How Industrial Decommissioning Manages Carbon Tetrachloride Waste

JUL 31, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Decommissioning Background and Objectives

Carbon tetrachloride (CCl4) has been widely used in various industrial applications for decades, including as a solvent, cleaning agent, and refrigerant. However, its harmful effects on human health and the environment have led to strict regulations and a global phase-out of its production and use. The decommissioning of industrial facilities that once handled CCl4 presents significant challenges in terms of waste management and environmental protection.

The primary objective of CCl4 decommissioning is to safely and effectively remove, treat, and dispose of any remaining CCl4 and contaminated materials while minimizing environmental impact and health risks. This process involves a comprehensive approach that combines technical expertise, regulatory compliance, and innovative waste management strategies.

The historical context of CCl4 usage dates back to the early 20th century when it was first synthesized and commercialized. Its versatile properties made it a popular choice in various industries, including dry cleaning, fire extinguishers, and pesticide production. However, the discovery of its ozone-depleting properties and carcinogenic effects led to its inclusion in the Montreal Protocol in 1987, which aimed to phase out ozone-depleting substances.

As industries transitioned away from CCl4, the focus shifted to addressing the legacy of its widespread use. Decommissioning efforts have evolved over time, with early approaches often focusing on simple containment or disposal. Modern decommissioning techniques aim for more comprehensive solutions that not only remove CCl4 but also remediate contaminated soil and groundwater.

The technological evolution in CCl4 decommissioning has seen significant advancements. Early methods relied heavily on physical removal and incineration, which were often costly and environmentally problematic. Current approaches incorporate a range of technologies, including in-situ chemical oxidation, bioremediation, and advanced filtration systems, which offer more efficient and environmentally friendly solutions.

Looking ahead, the goals of CCl4 decommissioning are becoming increasingly ambitious. There is a growing emphasis on achieving near-zero emissions during the decommissioning process, developing closed-loop systems for waste treatment, and exploring innovative methods for converting CCl4 into less harmful substances. Additionally, there is a push towards integrating decommissioning processes with broader sustainability initiatives, such as site redevelopment and ecosystem restoration.

The global nature of CCl4 use and its environmental impacts necessitate international cooperation in decommissioning efforts. Sharing best practices, technologies, and resources across borders is crucial for addressing this global challenge effectively. As such, the objectives of CCl4 decommissioning extend beyond individual sites to encompass a coordinated, worldwide effort to mitigate the long-term effects of this once-ubiquitous industrial chemical.

The primary objective of CCl4 decommissioning is to safely and effectively remove, treat, and dispose of any remaining CCl4 and contaminated materials while minimizing environmental impact and health risks. This process involves a comprehensive approach that combines technical expertise, regulatory compliance, and innovative waste management strategies.

The historical context of CCl4 usage dates back to the early 20th century when it was first synthesized and commercialized. Its versatile properties made it a popular choice in various industries, including dry cleaning, fire extinguishers, and pesticide production. However, the discovery of its ozone-depleting properties and carcinogenic effects led to its inclusion in the Montreal Protocol in 1987, which aimed to phase out ozone-depleting substances.

As industries transitioned away from CCl4, the focus shifted to addressing the legacy of its widespread use. Decommissioning efforts have evolved over time, with early approaches often focusing on simple containment or disposal. Modern decommissioning techniques aim for more comprehensive solutions that not only remove CCl4 but also remediate contaminated soil and groundwater.

The technological evolution in CCl4 decommissioning has seen significant advancements. Early methods relied heavily on physical removal and incineration, which were often costly and environmentally problematic. Current approaches incorporate a range of technologies, including in-situ chemical oxidation, bioremediation, and advanced filtration systems, which offer more efficient and environmentally friendly solutions.

