How Does Petroleum Ether Recovery By Batch Distillation Change Purity And Safety Margins?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Petroleum Ether Recovery Background and Objectives

Petroleum ether, a mixture of volatile hydrocarbons derived from petroleum refining, has been extensively utilized in various industrial applications including pharmaceutical manufacturing, extraction processes, and as a cleaning solvent since the early 20th century. The evolution of petroleum ether recovery techniques has paralleled advancements in chemical engineering, with batch distillation emerging as a predominant method for solvent recovery in both laboratory and industrial settings.

The historical trajectory of petroleum ether recovery reveals a gradual shift from simple distillation apparatus to more sophisticated systems incorporating enhanced safety features and precise temperature control mechanisms. This progression has been driven by dual imperatives: maximizing economic efficiency through solvent reuse and addressing increasingly stringent environmental regulations regarding volatile organic compound emissions.

Recent technological developments have focused on optimizing the batch distillation process to maintain high purity levels while enhancing operational safety. The relationship between distillation parameters and recovered solvent quality represents a critical area of investigation, as even minor variations in process conditions can significantly impact both purity profiles and associated safety margins.

The primary objective of this technical research is to comprehensively analyze how batch distillation parameters influence the purity and safety characteristics of recovered petroleum ether. Specifically, we aim to establish quantifiable correlations between key operational variables—including heating rates, reflux ratios, cut point determination methods, and cooling efficiency—and resultant solvent quality metrics such as hydrocarbon composition stability, contaminant profiles, and flash point alterations.

Secondary objectives include identifying optimal process windows that balance recovery efficiency with purity maintenance, developing predictive models for safety parameter degradation across multiple recovery cycles, and establishing standardized protocols for quality assessment of recovered petroleum ether in different application contexts.

This investigation addresses a significant knowledge gap in current literature, where despite widespread industrial reliance on petroleum ether recovery, systematic studies examining the progressive changes in both chemical composition and safety parameters through successive distillation cycles remain limited. The findings will provide valuable guidance for industries seeking to maximize solvent recovery economics while maintaining stringent quality and safety standards.

The technological trajectory suggests continued refinement of recovery methodologies, with emerging innovations in real-time monitoring, automated cut-point adjustment, and hybrid recovery systems potentially transforming current practices. Understanding the fundamental relationships between distillation parameters and recovered solvent characteristics will be essential for effectively implementing these advanced technologies.

The historical trajectory of petroleum ether recovery reveals a gradual shift from simple distillation apparatus to more sophisticated systems incorporating enhanced safety features and precise temperature control mechanisms. This progression has been driven by dual imperatives: maximizing economic efficiency through solvent reuse and addressing increasingly stringent environmental regulations regarding volatile organic compound emissions.

Recent technological developments have focused on optimizing the batch distillation process to maintain high purity levels while enhancing operational safety. The relationship between distillation parameters and recovered solvent quality represents a critical area of investigation, as even minor variations in process conditions can significantly impact both purity profiles and associated safety margins.

The primary objective of this technical research is to comprehensively analyze how batch distillation parameters influence the purity and safety characteristics of recovered petroleum ether. Specifically, we aim to establish quantifiable correlations between key operational variables—including heating rates, reflux ratios, cut point determination methods, and cooling efficiency—and resultant solvent quality metrics such as hydrocarbon composition stability, contaminant profiles, and flash point alterations.

Secondary objectives include identifying optimal process windows that balance recovery efficiency with purity maintenance, developing predictive models for safety parameter degradation across multiple recovery cycles, and establishing standardized protocols for quality assessment of recovered petroleum ether in different application contexts.

This investigation addresses a significant knowledge gap in current literature, where despite widespread industrial reliance on petroleum ether recovery, systematic studies examining the progressive changes in both chemical composition and safety parameters through successive distillation cycles remain limited. The findings will provide valuable guidance for industries seeking to maximize solvent recovery economics while maintaining stringent quality and safety standards.

The technological trajectory suggests continued refinement of recovery methodologies, with emerging innovations in real-time monitoring, automated cut-point adjustment, and hybrid recovery systems potentially transforming current practices. Understanding the fundamental relationships between distillation parameters and recovered solvent characteristics will be essential for effectively implementing these advanced technologies.

