Petroleum Ether For Waxy Crude Simulants: Precipitation, Pour Surrogates And Repeatability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Technology Background and Objectives

Petroleum ether has emerged as a critical solvent in the petroleum industry, particularly for addressing challenges related to waxy crude oil handling and transportation. The evolution of petroleum ether technology can be traced back to the early 20th century when fractional distillation processes were refined to isolate specific hydrocarbon fractions. Over decades, the applications of petroleum ether have expanded from simple laboratory uses to sophisticated industrial applications in crude oil processing.

The technological trajectory has been marked by significant improvements in petroleum ether's purity, consistency, and application specificity. Initially used primarily as a general-purpose solvent, petroleum ether has evolved to become a precision tool in petroleum engineering, especially for managing waxy crude oils that present substantial flow assurance challenges in production and transportation systems.

Recent technological advancements have focused on optimizing petroleum ether's effectiveness in simulating and predicting wax precipitation behaviors in crude oils under various temperature and pressure conditions. This has become increasingly important as oil exploration moves into deeper waters and more challenging environments where waxy crude oils are commonly encountered.

The current research emphasis lies in developing standardized methodologies for using petroleum ether in creating reliable waxy crude simulants. These simulants serve as essential tools for laboratory testing and field application development, allowing engineers to predict and mitigate flow assurance issues before they occur in actual production environments.

A key technological objective is to enhance the repeatability and reliability of petroleum ether-based testing protocols. The industry seeks to establish consistent standards for wax precipitation studies, pour point determinations, and rheological assessments of waxy crude oils. This standardization is crucial for comparing results across different laboratories and field conditions.

Another significant goal is to improve the correlation between laboratory simulants and real-world crude oil behaviors. This includes developing more sophisticated models that account for the complex interactions between petroleum ether and the diverse components present in waxy crude oils, particularly asphaltenes and resins that can significantly influence precipitation dynamics.

The technology also aims to address environmental and safety concerns associated with petroleum ether usage. Research is underway to develop greener alternatives or modified processes that maintain technical effectiveness while reducing environmental impact and improving worker safety profiles in both laboratory and field applications.

The technological trajectory has been marked by significant improvements in petroleum ether's purity, consistency, and application specificity. Initially used primarily as a general-purpose solvent, petroleum ether has evolved to become a precision tool in petroleum engineering, especially for managing waxy crude oils that present substantial flow assurance challenges in production and transportation systems.

Recent technological advancements have focused on optimizing petroleum ether's effectiveness in simulating and predicting wax precipitation behaviors in crude oils under various temperature and pressure conditions. This has become increasingly important as oil exploration moves into deeper waters and more challenging environments where waxy crude oils are commonly encountered.

The current research emphasis lies in developing standardized methodologies for using petroleum ether in creating reliable waxy crude simulants. These simulants serve as essential tools for laboratory testing and field application development, allowing engineers to predict and mitigate flow assurance issues before they occur in actual production environments.

A key technological objective is to enhance the repeatability and reliability of petroleum ether-based testing protocols. The industry seeks to establish consistent standards for wax precipitation studies, pour point determinations, and rheological assessments of waxy crude oils. This standardization is crucial for comparing results across different laboratories and field conditions.

Another significant goal is to improve the correlation between laboratory simulants and real-world crude oil behaviors. This includes developing more sophisticated models that account for the complex interactions between petroleum ether and the diverse components present in waxy crude oils, particularly asphaltenes and resins that can significantly influence precipitation dynamics.

The technology also aims to address environmental and safety concerns associated with petroleum ether usage. Research is underway to develop greener alternatives or modified processes that maintain technical effectiveness while reducing environmental impact and improving worker safety profiles in both laboratory and field applications.

Market Analysis for Waxy Crude Processing Solutions

The global market for waxy crude processing solutions has experienced significant growth in recent years, driven by the increasing exploitation of unconventional oil reserves. The market size for waxy crude treatment technologies was valued at approximately $3.2 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 6.5%. This growth trajectory is primarily attributed to the rising production of waxy crude oil in regions such as China, Russia, the Middle East, and parts of Africa.

