compliance tracking, documentation management, permitting assistance, and regulatory updates to ensure ongoing adherence to local, national, and international VOC regulations. Such systems help facilities manage their compliance obligations efficiently, reducing administrative burden while minimizing the risk of violations and associated penalties.Expand Specific Solutions

Key Industry Players in VOC Compliance Solutions

The petroleum ether VOC compliance landscape is evolving rapidly as the industry transitions from early-stage regulatory frameworks to more mature compliance mechanisms. The global VOC control market is projected to reach approximately $2.5 billion by 2025, driven by increasingly stringent environmental regulations. Major oil corporations like China Petroleum & Chemical Corp., Saudi Aramco, and ExxonMobil are leading technological advancements in VOC capture efficiency, while chemical specialists such as Henkel AG and LANXESS Deutschland are developing innovative low-VOC alternatives. Research institutions including University of Houston and Changchun Institute of Applied Chemistry are contributing breakthrough technologies in VOC monitoring and abatement. The competitive landscape features both established players optimizing existing petroleum ether applications and emerging companies developing novel capture technologies to meet increasingly demanding efficiency targets.

China Petroleum & Chemical Corp.

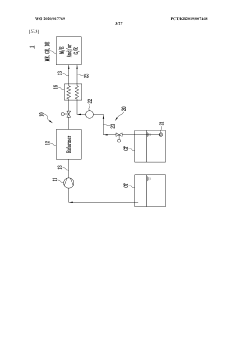

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive VOC management system specifically addressing petroleum ether emissions. Their approach integrates advanced Leak Detection and Repair (LDAR) programs with regenerative thermal oxidizers (RTOs) that achieve over 98% VOC destruction efficiency. Sinopec's technology employs dual-phase extraction systems for capturing petroleum ether vapors during storage and transfer operations, significantly reducing fugitive emissions. Their proprietary adsorption-catalytic oxidation technology combines activated carbon adsorption with catalytic oxidation, allowing for efficient VOC capture even at low concentrations (5-500 ppm). This system is particularly effective for petroleum ether with its high volatility and low boiling point characteristics. Sinopec has also implemented real-time monitoring networks across their facilities that utilize infrared imaging and photoionization detection to identify emission sources, enabling rapid response to leaks and process upsets that could impact compliance.

Strengths: Integrated approach combining prevention, capture, and destruction technologies; High destruction efficiency (>98%); Real-time monitoring capabilities for immediate intervention. Weaknesses: High capital investment requirements; Energy-intensive thermal oxidation processes; System complexity requires specialized maintenance and operation expertise.

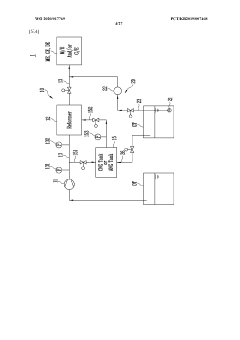

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has pioneered a multi-tiered VOC compliance strategy specifically addressing petroleum ether emissions throughout their operations. Their approach centers on a proprietary Vapor Recovery Unit (VRU) system that employs cryogenic condensation technology, achieving capture efficiencies exceeding 95% for petroleum ether vapors. This system is particularly effective due to petroleum ether's low boiling point range (30-60°C). CNPC has also developed specialized floating roof tank designs with advanced rim seals that reduce petroleum ether emissions by up to 90% compared to fixed roof alternatives. Their compliance program incorporates optical gas imaging (OGI) technology for continuous monitoring, allowing for detection of petroleum ether leaks as small as 0.35 g/hr. Additionally, CNPC has implemented process modifications that reduce petroleum ether usage in extraction processes by substituting with less volatile alternatives where feasible, while maintaining product quality specifications.

Strengths: High capture efficiency for petroleum ether vapors; Comprehensive approach addressing storage, transfer, and process emissions; Advanced monitoring technology enabling rapid leak detection. Weaknesses: Cryogenic systems require significant energy input; High implementation costs across large facilities; Substitution strategies may not be feasible for all applications requiring petroleum ether's specific properties.

Critical Patents in Petroleum Ether Emission Reduction

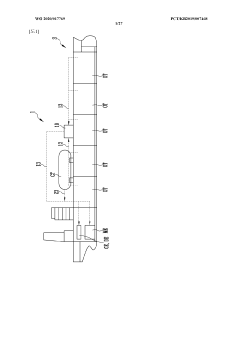

Volatile organic compound treatment system and ship

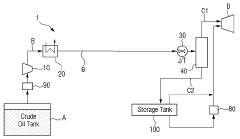

PatentWO2020017769A1

Innovation

- A VOC treatment system that includes oil storage tanks, a VOC compressor to pressurize and recover VOCs, and a VOC return line to recycle them back into the tanks, allowing the VOCs to be used as fuel for ship engines, thereby reducing emissions and energy consumption.