Industrial Demand Analysis for Solvent Recovery

The global solvent recovery market has witnessed substantial growth in recent years, driven primarily by increasing environmental regulations and cost-saving initiatives across industries. The petroleum ether recovery segment specifically represents a significant portion of this market due to its widespread use in pharmaceutical manufacturing, oil extraction processes, and chemical synthesis. Current market valuations indicate the global solvent recovery systems market exceeds $1.2 billion, with projected annual growth rates of 5-7% through 2028.

Industries utilizing petroleum ether face mounting pressure to implement efficient recovery systems due to both economic and regulatory factors. The pharmaceutical sector, which consumes approximately 28% of recovered petroleum ether, has particularly stringent requirements for solvent purity. Even minor impurities can compromise product quality and safety, making efficient recovery processes essential. Similarly, the chemical manufacturing industry, representing about 32% of market demand, requires high-purity recovered solvents to maintain production standards.

Cost considerations remain a primary driver for solvent recovery implementation. Virgin petroleum ether prices have increased by nearly 18% over the past three years, significantly impacting operational expenses for solvent-intensive processes. Companies implementing effective batch distillation recovery systems report operational cost reductions between 40-60% compared to continuous virgin solvent procurement, with typical ROI periods of 12-18 months for modern recovery equipment.

Environmental regulations have become increasingly stringent regarding VOC emissions and waste disposal. The European Union's Industrial Emissions Directive and similar regulations in North America have established strict limits on solvent emissions, with non-compliance penalties reaching up to €200,000 per violation in some regions. These regulatory pressures have accelerated adoption of recovery technologies, with batch distillation systems seeing a 23% increase in installation rates since 2020.

Regional analysis reveals varying adoption patterns, with Western Europe leading implementation of advanced recovery systems at 37% market share, followed by North America at 29% and Asia-Pacific at 24%. Emerging economies show the highest growth potential, with India and China experiencing annual growth rates exceeding 9% in solvent recovery equipment installations.

Industry surveys indicate that batch distillation recovery systems are preferred by 62% of mid-sized operations due to their flexibility and lower initial capital requirements compared to continuous systems. However, concerns regarding purity maintenance and safety margins during recovery cycles remain significant barriers to wider adoption, particularly in highly regulated industries like pharmaceuticals and food processing.

Industries utilizing petroleum ether face mounting pressure to implement efficient recovery systems due to both economic and regulatory factors. The pharmaceutical sector, which consumes approximately 28% of recovered petroleum ether, has particularly stringent requirements for solvent purity. Even minor impurities can compromise product quality and safety, making efficient recovery processes essential. Similarly, the chemical manufacturing industry, representing about 32% of market demand, requires high-purity recovered solvents to maintain production standards.

Cost considerations remain a primary driver for solvent recovery implementation. Virgin petroleum ether prices have increased by nearly 18% over the past three years, significantly impacting operational expenses for solvent-intensive processes. Companies implementing effective batch distillation recovery systems report operational cost reductions between 40-60% compared to continuous virgin solvent procurement, with typical ROI periods of 12-18 months for modern recovery equipment.

Environmental regulations have become increasingly stringent regarding VOC emissions and waste disposal. The European Union's Industrial Emissions Directive and similar regulations in North America have established strict limits on solvent emissions, with non-compliance penalties reaching up to €200,000 per violation in some regions. These regulatory pressures have accelerated adoption of recovery technologies, with batch distillation systems seeing a 23% increase in installation rates since 2020.

Regional analysis reveals varying adoption patterns, with Western Europe leading implementation of advanced recovery systems at 37% market share, followed by North America at 29% and Asia-Pacific at 24%. Emerging economies show the highest growth potential, with India and China experiencing annual growth rates exceeding 9% in solvent recovery equipment installations.

Industry surveys indicate that batch distillation recovery systems are preferred by 62% of mid-sized operations due to their flexibility and lower initial capital requirements compared to continuous systems. However, concerns regarding purity maintenance and safety margins during recovery cycles remain significant barriers to wider adoption, particularly in highly regulated industries like pharmaceuticals and food processing.