Petroleum ether-based solutions for waxy crude treatment have emerged as a particularly promising segment within this market. These solutions address critical challenges in waxy crude handling, including high pour points, precipitation issues, and flow assurance problems. The demand for such solutions is especially strong in cold climate regions where waxy crude transportation faces severe operational difficulties.

Industry analysis indicates that the market for petroleum ether applications in waxy crude simulants is growing at a faster rate than the overall waxy crude processing market, with an estimated growth rate of 8.3% annually. This accelerated growth reflects the increasing recognition of petroleum ether's effectiveness in developing accurate simulants for research and development purposes.

The market landscape is characterized by regional variations in demand patterns. North America and Europe primarily focus on advanced technological solutions for existing infrastructure, while Asia-Pacific and Middle Eastern markets demonstrate stronger demand for cost-effective, scalable solutions that can be implemented in rapidly expanding production facilities.

End-user segmentation reveals that major oil producers account for approximately 45% of the market share, followed by pipeline operators (30%), refineries (20%), and research institutions (5%). This distribution highlights the diverse application potential of petroleum ether-based waxy crude simulants across the petroleum value chain.

Market drivers include increasingly stringent environmental regulations regarding oil spill prevention, rising operational costs associated with waxy crude handling, and the industry-wide push toward more efficient extraction and transportation methods. The development of repeatable and reliable waxy crude simulants using petroleum ether has become crucial for testing new technologies and methodologies before field implementation.

Challenges in market expansion include price volatility of petroleum ether, technical limitations in accurately simulating the complex behavior of different waxy crude varieties, and competition from alternative technologies such as pour point depressants and pipeline heating systems. Despite these challenges, the market outlook remains positive, supported by ongoing research and development efforts to enhance the precision and repeatability of petroleum ether-based waxy crude simulants.

Petroleum ether-based solutions for waxy crude treatment have emerged as a particularly promising segment within this market. These solutions address critical challenges in waxy crude handling, including high pour points, precipitation issues, and flow assurance problems. The demand for such solutions is especially strong in cold climate regions where waxy crude transportation faces severe operational difficulties.

Industry analysis indicates that the market for petroleum ether applications in waxy crude simulants is growing at a faster rate than the overall waxy crude processing market, with an estimated growth rate of 8.3% annually. This accelerated growth reflects the increasing recognition of petroleum ether's effectiveness in developing accurate simulants for research and development purposes.

The market landscape is characterized by regional variations in demand patterns. North America and Europe primarily focus on advanced technological solutions for existing infrastructure, while Asia-Pacific and Middle Eastern markets demonstrate stronger demand for cost-effective, scalable solutions that can be implemented in rapidly expanding production facilities.

End-user segmentation reveals that major oil producers account for approximately 45% of the market share, followed by pipeline operators (30%), refineries (20%), and research institutions (5%). This distribution highlights the diverse application potential of petroleum ether-based waxy crude simulants across the petroleum value chain.

Market drivers include increasingly stringent environmental regulations regarding oil spill prevention, rising operational costs associated with waxy crude handling, and the industry-wide push toward more efficient extraction and transportation methods. The development of repeatable and reliable waxy crude simulants using petroleum ether has become crucial for testing new technologies and methodologies before field implementation.

Challenges in market expansion include price volatility of petroleum ether, technical limitations in accurately simulating the complex behavior of different waxy crude varieties, and competition from alternative technologies such as pour point depressants and pipeline heating systems. Despite these challenges, the market outlook remains positive, supported by ongoing research and development efforts to enhance the precision and repeatability of petroleum ether-based waxy crude simulants.

Current Challenges in Petroleum Ether Applications

Despite the widespread use of petroleum ether in waxy crude simulants, several significant challenges persist in its application. The primary issue revolves around consistency in precipitation patterns when petroleum ether is used as a solvent for wax extraction. Research indicates that variations in petroleum ether composition, even within the same grade classification, can lead to substantially different precipitation behaviors in identical crude oil samples. This inconsistency undermines the reliability of laboratory tests and makes it difficult to establish standardized protocols for wax content determination.