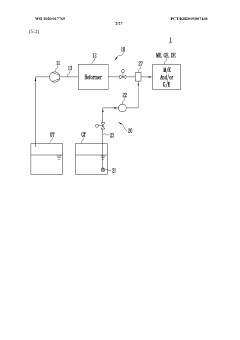

Volatile organic compound recovery apparatus

PatentWO2017222239A1

Innovation

- A VOC recovery device comprising a compressor, heat exchangers, an expansion valve, and a gas-liquid separator, which compresses, cools, and decompresses oil vapors to separate and recover VOCs, utilizing them as fuel and storing the liquids, thereby enhancing energy efficiency and reducing emissions through continuous treatment processes.

Environmental Impact Assessment of Petroleum Ether Usage

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, presents significant environmental challenges when used in industrial processes. The compound's high volatility directly contributes to atmospheric Volatile Organic Compound (VOC) levels, which play a critical role in photochemical smog formation and ground-level ozone development. These environmental consequences extend beyond local air quality issues to broader regional atmospheric chemistry disruptions.

When released into the environment, petroleum ether compounds can persist in soil and water systems, potentially contaminating groundwater resources. The bioaccumulation potential in aquatic organisms represents a concerning vector for ecosystem disruption, as these compounds may transfer through food chains and affect multiple trophic levels. Studies have documented reduced biodiversity in aquatic environments with elevated petroleum hydrocarbon concentrations.

Atmospheric emissions from petroleum ether usage contribute to both local air quality degradation and global climate impacts. As VOCs interact with nitrogen oxides in the presence of sunlight, they catalyze the formation of photochemical oxidants, including tropospheric ozone. This process not only affects human respiratory health but also damages vegetation and agricultural crops, resulting in economic losses beyond direct environmental damage.

The greenhouse warming potential of petroleum ether compounds, while lower than some other industrial chemicals, still contributes to climate change effects when released at industrial scales. Particularly concerning are the secondary atmospheric reactions that can produce more persistent compounds with higher global warming potentials than the original emissions.

Regulatory frameworks increasingly recognize these multifaceted environmental impacts. The classification of petroleum ether as a hazardous air pollutant under various national and international regulations has driven industries to implement more stringent control technologies and operational practices. Capture efficiency requirements typically mandate 95-99% reduction in emissions, depending on the jurisdiction and specific application.

Waste streams containing petroleum ether residues require specialized treatment protocols to prevent environmental contamination. Conventional wastewater treatment systems often prove inadequate for removing these compounds, necessitating advanced oxidation processes or activated carbon filtration systems. The disposal of spent adsorbents and treatment residues creates additional environmental management challenges that must be addressed within comprehensive compliance programs.

Recent environmental impact assessments have highlighted the need for life-cycle approaches when evaluating petroleum ether usage. Such analyses reveal that environmental impacts extend beyond the immediate usage phase to include extraction, refining, transportation, and ultimate disposal considerations. This holistic perspective is increasingly required by regulatory authorities when evaluating permit applications for facilities utilizing significant quantities of petroleum ether in their operations.

When released into the environment, petroleum ether compounds can persist in soil and water systems, potentially contaminating groundwater resources. The bioaccumulation potential in aquatic organisms represents a concerning vector for ecosystem disruption, as these compounds may transfer through food chains and affect multiple trophic levels. Studies have documented reduced biodiversity in aquatic environments with elevated petroleum hydrocarbon concentrations.

Atmospheric emissions from petroleum ether usage contribute to both local air quality degradation and global climate impacts. As VOCs interact with nitrogen oxides in the presence of sunlight, they catalyze the formation of photochemical oxidants, including tropospheric ozone. This process not only affects human respiratory health but also damages vegetation and agricultural crops, resulting in economic losses beyond direct environmental damage.

The greenhouse warming potential of petroleum ether compounds, while lower than some other industrial chemicals, still contributes to climate change effects when released at industrial scales. Particularly concerning are the secondary atmospheric reactions that can produce more persistent compounds with higher global warming potentials than the original emissions.

Regulatory frameworks increasingly recognize these multifaceted environmental impacts. The classification of petroleum ether as a hazardous air pollutant under various national and international regulations has driven industries to implement more stringent control technologies and operational practices. Capture efficiency requirements typically mandate 95-99% reduction in emissions, depending on the jurisdiction and specific application.