Looking ahead, the goals of CCl4 decommissioning are becoming increasingly ambitious. There is a growing emphasis on achieving near-zero emissions during the decommissioning process, developing closed-loop systems for waste treatment, and exploring innovative methods for converting CCl4 into less harmful substances. Additionally, there is a push towards integrating decommissioning processes with broader sustainability initiatives, such as site redevelopment and ecosystem restoration.

The global nature of CCl4 use and its environmental impacts necessitate international cooperation in decommissioning efforts. Sharing best practices, technologies, and resources across borders is crucial for addressing this global challenge effectively. As such, the objectives of CCl4 decommissioning extend beyond individual sites to encompass a coordinated, worldwide effort to mitigate the long-term effects of this once-ubiquitous industrial chemical.

Market Analysis for CCl4 Waste Management

The market for carbon tetrachloride (CCl4) waste management is experiencing significant growth due to increasing environmental regulations and industrial decommissioning activities. As industries phase out the use of CCl4 due to its ozone-depleting properties, the demand for proper disposal and treatment solutions has risen sharply.

The global CCl4 waste management market is primarily driven by the chemical, pharmaceutical, and manufacturing sectors. These industries generate substantial amounts of CCl4 waste during production processes and equipment cleaning. The market is further bolstered by the ongoing decommissioning of older industrial facilities that historically used CCl4 in large quantities.

Geographically, North America and Europe lead the CCl4 waste management market, owing to stringent environmental regulations and well-established waste treatment infrastructure. However, emerging economies in Asia-Pacific and Latin America are witnessing rapid market growth as they implement stricter environmental policies and invest in advanced waste management technologies.

The market is characterized by a mix of specialized waste management companies and larger environmental service providers. Key players are focusing on developing innovative treatment technologies to improve efficiency and reduce costs. Incineration remains the most common method for CCl4 waste disposal, but there is a growing trend towards more sustainable alternatives such as chemical decomposition and advanced oxidation processes.

Regulatory frameworks play a crucial role in shaping the CCl4 waste management market. The Montreal Protocol and subsequent amendments have significantly impacted the production and use of CCl4, driving the need for proper disposal of existing stocks and contaminated materials. National and regional environmental agencies continue to tighten regulations on hazardous waste handling, creating opportunities for waste management service providers.

The market faces challenges such as high treatment costs and the technical complexity of handling CCl4 waste safely. However, these challenges also present opportunities for innovation and technological advancement in the sector. Companies investing in research and development of more cost-effective and environmentally friendly treatment methods are likely to gain a competitive edge.

Looking ahead, the CCl4 waste management market is expected to continue its growth trajectory. Factors such as increasing awareness of environmental issues, ongoing industrial modernization, and the push for circular economy principles will drive demand for specialized waste management services. The market is also likely to see increased consolidation as larger environmental service providers acquire specialized CCl4 treatment companies to expand their service offerings.

The global CCl4 waste management market is primarily driven by the chemical, pharmaceutical, and manufacturing sectors. These industries generate substantial amounts of CCl4 waste during production processes and equipment cleaning. The market is further bolstered by the ongoing decommissioning of older industrial facilities that historically used CCl4 in large quantities.

Geographically, North America and Europe lead the CCl4 waste management market, owing to stringent environmental regulations and well-established waste treatment infrastructure. However, emerging economies in Asia-Pacific and Latin America are witnessing rapid market growth as they implement stricter environmental policies and invest in advanced waste management technologies.

The market is characterized by a mix of specialized waste management companies and larger environmental service providers. Key players are focusing on developing innovative treatment technologies to improve efficiency and reduce costs. Incineration remains the most common method for CCl4 waste disposal, but there is a growing trend towards more sustainable alternatives such as chemical decomposition and advanced oxidation processes.

Regulatory frameworks play a crucial role in shaping the CCl4 waste management market. The Montreal Protocol and subsequent amendments have significantly impacted the production and use of CCl4, driving the need for proper disposal of existing stocks and contaminated materials. National and regional environmental agencies continue to tighten regulations on hazardous waste handling, creating opportunities for waste management service providers.