Temperature sensitivity presents another major challenge. Petroleum ether's effectiveness in precipitating wax compounds varies dramatically across different temperature ranges, creating difficulties in maintaining consistent experimental conditions. Even minor temperature fluctuations during testing can significantly alter precipitation rates and patterns, leading to poor repeatability in experimental results. This is particularly problematic when attempting to simulate real-world pipeline conditions where temperature gradients are common.

The volatility of petroleum ether compounds introduces additional complications in long-duration experiments. Evaporation rates can vary based on environmental conditions, changing the solvent-to-crude ratio throughout the experiment. This dynamic shift in concentration affects the precipitation kinetics and can lead to misleading results, especially in pour point determinations where test duration is a critical factor.

Batch-to-batch variation in commercial petroleum ether represents a significant obstacle to research reproducibility. Studies have documented up to 15% variation in wax precipitation yield when using different batches of nominally identical petroleum ether. This variation stems from subtle differences in hydrocarbon chain distribution and the presence of trace impurities that can act as nucleation sites or inhibitors for wax crystal formation.

Safety concerns also limit petroleum ether applications in certain research environments. Its high flammability and potential for creating explosive atmospheres necessitate specialized handling equipment and ventilation systems. These requirements can restrict the scope and scale of experiments, particularly in facilities not specifically designed for working with highly volatile solvents.

Furthermore, environmental regulations increasingly restrict the use of petroleum ether due to its contribution to volatile organic compound (VOC) emissions. Researchers face growing pressure to develop alternative methodologies that maintain analytical accuracy while reducing environmental impact, creating a challenging balance between scientific rigor and sustainability considerations.

Temperature sensitivity presents another major challenge. Petroleum ether's effectiveness in precipitating wax compounds varies dramatically across different temperature ranges, creating difficulties in maintaining consistent experimental conditions. Even minor temperature fluctuations during testing can significantly alter precipitation rates and patterns, leading to poor repeatability in experimental results. This is particularly problematic when attempting to simulate real-world pipeline conditions where temperature gradients are common.

The volatility of petroleum ether compounds introduces additional complications in long-duration experiments. Evaporation rates can vary based on environmental conditions, changing the solvent-to-crude ratio throughout the experiment. This dynamic shift in concentration affects the precipitation kinetics and can lead to misleading results, especially in pour point determinations where test duration is a critical factor.

Batch-to-batch variation in commercial petroleum ether represents a significant obstacle to research reproducibility. Studies have documented up to 15% variation in wax precipitation yield when using different batches of nominally identical petroleum ether. This variation stems from subtle differences in hydrocarbon chain distribution and the presence of trace impurities that can act as nucleation sites or inhibitors for wax crystal formation.

Safety concerns also limit petroleum ether applications in certain research environments. Its high flammability and potential for creating explosive atmospheres necessitate specialized handling equipment and ventilation systems. These requirements can restrict the scope and scale of experiments, particularly in facilities not specifically designed for working with highly volatile solvents.

Furthermore, environmental regulations increasingly restrict the use of petroleum ether due to its contribution to volatile organic compound (VOC) emissions. Researchers face growing pressure to develop alternative methodologies that maintain analytical accuracy while reducing environmental impact, creating a challenging balance between scientific rigor and sustainability considerations.

Current Precipitation and Pour Point Solutions

01 Petroleum ether precipitation methods for asphaltene analysis

Petroleum ether is commonly used as a precipitating agent for asphaltenes in crude oil analysis. The precipitation process typically involves mixing the oil sample with petroleum ether at specific ratios, followed by filtration and quantification of the precipitated asphaltenes. This method is crucial for determining asphaltene content in petroleum products, which affects their stability and processing characteristics. The precipitation conditions, including temperature, solvent ratio, and contact time, significantly influence the repeatability of the results.- Petroleum ether precipitation methods for asphaltene analysis: Petroleum ether is commonly used as a precipitating agent for asphaltenes in crude oil analysis. The precipitation process typically involves mixing the oil sample with petroleum ether at specific ratios, followed by filtration to separate the precipitated asphaltenes. This method is crucial for determining asphaltene content in petroleum products and can be optimized by controlling factors such as temperature, solvent-to-oil ratio, and contact time to improve repeatability of results.