Current Challenges in Batch Distillation Technology

Batch distillation technology for petroleum ether recovery faces significant challenges that impact both product purity and operational safety. The conventional batch distillation process, while widely used in chemical and petrochemical industries, struggles with maintaining consistent separation efficiency throughout the distillation cycle. As the composition of the still pot changes over time, the vapor-liquid equilibrium shifts continuously, making it difficult to maintain optimal separation conditions without sophisticated control systems.

Temperature control represents a critical challenge in petroleum ether recovery, as even minor fluctuations can significantly alter product purity. The low boiling point of petroleum ether (typically 30-60°C) creates a narrow operational window, requiring precise heating systems and responsive cooling mechanisms. Many existing industrial setups lack the necessary precision in their temperature control systems, resulting in inconsistent product quality across batches.

Energy efficiency remains a persistent issue in batch distillation operations. The process inherently involves repeated heating and cooling cycles, leading to substantial energy consumption. This not only increases operational costs but also contributes to larger carbon footprints. The intermittent nature of batch operations further exacerbates these inefficiencies compared to continuous distillation alternatives.

Safety concerns are particularly pronounced when handling petroleum ether due to its high volatility and flammability. The risk of vapor leakage during the distillation process presents significant explosion hazards, especially when operating near the substance's flash point. Inadequate ventilation systems and suboptimal condenser designs often fail to prevent the accumulation of flammable vapors, creating dangerous working environments.

Cross-contamination between batches poses another significant challenge. Residual materials from previous runs can compromise product purity in subsequent batches, necessitating thorough cleaning procedures that increase downtime and operational costs. This issue becomes particularly problematic when processing different grades of petroleum ether or when the equipment is used for multiple products.

Scaling issues further complicate batch distillation operations. Laboratory-scale processes often demonstrate excellent separation efficiency, but maintaining comparable performance at industrial scales presents significant engineering challenges. Heat transfer limitations, liquid distribution problems, and vapor flow inconsistencies all contribute to reduced separation efficiency in larger distillation columns.

Modern batch distillation facilities also face challenges in implementing advanced process analytical technology (PAT) for real-time monitoring. The lack of reliable in-line sensors capable of withstanding the harsh chemical environment limits the ability to make dynamic adjustments during the distillation process, resulting in suboptimal recovery rates and purity levels.

Temperature control represents a critical challenge in petroleum ether recovery, as even minor fluctuations can significantly alter product purity. The low boiling point of petroleum ether (typically 30-60°C) creates a narrow operational window, requiring precise heating systems and responsive cooling mechanisms. Many existing industrial setups lack the necessary precision in their temperature control systems, resulting in inconsistent product quality across batches.

Energy efficiency remains a persistent issue in batch distillation operations. The process inherently involves repeated heating and cooling cycles, leading to substantial energy consumption. This not only increases operational costs but also contributes to larger carbon footprints. The intermittent nature of batch operations further exacerbates these inefficiencies compared to continuous distillation alternatives.

Safety concerns are particularly pronounced when handling petroleum ether due to its high volatility and flammability. The risk of vapor leakage during the distillation process presents significant explosion hazards, especially when operating near the substance's flash point. Inadequate ventilation systems and suboptimal condenser designs often fail to prevent the accumulation of flammable vapors, creating dangerous working environments.

Cross-contamination between batches poses another significant challenge. Residual materials from previous runs can compromise product purity in subsequent batches, necessitating thorough cleaning procedures that increase downtime and operational costs. This issue becomes particularly problematic when processing different grades of petroleum ether or when the equipment is used for multiple products.

Scaling issues further complicate batch distillation operations. Laboratory-scale processes often demonstrate excellent separation efficiency, but maintaining comparable performance at industrial scales presents significant engineering challenges. Heat transfer limitations, liquid distribution problems, and vapor flow inconsistencies all contribute to reduced separation efficiency in larger distillation columns.

Modern batch distillation facilities also face challenges in implementing advanced process analytical technology (PAT) for real-time monitoring. The lack of reliable in-line sensors capable of withstanding the harsh chemical environment limits the ability to make dynamic adjustments during the distillation process, resulting in suboptimal recovery rates and purity levels.

