How Feedback Loop Systems Enhance LS Engine Fuel Economy

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Fuel Economy Evolution and Objectives

The evolution of LS engine fuel economy has been a continuous journey of technological advancement and innovation. Initially introduced in 1997, the LS engine series has undergone significant improvements in fuel efficiency over the past two decades. The primary objective has always been to enhance performance while simultaneously reducing fuel consumption and emissions.

In the early stages, LS engines relied on traditional fuel injection systems and basic engine management controls. However, as environmental regulations became more stringent and consumer demand for fuel-efficient vehicles increased, General Motors recognized the need for more sophisticated fuel economy strategies. This led to the integration of advanced technologies such as variable valve timing, direct fuel injection, and cylinder deactivation.

The introduction of feedback loop systems marked a pivotal moment in LS engine fuel economy evolution. These systems continuously monitor various engine parameters and adjust fuel delivery and combustion processes in real-time. By implementing closed-loop control strategies, LS engines can maintain optimal air-fuel ratios across a wide range of operating conditions, resulting in improved fuel efficiency and reduced emissions.

One of the key objectives in enhancing LS engine fuel economy has been to minimize energy losses throughout the powertrain. This has involved optimizing combustion efficiency, reducing friction within engine components, and improving thermal management. Engineers have focused on developing lightweight materials and advanced coatings to reduce overall engine weight and internal friction, further contributing to fuel economy gains.

Another significant goal has been to expand the operating range of fuel-saving technologies. For instance, cylinder deactivation systems, which were initially limited to specific load conditions, have been refined to function across a broader spectrum of engine speeds and loads. This expansion has allowed LS engines to maximize fuel efficiency in a wider variety of driving scenarios.

The integration of electronic control units (ECUs) with increasingly sophisticated algorithms has been crucial in achieving these objectives. Modern LS engines utilize complex software that can predict and adapt to various driving conditions, optimizing fuel delivery and engine performance on-the-fly. This predictive capability, combined with real-time feedback from multiple sensors, enables the engine to operate at peak efficiency consistently.

Looking forward, the objectives for LS engine fuel economy continue to evolve. Current goals include further refinement of existing technologies and the exploration of new innovations such as advanced combustion modes and electrification strategies. The ultimate aim is to develop LS engines that can meet increasingly stringent emissions standards while delivering the power and efficiency that consumers expect from this iconic engine series.

In the early stages, LS engines relied on traditional fuel injection systems and basic engine management controls. However, as environmental regulations became more stringent and consumer demand for fuel-efficient vehicles increased, General Motors recognized the need for more sophisticated fuel economy strategies. This led to the integration of advanced technologies such as variable valve timing, direct fuel injection, and cylinder deactivation.

The introduction of feedback loop systems marked a pivotal moment in LS engine fuel economy evolution. These systems continuously monitor various engine parameters and adjust fuel delivery and combustion processes in real-time. By implementing closed-loop control strategies, LS engines can maintain optimal air-fuel ratios across a wide range of operating conditions, resulting in improved fuel efficiency and reduced emissions.

One of the key objectives in enhancing LS engine fuel economy has been to minimize energy losses throughout the powertrain. This has involved optimizing combustion efficiency, reducing friction within engine components, and improving thermal management. Engineers have focused on developing lightweight materials and advanced coatings to reduce overall engine weight and internal friction, further contributing to fuel economy gains.

Another significant goal has been to expand the operating range of fuel-saving technologies. For instance, cylinder deactivation systems, which were initially limited to specific load conditions, have been refined to function across a broader spectrum of engine speeds and loads. This expansion has allowed LS engines to maximize fuel efficiency in a wider variety of driving scenarios.

The integration of electronic control units (ECUs) with increasingly sophisticated algorithms has been crucial in achieving these objectives. Modern LS engines utilize complex software that can predict and adapt to various driving conditions, optimizing fuel delivery and engine performance on-the-fly. This predictive capability, combined with real-time feedback from multiple sensors, enables the engine to operate at peak efficiency consistently.

Looking forward, the objectives for LS engine fuel economy continue to evolve. Current goals include further refinement of existing technologies and the exploration of new innovations such as advanced combustion modes and electrification strategies. The ultimate aim is to develop LS engines that can meet increasingly stringent emissions standards while delivering the power and efficiency that consumers expect from this iconic engine series.

Market Demand for Fuel-Efficient LS Engines

The market demand for fuel-efficient LS engines has been steadily increasing in recent years, driven by a combination of economic, environmental, and regulatory factors. As fuel prices continue to fluctuate and environmental concerns grow, consumers and businesses alike are seeking more economical and eco-friendly transportation options. This trend has created a significant opportunity for engine manufacturers to develop and market fuel-efficient LS engines.

