Petroleum Ether In Compact Lab Distillation Systems: Reflux Ratios, Safety And Throughput

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Distillation Background and Objectives

Petroleum ether has been a cornerstone solvent in laboratory distillation processes since the early 20th century, evolving from simple batch distillation methods to today's sophisticated compact systems. This hydrocarbon mixture, typically consisting of pentanes and hexanes with boiling points between 30-60°C, has gained prominence due to its excellent solvation properties for non-polar compounds and relatively low boiling point range.

The evolution of petroleum ether distillation technology has followed a trajectory from rudimentary glass apparatus to modern automated systems with enhanced safety features and precise control mechanisms. The 1970s marked a significant turning point with the introduction of digital temperature controls, while the 1990s saw the integration of computerized monitoring systems that revolutionized laboratory distillation practices.

Current technological trends in compact lab distillation systems focus on miniaturization, energy efficiency, and enhanced safety protocols. The development of micro-distillation units capable of handling small sample volumes while maintaining separation efficiency represents a significant advancement in this field. Additionally, the integration of IoT capabilities for remote monitoring and control is emerging as a promising direction for laboratory operations.

The primary objective of our technical research is to optimize the relationship between reflux ratios, safety parameters, and throughput efficiency in compact petroleum ether distillation systems. Specifically, we aim to determine the optimal reflux ratio ranges that maximize separation efficiency while minimizing energy consumption and processing time. This involves investigating the thermal dynamics of petroleum ether under various distillation conditions and identifying potential safety hazards associated with its volatile nature.

Furthermore, we seek to develop enhanced safety protocols that address the specific challenges posed by petroleum ether's low flash point (approximately -40°C) and high flammability. This includes exploring innovative cooling systems, vapor containment mechanisms, and automated emergency shutdown procedures tailored to compact laboratory environments.

The technological goal extends to increasing throughput capacity without compromising separation quality or safety standards. This necessitates investigating novel column designs, packing materials, and heat transfer mechanisms that can enhance mass transfer efficiency in limited spatial configurations. Additionally, we aim to establish standardized operating procedures that can be adapted across different laboratory settings and scales.

By comprehensively addressing these objectives, we anticipate contributing to the next generation of compact distillation systems that offer superior performance, enhanced safety features, and improved user experience for petroleum ether processing in laboratory environments.

The evolution of petroleum ether distillation technology has followed a trajectory from rudimentary glass apparatus to modern automated systems with enhanced safety features and precise control mechanisms. The 1970s marked a significant turning point with the introduction of digital temperature controls, while the 1990s saw the integration of computerized monitoring systems that revolutionized laboratory distillation practices.

Current technological trends in compact lab distillation systems focus on miniaturization, energy efficiency, and enhanced safety protocols. The development of micro-distillation units capable of handling small sample volumes while maintaining separation efficiency represents a significant advancement in this field. Additionally, the integration of IoT capabilities for remote monitoring and control is emerging as a promising direction for laboratory operations.

The primary objective of our technical research is to optimize the relationship between reflux ratios, safety parameters, and throughput efficiency in compact petroleum ether distillation systems. Specifically, we aim to determine the optimal reflux ratio ranges that maximize separation efficiency while minimizing energy consumption and processing time. This involves investigating the thermal dynamics of petroleum ether under various distillation conditions and identifying potential safety hazards associated with its volatile nature.

Furthermore, we seek to develop enhanced safety protocols that address the specific challenges posed by petroleum ether's low flash point (approximately -40°C) and high flammability. This includes exploring innovative cooling systems, vapor containment mechanisms, and automated emergency shutdown procedures tailored to compact laboratory environments.

The technological goal extends to increasing throughput capacity without compromising separation quality or safety standards. This necessitates investigating novel column designs, packing materials, and heat transfer mechanisms that can enhance mass transfer efficiency in limited spatial configurations. Additionally, we aim to establish standardized operating procedures that can be adapted across different laboratory settings and scales.

By comprehensively addressing these objectives, we anticipate contributing to the next generation of compact distillation systems that offer superior performance, enhanced safety features, and improved user experience for petroleum ether processing in laboratory environments.