- Pour point determination using surrogate compounds: Pour point surrogates are compounds that mimic the low-temperature flow behavior of petroleum products. These surrogate compounds are used in standardized tests to predict the temperature at which oil becomes semi-solid and loses its flow characteristics. The use of well-defined surrogate mixtures improves the repeatability of pour point measurements compared to testing with variable composition crude oils, allowing for more consistent quality control in petroleum product specifications.

- Repeatability enhancement in petroleum testing procedures: Improving repeatability in petroleum analysis involves standardizing test conditions, calibrating equipment regularly, and implementing precise procedural controls. Statistical methods are employed to validate test results and establish repeatability limits. Automated testing systems have been developed to minimize human error and ensure consistent application of test protocols. These approaches are essential for achieving reliable and reproducible results in petroleum characterization, particularly for critical parameters like precipitation behavior and pour points.

- Advanced equipment for petroleum precipitation analysis: Specialized equipment has been developed to improve the precision and repeatability of petroleum ether precipitation tests. These include automated precipitation units with temperature control systems, filtration apparatus designed specifically for asphaltene separation, and optical monitoring systems that can detect precipitation in real-time. Such equipment helps standardize the precipitation process by eliminating variables introduced through manual handling, thereby enhancing the repeatability of results across different laboratories and operators.

- Novel methodologies for improving test repeatability in petroleum analysis: Innovative approaches have been developed to enhance the repeatability of petroleum testing, including modified precipitation techniques that incorporate ultrasonic treatment, controlled cooling rates, and precise solvent addition systems. Machine learning algorithms are being applied to predict precipitation behavior and identify factors affecting repeatability. Additionally, standardized reference materials specifically designed for calibration of petroleum tests help ensure consistent results across different laboratories, contributing to improved repeatability in industry-standard test methods.

02 Pour point determination using surrogate materials

Pour point surrogates are reference materials used to calibrate and validate pour point testing equipment and methodologies. These surrogates mimic the flow behavior of petroleum products at low temperatures and provide a standard for comparison. The use of pour point surrogates enhances the accuracy and repeatability of pour point measurements, which are critical for predicting the low-temperature handling characteristics of fuels and lubricants. Standardized surrogate materials help laboratories achieve consistent results across different testing facilities.Expand Specific Solutions03 Repeatability improvement in petroleum testing procedures

Enhancing repeatability in petroleum testing involves standardizing test conditions, calibrating equipment regularly, and implementing robust quality control measures. Statistical methods are employed to evaluate and improve the repeatability of test results, including the use of control charts and round-robin testing between laboratories. Automated testing systems can reduce human error and increase consistency in measurements. Proper sample handling and preparation techniques are also essential for achieving reliable and reproducible test results in petroleum analysis.Expand Specific Solutions04 Advanced equipment and apparatus for petroleum precipitation analysis

Specialized equipment has been developed to improve the precision and efficiency of petroleum precipitation tests. These include automated precipitation units, filtration systems with controlled pressure and temperature, and analytical instruments for quantifying precipitated materials. Modern apparatus often incorporates digital controls and data recording capabilities to enhance repeatability and reduce operator variability. Some systems integrate multiple testing functions, allowing for comprehensive analysis of petroleum samples under standardized conditions.Expand Specific Solutions05 Novel methodologies for improving petroleum testing accuracy

Innovative approaches to petroleum testing include the development of new solvent systems for more selective precipitation, spectroscopic techniques for real-time monitoring of precipitation processes, and computational models for predicting precipitation behavior. Machine learning algorithms are being applied to analyze test data and identify factors affecting repeatability. Additionally, microfluidic devices enable precise control over precipitation conditions using minimal sample volumes. These advancements contribute to more accurate characterization of petroleum products and better prediction of their behavior during processing and use.Expand Specific Solutions

