How Isocyanates Stretch Limits in Scientific Exploration?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isocyanate Evolution

Isocyanates have undergone a remarkable evolution since their discovery in the mid-19th century, transforming from laboratory curiosities to indispensable components in various industries. This evolution has been characterized by continuous innovation, expanding applications, and a deepening understanding of their chemical properties and potential.

The journey of isocyanates began with their synthesis by Wurtz in 1848, but it wasn't until the 1930s that their true potential was recognized. Otto Bayer's groundbreaking work on polyurethane chemistry in 1937 marked a pivotal moment, unleashing a wave of research and development that would reshape multiple industries.

Throughout the 1940s and 1950s, isocyanates found their way into the production of foams, coatings, and adhesives. This period saw rapid advancements in synthesis methods and the development of various isocyanate types, each with unique properties suited for specific applications. The versatility of isocyanates became increasingly apparent, leading to their adoption in automotive, construction, and furniture industries.

The 1960s and 1970s witnessed a surge in isocyanate research, focusing on improving their performance and expanding their application range. This era saw the development of more sophisticated polyurethane formulations, enabling the creation of materials with enhanced durability, flexibility, and insulation properties. Concurrently, concerns about the health and environmental impacts of isocyanates began to emerge, prompting research into safer handling methods and alternative formulations.

In the following decades, the evolution of isocyanates was characterized by a dual focus on innovation and safety. The 1980s and 1990s saw the development of low-emission and water-based isocyanate systems, addressing environmental concerns while maintaining performance. This period also marked the expansion of isocyanates into high-tech applications, including aerospace and medical industries.

The turn of the millennium brought renewed interest in sustainable and bio-based isocyanates. Researchers began exploring ways to synthesize isocyanates from renewable resources, aiming to reduce dependence on petrochemicals. This shift aligned with growing global emphasis on sustainability and circular economy principles.

Recent years have seen isocyanates pushing the boundaries of material science. Advanced formulations have enabled the creation of self-healing polymers, shape-memory materials, and ultra-high-performance composites. The integration of nanotechnology with isocyanate chemistry has opened new frontiers, promising materials with unprecedented properties and functionalities.

Throughout their evolution, isocyanates have consistently demonstrated their ability to stretch the limits of scientific exploration. From their humble beginnings to their current status as key enablers of cutting-edge materials, isocyanates have played a crucial role in advancing technology across multiple sectors. As research continues, the potential for further innovation remains vast, suggesting that the evolution of isocyanates is far from complete.

The journey of isocyanates began with their synthesis by Wurtz in 1848, but it wasn't until the 1930s that their true potential was recognized. Otto Bayer's groundbreaking work on polyurethane chemistry in 1937 marked a pivotal moment, unleashing a wave of research and development that would reshape multiple industries.

Throughout the 1940s and 1950s, isocyanates found their way into the production of foams, coatings, and adhesives. This period saw rapid advancements in synthesis methods and the development of various isocyanate types, each with unique properties suited for specific applications. The versatility of isocyanates became increasingly apparent, leading to their adoption in automotive, construction, and furniture industries.

The 1960s and 1970s witnessed a surge in isocyanate research, focusing on improving their performance and expanding their application range. This era saw the development of more sophisticated polyurethane formulations, enabling the creation of materials with enhanced durability, flexibility, and insulation properties. Concurrently, concerns about the health and environmental impacts of isocyanates began to emerge, prompting research into safer handling methods and alternative formulations.

In the following decades, the evolution of isocyanates was characterized by a dual focus on innovation and safety. The 1980s and 1990s saw the development of low-emission and water-based isocyanate systems, addressing environmental concerns while maintaining performance. This period also marked the expansion of isocyanates into high-tech applications, including aerospace and medical industries.

The turn of the millennium brought renewed interest in sustainable and bio-based isocyanates. Researchers began exploring ways to synthesize isocyanates from renewable resources, aiming to reduce dependence on petrochemicals. This shift aligned with growing global emphasis on sustainability and circular economy principles.