In the automotive sector, there is a strong demand for LS engines that can deliver improved fuel economy without sacrificing performance. Fleet operators, in particular, are looking to reduce their operational costs by investing in vehicles equipped with fuel-efficient engines. The trucking industry, which relies heavily on LS engines, has shown a keen interest in technologies that can enhance fuel economy, as even small improvements in efficiency can lead to substantial cost savings over time.

The marine industry has also emerged as a key market for fuel-efficient LS engines. Boat manufacturers and operators are increasingly prioritizing fuel efficiency to reduce operating costs and comply with stricter environmental regulations. This has led to a growing demand for LS engines that can provide optimal performance while minimizing fuel consumption in marine applications.

In the power generation sector, there is a rising demand for fuel-efficient LS engines in backup power systems and off-grid applications. As businesses and communities seek to reduce their carbon footprint and energy costs, the market for efficient generators powered by LS engines has expanded. This trend is particularly evident in remote locations and developing regions where fuel costs and availability are significant concerns.

The agricultural sector represents another important market for fuel-efficient LS engines. Farmers and agricultural equipment manufacturers are increasingly adopting advanced engine technologies to reduce fuel consumption in tractors, harvesters, and other machinery. This demand is driven by the need to improve operational efficiency and reduce production costs in an industry with tight profit margins.

Market research indicates that the global demand for fuel-efficient engines, including LS engines, is expected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is supported by stringent emission regulations in many countries, which are pushing manufacturers to develop more efficient and cleaner engine technologies.

As the market for fuel-efficient LS engines continues to expand, manufacturers are investing heavily in research and development to meet this demand. The integration of advanced technologies, such as feedback loop systems, is becoming increasingly important in achieving the desired balance between performance and fuel economy. This trend is likely to drive further innovation in LS engine design and fuel management systems, creating new opportunities for companies that can deliver effective solutions to meet the growing market demand for fuel-efficient engines.

In the automotive sector, there is a strong demand for LS engines that can deliver improved fuel economy without sacrificing performance. Fleet operators, in particular, are looking to reduce their operational costs by investing in vehicles equipped with fuel-efficient engines. The trucking industry, which relies heavily on LS engines, has shown a keen interest in technologies that can enhance fuel economy, as even small improvements in efficiency can lead to substantial cost savings over time.

The marine industry has also emerged as a key market for fuel-efficient LS engines. Boat manufacturers and operators are increasingly prioritizing fuel efficiency to reduce operating costs and comply with stricter environmental regulations. This has led to a growing demand for LS engines that can provide optimal performance while minimizing fuel consumption in marine applications.

In the power generation sector, there is a rising demand for fuel-efficient LS engines in backup power systems and off-grid applications. As businesses and communities seek to reduce their carbon footprint and energy costs, the market for efficient generators powered by LS engines has expanded. This trend is particularly evident in remote locations and developing regions where fuel costs and availability are significant concerns.

The agricultural sector represents another important market for fuel-efficient LS engines. Farmers and agricultural equipment manufacturers are increasingly adopting advanced engine technologies to reduce fuel consumption in tractors, harvesters, and other machinery. This demand is driven by the need to improve operational efficiency and reduce production costs in an industry with tight profit margins.

Market research indicates that the global demand for fuel-efficient engines, including LS engines, is expected to grow at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is supported by stringent emission regulations in many countries, which are pushing manufacturers to develop more efficient and cleaner engine technologies.

As the market for fuel-efficient LS engines continues to expand, manufacturers are investing heavily in research and development to meet this demand. The integration of advanced technologies, such as feedback loop systems, is becoming increasingly important in achieving the desired balance between performance and fuel economy. This trend is likely to drive further innovation in LS engine design and fuel management systems, creating new opportunities for companies that can deliver effective solutions to meet the growing market demand for fuel-efficient engines.

Feedback Loop Systems in LS Engines: Current State

Feedback loop systems in LS engines have evolved significantly over the years, becoming increasingly sophisticated and efficient. These systems play a crucial role in optimizing fuel economy by continuously monitoring and adjusting various engine parameters in real-time. The current state of feedback loop systems in LS engines represents a culmination of advanced engineering and technological innovations.

At the heart of modern LS engine feedback systems is the Engine Control Module (ECM), which serves as the central processing unit. The ECM receives input from a network of sensors strategically placed throughout the engine, including oxygen sensors, mass airflow sensors, and temperature sensors. This constant stream of data allows the ECM to make precise adjustments to fuel injection timing, air-fuel mixture, and ignition timing, among other parameters.

One of the key advancements in current feedback loop systems is the implementation of closed-loop fuel control. This system utilizes oxygen sensors in the exhaust stream to measure the air-fuel ratio and make real-time adjustments to maintain the ideal stoichiometric ratio of 14.7:1. This precise control ensures optimal combustion efficiency, reducing fuel consumption and emissions.

Another significant feature of modern feedback systems is adaptive learning capabilities. The ECM can learn and adapt to changes in engine performance over time, compensating for factors such as wear and tear, environmental conditions, and variations in fuel quality. This adaptive nature allows the engine to maintain peak efficiency throughout its lifespan.