Batch Distillation Techniques for Petroleum Ether

01 Batch distillation equipment design for petroleum ether recovery

Specialized equipment designs for batch distillation of petroleum ether focus on improving recovery efficiency and purity. These designs incorporate features such as optimized column configurations, reflux control systems, and specialized condensers that enhance separation efficiency. The equipment often includes monitoring systems for temperature and pressure control to maintain consistent distillation conditions, which directly impacts the purity of the recovered petroleum ether.- Batch distillation equipment for petroleum ether recovery: Specialized equipment designed for batch distillation of petroleum ether includes safety features such as explosion-proof components, temperature control systems, and pressure relief mechanisms. These systems are engineered to maintain precise distillation conditions while preventing hazardous situations. The equipment typically incorporates condensers, fractionating columns, and collection vessels designed specifically for volatile solvents like petroleum ether.

- Purity enhancement techniques in petroleum ether recovery: Various techniques can be employed to enhance the purity of recovered petroleum ether during batch distillation. These include multi-stage distillation processes, reflux optimization, and the use of specialized fractionating columns. Temperature gradient control and precise cut point determination are critical for achieving high purity levels. Additional purification steps such as molecular sieves or adsorption media may be incorporated to remove trace contaminants and achieve the desired purity specifications.

- Safety margins and risk mitigation in petroleum ether distillation: Establishing appropriate safety margins for petroleum ether recovery involves implementing multiple layers of protection. This includes maintaining operating temperatures well below the autoignition point, controlling vapor concentrations below the lower explosive limit, and implementing inert gas blanketing systems. Automated emergency shutdown systems, flame arrestors, and proper ventilation are essential safety features. Regular equipment inspection and maintenance protocols help ensure the integrity of the distillation system and prevent potential hazards.

- Process optimization for efficient petroleum ether recovery: Optimizing the batch distillation process for petroleum ether recovery involves careful control of heating rates, reflux ratios, and collection timing. Advanced process control strategies, including real-time monitoring of distillate composition and adaptive control algorithms, can maximize recovery efficiency while maintaining product quality. Energy integration techniques, such as heat recovery systems, can improve the overall efficiency of the distillation process. Proper batch scheduling and equipment sizing also contribute to optimized recovery operations.

- Monitoring and quality control systems for petroleum ether purity: Implementing robust monitoring and quality control systems is essential for ensuring consistent purity in recovered petroleum ether. This includes online analytical techniques such as gas chromatography, refractive index monitoring, and density measurements to verify product specifications. Statistical process control methods help identify trends and deviations before they affect product quality. Automated sampling systems and laboratory testing protocols provide verification of batch-to-batch consistency and compliance with purity requirements.

02 Safety systems for petroleum ether distillation

Safety systems for petroleum ether distillation address the flammability and volatility risks associated with the process. These include explosion-proof components, automated emergency shutdown mechanisms, and pressure relief systems to prevent accidents. Proper ventilation systems are incorporated to manage vapor accumulation, while temperature monitoring prevents overheating. These safety margins are critical given petroleum ether's low flash point and high flammability, ensuring operator safety and preventing environmental contamination.Expand Specific Solutions03 Purity enhancement techniques in petroleum ether recovery

Various techniques are employed to enhance the purity of recovered petroleum ether during batch distillation. These include multi-stage distillation processes, precise fractional distillation parameters, and specialized adsorbents to remove impurities. Temperature-controlled distillation with optimized reflux ratios helps achieve higher purity levels by improving separation efficiency. Some systems incorporate molecular sieves or other filtration methods to further purify the recovered solvent, ensuring it meets quality specifications for reuse.Expand Specific Solutions04 Automated control systems for batch distillation

Automated control systems improve the precision and consistency of petroleum ether recovery processes. These systems monitor and adjust critical parameters such as temperature profiles, pressure conditions, and reflux ratios throughout the distillation cycle. Real-time monitoring allows for immediate adjustments to maintain optimal separation conditions, while programmed distillation curves ensure consistent product quality. Advanced systems may incorporate predictive algorithms to optimize the distillation process based on feed composition and desired purity specifications.Expand Specific Solutions05 Energy efficiency and solvent loss reduction methods

Energy-efficient approaches to petroleum ether recovery focus on minimizing heat requirements and reducing solvent losses during the distillation process. Heat integration systems recover and reuse thermal energy, while improved condenser designs minimize vapor losses. Vacuum distillation techniques lower the boiling point requirements, reducing energy consumption and thermal degradation of the solvent. These methods not only improve economic efficiency but also enhance safety by reducing the volume of flammable vapors generated during the recovery process.Expand Specific Solutions