Recent years have seen isocyanates pushing the boundaries of material science. Advanced formulations have enabled the creation of self-healing polymers, shape-memory materials, and ultra-high-performance composites. The integration of nanotechnology with isocyanate chemistry has opened new frontiers, promising materials with unprecedented properties and functionalities.

Throughout their evolution, isocyanates have consistently demonstrated their ability to stretch the limits of scientific exploration. From their humble beginnings to their current status as key enablers of cutting-edge materials, isocyanates have played a crucial role in advancing technology across multiple sectors. As research continues, the potential for further innovation remains vast, suggesting that the evolution of isocyanates is far from complete.

Market Applications

Isocyanates have found extensive applications across various industries, revolutionizing product development and scientific exploration. In the automotive sector, these versatile compounds play a crucial role in manufacturing polyurethane foams for car seats, headrests, and insulation materials. Their ability to form strong, flexible bonds has led to improved durability and comfort in vehicle interiors. Additionally, isocyanates are essential in producing high-performance coatings for automotive exteriors, offering superior protection against corrosion and weathering.

The construction industry has also embraced isocyanates for their exceptional insulation properties. Spray polyurethane foam, derived from isocyanates, is widely used in building insulation, providing energy efficiency and moisture resistance. This application has significantly contributed to the development of more sustainable and environmentally friendly construction practices.

In the medical field, isocyanates have enabled the creation of advanced wound dressings and medical devices. Their biocompatibility and ability to form flexible, breathable materials have led to improved patient care and faster healing processes. Furthermore, isocyanates are utilized in the production of prosthetics and orthotics, offering lightweight yet durable solutions for individuals with mobility challenges.

The electronics industry has benefited from isocyanates in the manufacturing of printed circuit boards and electronic components. Their excellent adhesive properties and resistance to heat and chemicals make them ideal for encapsulating and protecting sensitive electronic parts. This application has contributed to the miniaturization and increased reliability of electronic devices.

Isocyanates have also found their way into the sports and leisure industry. They are used in the production of high-performance athletic footwear, providing cushioning and support for athletes. In the realm of outdoor equipment, isocyanates are employed in the manufacturing of durable, weather-resistant gear such as tents, backpacks, and sleeping bags.

The aerospace industry has leveraged isocyanates for their lightweight and strong characteristics. These compounds are used in the production of composite materials for aircraft components, contributing to fuel efficiency and overall performance. Additionally, isocyanates play a role in developing specialized coatings for aircraft exteriors, offering protection against extreme temperatures and atmospheric conditions.

As scientific exploration continues to push boundaries, isocyanates are finding new applications in emerging fields. In the realm of nanotechnology, researchers are exploring the potential of isocyanate-based materials for drug delivery systems and advanced sensors. The unique properties of isocyanates are also being investigated for use in energy storage solutions, such as improved battery technologies and fuel cells.

The construction industry has also embraced isocyanates for their exceptional insulation properties. Spray polyurethane foam, derived from isocyanates, is widely used in building insulation, providing energy efficiency and moisture resistance. This application has significantly contributed to the development of more sustainable and environmentally friendly construction practices.

In the medical field, isocyanates have enabled the creation of advanced wound dressings and medical devices. Their biocompatibility and ability to form flexible, breathable materials have led to improved patient care and faster healing processes. Furthermore, isocyanates are utilized in the production of prosthetics and orthotics, offering lightweight yet durable solutions for individuals with mobility challenges.

The electronics industry has benefited from isocyanates in the manufacturing of printed circuit boards and electronic components. Their excellent adhesive properties and resistance to heat and chemicals make them ideal for encapsulating and protecting sensitive electronic parts. This application has contributed to the miniaturization and increased reliability of electronic devices.

Isocyanates have also found their way into the sports and leisure industry. They are used in the production of high-performance athletic footwear, providing cushioning and support for athletes. In the realm of outdoor equipment, isocyanates are employed in the manufacturing of durable, weather-resistant gear such as tents, backpacks, and sleeping bags.