Key Industry Players in Petroleum Ether Technology

The petroleum ether for waxy crude simulants market is in a growth phase, driven by increasing demand for effective solutions in managing waxy crude oil challenges. The market is expanding as oil exploration moves into regions with higher wax content crude. Technologically, the field is moderately mature but continues to evolve with innovations in precipitation techniques and pour point reduction. Key players include major oil corporations like PetroChina, Sinopec, and CNOOC, who lead research efforts in waxy crude management. Western companies such as Schlumberger and BASF contribute significant chemical expertise. Research institutes affiliated with China Petroleum University and Shengli Oilfield are advancing the technical understanding of petroleum ether applications, focusing on improving repeatability and standardization of testing methods.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered innovative approaches to waxy crude simulants using petroleum ether fractions. Their technical solution centers on a differential scanning calorimetry (DSC) integrated system that precisely controls the cooling rate (0.5-10°C/min) during petroleum ether-based precipitation studies. Sinopec's methodology employs a proprietary blend of petroleum ether with specific carbon number distributions (C5-C9) to create surrogate models that accurately mimic the rheological properties of waxy crudes at varying temperatures. Their research has established correlations between petroleum ether composition and the resulting pour point characteristics of the simulants, allowing for customized formulations based on specific pipeline conditions. The company has developed a comprehensive database of petroleum ether-crude oil interaction parameters for over 50 different crude compositions, enabling rapid development of tailored simulants with predictable properties. Sinopec's approach includes standardized repeatability testing protocols that have demonstrated variance below 5% across multiple laboratory settings, significantly improving the reliability of flow assurance predictions.

Strengths: Highly systematic approach with extensive documentation and standardization leads to exceptional repeatability in laboratory testing. Their large database of interaction parameters allows for rapid customization of simulants for specific crude types. Weaknesses: The complex methodology requires specialized equipment and highly trained personnel, making field implementation challenging in remote locations.

China National Petroleum Corp.

Technical Solution: China National Petroleum Corp. (CNPC) has developed advanced technical solutions for waxy crude oil treatment using petroleum ether as a key component. Their approach involves a multi-stage precipitation process where petroleum ether is used as a solvent to create accurate simulants of waxy crude behavior. The technology employs precise temperature control systems (ranging from -20°C to 80°C) to study wax precipitation kinetics under various conditions. CNPC's research has established standardized protocols for creating reproducible waxy crude simulants with controlled pour point characteristics, enabling more accurate prediction of flow assurance issues in pipeline operations. Their methodology includes a proprietary blend of petroleum ether fractions optimized for different crude oil compositions, particularly those from their major production fields with wax content exceeding 20%. The company has also developed specialized analytical equipment for quantifying the effectiveness of pour point depressants when used in conjunction with petroleum ether treatments.

Strengths: Extensive field experience with diverse waxy crude compositions from Chinese oilfields provides practical validation of their simulant methodologies. Their standardized testing protocols ensure high repeatability across different laboratory settings. Weaknesses: The technology is primarily optimized for waxy crude compositions typical of Chinese oilfields, which may limit applicability to significantly different crude compositions from other regions.

Core Patents in Waxy Crude Simulant Development

Low pour point gas fuel from waxy crudes

PatentInactiveUS3862825A

Innovation

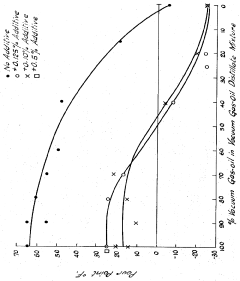

- A turbine fuel composition comprising 55-90% crude gas oil, 10-45% middle distillate oil, and 0.01-0.5% high molecular weight ethylene-vinyl fatty acid ester copolymers, which are added to the gas oil and mixed with the middle distillate, effectively depressing the pour point and improving flow characteristics at low temperatures.

Environmental Impact Assessment of Petroleum Ether Usage

The environmental impact of petroleum ether usage in waxy crude simulants requires comprehensive assessment due to its volatile organic compound (VOC) nature. Petroleum ether, primarily composed of pentane and hexane isomers, presents significant environmental concerns throughout its lifecycle from production to disposal. When used in precipitation studies and pour point determinations for waxy crude oil, these impacts become particularly relevant.