The market faces challenges such as high treatment costs and the technical complexity of handling CCl4 waste safely. However, these challenges also present opportunities for innovation and technological advancement in the sector. Companies investing in research and development of more cost-effective and environmentally friendly treatment methods are likely to gain a competitive edge.

Looking ahead, the CCl4 waste management market is expected to continue its growth trajectory. Factors such as increasing awareness of environmental issues, ongoing industrial modernization, and the push for circular economy principles will drive demand for specialized waste management services. The market is also likely to see increased consolidation as larger environmental service providers acquire specialized CCl4 treatment companies to expand their service offerings.

CCl4 Decontamination Challenges

Carbon tetrachloride (CCl4) decontamination presents significant challenges in industrial decommissioning processes due to its persistent nature and hazardous properties. The primary obstacle lies in the compound's high stability and resistance to degradation, making it difficult to break down or neutralize through conventional treatment methods.

One of the major challenges is the volatility of CCl4, which can easily vaporize and spread through air, soil, and groundwater. This characteristic necessitates careful handling and containment strategies to prevent environmental contamination and protect worker safety during decommissioning activities. The potential for vapor intrusion into buildings and structures further complicates remediation efforts.

CCl4's low solubility in water poses another significant hurdle in decontamination processes. Traditional pump-and-treat methods often prove ineffective, as the compound tends to form dense non-aqueous phase liquids (DNAPLs) that sink below the water table. These DNAPLs act as long-term sources of contamination, slowly releasing CCl4 into groundwater over extended periods.

The compound's ability to adsorb onto soil particles and organic matter creates additional complexities in soil remediation. This property makes it challenging to completely remove CCl4 from contaminated soils, often requiring multiple treatment approaches or extended remediation timeframes.

Furthermore, the toxicity of CCl4 poses serious health risks to workers involved in decontamination activities. Exposure can lead to liver and kidney damage, as well as potential carcinogenic effects. This necessitates stringent safety protocols and personal protective equipment, which can impede the efficiency and speed of decontamination processes.

Another challenge lies in the detection and quantification of CCl4 in various environmental matrices. Accurate assessment of contamination levels is crucial for designing effective remediation strategies and monitoring progress. However, the compound's volatility and tendency to form DNAPLs can complicate sampling and analysis procedures.

The regulatory framework surrounding CCl4 decontamination adds another layer of complexity. Stringent environmental standards and disposal regulations require careful planning and execution of remediation activities. Compliance with these regulations often necessitates specialized treatment technologies and disposal methods, increasing the overall cost and complexity of decommissioning projects.

Lastly, the historical widespread use of CCl4 in various industrial applications has resulted in numerous contaminated sites worldwide. Many of these sites have complex contamination profiles, with CCl4 often co-existing with other pollutants. This multi-contaminant scenario further complicates decontamination efforts, requiring integrated treatment approaches that can effectively address all present contaminants simultaneously.

One of the major challenges is the volatility of CCl4, which can easily vaporize and spread through air, soil, and groundwater. This characteristic necessitates careful handling and containment strategies to prevent environmental contamination and protect worker safety during decommissioning activities. The potential for vapor intrusion into buildings and structures further complicates remediation efforts.

CCl4's low solubility in water poses another significant hurdle in decontamination processes. Traditional pump-and-treat methods often prove ineffective, as the compound tends to form dense non-aqueous phase liquids (DNAPLs) that sink below the water table. These DNAPLs act as long-term sources of contamination, slowly releasing CCl4 into groundwater over extended periods.

The compound's ability to adsorb onto soil particles and organic matter creates additional complexities in soil remediation. This property makes it challenging to completely remove CCl4 from contaminated soils, often requiring multiple treatment approaches or extended remediation timeframes.