Market Applications and Demand Analysis

The petroleum ether market for compact laboratory distillation systems has experienced significant growth in recent years, driven primarily by expanding research activities in pharmaceutical, chemical, and academic sectors. Current market analysis indicates that the global laboratory distillation equipment market, which includes petroleum ether applications, is valued at approximately $1.2 billion, with a compound annual growth rate of 5.7% projected through 2028.

Petroleum ether's unique properties as a low-boiling hydrocarbon mixture make it particularly valuable in laboratory settings where precise separation and purification are required. The demand is especially strong in pharmaceutical research and development, where the need for high-purity compounds continues to drive investment in advanced distillation technologies that can maintain optimal reflux ratios while ensuring safety and maximizing throughput.

Academic and research institutions represent another substantial market segment, accounting for roughly 30% of the demand for compact distillation systems using petroleum ether. These institutions typically require systems that balance performance with educational value, allowing for clear observation of distillation processes while maintaining strict safety standards due to petroleum ether's high flammability.

The petrochemical industry remains the largest consumer of petroleum ether distillation systems, utilizing these technologies for quality control testing and small-scale process development. This sector values systems that can accurately model larger industrial processes while requiring minimal laboratory space and offering enhanced safety features to mitigate the risks associated with petroleum ether's volatility.

Regional market analysis reveals that North America and Europe currently dominate the market for advanced laboratory distillation equipment, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to increasing investments in pharmaceutical research and chemical manufacturing infrastructure.

A notable market trend is the growing demand for automated and digitally controlled distillation systems that can precisely maintain optimal reflux ratios while monitoring safety parameters in real-time. This shift reflects broader industry movements toward laboratory automation and represents a premium segment of the market with higher profit margins and technological barriers to entry.

Environmental regulations and safety standards are increasingly influencing market dynamics, with customers showing preference for systems that incorporate advanced safety features such as automatic shutdown capabilities, improved ventilation designs, and explosion-proof components specifically engineered for volatile substances like petroleum ether.

Petroleum ether's unique properties as a low-boiling hydrocarbon mixture make it particularly valuable in laboratory settings where precise separation and purification are required. The demand is especially strong in pharmaceutical research and development, where the need for high-purity compounds continues to drive investment in advanced distillation technologies that can maintain optimal reflux ratios while ensuring safety and maximizing throughput.

Academic and research institutions represent another substantial market segment, accounting for roughly 30% of the demand for compact distillation systems using petroleum ether. These institutions typically require systems that balance performance with educational value, allowing for clear observation of distillation processes while maintaining strict safety standards due to petroleum ether's high flammability.

The petrochemical industry remains the largest consumer of petroleum ether distillation systems, utilizing these technologies for quality control testing and small-scale process development. This sector values systems that can accurately model larger industrial processes while requiring minimal laboratory space and offering enhanced safety features to mitigate the risks associated with petroleum ether's volatility.

Regional market analysis reveals that North America and Europe currently dominate the market for advanced laboratory distillation equipment, collectively accounting for over 60% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to increasing investments in pharmaceutical research and chemical manufacturing infrastructure.

A notable market trend is the growing demand for automated and digitally controlled distillation systems that can precisely maintain optimal reflux ratios while monitoring safety parameters in real-time. This shift reflects broader industry movements toward laboratory automation and represents a premium segment of the market with higher profit margins and technological barriers to entry.

Environmental regulations and safety standards are increasingly influencing market dynamics, with customers showing preference for systems that incorporate advanced safety features such as automatic shutdown capabilities, improved ventilation designs, and explosion-proof components specifically engineered for volatile substances like petroleum ether.

Technical Challenges in Compact Lab Distillation

Compact laboratory distillation systems face significant technical challenges when working with petroleum ether, primarily due to its volatile nature and specific physical properties. The low boiling point range of petroleum ether (typically 30-60°C) creates difficulties in maintaining stable temperature control within compact systems that have limited thermal mass and insulation capabilities. This results in temperature fluctuations that can compromise separation efficiency and product purity.

Heat distribution represents another major challenge, as compact systems often exhibit thermal gradients across their components. These gradients can lead to inconsistent vaporization rates and condensation patterns when distilling petroleum ether, affecting the establishment of equilibrium conditions necessary for proper fractionation. The limited surface area available for heat exchange in compact systems exacerbates this issue.