Key Industry Players in Solvent Recovery Equipment

The petroleum ether recovery by batch distillation market is currently in a growth phase, with increasing focus on process optimization and safety standards. The global market size for petroleum distillation equipment is projected to expand significantly due to rising demand in chemical processing industries. Technologically, the field is moderately mature but evolving, with major players like China Petroleum & Chemical Corp. (Sinopec) and Saudi Arabian Oil Co. (Saudi Aramco) leading innovation in large-scale applications. Shell and Dow Global Technologies are advancing safety protocols and purity enhancement techniques, while research institutions like Tsinghua University and CSIR are developing improved distillation methodologies. IFP Energies Nouvelles and Eastman Chemical are focusing on sustainability aspects, creating a competitive landscape where safety margins and product purity are becoming key differentiators in this technically complex market.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced batch distillation systems for petroleum ether recovery that incorporate real-time monitoring and adaptive control algorithms. Their technology utilizes a multi-stage distillation process with optimized reflux ratios that dynamically adjust based on vapor composition analysis. This approach enables precise separation of petroleum ether fractions with different boiling points (30-60°C range), achieving purities exceeding 99% while minimizing energy consumption. Sinopec's systems incorporate safety features including automated pressure regulation, temperature monitoring across multiple column points, and vapor detection systems that trigger emergency protocols when threshold values are exceeded. Their batch distillation units also feature specialized condensers designed to maximize recovery rates (typically 95-98%) while preventing volatile organic compound emissions through closed-loop vapor recovery systems[1][3]. Recent innovations include the implementation of digital twin technology to predict distillation outcomes and optimize operational parameters in real-time.

Strengths: Superior purity control through adaptive algorithms; integrated safety systems with multiple redundancies; high recovery efficiency with minimal environmental impact. Weaknesses: Higher initial capital investment compared to simpler systems; requires specialized technical expertise for operation and maintenance; system complexity can increase troubleshooting challenges.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has pioneered innovative batch distillation technologies specifically designed for petroleum ether recovery with enhanced safety profiles. Their approach incorporates a proprietary divided-wall column design that enables simultaneous separation of multiple petroleum ether fractions in a single distillation unit, significantly improving energy efficiency by up to 30% compared to conventional methods[2]. The system utilizes advanced process intensification techniques with structured packing materials that enhance mass transfer efficiency while reducing HETP (Height Equivalent to a Theoretical Plate). For safety enhancement, IFP has developed an integrated risk management framework that combines predictive modeling with real-time monitoring of critical parameters including vapor pressure, temperature gradients, and oxygen concentration in the distillation environment. Their batch distillation units feature automated nitrogen blanketing systems that maintain inert atmospheres throughout the recovery process, effectively minimizing fire and explosion risks. Additionally, IFP's technology incorporates specialized heat integration systems that recover thermal energy from distillate streams to preheat feed material, further improving energy efficiency while reducing process variability that could impact product purity.

Strengths: Exceptional energy efficiency through process intensification and heat integration; comprehensive safety systems with predictive capabilities; ability to handle variable feedstock compositions while maintaining product specifications. Weaknesses: Complex control systems require specialized training; higher maintenance requirements for structured packing materials; performance advantages diminish at smaller production scales.

Critical Parameters Affecting Purity in Solvent Recovery

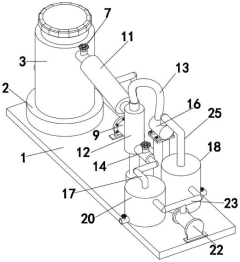

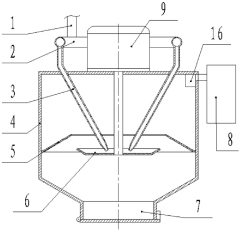

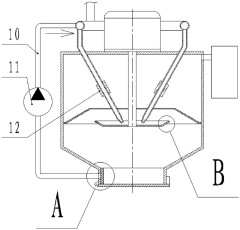

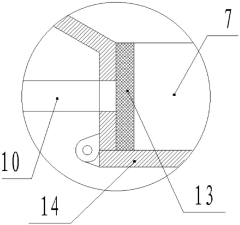

Petroleum ether recovery device

PatentActiveCN220370454U

Innovation

- A petroleum ether recovery device is designed, including a distillation tank, a guide pipe, a water separator, a cooling cylinder, the first and second refrigerators, a collection tank and an air extraction pump. It can quickly liquefy water vapor and reduce the storage temperature to improve petroleum ether recovery. Ether transfer and storage efficiency.