The aerospace industry has leveraged isocyanates for their lightweight and strong characteristics. These compounds are used in the production of composite materials for aircraft components, contributing to fuel efficiency and overall performance. Additionally, isocyanates play a role in developing specialized coatings for aircraft exteriors, offering protection against extreme temperatures and atmospheric conditions.

As scientific exploration continues to push boundaries, isocyanates are finding new applications in emerging fields. In the realm of nanotechnology, researchers are exploring the potential of isocyanate-based materials for drug delivery systems and advanced sensors. The unique properties of isocyanates are also being investigated for use in energy storage solutions, such as improved battery technologies and fuel cells.

Technical Challenges

Isocyanates, while offering remarkable versatility in scientific applications, present significant technical challenges that researchers and industries must overcome. One of the primary hurdles is their high reactivity, which makes them difficult to handle and control. This reactivity, while beneficial for many applications, can lead to unwanted side reactions and premature curing, complicating manufacturing processes and potentially compromising product quality.

The toxicity of isocyanates poses another major challenge, particularly in terms of occupational health and safety. Exposure to these compounds can cause severe respiratory issues and skin irritation, necessitating stringent safety protocols and protective measures. This not only increases production costs but also limits the environments in which isocyanates can be used, potentially hindering their broader application in certain fields.

Environmental concerns also present significant obstacles. The production and use of isocyanates can result in the release of volatile organic compounds (VOCs) and other pollutants. As global environmental regulations become increasingly stringent, industries must invest in developing cleaner production methods and more environmentally friendly alternatives, which can be both technically challenging and economically demanding.

Another technical challenge lies in achieving precise control over the properties of isocyanate-based materials. The final characteristics of products such as polyurethanes are highly dependent on the exact stoichiometry and reaction conditions during synthesis. Maintaining consistency in large-scale production while optimizing for specific properties requires advanced process control and analytical techniques.

The development of bio-based or sustainable isocyanates represents a frontier challenge in the field. As the demand for more sustainable materials grows, researchers are exploring ways to synthesize isocyanates from renewable resources. However, achieving comparable performance to traditional petroleum-based isocyanates while ensuring economic viability remains a significant hurdle.

Lastly, the complexity of isocyanate chemistry poses challenges in predicting and modeling reaction outcomes, especially in novel applications. This complexity makes it difficult to develop new products or optimize existing ones without extensive experimental work, slowing down innovation and increasing development costs. Advances in computational chemistry and machine learning are needed to better understand and predict isocyanate behavior in various systems.

The toxicity of isocyanates poses another major challenge, particularly in terms of occupational health and safety. Exposure to these compounds can cause severe respiratory issues and skin irritation, necessitating stringent safety protocols and protective measures. This not only increases production costs but also limits the environments in which isocyanates can be used, potentially hindering their broader application in certain fields.

Environmental concerns also present significant obstacles. The production and use of isocyanates can result in the release of volatile organic compounds (VOCs) and other pollutants. As global environmental regulations become increasingly stringent, industries must invest in developing cleaner production methods and more environmentally friendly alternatives, which can be both technically challenging and economically demanding.

Another technical challenge lies in achieving precise control over the properties of isocyanate-based materials. The final characteristics of products such as polyurethanes are highly dependent on the exact stoichiometry and reaction conditions during synthesis. Maintaining consistency in large-scale production while optimizing for specific properties requires advanced process control and analytical techniques.

The development of bio-based or sustainable isocyanates represents a frontier challenge in the field. As the demand for more sustainable materials grows, researchers are exploring ways to synthesize isocyanates from renewable resources. However, achieving comparable performance to traditional petroleum-based isocyanates while ensuring economic viability remains a significant hurdle.

Lastly, the complexity of isocyanate chemistry poses challenges in predicting and modeling reaction outcomes, especially in novel applications. This complexity makes it difficult to develop new products or optimize existing ones without extensive experimental work, slowing down innovation and increasing development costs. Advances in computational chemistry and machine learning are needed to better understand and predict isocyanate behavior in various systems.