Waste streams containing petroleum ether residues require specialized treatment protocols to prevent environmental contamination. Conventional wastewater treatment systems often prove inadequate for removing these compounds, necessitating advanced oxidation processes or activated carbon filtration systems. The disposal of spent adsorbents and treatment residues creates additional environmental management challenges that must be addressed within comprehensive compliance programs.

Recent environmental impact assessments have highlighted the need for life-cycle approaches when evaluating petroleum ether usage. Such analyses reveal that environmental impacts extend beyond the immediate usage phase to include extraction, refining, transportation, and ultimate disposal considerations. This holistic perspective is increasingly required by regulatory authorities when evaluating permit applications for facilities utilizing significant quantities of petroleum ether in their operations.

Cost-Benefit Analysis of VOC Compliance Technologies

Implementing VOC compliance technologies requires careful evaluation of both initial investments and long-term operational implications. When considering petroleum ether usage specifically, organizations must weigh several financial factors against regulatory requirements and environmental benefits.

The capital expenditure for VOC capture systems varies significantly based on facility size and process requirements. Traditional carbon adsorption systems typically cost between $25,000-$100,000 for small to medium operations, while thermal oxidizers may require investments of $200,000-$1,500,000 depending on throughput capacity. Regenerative thermal oxidizers (RTOs), though more expensive initially, offer superior efficiency for petroleum ether capture.

Operational costs present another critical dimension. Petroleum ether's high volatility necessitates more frequent carbon replacement in adsorption systems, increasing maintenance expenses by approximately 15-30% compared to less volatile solvents. Energy consumption for thermal treatment systems processing petroleum ether can be substantial, with RTOs consuming 25-40% less energy than conventional thermal oxidizers when properly optimized.

Regulatory non-compliance carries significant financial risk. Facilities using petroleum ether face potential EPA penalties ranging from $7,500 to $97,229 per violation day under current Clean Air Act provisions. These penalties have increased by approximately 7% annually over the past decade, indicating a trend toward stricter enforcement.

Return on investment calculations reveal that facilities processing high volumes of petroleum ether typically achieve ROI within 2-4 years when implementing modern VOC control technologies. This timeline shortens in regions with stricter emissions regulations or where emissions trading programs exist. Notably, facilities that have upgraded from older control technologies report average operational cost reductions of 22-35%.

Tax incentives and grants available for environmental compliance technologies further improve the financial equation. The Modified Accelerated Cost Recovery System (MACRS) allows businesses to recover investments in qualifying pollution control equipment through depreciation deductions, while various state-level programs offer grants covering 10-40% of capital costs for VOC reduction technologies.

When evaluating total cost of ownership, facilities must consider that petroleum ether's high volatility often requires more robust capture systems but may enable more efficient recovery and reuse compared to heavier solvents. Advanced monitoring systems, while adding $15,000-$50,000 to initial costs, typically reduce compliance verification expenses by 40-60% over a five-year period.

The capital expenditure for VOC capture systems varies significantly based on facility size and process requirements. Traditional carbon adsorption systems typically cost between $25,000-$100,000 for small to medium operations, while thermal oxidizers may require investments of $200,000-$1,500,000 depending on throughput capacity. Regenerative thermal oxidizers (RTOs), though more expensive initially, offer superior efficiency for petroleum ether capture.

Operational costs present another critical dimension. Petroleum ether's high volatility necessitates more frequent carbon replacement in adsorption systems, increasing maintenance expenses by approximately 15-30% compared to less volatile solvents. Energy consumption for thermal treatment systems processing petroleum ether can be substantial, with RTOs consuming 25-40% less energy than conventional thermal oxidizers when properly optimized.

Regulatory non-compliance carries significant financial risk. Facilities using petroleum ether face potential EPA penalties ranging from $7,500 to $97,229 per violation day under current Clean Air Act provisions. These penalties have increased by approximately 7% annually over the past decade, indicating a trend toward stricter enforcement.

Return on investment calculations reveal that facilities processing high volumes of petroleum ether typically achieve ROI within 2-4 years when implementing modern VOC control technologies. This timeline shortens in regions with stricter emissions regulations or where emissions trading programs exist. Notably, facilities that have upgraded from older control technologies report average operational cost reductions of 22-35%.

Tax incentives and grants available for environmental compliance technologies further improve the financial equation. The Modified Accelerated Cost Recovery System (MACRS) allows businesses to recover investments in qualifying pollution control equipment through depreciation deductions, while various state-level programs offer grants covering 10-40% of capital costs for VOC reduction technologies.

When evaluating total cost of ownership, facilities must consider that petroleum ether's high volatility often requires more robust capture systems but may enable more efficient recovery and reuse compared to heavier solvents. Advanced monitoring systems, while adding $15,000-$50,000 to initial costs, typically reduce compliance verification expenses by 40-60% over a five-year period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!