Atmospheric emissions constitute the primary environmental concern, as petroleum ether readily evaporates at room temperature, contributing to air pollution and potential photochemical smog formation when reacting with nitrogen oxides under sunlight. These reactions can lead to ground-level ozone formation, which negatively affects both human respiratory health and vegetation. Studies indicate that laboratory-scale operations can release between 5-15% of petroleum ether to the atmosphere during normal handling procedures.

Water contamination represents another critical impact pathway. Even small quantities of petroleum ether can significantly compromise water quality due to its low water solubility (typically <50 mg/L) but high toxicity to aquatic organisms. Research demonstrates that petroleum ether concentrations as low as 0.1 ppm can adversely affect sensitive aquatic species, particularly during developmental stages. Improper disposal or accidental spills during waxy crude simulation experiments can lead to groundwater or surface water contamination.

Soil contamination occurs when petroleum ether is spilled or improperly disposed of, potentially altering soil chemistry and microbial communities. The compound's mobility in soil varies depending on organic content and moisture levels, with persistence ranging from days to weeks under typical environmental conditions. This contamination pathway is particularly concerning in laboratory settings where small, repeated releases might go unnoticed but accumulate over time.

Energy consumption associated with petroleum ether production represents an indirect environmental impact. The distillation and refinement processes are energy-intensive, contributing to greenhouse gas emissions. Life cycle assessments indicate that producing one kilogram of laboratory-grade petroleum ether generates approximately 4-6 kg of CO2 equivalent emissions, depending on production efficiency and energy sources.

Waste management challenges arise from petroleum ether-contaminated materials used in waxy crude simulant studies. These materials require specialized disposal procedures to prevent environmental release. Current best practices include solvent recovery systems that can recapture up to 85% of used petroleum ether, significantly reducing both waste generation and fresh solvent requirements in laboratory settings.

Atmospheric emissions constitute the primary environmental concern, as petroleum ether readily evaporates at room temperature, contributing to air pollution and potential photochemical smog formation when reacting with nitrogen oxides under sunlight. These reactions can lead to ground-level ozone formation, which negatively affects both human respiratory health and vegetation. Studies indicate that laboratory-scale operations can release between 5-15% of petroleum ether to the atmosphere during normal handling procedures.

Water contamination represents another critical impact pathway. Even small quantities of petroleum ether can significantly compromise water quality due to its low water solubility (typically <50 mg/L) but high toxicity to aquatic organisms. Research demonstrates that petroleum ether concentrations as low as 0.1 ppm can adversely affect sensitive aquatic species, particularly during developmental stages. Improper disposal or accidental spills during waxy crude simulation experiments can lead to groundwater or surface water contamination.

Soil contamination occurs when petroleum ether is spilled or improperly disposed of, potentially altering soil chemistry and microbial communities. The compound's mobility in soil varies depending on organic content and moisture levels, with persistence ranging from days to weeks under typical environmental conditions. This contamination pathway is particularly concerning in laboratory settings where small, repeated releases might go unnoticed but accumulate over time.

Energy consumption associated with petroleum ether production represents an indirect environmental impact. The distillation and refinement processes are energy-intensive, contributing to greenhouse gas emissions. Life cycle assessments indicate that producing one kilogram of laboratory-grade petroleum ether generates approximately 4-6 kg of CO2 equivalent emissions, depending on production efficiency and energy sources.

Waste management challenges arise from petroleum ether-contaminated materials used in waxy crude simulant studies. These materials require specialized disposal procedures to prevent environmental release. Current best practices include solvent recovery systems that can recapture up to 85% of used petroleum ether, significantly reducing both waste generation and fresh solvent requirements in laboratory settings.

Standardization and Quality Control Protocols

The establishment of standardized protocols for petroleum ether usage in waxy crude simulants represents a critical advancement in ensuring experimental consistency and reliability. Current industry practices exhibit significant variability in methodology, leading to inconsistent results across different research facilities and laboratories. To address this challenge, comprehensive standardization frameworks must be developed, encompassing sample preparation, petroleum ether quality specifications, and procedural guidelines.

