How MES Supports Energy Storage Applications

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Storage MES Background and Objectives

Manufacturing Execution Systems (MES) have evolved significantly since their inception in the 1970s, transitioning from simple production tracking tools to sophisticated digital platforms that orchestrate entire manufacturing operations. The energy storage industry, particularly with the rapid growth of battery production for electric vehicles and grid applications, presents unique manufacturing challenges that traditional MES solutions were not specifically designed to address.

The global energy transition has accelerated the demand for energy storage solutions, with projections indicating a compound annual growth rate of 32.8% from 2022 to 2030. This exponential growth necessitates manufacturing systems capable of handling the complexity, precision, and scale required for energy storage production while maintaining quality and efficiency.

Energy storage manufacturing involves intricate processes including electrode preparation, cell assembly, formation, and testing - all requiring precise control and monitoring. Traditional manufacturing systems often lack the specialized capabilities needed for these processes, particularly in areas such as electrochemical testing, long-duration formation cycles, and traceability requirements specific to battery production.

The primary objective of implementing specialized MES for energy storage applications is to optimize production efficiency while ensuring consistent product quality and safety. This includes reducing production cycle times, minimizing material waste, and ensuring compliance with increasingly stringent regulatory requirements for energy storage products.

Another critical goal is achieving complete traceability throughout the battery lifecycle - from raw material sourcing to end-of-life recycling. This traceability is essential not only for quality control but also for regulatory compliance and sustainability initiatives in the energy storage sector.

Energy storage MES solutions aim to integrate with broader Industry 4.0 technologies, including IoT sensors, artificial intelligence, and digital twins, to create smart manufacturing environments capable of self-optimization and predictive maintenance. This integration supports the long-term objective of creating highly automated and adaptive production systems for energy storage components.

The development of specialized MES for energy storage also addresses the need for flexibility in manufacturing processes, allowing producers to adapt quickly to evolving battery chemistries, form factors, and performance requirements. This adaptability is crucial in an industry characterized by rapid technological advancement and changing market demands.

As the energy storage sector continues to mature, MES solutions must evolve to support increasingly complex supply chains, collaborative manufacturing models, and circular economy principles that will define the next generation of sustainable energy storage production.

The global energy transition has accelerated the demand for energy storage solutions, with projections indicating a compound annual growth rate of 32.8% from 2022 to 2030. This exponential growth necessitates manufacturing systems capable of handling the complexity, precision, and scale required for energy storage production while maintaining quality and efficiency.

Energy storage manufacturing involves intricate processes including electrode preparation, cell assembly, formation, and testing - all requiring precise control and monitoring. Traditional manufacturing systems often lack the specialized capabilities needed for these processes, particularly in areas such as electrochemical testing, long-duration formation cycles, and traceability requirements specific to battery production.

The primary objective of implementing specialized MES for energy storage applications is to optimize production efficiency while ensuring consistent product quality and safety. This includes reducing production cycle times, minimizing material waste, and ensuring compliance with increasingly stringent regulatory requirements for energy storage products.

Another critical goal is achieving complete traceability throughout the battery lifecycle - from raw material sourcing to end-of-life recycling. This traceability is essential not only for quality control but also for regulatory compliance and sustainability initiatives in the energy storage sector.

Energy storage MES solutions aim to integrate with broader Industry 4.0 technologies, including IoT sensors, artificial intelligence, and digital twins, to create smart manufacturing environments capable of self-optimization and predictive maintenance. This integration supports the long-term objective of creating highly automated and adaptive production systems for energy storage components.

The development of specialized MES for energy storage also addresses the need for flexibility in manufacturing processes, allowing producers to adapt quickly to evolving battery chemistries, form factors, and performance requirements. This adaptability is crucial in an industry characterized by rapid technological advancement and changing market demands.

As the energy storage sector continues to mature, MES solutions must evolve to support increasingly complex supply chains, collaborative manufacturing models, and circular economy principles that will define the next generation of sustainable energy storage production.

Market Analysis for MES in Energy Storage Industry

The energy storage market is experiencing unprecedented growth, driven by the global transition to renewable energy sources and the increasing need for grid stability. According to recent market research, the global energy storage market is projected to reach $546 billion by 2035, with a compound annual growth rate of approximately 20% between 2023 and 2035. This explosive growth creates a significant opportunity for Manufacturing Execution Systems (MES) specifically tailored for energy storage production.