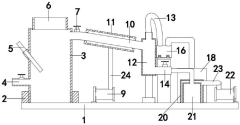

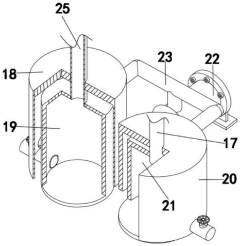

Distillation recovery device for petroleum ether production

PatentActiveCN219929972U

Innovation

- Design a distillation recovery device for petroleum ether production, including a tank, motor, rotating shaft, atomization disk and liquid inlet nozzle. The cavitation effect is generated through the contact between the liquid and the high-speed rotating atomization disk, which promotes the gasification and Atomize, use the condenser to recover the volatilized petroleum ether, and use the collection chamber and filter cotton to separate impurities.

Safety Protocols and Risk Assessment

The recovery of petroleum ether through batch distillation processes necessitates comprehensive safety protocols and thorough risk assessment due to the highly flammable nature of the solvent. Standard operating procedures must include proper equipment inspection before each distillation cycle, focusing on integrity checks of seals, connections, and pressure relief systems. Temperature and pressure monitoring systems should be calibrated regularly, with automated shutdown mechanisms implemented to prevent dangerous operating conditions.

Personal protective equipment requirements for operators include chemical-resistant gloves, safety goggles, lab coats, and in some cases, respiratory protection depending on the scale of operation. Ventilation systems must maintain negative pressure in distillation areas, with air exchange rates sufficient to prevent accumulation of flammable vapors below their lower explosive limit (LEL).

Emergency response protocols specific to petroleum ether recovery should address potential scenarios including fires, spills, and vapor releases. Operators must be trained in the proper use of fire suppression equipment suitable for flammable solvent fires. Spill containment materials and procedures should be readily accessible, with clear guidelines for containment, neutralization, and disposal of waste materials.

Risk assessment methodologies for petroleum ether recovery operations should employ HAZOP (Hazard and Operability Study) or FMEA (Failure Mode and Effects Analysis) approaches to systematically identify potential failure points. Critical control points include heating elements, condensers, collection vessels, and vacuum systems when applicable. Each distillation parameter variation should be evaluated for its impact on both purity outcomes and safety margins.

Particular attention must be paid to the changing risk profile as distillation progresses. As the concentration of higher-boiling impurities increases in the distillation pot, the risk of superheating and potential bumping increases significantly. Implementation of staged heating protocols and careful monitoring of temperature differentials between the vapor and liquid phases can mitigate these risks.

Documentation requirements include batch records with safety parameter verification, incident reporting mechanisms, and periodic safety audits. Training programs should incorporate both theoretical knowledge of petroleum ether properties and hands-on practice with emergency scenarios. Refresher training should be conducted annually, with competency verification through practical demonstrations.

Personal protective equipment requirements for operators include chemical-resistant gloves, safety goggles, lab coats, and in some cases, respiratory protection depending on the scale of operation. Ventilation systems must maintain negative pressure in distillation areas, with air exchange rates sufficient to prevent accumulation of flammable vapors below their lower explosive limit (LEL).

Emergency response protocols specific to petroleum ether recovery should address potential scenarios including fires, spills, and vapor releases. Operators must be trained in the proper use of fire suppression equipment suitable for flammable solvent fires. Spill containment materials and procedures should be readily accessible, with clear guidelines for containment, neutralization, and disposal of waste materials.

Risk assessment methodologies for petroleum ether recovery operations should employ HAZOP (Hazard and Operability Study) or FMEA (Failure Mode and Effects Analysis) approaches to systematically identify potential failure points. Critical control points include heating elements, condensers, collection vessels, and vacuum systems when applicable. Each distillation parameter variation should be evaluated for its impact on both purity outcomes and safety margins.

Particular attention must be paid to the changing risk profile as distillation progresses. As the concentration of higher-boiling impurities increases in the distillation pot, the risk of superheating and potential bumping increases significantly. Implementation of staged heating protocols and careful monitoring of temperature differentials between the vapor and liquid phases can mitigate these risks.