Reflux management presents particular difficulties in compact systems processing petroleum ether. The optimal reflux ratio for petroleum ether distillation typically requires precise control mechanisms that may be constrained by the miniaturized dimensions of compact equipment. Inadequate reflux control directly impacts separation efficiency and throughput capacity, creating a technical bottleneck in system performance.

Pressure regulation emerges as a critical challenge due to petroleum ether's high vapor pressure. Compact systems may struggle to maintain consistent internal pressure, leading to fluctuations that affect boiling points and separation characteristics. The limited structural robustness of compact systems also raises concerns about their ability to safely contain pressurized petroleum ether vapors during operation.

Material compatibility issues arise as petroleum ether can degrade certain polymers and elastomers commonly used in compact system components such as seals and gaskets. This degradation not only compromises system integrity but also risks contaminating the distillate with leached compounds, affecting analytical results and product quality.

Scaling effects become pronounced in compact systems, where the surface-to-volume ratio significantly differs from larger industrial equipment. These differences alter heat and mass transfer dynamics when working with petroleum ether, requiring specialized design considerations that may not be directly extrapolated from conventional distillation principles.

Safety systems integration presents substantial challenges due to space constraints. Incorporating adequate ventilation, vapor containment, and emergency shutdown mechanisms within the limited footprint of compact distillation systems requires innovative engineering solutions that do not compromise operational efficiency or increase system complexity beyond practical limits.

Heat distribution represents another major challenge, as compact systems often exhibit thermal gradients across their components. These gradients can lead to inconsistent vaporization rates and condensation patterns when distilling petroleum ether, affecting the establishment of equilibrium conditions necessary for proper fractionation. The limited surface area available for heat exchange in compact systems exacerbates this issue.

Reflux management presents particular difficulties in compact systems processing petroleum ether. The optimal reflux ratio for petroleum ether distillation typically requires precise control mechanisms that may be constrained by the miniaturized dimensions of compact equipment. Inadequate reflux control directly impacts separation efficiency and throughput capacity, creating a technical bottleneck in system performance.

Pressure regulation emerges as a critical challenge due to petroleum ether's high vapor pressure. Compact systems may struggle to maintain consistent internal pressure, leading to fluctuations that affect boiling points and separation characteristics. The limited structural robustness of compact systems also raises concerns about their ability to safely contain pressurized petroleum ether vapors during operation.

Material compatibility issues arise as petroleum ether can degrade certain polymers and elastomers commonly used in compact system components such as seals and gaskets. This degradation not only compromises system integrity but also risks contaminating the distillate with leached compounds, affecting analytical results and product quality.

Scaling effects become pronounced in compact systems, where the surface-to-volume ratio significantly differs from larger industrial equipment. These differences alter heat and mass transfer dynamics when working with petroleum ether, requiring specialized design considerations that may not be directly extrapolated from conventional distillation principles.

Safety systems integration presents substantial challenges due to space constraints. Incorporating adequate ventilation, vapor containment, and emergency shutdown mechanisms within the limited footprint of compact distillation systems requires innovative engineering solutions that do not compromise operational efficiency or increase system complexity beyond practical limits.

Current Reflux Ratio Optimization Methods

01 Safety measures for petroleum ether distillation

Petroleum ether is highly flammable and volatile, requiring specific safety measures in compact lab distillation systems. These include proper ventilation systems, explosion-proof equipment, temperature monitoring devices, and emergency shutdown mechanisms. Safety protocols should address vapor containment, pressure regulation, and prevention of static electricity buildup to minimize fire and explosion risks during distillation processes.- Reflux ratio optimization in petroleum ether distillation: Optimizing reflux ratios is critical when distilling petroleum ether in compact laboratory systems. The proper reflux ratio ensures efficient separation of components while maintaining throughput. Advanced control systems can be implemented to automatically adjust reflux ratios based on temperature and pressure readings, improving the purity of the distillate. These systems typically incorporate sensors and feedback mechanisms to maintain optimal conditions throughout the distillation process.