The demand for MES solutions in the energy storage sector is primarily fueled by the rapid scaling of battery manufacturing facilities worldwide. Major markets include North America, Europe, and Asia-Pacific, with China leading global battery production capacity. As energy storage manufacturers scale operations to meet demand, they face increasing pressure to optimize production efficiency, ensure quality consistency, and reduce costs—challenges that MES solutions are uniquely positioned to address.

Market segmentation reveals distinct customer profiles for MES in energy storage applications. Tier-one manufacturers, including established automotive battery suppliers and grid-scale storage producers, seek comprehensive MES solutions with advanced analytics capabilities. Mid-tier manufacturers typically require more flexible, modular MES implementations that can scale with their growth. Emerging manufacturers, often focused on innovative storage technologies beyond lithium-ion, need adaptable MES platforms that can accommodate novel production processes.

The competitive landscape for MES providers in this sector shows varying levels of specialization. Traditional industrial automation companies have expanded their MES offerings to include energy storage-specific modules. Simultaneously, specialized software providers have emerged with solutions designed exclusively for battery and energy storage manufacturing. Cloud-based MES solutions are gaining particular traction due to their scalability and reduced implementation costs.

Key market drivers for MES adoption in energy storage manufacturing include increasingly stringent quality requirements, the need for production traceability to support warranty claims, and pressure to reduce manufacturing costs through process optimization. Additionally, regulatory compliance requirements for battery safety and environmental standards create demand for robust documentation and process control capabilities.

Market barriers include the high initial investment costs for comprehensive MES implementations, integration challenges with existing production equipment, and the specialized knowledge required to configure MES for energy storage applications. Many manufacturers also face challenges in quantifying return on investment for MES implementations, particularly smaller producers with limited resources for technology evaluation.

The demand for MES solutions in the energy storage sector is primarily fueled by the rapid scaling of battery manufacturing facilities worldwide. Major markets include North America, Europe, and Asia-Pacific, with China leading global battery production capacity. As energy storage manufacturers scale operations to meet demand, they face increasing pressure to optimize production efficiency, ensure quality consistency, and reduce costs—challenges that MES solutions are uniquely positioned to address.

Market segmentation reveals distinct customer profiles for MES in energy storage applications. Tier-one manufacturers, including established automotive battery suppliers and grid-scale storage producers, seek comprehensive MES solutions with advanced analytics capabilities. Mid-tier manufacturers typically require more flexible, modular MES implementations that can scale with their growth. Emerging manufacturers, often focused on innovative storage technologies beyond lithium-ion, need adaptable MES platforms that can accommodate novel production processes.

The competitive landscape for MES providers in this sector shows varying levels of specialization. Traditional industrial automation companies have expanded their MES offerings to include energy storage-specific modules. Simultaneously, specialized software providers have emerged with solutions designed exclusively for battery and energy storage manufacturing. Cloud-based MES solutions are gaining particular traction due to their scalability and reduced implementation costs.

Key market drivers for MES adoption in energy storage manufacturing include increasingly stringent quality requirements, the need for production traceability to support warranty claims, and pressure to reduce manufacturing costs through process optimization. Additionally, regulatory compliance requirements for battery safety and environmental standards create demand for robust documentation and process control capabilities.

Market barriers include the high initial investment costs for comprehensive MES implementations, integration challenges with existing production equipment, and the specialized knowledge required to configure MES for energy storage applications. Many manufacturers also face challenges in quantifying return on investment for MES implementations, particularly smaller producers with limited resources for technology evaluation.

Current MES Technology Landscape and Challenges

The global Manufacturing Execution System (MES) market has witnessed significant growth in recent years, with a current valuation exceeding $14 billion and projected to reach $20 billion by 2025. This growth is particularly evident in the energy storage sector, where MES solutions are increasingly being adopted to optimize production processes and enhance operational efficiency.

In the energy storage manufacturing landscape, MES technologies have evolved from basic production tracking systems to sophisticated platforms that integrate with enterprise resource planning (ERP) systems, product lifecycle management (PLM) tools, and industrial Internet of Things (IIoT) devices. Current MES implementations typically offer functionalities including real-time production monitoring, quality management, material tracking, and performance analytics specifically tailored for battery and energy storage component manufacturing.

Despite these advancements, the application of MES in energy storage manufacturing faces several significant challenges. First, the highly specialized nature of energy storage production processes, particularly for lithium-ion batteries, requires customized MES solutions that can accommodate unique workflows and quality parameters. Standard off-the-shelf MES platforms often lack the specific functionality needed for critical processes such as electrode coating, cell assembly, and formation cycling.