Current Solutions

01 Synthesis and production of isocyanates

Various methods and processes for synthesizing and producing isocyanates are described. These include novel reaction pathways, catalysts, and production techniques to improve yield, purity, and efficiency in isocyanate manufacturing.- Synthesis and production of isocyanates: Various methods and processes for synthesizing and producing isocyanates are described. These include novel catalysts, reaction conditions, and precursor materials to improve yield, purity, and efficiency in isocyanate production.

- Applications of isocyanates in polymer chemistry: Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents describe various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.

- Isocyanate-based catalysts and additives: Some patents focus on the development of isocyanate-based catalysts and additives for various chemical processes. These include novel compounds that enhance reaction rates, improve selectivity, or provide specific properties to the final products.

- Safety and handling of isocyanates: Given the reactive nature of isocyanates, several patents address safety concerns and handling procedures. These include methods for reducing toxicity, improving storage stability, and developing safer alternatives or modified isocyanates with reduced health risks.

- Isocyanate-free alternatives and substitutes: Some patents describe the development of isocyanate-free alternatives or substitutes for applications traditionally using isocyanates. These include novel chemistries, bio-based materials, and alternative crosslinking systems that aim to provide similar performance characteristics without the associated health and environmental concerns of isocyanates.

02 Applications of isocyanates in polymer chemistry

Isocyanates are widely used in polymer chemistry, particularly in the production of polyurethanes. The patents discuss various applications, including coatings, adhesives, foams, and elastomers, as well as novel formulations and processing techniques.Expand Specific Solutions03 Isocyanate-based catalysts and reaction modifiers

Several patents focus on the development of isocyanate-based catalysts and reaction modifiers. These compounds are used to enhance chemical reactions, improve product properties, or catalyze specific transformations in various industrial processes.Expand Specific Solutions04 Safety and handling of isocyanates

Given the reactive nature of isocyanates, patents address safety concerns and handling procedures. This includes methods for reducing toxicity, improving storage stability, and developing safer formulations for industrial use.Expand Specific Solutions05 Isocyanate-free alternatives and substitutes

Some patents explore alternatives to traditional isocyanates, aiming to develop more environmentally friendly or less hazardous options. This includes novel compounds, formulations, or processes that can replace isocyanates in certain applications while maintaining desired product properties.Expand Specific Solutions

Industry Leaders

The isocyanates market is in a mature growth phase, with a global market size expected to reach $38.7 billion by 2027. Technological advancements are driving innovation in this sector, particularly in scientific exploration. Key players like Wanhua Chemical Group, BASF, and Bayer AG are leading the field with their extensive R&D capabilities and product portfolios. Emerging companies such as Vencorex and Evonik are also making significant contributions. The technology's maturity is evident in its widespread application across industries, including automotive, construction, and electronics. However, ongoing research by academic institutions like Rutgers and Texas A&M University suggests potential for further breakthroughs, especially in areas of sustainability and performance enhancement.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced isocyanate-based materials for scientific exploration. Their innovative MDI (methylene diphenyl diisocyanate) technology enables the creation of high-performance polyurethanes with enhanced thermal insulation properties[1]. These materials are utilized in cryogenic applications, allowing for more efficient storage and transportation of liquefied gases in scientific research[2]. Wanhua's isocyanate products also contribute to the development of lightweight, durable materials for space exploration, offering improved fuel efficiency and payload capacity for spacecraft[3].

Strengths: Industry-leading MDI technology, diverse product portfolio, strong R&D capabilities. Weaknesses: Potential environmental concerns, dependency on petrochemical feedstocks.

Bayer AG

Technical Solution: Bayer AG has pioneered the use of isocyanates in scientific exploration through their development of high-performance polyurethane materials. Their proprietary technology focuses on creating isocyanate-based coatings and adhesives that withstand extreme conditions, crucial for scientific instruments and equipment[4]. Bayer's isocyanate formulations have been utilized in the production of advanced composite materials for aerospace applications, enabling lighter and more durable components for satellites and space probes[5]. Additionally, their research into bio-based isocyanates has opened new avenues for sustainable materials in scientific research[6].

Strengths: Extensive R&D infrastructure, diverse application expertise, strong patent portfolio. Weaknesses: Regulatory challenges, potential health and safety concerns associated with isocyanates.