- Safety features for petroleum ether handling in lab distillation: Due to petroleum ether's high volatility and flammability, specialized safety features are essential in compact distillation systems. These include explosion-proof components, automatic shutdown mechanisms triggered by temperature or pressure anomalies, and proper ventilation systems to prevent accumulation of flammable vapors. Some systems incorporate flame arrestors and pressure relief valves to mitigate risks during operation. Proper grounding and anti-static measures are also implemented to prevent ignition from static electricity.

- Throughput enhancement techniques for petroleum ether distillation: Various design innovations can enhance throughput when distilling petroleum ether in compact laboratory systems. These include optimized column designs with increased surface area, improved heat exchange efficiency, and strategic feed introduction points. Some systems employ multiple distillation stages or parallel processing to increase overall throughput while maintaining separation quality. Advanced packing materials and column internals can also significantly improve mass transfer efficiency, allowing for higher processing rates without sacrificing purity.

- Energy efficiency in compact petroleum ether distillation systems: Energy-efficient designs for petroleum ether distillation incorporate heat recovery systems, insulation improvements, and optimized heating elements. These systems often utilize waste heat from the condenser to preheat incoming feed, reducing overall energy consumption. Some designs implement vacuum distillation to lower the boiling point of petroleum ether, further reducing energy requirements. Advanced control algorithms can dynamically adjust heating parameters to minimize energy usage while maintaining desired separation performance.

- Innovative column designs for petroleum ether separation: Novel column designs specifically tailored for petroleum ether distillation include modular components that allow for easy reconfiguration based on separation requirements. These designs often feature specialized packing materials or trays that enhance separation efficiency while minimizing pressure drop. Some systems incorporate adjustable column sections to modify theoretical plate numbers as needed. Advanced materials resistant to petroleum ether's chemical properties ensure longevity and consistent performance, while transparent sections allow for visual monitoring of the distillation process.

02 Optimizing reflux ratios for petroleum ether distillation

Achieving optimal reflux ratios is critical for efficient petroleum ether distillation in compact lab systems. Higher reflux ratios improve separation quality but reduce throughput, while lower ratios increase throughput at the expense of separation efficiency. Automated reflux control systems can maintain precise ratios based on temperature differentials and vapor composition, allowing for better fraction collection and purity in petroleum ether processing.Expand Specific Solutions03 Throughput enhancement techniques

Various design modifications can enhance petroleum ether throughput in compact distillation systems. These include optimized column packing materials, improved heat transfer surfaces, efficient condensers, and precise feed rate control mechanisms. Advanced column designs with multiple theoretical plates in minimal space allow for increased processing capacity while maintaining separation efficiency, making compact systems more productive for petroleum ether distillation.Expand Specific Solutions04 Energy efficiency in compact distillation systems

Energy-efficient designs for petroleum ether distillation incorporate heat recovery systems, insulated columns, and optimized heating elements. Vacuum distillation techniques allow for lower boiling points, reducing energy requirements and thermal degradation risks. Smart control systems that adjust heating based on distillation progress further reduce energy consumption while maintaining throughput and separation quality in compact laboratory settings.Expand Specific Solutions05 Advanced monitoring and control systems

Modern compact distillation systems for petroleum ether incorporate sophisticated monitoring and control technologies. These include real-time composition analysis, automated fraction collection based on predetermined parameters, and digital interfaces for precise process control. Integrated sensors monitor temperature profiles, pressure conditions, and vapor composition throughout the distillation process, enabling safer operation and more consistent results when working with volatile petroleum ether.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The petroleum ether distillation systems market is in a growth phase, driven by increasing demand for efficient laboratory-scale separation processes in petrochemical research. The global market size for compact lab distillation systems is expanding at approximately 5-7% annually, with particular acceleration in emerging economies. Technologically, the field is moderately mature but evolving toward enhanced safety features and automation. Leading players include China Petroleum & Chemical Corp. and ExxonMobil Chemical Patents, which focus on high-throughput systems with advanced reflux control, while LG Chem and Nippon Shokubai are developing innovative safety mechanisms for volatile petroleum ether handling. Research institutions like Fraunhofer-Gesellschaft and IFP Energies Nouvelles are pioneering next-generation distillation technologies with improved energy efficiency and reduced environmental impact.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced compact lab distillation systems for petroleum ether processing that incorporate precise electronic control of reflux ratios. Their technology utilizes a dual-cooling system with programmable temperature gradients to maintain optimal reflux conditions while preventing vapor loss. Sinopec's systems feature integrated safety mechanisms including pressure relief valves, automated shutdown protocols triggered by temperature or pressure anomalies, and specialized vapor containment designs that minimize exposure risks. Their latest models incorporate real-time monitoring through digital interfaces that allow researchers to adjust parameters remotely while maximizing throughput via optimized heat transfer surfaces and enhanced column packing materials that improve separation efficiency while maintaining safety standards.