Variable valve timing (VVT) systems have also been integrated into the feedback loop, allowing for dynamic adjustment of valve timing based on engine load and speed. This technology enhances both power output and fuel economy by optimizing airflow into the combustion chamber under various operating conditions.

Current LS engine feedback systems also incorporate advanced knock detection algorithms. These systems use acoustic sensors to detect and mitigate engine knock, allowing for more aggressive ignition timing without risking engine damage. This fine-tuning of ignition timing contributes to improved fuel economy and performance.

The integration of direct fuel injection technology has further enhanced the capabilities of feedback loop systems. By precisely controlling the amount and timing of fuel injection directly into the combustion chamber, these systems can achieve even greater fuel efficiency and power output.

In summary, the current state of feedback loop systems in LS engines represents a highly advanced and integrated approach to engine management. These systems leverage a combination of sophisticated sensors, adaptive algorithms, and precise control mechanisms to continuously optimize engine performance and fuel economy in real-time.

At the heart of modern LS engine feedback systems is the Engine Control Module (ECM), which serves as the central processing unit. The ECM receives input from a network of sensors strategically placed throughout the engine, including oxygen sensors, mass airflow sensors, and temperature sensors. This constant stream of data allows the ECM to make precise adjustments to fuel injection timing, air-fuel mixture, and ignition timing, among other parameters.

One of the key advancements in current feedback loop systems is the implementation of closed-loop fuel control. This system utilizes oxygen sensors in the exhaust stream to measure the air-fuel ratio and make real-time adjustments to maintain the ideal stoichiometric ratio of 14.7:1. This precise control ensures optimal combustion efficiency, reducing fuel consumption and emissions.

Another significant feature of modern feedback systems is adaptive learning capabilities. The ECM can learn and adapt to changes in engine performance over time, compensating for factors such as wear and tear, environmental conditions, and variations in fuel quality. This adaptive nature allows the engine to maintain peak efficiency throughout its lifespan.

Variable valve timing (VVT) systems have also been integrated into the feedback loop, allowing for dynamic adjustment of valve timing based on engine load and speed. This technology enhances both power output and fuel economy by optimizing airflow into the combustion chamber under various operating conditions.

Current LS engine feedback systems also incorporate advanced knock detection algorithms. These systems use acoustic sensors to detect and mitigate engine knock, allowing for more aggressive ignition timing without risking engine damage. This fine-tuning of ignition timing contributes to improved fuel economy and performance.

The integration of direct fuel injection technology has further enhanced the capabilities of feedback loop systems. By precisely controlling the amount and timing of fuel injection directly into the combustion chamber, these systems can achieve even greater fuel efficiency and power output.

In summary, the current state of feedback loop systems in LS engines represents a highly advanced and integrated approach to engine management. These systems leverage a combination of sophisticated sensors, adaptive algorithms, and precise control mechanisms to continuously optimize engine performance and fuel economy in real-time.

Existing Feedback Loop Solutions for LS Engines

01 Adaptive control systems for fuel economy optimization

These systems use real-time data and feedback loops to continuously adjust engine parameters, transmission settings, and other vehicle systems to optimize fuel efficiency. They can adapt to changing driving conditions, driver behavior, and vehicle load to maintain optimal fuel economy.- Adaptive control systems for fuel economy optimization: Feedback loop systems that continuously monitor and adjust vehicle parameters to optimize fuel economy. These systems use real-time data from various sensors to make dynamic adjustments to engine performance, transmission shifts, and other vehicle systems to maximize efficiency based on current driving conditions.

- Machine learning algorithms for fuel efficiency prediction: Implementation of machine learning and artificial intelligence algorithms to analyze historical and real-time data for predicting and improving fuel economy. These systems learn from driving patterns, environmental conditions, and vehicle performance to provide accurate fuel consumption estimates and suggest optimal driving strategies.

- Integration of GPS and traffic data for route optimization: Feedback systems that incorporate GPS navigation and real-time traffic information to optimize route selection for improved fuel economy. These systems consider factors such as road gradients, traffic congestion, and speed limits to suggest the most fuel-efficient routes and driving speeds.

- Driver behavior analysis and coaching systems: Feedback loop systems that monitor and analyze driver behavior, providing real-time coaching and suggestions to improve fuel economy. These systems track acceleration, braking, idling, and other driving habits, offering personalized recommendations to drivers for more efficient vehicle operation.

- Advanced sensor networks for precise fuel consumption measurement: Implementation of sophisticated sensor networks throughout the vehicle to accurately measure and analyze fuel consumption in real-time. These systems provide high-precision data on engine performance, fuel flow, and combustion efficiency, enabling more effective feedback loops for fuel economy optimization.