Furthermore, the toxicity of CCl4 poses serious health risks to workers involved in decontamination activities. Exposure can lead to liver and kidney damage, as well as potential carcinogenic effects. This necessitates stringent safety protocols and personal protective equipment, which can impede the efficiency and speed of decontamination processes.

Another challenge lies in the detection and quantification of CCl4 in various environmental matrices. Accurate assessment of contamination levels is crucial for designing effective remediation strategies and monitoring progress. However, the compound's volatility and tendency to form DNAPLs can complicate sampling and analysis procedures.

The regulatory framework surrounding CCl4 decontamination adds another layer of complexity. Stringent environmental standards and disposal regulations require careful planning and execution of remediation activities. Compliance with these regulations often necessitates specialized treatment technologies and disposal methods, increasing the overall cost and complexity of decommissioning projects.

Lastly, the historical widespread use of CCl4 in various industrial applications has resulted in numerous contaminated sites worldwide. Many of these sites have complex contamination profiles, with CCl4 often co-existing with other pollutants. This multi-contaminant scenario further complicates decontamination efforts, requiring integrated treatment approaches that can effectively address all present contaminants simultaneously.

Current CCl4 Decommissioning Methods

01 Chemical treatment and decomposition

Carbon tetrachloride waste can be managed through chemical treatment and decomposition processes. These methods involve using specific chemical reactions to break down the compound into less harmful substances, reducing its environmental impact and toxicity. This approach can be particularly effective for treating concentrated waste streams.- Chemical treatment and decomposition: Carbon tetrachloride waste can be managed through chemical treatment and decomposition processes. These methods involve using specific chemical reactions to break down the harmful compound into less toxic substances. This approach can significantly reduce the environmental impact of carbon tetrachloride waste.

- Adsorption and filtration techniques: Adsorption and filtration techniques can be employed to remove carbon tetrachloride from waste streams. These methods utilize specialized materials or membranes to capture and separate the compound from other substances. This approach is particularly useful for treating contaminated water or air.

- Thermal treatment and incineration: Thermal treatment and incineration can be used to destroy carbon tetrachloride waste. These high-temperature processes break down the compound into simpler, less harmful substances. Proper emission control measures are essential to prevent the release of toxic byproducts during incineration.

- Biological remediation: Biological remediation techniques can be applied to manage carbon tetrachloride waste. This approach involves using microorganisms or plants to break down or absorb the compound. Bioremediation can be an environmentally friendly and cost-effective method for treating contaminated soil or groundwater.

- Recycling and recovery: Recycling and recovery methods can be implemented to manage carbon tetrachloride waste. These techniques aim to purify and reuse the compound, reducing the overall waste generated. Proper handling and safety measures are crucial when recycling this hazardous substance.

02 Adsorption and filtration techniques

Adsorption and filtration techniques can be employed to remove carbon tetrachloride from waste streams. These methods utilize specialized materials or membranes to capture and separate the compound from other substances. This approach is particularly useful for treating contaminated water or air streams containing carbon tetrachloride.Expand Specific Solutions03 Thermal treatment and incineration

Thermal treatment and incineration processes can be used to destroy carbon tetrachloride waste. These methods involve exposing the waste to high temperatures, which break down the compound into simpler, less harmful substances. Proper emission control measures are essential to prevent the release of toxic byproducts during the incineration process.Expand Specific Solutions04 Biological treatment and bioremediation

Biological treatment and bioremediation techniques can be applied to manage carbon tetrachloride waste. These methods utilize microorganisms or plants to break down or absorb the compound. This approach is particularly suitable for treating contaminated soil or groundwater and can be implemented in situ or ex situ.Expand Specific Solutions05 Recycling and recovery processes

Recycling and recovery processes can be implemented to manage carbon tetrachloride waste. These methods involve separating and purifying the compound for reuse in industrial applications or as a feedstock for other chemical processes. This approach helps reduce the overall waste volume and promotes a more circular economy.Expand Specific Solutions