Strengths: Superior integration of safety systems with production efficiency; excellent vapor containment technology reducing exposure risks; advanced digital control systems enabling precise reflux ratio management. Weaknesses: Higher initial investment costs compared to simpler systems; requires specialized training for operators; some components have limited service life in continuous operation environments.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil Technology & Engineering Co. has pioneered compact lab distillation systems specifically designed for petroleum ether applications with their ProDistill™ series. These systems feature proprietary microprocessor-controlled reflux management that automatically adjusts ratios based on real-time vapor composition analysis. Their innovation includes a patented heat exchange network that reduces energy consumption while maintaining precise temperature control throughout the distillation process. Safety features include intrinsically safe electrical components, multi-point leak detection systems, and redundant pressure monitoring with automated venting protocols. ExxonMobil's systems incorporate specialized borosilicate glass components with reinforced connection points to withstand the volatile nature of petroleum ether while maintaining visibility of the process. Their throughput optimization includes variable speed magnetic drive stirrers and high-efficiency condensers that maximize recovery rates.

Strengths: Industry-leading energy efficiency; exceptional automation capabilities reducing operator intervention; robust safety systems with redundant failsafes. Weaknesses: Higher maintenance requirements due to complex control systems; limited scalability for certain applications; proprietary components can increase long-term operational costs.

Safety Protocol Innovations for Volatile Solvents

Method for separating and purifying mixture having small difference in boiling points

PatentWO2019039798A1

Innovation

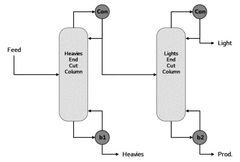

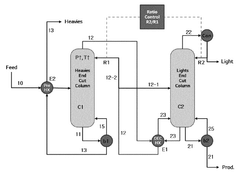

- A method involving a two-stage distillation process with specific heat exchanger configurations and reflux ratios to optimize energy use and stability, where the upper fraction from the first distillation column is used to preheat the second column, and refluxed to maintain efficient separation and purification.

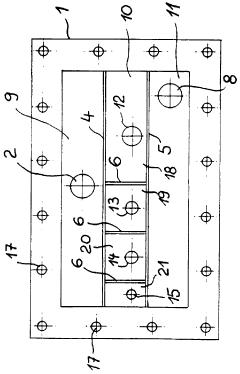

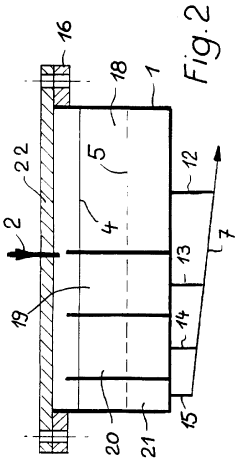

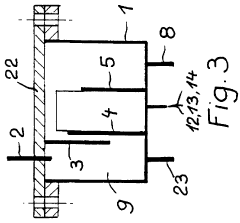

Separating device for currents of liquid, in particular, for distillation columns

PatentWO1997043022A1

Innovation

- A simple and inexpensive divider design with a distributor housing divided into three tanks separated by weirs, featuring transverse plates that create separate chambers with adjustable valves, allowing for precise control of reflux ratio without rotating parts or expensive seals, using the flow length between plates to determine distribution ratios.

Regulatory Compliance for Laboratory Distillation

Laboratory distillation processes involving petroleum ether are subject to stringent regulatory frameworks designed to ensure safety, environmental protection, and quality standards. In the United States, the Occupational Safety and Health Administration (OSHA) mandates specific requirements for handling volatile organic compounds like petroleum ether, including proper ventilation systems, personal protective equipment, and emergency response protocols.