02 Machine learning algorithms for fuel efficiency prediction

Advanced algorithms analyze historical and real-time data to predict and optimize fuel consumption. These systems can learn from past driving patterns, environmental conditions, and vehicle performance to make intelligent decisions that improve fuel economy over time.Expand Specific Solutions03 Integrated sensor networks for fuel economy monitoring

Comprehensive sensor networks throughout the vehicle collect data on various parameters affecting fuel efficiency. These sensors provide input to feedback loop systems, enabling real-time adjustments and long-term optimization strategies for improved fuel economy.Expand Specific Solutions04 Driver feedback systems for eco-driving

These systems provide real-time feedback to drivers on their driving behavior and its impact on fuel economy. They can suggest optimal acceleration, braking, and gear shifting patterns to maximize fuel efficiency, creating a feedback loop between the driver and the vehicle.Expand Specific Solutions05 Hybrid powertrain optimization using feedback loops

Feedback loop systems in hybrid vehicles optimize the balance between electric and combustion power sources. These systems continuously adjust power distribution, regenerative braking, and battery management to maximize overall fuel economy based on driving conditions and energy availability.Expand Specific Solutions

Key Players in LS Engine and Feedback Loop Industry

The feedback loop systems for enhancing LS engine fuel economy represent a mature technology in the automotive industry, with major players like GM Global Technology Operations, Ford Global Technologies, and Renault SA leading the development. The market for this technology is substantial, driven by increasing fuel efficiency regulations and consumer demand for economical vehicles. The competitive landscape is characterized by established automotive manufacturers and specialized technology providers like Tula Technology, Inc., which focuses on software solutions for improving engine efficiency. As the technology has evolved, it has become a standard feature in many modern vehicles, indicating a high level of market penetration and technological maturity across the industry.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced feedback loop system for LS engines that continuously monitors and adjusts fuel injection parameters in real-time. This system utilizes a combination of sensors, including mass airflow, oxygen, and knock sensors, to gather data on engine performance and combustion efficiency[1]. The collected data is processed by the engine control unit (ECU) which then makes precise adjustments to fuel injection timing and duration. GM's system also incorporates adaptive learning algorithms that can adjust to changes in driving conditions and engine wear over time, ensuring optimal fuel economy throughout the vehicle's lifecycle[3]. Additionally, GM has implemented a cylinder deactivation technology that works in conjunction with the feedback loop system to further enhance fuel efficiency by shutting down unnecessary cylinders during light load conditions[5].

Strengths: Comprehensive sensor integration, adaptive learning capabilities, and cylinder deactivation technology. Weaknesses: Complexity may lead to higher maintenance costs and potential reliability issues in the long term.

Ford Global Technologies LLC

Technical Solution: Ford has implemented a sophisticated feedback loop system in their EcoBoost engines, which are adaptable for use in LS engine platforms. The system employs direct fuel injection technology coupled with turbocharging to optimize fuel economy. Ford's feedback loop incorporates a wide-band oxygen sensor that provides precise air-fuel ratio measurements, allowing for more accurate fuel metering[2]. The system also utilizes a unique low-pressure EGR (Exhaust Gas Recirculation) system that reduces pumping losses and improves thermal efficiency[4]. Ford's technology includes an innovative dual-loop cooling system that allows for rapid warm-up and precise temperature control, further enhancing fuel efficiency. The ECU uses predictive algorithms to anticipate driving conditions and adjust engine parameters proactively, resulting in improved real-world fuel economy[6].

Strengths: Advanced direct injection and turbocharging integration, innovative EGR and cooling systems. Weaknesses: Potential for increased complexity and cost in manufacturing and maintenance.