Quality control measures should begin with the specification of petroleum ether grades suitable for waxy crude simulation. The recommended petroleum ether should maintain a consistent boiling range of 35-60°C, with hydrocarbon composition variability not exceeding ±2%. Certificates of analysis must accompany each batch, documenting purity levels (minimum 99.5%), aromatic content (below 0.1%), and moisture levels (below 0.01%).

Procedural standardization should include precise protocols for petroleum ether-to-crude ratios, with recommended volumetric ratios ranging from 10:1 to 40:1 depending on wax content. Temperature control during precipitation processes must be maintained within ±0.5°C of target values, with cooling rates standardized at 1-2°C per minute to ensure reproducible wax crystallization patterns.

Statistical quality control methods should be implemented to monitor experimental repeatability. These include the calculation of coefficient of variation (CV) values for key parameters such as precipitation onset temperature and pour point measurements, with acceptable CV thresholds established at ≤5% for intra-laboratory testing and ≤8% for inter-laboratory comparisons.

Validation protocols should incorporate reference materials with certified wax content and precipitation characteristics. Each laboratory should maintain control charts tracking the performance of these reference materials over time, with action limits set at ±2 standard deviations from established mean values. Deviations beyond these limits should trigger investigation and corrective action procedures.

Equipment calibration represents another critical aspect of quality control. Differential scanning calorimetry (DSC) instruments used for wax precipitation analysis should undergo quarterly calibration using certified standards, while rheometers for pour point determination require monthly verification using reference oils of known viscosity profiles.

Documentation requirements should be standardized to include detailed experimental conditions, raw data preservation, and statistical analysis of replicate measurements. A minimum of three replicate analyses should be performed for each sample, with outlier detection and handling procedures clearly defined according to established statistical methods such as Grubbs' test or Dixon's Q test.

Through implementation of these standardization and quality control protocols, the petroleum industry can achieve significantly improved consistency in waxy crude simulant research, facilitating more reliable technology development and enhanced cross-institutional collaboration.

Quality control measures should begin with the specification of petroleum ether grades suitable for waxy crude simulation. The recommended petroleum ether should maintain a consistent boiling range of 35-60°C, with hydrocarbon composition variability not exceeding ±2%. Certificates of analysis must accompany each batch, documenting purity levels (minimum 99.5%), aromatic content (below 0.1%), and moisture levels (below 0.01%).

Procedural standardization should include precise protocols for petroleum ether-to-crude ratios, with recommended volumetric ratios ranging from 10:1 to 40:1 depending on wax content. Temperature control during precipitation processes must be maintained within ±0.5°C of target values, with cooling rates standardized at 1-2°C per minute to ensure reproducible wax crystallization patterns.

Statistical quality control methods should be implemented to monitor experimental repeatability. These include the calculation of coefficient of variation (CV) values for key parameters such as precipitation onset temperature and pour point measurements, with acceptable CV thresholds established at ≤5% for intra-laboratory testing and ≤8% for inter-laboratory comparisons.

Validation protocols should incorporate reference materials with certified wax content and precipitation characteristics. Each laboratory should maintain control charts tracking the performance of these reference materials over time, with action limits set at ±2 standard deviations from established mean values. Deviations beyond these limits should trigger investigation and corrective action procedures.

Equipment calibration represents another critical aspect of quality control. Differential scanning calorimetry (DSC) instruments used for wax precipitation analysis should undergo quarterly calibration using certified standards, while rheometers for pour point determination require monthly verification using reference oils of known viscosity profiles.

Documentation requirements should be standardized to include detailed experimental conditions, raw data preservation, and statistical analysis of replicate measurements. A minimum of three replicate analyses should be performed for each sample, with outlier detection and handling procedures clearly defined according to established statistical methods such as Grubbs' test or Dixon's Q test.

Through implementation of these standardization and quality control protocols, the petroleum industry can achieve significantly improved consistency in waxy crude simulant research, facilitating more reliable technology development and enhanced cross-institutional collaboration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!