Documentation requirements include batch records with safety parameter verification, incident reporting mechanisms, and periodic safety audits. Training programs should incorporate both theoretical knowledge of petroleum ether properties and hands-on practice with emergency scenarios. Refresher training should be conducted annually, with competency verification through practical demonstrations.

Environmental Impact and Regulatory Compliance

The recovery of petroleum ether through batch distillation processes presents significant environmental challenges and regulatory considerations that must be addressed comprehensively. Petroleum ether, a volatile hydrocarbon mixture, poses environmental risks through potential air emissions, water contamination, and soil pollution if not properly managed during recovery operations. Volatile organic compound (VOC) emissions from the distillation process contribute to photochemical smog formation and can impact local air quality, requiring appropriate emission control technologies such as condensers, scrubbers, or thermal oxidizers to maintain compliance with increasingly stringent air quality regulations.

Wastewater generated during petroleum ether recovery contains trace hydrocarbons and other contaminants that require treatment before discharge. Most jurisdictions mandate specific treatment protocols and discharge limits for industrial effluents containing petroleum derivatives. Additionally, the potential for accidental spills necessitates robust containment systems and emergency response protocols to prevent soil and groundwater contamination, which could lead to long-term environmental damage and costly remediation efforts.

Regulatory frameworks governing petroleum ether recovery vary globally but generally include multiple layers of compliance requirements. In the United States, operations must adhere to EPA regulations under the Clean Air Act, Clean Water Act, and Resource Conservation and Recovery Act. The EU's REACH regulation and Industrial Emissions Directive impose similar but often more stringent requirements on chemical recovery processes. Many Asian countries have also implemented comprehensive environmental protection frameworks that specifically address solvent recovery operations.

Permit requirements typically include detailed documentation of process parameters, emission levels, waste management protocols, and safety measures. Regular monitoring and reporting are mandatory, with non-compliance potentially resulting in substantial fines, operational restrictions, or facility closure. The relationship between purity levels and environmental compliance is particularly noteworthy, as higher purity standards often necessitate more intensive processing, potentially increasing environmental footprint unless offset by improved technology.

Sustainable practices in petroleum ether recovery are increasingly becoming both regulatory requirements and business imperatives. Closed-loop systems that minimize waste generation, energy-efficient distillation technologies, and solvent substitution strategies represent evolving best practices. Life cycle assessment approaches are gaining prominence in regulatory frameworks, requiring operators to consider the environmental impact across the entire process chain rather than focusing solely on end-of-pipe emissions.

Wastewater generated during petroleum ether recovery contains trace hydrocarbons and other contaminants that require treatment before discharge. Most jurisdictions mandate specific treatment protocols and discharge limits for industrial effluents containing petroleum derivatives. Additionally, the potential for accidental spills necessitates robust containment systems and emergency response protocols to prevent soil and groundwater contamination, which could lead to long-term environmental damage and costly remediation efforts.

Regulatory frameworks governing petroleum ether recovery vary globally but generally include multiple layers of compliance requirements. In the United States, operations must adhere to EPA regulations under the Clean Air Act, Clean Water Act, and Resource Conservation and Recovery Act. The EU's REACH regulation and Industrial Emissions Directive impose similar but often more stringent requirements on chemical recovery processes. Many Asian countries have also implemented comprehensive environmental protection frameworks that specifically address solvent recovery operations.

Permit requirements typically include detailed documentation of process parameters, emission levels, waste management protocols, and safety measures. Regular monitoring and reporting are mandatory, with non-compliance potentially resulting in substantial fines, operational restrictions, or facility closure. The relationship between purity levels and environmental compliance is particularly noteworthy, as higher purity standards often necessitate more intensive processing, potentially increasing environmental footprint unless offset by improved technology.

Sustainable practices in petroleum ether recovery are increasingly becoming both regulatory requirements and business imperatives. Closed-loop systems that minimize waste generation, energy-efficient distillation technologies, and solvent substitution strategies represent evolving best practices. Life cycle assessment approaches are gaining prominence in regulatory frameworks, requiring operators to consider the environmental impact across the entire process chain rather than focusing solely on end-of-pipe emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!