Core Innovations in LS Engine Feedback Systems

Control system

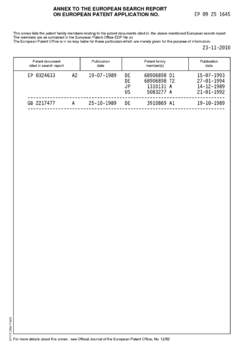

PatentInactiveUS8321104B2

Innovation

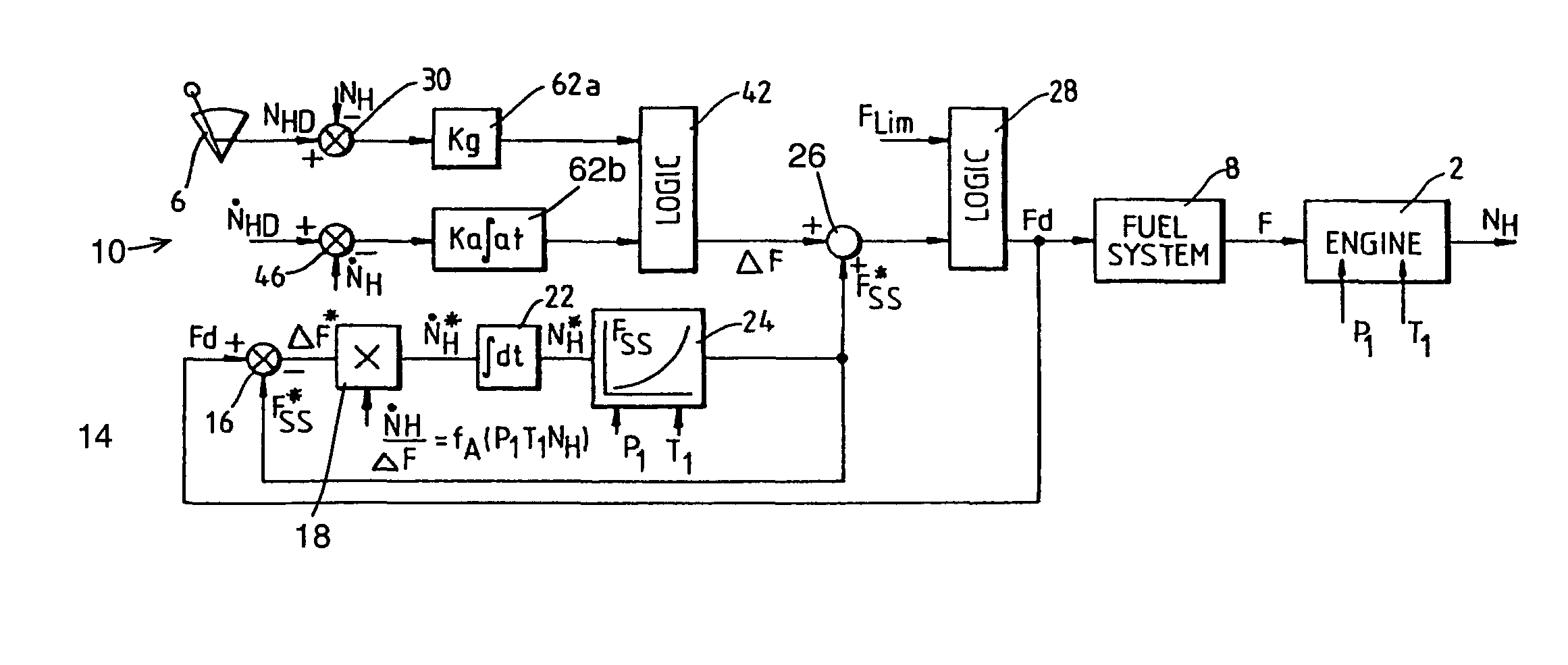

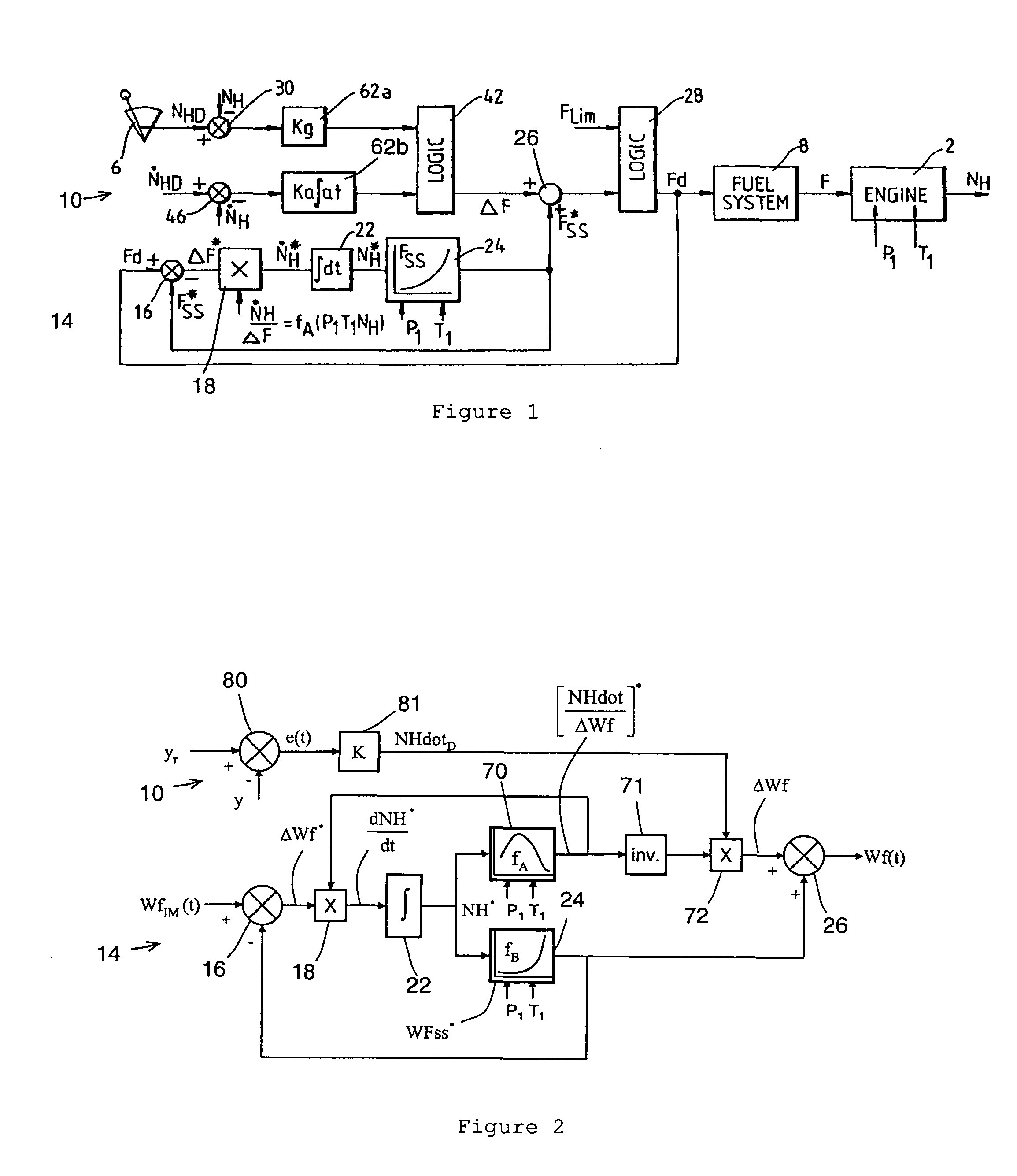

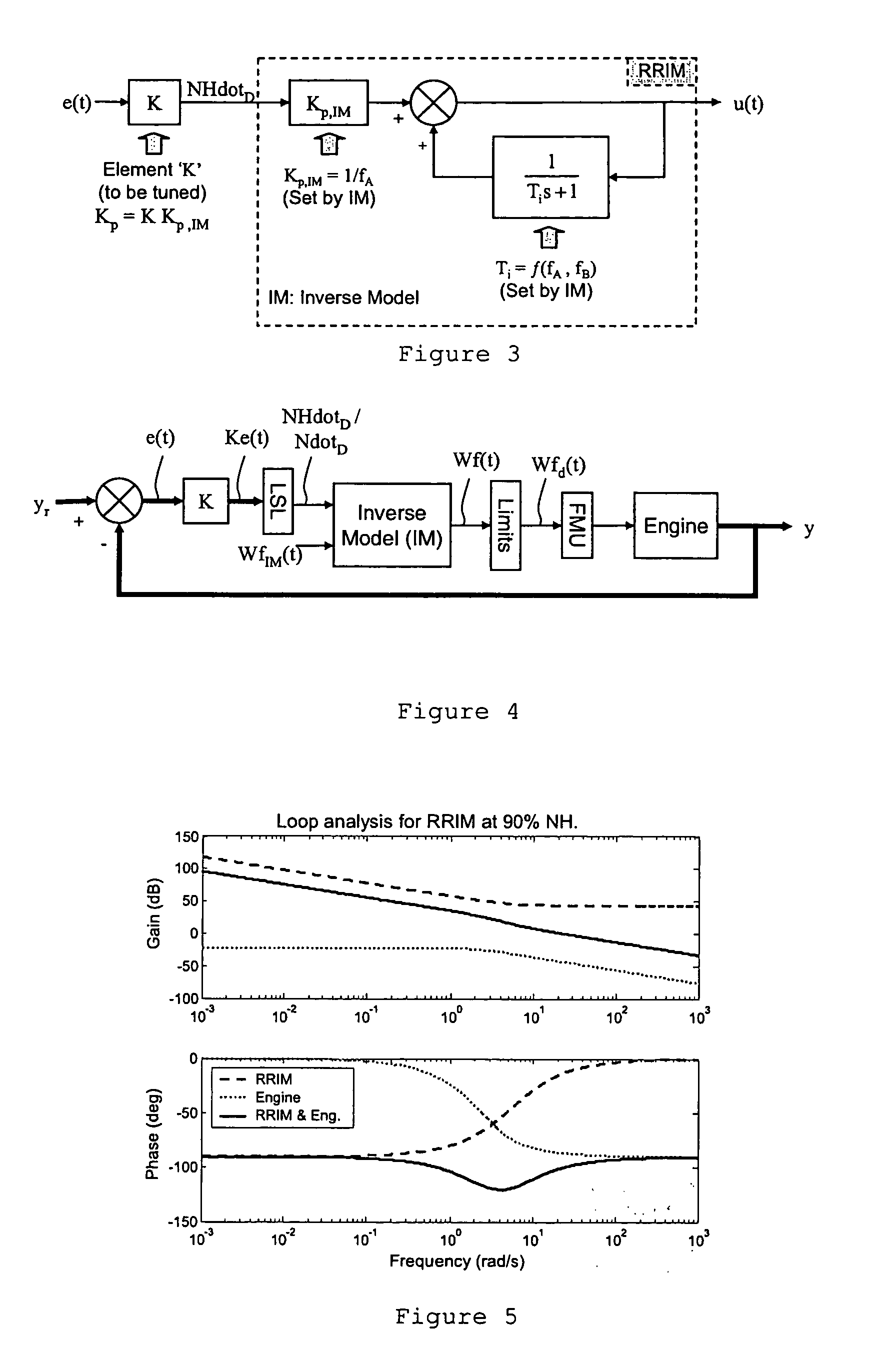

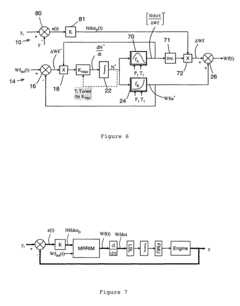

- A control system that generates an aggregate fuel flow demand signal by summing a steady state fuel flow requirement and an overfuelling demand signal, with a feedback loop that includes a second variable gain to tune the convergence rate, improving phase margins and reducing engine output overshoots, and an engine-casing cooling air control system that adjusts clearance by regulating cooling air flow to reduce leakage.

Control system

PatentActiveEP2154588A3

Innovation

- A control system with a feedback loop that includes a second variable gain to tune the rate of convergence to a steady state fuel flow requirement, improving phase margins and reducing engine output overshoots, and an engine-casing cooling air control system that adjusts clearance by modifying the rate at which the feedback loop converges on a steady state valve position requirement.

Environmental Impact of Improved LS Engine Efficiency

The implementation of feedback loop systems in LS engines to enhance fuel economy has significant positive implications for environmental sustainability. As these engines become more efficient, they consume less fuel per unit of power output, leading to a reduction in overall fuel consumption and, consequently, lower emissions of greenhouse gases and other pollutants.

One of the primary environmental benefits of improved LS engine efficiency is the reduction in carbon dioxide (CO2) emissions. CO2 is a major contributor to global warming and climate change. By optimizing fuel consumption through feedback loop systems, LS engines can significantly decrease their carbon footprint. This reduction in CO2 emissions aligns with global efforts to mitigate climate change and helps automotive manufacturers meet increasingly stringent environmental regulations.