Key Players in CCl4 Waste Management

The industrial decommissioning of carbon tetrachloride waste management is in a mature stage, with established technologies and regulations in place. The global market for hazardous waste management, including carbon tetrachloride, is projected to reach $28 billion by 2025. Companies like Solvay SA, Air Liquide SA, and Wanhua Chemical Group Co., Ltd. have developed advanced treatment processes, while research institutions such as King Saud University and Kunming University of Science & Technology contribute to technological advancements. The industry is characterized by a mix of large multinational corporations and specialized environmental service providers, with increasing focus on sustainable and cost-effective solutions for managing this persistent organic pollutant.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The CEA has developed a supercritical water oxidation (SCWO) process for managing carbon tetrachloride waste. This technology utilizes the unique properties of water above its critical point (374°C, 221 bar) to rapidly oxidize organic compounds. The SCWO process achieves complete destruction of carbon tetrachloride within seconds, with an efficiency exceeding 99.99%[7]. CEA's system also incorporates corrosion-resistant materials to withstand the harsh operating conditions. The process generates only CO2, water, and easily treatable inorganic salts as byproducts. CEA has demonstrated this technology at pilot scale, treating up to 100 kg/h of carbon tetrachloride-containing waste[8].

Strengths: Rapid and complete destruction, generates benign byproducts, compact system footprint. Weaknesses: High operating pressure and temperature requirements, potential for corrosion issues.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a catalytic hydrodechlorination process for managing carbon tetrachloride waste. This method uses a proprietary palladium-based catalyst to convert carbon tetrachloride into less harmful hydrocarbons, primarily methane. The process operates at moderate temperatures (200-300°C) and pressures (20-30 bar), achieving a conversion rate of over 99% for carbon tetrachloride[9]. Wanhua's system also incorporates a gas recirculation loop to maximize conversion efficiency. The methane produced can be used as a fuel source, providing energy recovery. Wanhua has implemented this technology at its production facilities, significantly reducing carbon tetrachloride emissions and waste[10].

Strengths: High conversion rate, operates at moderate conditions, produces useful fuel byproduct. Weaknesses: Requires careful catalyst management, potential for catalyst deactivation over time.

Innovative CCl4 Treatment Technologies

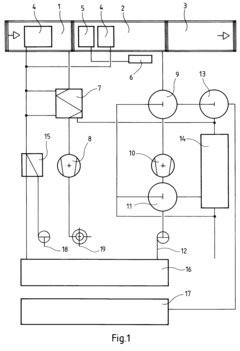

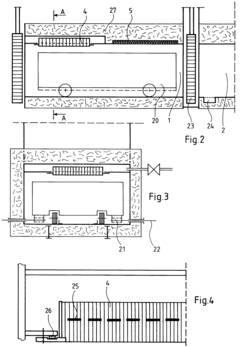

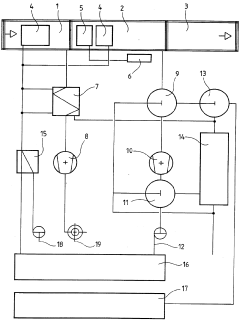

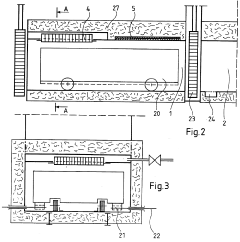

System for the treatment by thermolyses of solid products whose disposal is damaging to the environment

PatentInactiveEP0505278A1

Innovation

- A system comprising a reactor with a dehydration zone, a thermolysis zone at medium temperatures (around 600° C), and a cooling zone, isolated from each other to prevent air entry, using catalytic radiant panels and electrical resistors for heating, and a gas scrubber for purification, with a vacuum system for gas management and recycling.

System for the treatment by thermolysis of solid products whose rejection is harmful to the environment

PatentWO1992016599A1

Innovation

- A system comprising a reactor with a dehydration zone, a thermolysis zone at medium temperatures (around 600°C) under vacuum, and a cooling zone, isolated from each other to control decomposition products, using catalytic radiant panels and gas scrubbers for purification, and a mechanical system for product handling.