The Environmental Protection Agency (EPA) regulates emissions and waste disposal associated with laboratory distillation processes through the Resource Conservation and Recovery Act (RCRA) and Clean Air Act provisions. Laboratories must maintain detailed documentation of petroleum ether usage, storage conditions, and disposal methods to demonstrate compliance with these regulations.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose additional requirements for chemical registration and safety assessments. The EU's laboratory safety directive 2019/1243 specifically addresses distillation processes involving flammable solvents, mandating risk assessments and implementation of engineering controls.

For compact lab distillation systems, regulatory compliance becomes particularly challenging due to space constraints. These systems must incorporate safety features such as automatic shutdown mechanisms, pressure relief valves, and explosion-proof electrical components while maintaining a small footprint. The International Electrotechnical Commission (IEC) standard 60079 provides guidelines for electrical equipment in potentially explosive atmospheres that apply to these systems.

Reflux ratio management in petroleum ether distillation carries specific regulatory implications. Higher reflux ratios, while improving separation efficiency, increase process duration and energy consumption, potentially triggering additional regulatory requirements under energy efficiency directives. The American Chemical Society's guidelines recommend optimized reflux ratios that balance throughput with safety considerations.

Throughput optimization must occur within regulatory boundaries. The National Fire Protection Association (NFPA) code 45 establishes maximum quantities of flammable liquids permitted in laboratories, directly impacting allowable throughput levels. Compliance with these quantity limitations requires careful process design and scheduling.

Laboratory certification standards such as ISO/IEC 17025 impose additional requirements for distillation processes, including validation protocols, equipment calibration, and personnel training. Laboratories must demonstrate that their compact distillation systems can consistently produce reliable results while maintaining compliance with all applicable regulations.

Recent regulatory trends indicate increasing scrutiny of energy efficiency and waste minimization in laboratory operations. The implementation of green chemistry principles is becoming a de facto regulatory expectation, with some jurisdictions offering incentives for laboratories that adopt more sustainable distillation techniques and solvent recovery systems.

The Environmental Protection Agency (EPA) regulates emissions and waste disposal associated with laboratory distillation processes through the Resource Conservation and Recovery Act (RCRA) and Clean Air Act provisions. Laboratories must maintain detailed documentation of petroleum ether usage, storage conditions, and disposal methods to demonstrate compliance with these regulations.

European regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), impose additional requirements for chemical registration and safety assessments. The EU's laboratory safety directive 2019/1243 specifically addresses distillation processes involving flammable solvents, mandating risk assessments and implementation of engineering controls.

For compact lab distillation systems, regulatory compliance becomes particularly challenging due to space constraints. These systems must incorporate safety features such as automatic shutdown mechanisms, pressure relief valves, and explosion-proof electrical components while maintaining a small footprint. The International Electrotechnical Commission (IEC) standard 60079 provides guidelines for electrical equipment in potentially explosive atmospheres that apply to these systems.

Reflux ratio management in petroleum ether distillation carries specific regulatory implications. Higher reflux ratios, while improving separation efficiency, increase process duration and energy consumption, potentially triggering additional regulatory requirements under energy efficiency directives. The American Chemical Society's guidelines recommend optimized reflux ratios that balance throughput with safety considerations.

Throughput optimization must occur within regulatory boundaries. The National Fire Protection Association (NFPA) code 45 establishes maximum quantities of flammable liquids permitted in laboratories, directly impacting allowable throughput levels. Compliance with these quantity limitations requires careful process design and scheduling.

Laboratory certification standards such as ISO/IEC 17025 impose additional requirements for distillation processes, including validation protocols, equipment calibration, and personnel training. Laboratories must demonstrate that their compact distillation systems can consistently produce reliable results while maintaining compliance with all applicable regulations.

Recent regulatory trends indicate increasing scrutiny of energy efficiency and waste minimization in laboratory operations. The implementation of green chemistry principles is becoming a de facto regulatory expectation, with some jurisdictions offering incentives for laboratories that adopt more sustainable distillation techniques and solvent recovery systems.