Moreover, the enhanced fuel economy of LS engines contributes to the conservation of fossil fuel resources. As these engines require less fuel to operate, the demand for petroleum-based products decreases, potentially slowing the rate of resource depletion. This conservation effect can have far-reaching implications for energy security and reduce the environmental impacts associated with oil extraction and refining processes.

The improved efficiency also leads to a reduction in other harmful emissions, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These pollutants are known to have detrimental effects on air quality and human health. By minimizing their release into the atmosphere, LS engines with advanced feedback loop systems contribute to cleaner air in urban areas and reduced respiratory health risks for populations.

Furthermore, the environmental benefits extend beyond the operational phase of the vehicle. As LS engines become more efficient, there is potential for downsizing without compromising performance. This could lead to the production of lighter vehicles, which require fewer raw materials to manufacture. The reduced material usage in vehicle production can result in lower environmental impacts throughout the entire lifecycle of the vehicle, from resource extraction to end-of-life disposal.

The adoption of more efficient LS engines also has indirect environmental benefits. As consumers become more aware of the economic advantages of fuel-efficient vehicles, there may be a shift in market demand towards these more environmentally friendly options. This shift can incentivize further research and development in engine efficiency technologies, creating a positive feedback loop for environmental innovation in the automotive industry.

In conclusion, the environmental impact of improved LS engine efficiency through feedback loop systems is multifaceted and predominantly positive. From reduced greenhouse gas emissions to improved air quality and resource conservation, these advancements play a crucial role in the automotive industry's efforts to minimize its environmental footprint and contribute to global sustainability goals.

One of the primary environmental benefits of improved LS engine efficiency is the reduction in carbon dioxide (CO2) emissions. CO2 is a major contributor to global warming and climate change. By optimizing fuel consumption through feedback loop systems, LS engines can significantly decrease their carbon footprint. This reduction in CO2 emissions aligns with global efforts to mitigate climate change and helps automotive manufacturers meet increasingly stringent environmental regulations.

Moreover, the enhanced fuel economy of LS engines contributes to the conservation of fossil fuel resources. As these engines require less fuel to operate, the demand for petroleum-based products decreases, potentially slowing the rate of resource depletion. This conservation effect can have far-reaching implications for energy security and reduce the environmental impacts associated with oil extraction and refining processes.

The improved efficiency also leads to a reduction in other harmful emissions, such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. These pollutants are known to have detrimental effects on air quality and human health. By minimizing their release into the atmosphere, LS engines with advanced feedback loop systems contribute to cleaner air in urban areas and reduced respiratory health risks for populations.