Key Innovations

Measurement of total reactive isocyanate groups in samples using bifunctional nucleophiles such as 1,8-diaminonaphthalene (DAN)

PatentInactiveEP1579207A2

Innovation

- A method using 1,8-diaminonaphthalene (DAN) as a bifunctional nucleophilic isocyanate derivatizing agent that reacts with isocyanates to form a cyclic reaction product, allowing for the detection and quantification of total isocyanate groups regardless of the specific species present, using a two-step process of derivatization and cyclization.

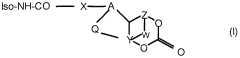

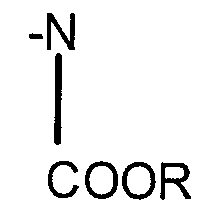

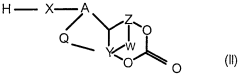

Modified isocyanates

PatentWO2000020477A1

Innovation

- Development of modified isocyanate derivatives with a crosslinking functional group that remains stable and reacts only under specific conditions, allowing for controlled crosslinking reactions without releasing isocyanate functions prematurely, using cyclic carbonates to form stable polyisocyanates that can react with nucleophilic compounds to create coatings and foams.

Safety Regulations

The use of isocyanates in scientific exploration has necessitated the development of comprehensive safety regulations to protect researchers, workers, and the environment. These regulations are crucial due to the highly reactive nature of isocyanates and their potential health hazards. Occupational safety and health administrations worldwide have established strict guidelines for handling, storage, and disposal of isocyanates in laboratory and industrial settings.

Personal protective equipment (PPE) is a cornerstone of isocyanate safety regulations. Researchers and workers are required to wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus, depending on the concentration and exposure risk. Impermeable gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact with isocyanates.

Ventilation requirements form another critical aspect of safety regulations. Laboratories and production facilities must be equipped with adequate local exhaust ventilation systems to minimize airborne isocyanate concentrations. Regular monitoring of air quality and exposure levels is mandated to ensure compliance with permissible exposure limits set by regulatory bodies.

Storage and handling protocols for isocyanates are strictly regulated. These chemicals must be stored in tightly sealed containers in cool, dry areas away from sources of heat, moisture, and incompatible materials. Spill response procedures and containment measures are required to be in place, with specialized training provided to personnel responsible for handling isocyanates.

Waste disposal regulations for isocyanates are equally stringent. Proper decontamination and neutralization procedures must be followed before disposal, and waste materials containing isocyanates are typically classified as hazardous waste, subject to specific transportation and disposal requirements.

Employee training and education programs are mandated by safety regulations to ensure that all personnel working with isocyanates are fully aware of the associated risks and proper handling procedures. This includes regular refresher courses and updates on new safety protocols or regulatory changes.

Medical surveillance programs are often required for workers regularly exposed to isocyanates. These programs typically include baseline and periodic health assessments, with particular attention to respiratory function and sensitization.

As scientific exploration continues to push the boundaries of isocyanate applications, safety regulations are evolving to keep pace. Ongoing research into the long-term effects of isocyanate exposure and the development of safer alternatives are informing updates to regulatory frameworks. International collaboration and harmonization efforts are also underway to establish consistent global standards for isocyanate safety in scientific and industrial settings.

Personal protective equipment (PPE) is a cornerstone of isocyanate safety regulations. Researchers and workers are required to wear appropriate respiratory protection, such as supplied-air respirators or self-contained breathing apparatus, depending on the concentration and exposure risk. Impermeable gloves, protective clothing, and eye protection are also mandatory to prevent skin and eye contact with isocyanates.

Ventilation requirements form another critical aspect of safety regulations. Laboratories and production facilities must be equipped with adequate local exhaust ventilation systems to minimize airborne isocyanate concentrations. Regular monitoring of air quality and exposure levels is mandated to ensure compliance with permissible exposure limits set by regulatory bodies.

Storage and handling protocols for isocyanates are strictly regulated. These chemicals must be stored in tightly sealed containers in cool, dry areas away from sources of heat, moisture, and incompatible materials. Spill response procedures and containment measures are required to be in place, with specialized training provided to personnel responsible for handling isocyanates.