Environmental Regulations for CCl4 Disposal

The management of carbon tetrachloride (CCl4) waste is subject to stringent environmental regulations due to its hazardous nature and potential environmental impact. In the United States, the Environmental Protection Agency (EPA) classifies CCl4 as a hazardous waste under the Resource Conservation and Recovery Act (RCRA). This classification mandates specific handling, storage, transportation, and disposal procedures for industries dealing with CCl4 waste.

Under the RCRA, facilities generating CCl4 waste must obtain EPA identification numbers and comply with strict waste management protocols. These include proper labeling, use of appropriate containers, and maintaining detailed records of waste generation and disposal. The EPA also enforces the Land Disposal Restrictions (LDR) program, which sets treatment standards for CCl4 waste before it can be disposed of in landfills.

Internationally, the disposal of CCl4 is regulated by the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. This treaty aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries. Signatories to the convention must adhere to its guidelines when handling and disposing of CCl4 waste.

The Montreal Protocol on Substances that Deplete the Ozone Layer also plays a crucial role in regulating CCl4. Although primarily focused on phasing out the production of ozone-depleting substances, it indirectly affects CCl4 waste management by limiting its production and use, thereby reducing the overall volume of waste generated.

In the European Union, the management of CCl4 waste falls under the Waste Framework Directive and the Industrial Emissions Directive. These regulations emphasize the principles of waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. They also set emission limits for industrial processes involving CCl4 and mandate the use of Best Available Techniques (BAT) for waste treatment.

Many countries have implemented extended producer responsibility (EPR) programs for hazardous chemicals, including CCl4. These programs require manufacturers and importers to take responsibility for the entire lifecycle of their products, including proper disposal at the end of life. This approach encourages the development of more sustainable production methods and improved waste management strategies.

Compliance with these regulations often requires significant investment in infrastructure and technology. Industries must implement advanced treatment technologies such as chemical oxidation, thermal desorption, or incineration to meet the stringent treatment standards for CCl4 waste. Additionally, companies are required to conduct regular environmental audits and maintain comprehensive documentation of their waste management practices to demonstrate compliance with regulatory requirements.

Under the RCRA, facilities generating CCl4 waste must obtain EPA identification numbers and comply with strict waste management protocols. These include proper labeling, use of appropriate containers, and maintaining detailed records of waste generation and disposal. The EPA also enforces the Land Disposal Restrictions (LDR) program, which sets treatment standards for CCl4 waste before it can be disposed of in landfills.

Internationally, the disposal of CCl4 is regulated by the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal. This treaty aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries. Signatories to the convention must adhere to its guidelines when handling and disposing of CCl4 waste.

The Montreal Protocol on Substances that Deplete the Ozone Layer also plays a crucial role in regulating CCl4. Although primarily focused on phasing out the production of ozone-depleting substances, it indirectly affects CCl4 waste management by limiting its production and use, thereby reducing the overall volume of waste generated.

In the European Union, the management of CCl4 waste falls under the Waste Framework Directive and the Industrial Emissions Directive. These regulations emphasize the principles of waste hierarchy, prioritizing prevention, reuse, and recycling over disposal. They also set emission limits for industrial processes involving CCl4 and mandate the use of Best Available Techniques (BAT) for waste treatment.

Many countries have implemented extended producer responsibility (EPR) programs for hazardous chemicals, including CCl4. These programs require manufacturers and importers to take responsibility for the entire lifecycle of their products, including proper disposal at the end of life. This approach encourages the development of more sustainable production methods and improved waste management strategies.

Compliance with these regulations often requires significant investment in infrastructure and technology. Industries must implement advanced treatment technologies such as chemical oxidation, thermal desorption, or incineration to meet the stringent treatment standards for CCl4 waste. Additionally, companies are required to conduct regular environmental audits and maintain comprehensive documentation of their waste management practices to demonstrate compliance with regulatory requirements.