Furthermore, the environmental benefits extend beyond the operational phase of the vehicle. As LS engines become more efficient, there is potential for downsizing without compromising performance. This could lead to the production of lighter vehicles, which require fewer raw materials to manufacture. The reduced material usage in vehicle production can result in lower environmental impacts throughout the entire lifecycle of the vehicle, from resource extraction to end-of-life disposal.

The adoption of more efficient LS engines also has indirect environmental benefits. As consumers become more aware of the economic advantages of fuel-efficient vehicles, there may be a shift in market demand towards these more environmentally friendly options. This shift can incentivize further research and development in engine efficiency technologies, creating a positive feedback loop for environmental innovation in the automotive industry.

In conclusion, the environmental impact of improved LS engine efficiency through feedback loop systems is multifaceted and predominantly positive. From reduced greenhouse gas emissions to improved air quality and resource conservation, these advancements play a crucial role in the automotive industry's efforts to minimize its environmental footprint and contribute to global sustainability goals.

Cost-Benefit Analysis of Feedback Loop Implementation

Implementing feedback loop systems in LS engines for improved fuel economy requires a thorough cost-benefit analysis to determine the economic viability and potential return on investment. The initial costs associated with feedback loop implementation include hardware components such as sensors, actuators, and control units, as well as software development and integration expenses. These upfront costs can vary significantly depending on the complexity of the system and the scale of production.

On the benefit side, the primary advantage of feedback loop systems is the potential for substantial fuel savings over the lifetime of the engine. By continuously monitoring and adjusting engine parameters in real-time, these systems can optimize fuel consumption under various operating conditions. The exact fuel economy improvements can range from 5% to 15%, depending on the sophistication of the feedback system and driving conditions.

To quantify the benefits, it is essential to consider the average annual mileage of vehicles equipped with LS engines, typical fuel prices, and the expected lifespan of the engine. For instance, a 10% improvement in fuel economy for a vehicle driven 15,000 miles annually could result in savings of 150 gallons of fuel per year. At an average fuel price of $3 per gallon, this translates to $450 in annual fuel cost savings.

The payback period for the feedback loop system investment depends on the initial implementation cost and the realized fuel savings. For example, if the system costs $1,500 to implement and saves $450 annually, the payback period would be approximately 3.3 years. Beyond this point, the system continues to generate savings for the remainder of the engine's life, potentially resulting in significant long-term economic benefits.

Additional benefits that should be factored into the analysis include reduced emissions, which may lead to regulatory compliance advantages and potential tax incentives. Improved engine performance and longevity resulting from optimized operation can also contribute to the overall value proposition of feedback loop systems.

It is important to note that the cost-benefit ratio may vary based on factors such as production volume, technological advancements, and fluctuations in fuel prices. As production scales up and technology matures, implementation costs are likely to decrease, potentially improving the economic viability of these systems across a broader range of applications.

In conclusion, while the initial investment in feedback loop systems for LS engines may be substantial, the long-term benefits in fuel economy, emissions reduction, and engine performance can often justify the costs, especially for high-mileage applications or in regions with high fuel prices. A detailed, case-specific analysis is recommended to accurately assess the economic impact for different vehicle models and usage scenarios.

On the benefit side, the primary advantage of feedback loop systems is the potential for substantial fuel savings over the lifetime of the engine. By continuously monitoring and adjusting engine parameters in real-time, these systems can optimize fuel consumption under various operating conditions. The exact fuel economy improvements can range from 5% to 15%, depending on the sophistication of the feedback system and driving conditions.

To quantify the benefits, it is essential to consider the average annual mileage of vehicles equipped with LS engines, typical fuel prices, and the expected lifespan of the engine. For instance, a 10% improvement in fuel economy for a vehicle driven 15,000 miles annually could result in savings of 150 gallons of fuel per year. At an average fuel price of $3 per gallon, this translates to $450 in annual fuel cost savings.

The payback period for the feedback loop system investment depends on the initial implementation cost and the realized fuel savings. For example, if the system costs $1,500 to implement and saves $450 annually, the payback period would be approximately 3.3 years. Beyond this point, the system continues to generate savings for the remainder of the engine's life, potentially resulting in significant long-term economic benefits.

Additional benefits that should be factored into the analysis include reduced emissions, which may lead to regulatory compliance advantages and potential tax incentives. Improved engine performance and longevity resulting from optimized operation can also contribute to the overall value proposition of feedback loop systems.

It is important to note that the cost-benefit ratio may vary based on factors such as production volume, technological advancements, and fluctuations in fuel prices. As production scales up and technology matures, implementation costs are likely to decrease, potentially improving the economic viability of these systems across a broader range of applications.

In conclusion, while the initial investment in feedback loop systems for LS engines may be substantial, the long-term benefits in fuel economy, emissions reduction, and engine performance can often justify the costs, especially for high-mileage applications or in regions with high fuel prices. A detailed, case-specific analysis is recommended to accurately assess the economic impact for different vehicle models and usage scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!