Waste disposal regulations for isocyanates are equally stringent. Proper decontamination and neutralization procedures must be followed before disposal, and waste materials containing isocyanates are typically classified as hazardous waste, subject to specific transportation and disposal requirements.

Employee training and education programs are mandated by safety regulations to ensure that all personnel working with isocyanates are fully aware of the associated risks and proper handling procedures. This includes regular refresher courses and updates on new safety protocols or regulatory changes.

Medical surveillance programs are often required for workers regularly exposed to isocyanates. These programs typically include baseline and periodic health assessments, with particular attention to respiratory function and sensitization.

As scientific exploration continues to push the boundaries of isocyanate applications, safety regulations are evolving to keep pace. Ongoing research into the long-term effects of isocyanate exposure and the development of safer alternatives are informing updates to regulatory frameworks. International collaboration and harmonization efforts are also underway to establish consistent global standards for isocyanate safety in scientific and industrial settings.

Environmental Impact

Isocyanates, while pivotal in various scientific and industrial applications, pose significant environmental concerns that warrant careful consideration. The production, use, and disposal of isocyanate-containing materials can have far-reaching impacts on ecosystems and human health. One of the primary environmental issues associated with isocyanates is their potential for air pollution. When released into the atmosphere, these compounds can contribute to the formation of ground-level ozone and smog, which negatively affect air quality and can harm both plant and animal life.

Water contamination is another critical environmental concern. Isocyanates that find their way into water bodies can be toxic to aquatic organisms, disrupting ecosystems and potentially entering the food chain. This contamination can occur through industrial discharges, improper disposal of isocyanate-containing products, or accidental spills during transportation and handling.

The persistence of isocyanates in the environment is a subject of ongoing research. While some isocyanates degrade relatively quickly under certain conditions, others may persist for longer periods, potentially accumulating in soil and sediments. This persistence can lead to long-term environmental impacts and challenges in remediation efforts.

Furthermore, the production of isocyanates often involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. The environmental footprint of isocyanate production extends beyond the immediate manufacturing sites, encompassing the entire supply chain and lifecycle of these materials.

Efforts to mitigate the environmental impact of isocyanates are multifaceted. Industry initiatives focus on developing more environmentally friendly production methods, improving containment and handling procedures, and exploring alternative materials with reduced environmental risks. Regulatory frameworks in many countries now impose strict controls on isocyanate emissions and disposal, aiming to minimize their environmental footprint.

Research into biodegradable alternatives and green chemistry approaches offers promising avenues for reducing the environmental impact of isocyanates. These efforts seek to maintain the beneficial properties of isocyanates while minimizing their ecological risks, aligning scientific exploration with sustainability goals.

Water contamination is another critical environmental concern. Isocyanates that find their way into water bodies can be toxic to aquatic organisms, disrupting ecosystems and potentially entering the food chain. This contamination can occur through industrial discharges, improper disposal of isocyanate-containing products, or accidental spills during transportation and handling.

The persistence of isocyanates in the environment is a subject of ongoing research. While some isocyanates degrade relatively quickly under certain conditions, others may persist for longer periods, potentially accumulating in soil and sediments. This persistence can lead to long-term environmental impacts and challenges in remediation efforts.

Furthermore, the production of isocyanates often involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. The environmental footprint of isocyanate production extends beyond the immediate manufacturing sites, encompassing the entire supply chain and lifecycle of these materials.

Efforts to mitigate the environmental impact of isocyanates are multifaceted. Industry initiatives focus on developing more environmentally friendly production methods, improving containment and handling procedures, and exploring alternative materials with reduced environmental risks. Regulatory frameworks in many countries now impose strict controls on isocyanate emissions and disposal, aiming to minimize their environmental footprint.

Research into biodegradable alternatives and green chemistry approaches offers promising avenues for reducing the environmental impact of isocyanates. These efforts seek to maintain the beneficial properties of isocyanates while minimizing their ecological risks, aligning scientific exploration with sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!