Health and Safety in CCl4 Handling

Carbon tetrachloride (CCl4) is a highly toxic and potentially carcinogenic substance that requires careful handling during industrial decommissioning processes. The health and safety of workers and the surrounding community are paramount when managing CCl4 waste. Proper personal protective equipment (PPE) is essential for all personnel involved in handling CCl4. This includes chemical-resistant suits, gloves, and boots, as well as respiratory protection with appropriate filters or supplied air systems.

Exposure monitoring is crucial to ensure worker safety. Regular air sampling and personal monitoring devices should be employed to detect any CCl4 vapors in the work environment. Strict exposure limits must be adhered to, with immediate evacuation procedures in place if levels exceed permissible limits. Decontamination stations should be set up at entry and exit points of work areas to prevent the spread of CCl4 contamination.

Proper ventilation systems are critical in areas where CCl4 is being handled or stored. These systems should be designed to capture and remove CCl4 vapors effectively, reducing the risk of inhalation exposure. Closed-system transfer methods should be utilized whenever possible to minimize the potential for spills or releases during waste handling and transportation.

Emergency response protocols must be well-established and regularly practiced. This includes spill containment and cleanup procedures, as well as medical response plans for potential exposures. On-site medical facilities should be equipped to handle CCl4-related emergencies, with staff trained in treating chemical exposures.

Worker training is a fundamental aspect of health and safety in CCl4 handling. All personnel involved in decommissioning activities should receive comprehensive training on the hazards of CCl4, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and safety briefings should be conducted to maintain awareness and reinforce best practices.

Environmental monitoring is also essential to protect the surrounding community and ecosystem. Air, soil, and water sampling should be conducted regularly in the vicinity of the decommissioning site to detect any potential CCl4 releases. Proper waste containment and storage facilities must be in place to prevent environmental contamination.

Risk assessment and management strategies should be continuously updated throughout the decommissioning process. This involves identifying potential hazards, evaluating risks, and implementing appropriate control measures. Regular safety audits and inspections should be conducted to ensure compliance with established protocols and to identify areas for improvement.

Exposure monitoring is crucial to ensure worker safety. Regular air sampling and personal monitoring devices should be employed to detect any CCl4 vapors in the work environment. Strict exposure limits must be adhered to, with immediate evacuation procedures in place if levels exceed permissible limits. Decontamination stations should be set up at entry and exit points of work areas to prevent the spread of CCl4 contamination.

Proper ventilation systems are critical in areas where CCl4 is being handled or stored. These systems should be designed to capture and remove CCl4 vapors effectively, reducing the risk of inhalation exposure. Closed-system transfer methods should be utilized whenever possible to minimize the potential for spills or releases during waste handling and transportation.

Emergency response protocols must be well-established and regularly practiced. This includes spill containment and cleanup procedures, as well as medical response plans for potential exposures. On-site medical facilities should be equipped to handle CCl4-related emergencies, with staff trained in treating chemical exposures.

Worker training is a fundamental aspect of health and safety in CCl4 handling. All personnel involved in decommissioning activities should receive comprehensive training on the hazards of CCl4, proper handling techniques, emergency procedures, and the correct use of PPE. Regular refresher courses and safety briefings should be conducted to maintain awareness and reinforce best practices.

Environmental monitoring is also essential to protect the surrounding community and ecosystem. Air, soil, and water sampling should be conducted regularly in the vicinity of the decommissioning site to detect any potential CCl4 releases. Proper waste containment and storage facilities must be in place to prevent environmental contamination.

Risk assessment and management strategies should be continuously updated throughout the decommissioning process. This involves identifying potential hazards, evaluating risks, and implementing appropriate control measures. Regular safety audits and inspections should be conducted to ensure compliance with established protocols and to identify areas for improvement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!