Energy Efficiency in Compact Distillation Systems

Energy efficiency in compact distillation systems for petroleum ether processing represents a critical area of focus for laboratory operations. Current compact systems demonstrate variable efficiency levels, with energy consumption typically ranging from 0.8 to 2.5 kWh per liter of distillate, depending on system design and operational parameters. This significant variation highlights the potential for substantial energy optimization.

The relationship between reflux ratio and energy consumption presents a key optimization opportunity. Higher reflux ratios, while improving separation quality, increase energy requirements exponentially. Research indicates that for petroleum ether distillation, maintaining reflux ratios between 3:1 and 5:1 offers an optimal balance between separation efficiency and energy consumption, reducing energy usage by up to 30% compared to higher reflux operations.

Heat recovery systems have emerged as essential components in energy-efficient compact distillation. Advanced heat exchangers that capture and reuse thermal energy from condensers can improve overall system efficiency by 15-25%. Particularly promising are micro-channel heat exchangers that maximize surface area while minimizing spatial requirements, perfectly suited for compact laboratory systems handling petroleum ether.

Insulation technologies specifically designed for compact systems represent another significant advancement. Vacuum-insulated panels and aerogel-based materials provide superior thermal resistance with minimal thickness, addressing the space constraints inherent in compact systems. These materials can reduce heat loss by 40-60% compared to conventional insulation, directly translating to energy savings.

Control system optimization through intelligent algorithms offers additional efficiency gains. Adaptive control systems that continuously adjust heating parameters based on real-time distillation conditions can reduce energy consumption by 10-20%. These systems are particularly valuable when processing petroleum ether, as they can respond to its narrow boiling range characteristics and maintain optimal energy input throughout the process.

Recent innovations in heating element design have yielded significant improvements. Targeted heating approaches using induction or microwave technology provide more direct energy transfer to the distillation mixture, reducing waste heat. These technologies have demonstrated energy efficiency improvements of 25-35% in compact systems processing volatile solvents like petroleum ether, while simultaneously enhancing safety by reducing external heating surface temperatures.

The integration of renewable energy sources represents an emerging trend in laboratory distillation systems. Small-scale solar thermal collectors or heat pumps can supplement or replace conventional electrical heating, potentially reducing carbon footprint by 40-70% depending on geographical location and available solar resources.

The relationship between reflux ratio and energy consumption presents a key optimization opportunity. Higher reflux ratios, while improving separation quality, increase energy requirements exponentially. Research indicates that for petroleum ether distillation, maintaining reflux ratios between 3:1 and 5:1 offers an optimal balance between separation efficiency and energy consumption, reducing energy usage by up to 30% compared to higher reflux operations.

Heat recovery systems have emerged as essential components in energy-efficient compact distillation. Advanced heat exchangers that capture and reuse thermal energy from condensers can improve overall system efficiency by 15-25%. Particularly promising are micro-channel heat exchangers that maximize surface area while minimizing spatial requirements, perfectly suited for compact laboratory systems handling petroleum ether.

Insulation technologies specifically designed for compact systems represent another significant advancement. Vacuum-insulated panels and aerogel-based materials provide superior thermal resistance with minimal thickness, addressing the space constraints inherent in compact systems. These materials can reduce heat loss by 40-60% compared to conventional insulation, directly translating to energy savings.

Control system optimization through intelligent algorithms offers additional efficiency gains. Adaptive control systems that continuously adjust heating parameters based on real-time distillation conditions can reduce energy consumption by 10-20%. These systems are particularly valuable when processing petroleum ether, as they can respond to its narrow boiling range characteristics and maintain optimal energy input throughout the process.

Recent innovations in heating element design have yielded significant improvements. Targeted heating approaches using induction or microwave technology provide more direct energy transfer to the distillation mixture, reducing waste heat. These technologies have demonstrated energy efficiency improvements of 25-35% in compact systems processing volatile solvents like petroleum ether, while simultaneously enhancing safety by reducing external heating surface temperatures.

The integration of renewable energy sources represents an emerging trend in laboratory distillation systems. Small-scale solar thermal collectors or heat pumps can supplement or replace conventional electrical heating, potentially reducing carbon footprint by 40-70% depending on geographical location and available solar resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!