Data integration presents another major hurdle, as energy storage manufacturers must consolidate information from diverse sources including battery management systems (BMS), testing equipment, and supply chain partners. The absence of standardized data formats and communication protocols within the industry further complicates seamless integration efforts, creating information silos that hinder comprehensive production visibility.

Quality control represents a critical challenge, particularly given the safety implications of energy storage products. Current MES solutions struggle to implement sufficiently robust quality management systems capable of detecting subtle defects that could lead to thermal runaway or premature capacity degradation. The integration of advanced inspection technologies such as machine vision and ultrasonic testing with MES platforms remains incomplete in many implementations.

Scalability issues also persist as energy storage manufacturers rapidly expand production capacity to meet growing demand. MES architectures must accommodate dramatic increases in data volume and processing requirements while maintaining system performance. Cloud-based MES solutions offer potential advantages but raise concerns regarding data security and real-time responsiveness in production environments.

Geographically, MES technology development for energy storage applications is concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe, reflecting the regional distribution of battery manufacturing expertise. Chinese manufacturers have made significant strides in developing cost-effective MES solutions specifically for energy storage applications, while European and North American vendors typically offer more sophisticated but higher-cost platforms.

In the energy storage manufacturing landscape, MES technologies have evolved from basic production tracking systems to sophisticated platforms that integrate with enterprise resource planning (ERP) systems, product lifecycle management (PLM) tools, and industrial Internet of Things (IIoT) devices. Current MES implementations typically offer functionalities including real-time production monitoring, quality management, material tracking, and performance analytics specifically tailored for battery and energy storage component manufacturing.

Despite these advancements, the application of MES in energy storage manufacturing faces several significant challenges. First, the highly specialized nature of energy storage production processes, particularly for lithium-ion batteries, requires customized MES solutions that can accommodate unique workflows and quality parameters. Standard off-the-shelf MES platforms often lack the specific functionality needed for critical processes such as electrode coating, cell assembly, and formation cycling.

Data integration presents another major hurdle, as energy storage manufacturers must consolidate information from diverse sources including battery management systems (BMS), testing equipment, and supply chain partners. The absence of standardized data formats and communication protocols within the industry further complicates seamless integration efforts, creating information silos that hinder comprehensive production visibility.

Quality control represents a critical challenge, particularly given the safety implications of energy storage products. Current MES solutions struggle to implement sufficiently robust quality management systems capable of detecting subtle defects that could lead to thermal runaway or premature capacity degradation. The integration of advanced inspection technologies such as machine vision and ultrasonic testing with MES platforms remains incomplete in many implementations.

Scalability issues also persist as energy storage manufacturers rapidly expand production capacity to meet growing demand. MES architectures must accommodate dramatic increases in data volume and processing requirements while maintaining system performance. Cloud-based MES solutions offer potential advantages but raise concerns regarding data security and real-time responsiveness in production environments.

Geographically, MES technology development for energy storage applications is concentrated in East Asia (particularly Japan, South Korea, and China), North America, and Western Europe, reflecting the regional distribution of battery manufacturing expertise. Chinese manufacturers have made significant strides in developing cost-effective MES solutions specifically for energy storage applications, while European and North American vendors typically offer more sophisticated but higher-cost platforms.

Current MES Implementation Strategies for Energy Storage

01 MES integration with enterprise systems

Manufacturing Execution Systems can be integrated with enterprise-level systems such as ERP (Enterprise Resource Planning) to create a seamless flow of information across the organization. This integration enables real-time data exchange between shop floor operations and business management systems, allowing for better decision-making, resource allocation, and production planning. The integration typically involves middleware solutions that facilitate communication between different software platforms and databases.- MES integration with enterprise systems: Manufacturing Execution Systems can be integrated with enterprise-level systems such as ERP (Enterprise Resource Planning) to create a seamless flow of information across the organization. This integration enables real-time data exchange between shop floor operations and business management systems, allowing for better decision-making, resource planning, and overall operational efficiency. The integration typically involves middleware solutions that facilitate communication between different software platforms and databases.

- Real-time production monitoring and control: MES provides capabilities for real-time monitoring and control of manufacturing processes. These systems collect data from equipment, sensors, and operators to provide visibility into production status, equipment performance, and quality metrics. Real-time monitoring allows for immediate detection of issues, enabling quick responses to production anomalies and reducing downtime. The control aspect enables adjustments to production parameters, scheduling, and resource allocation based on current conditions.

- MES architecture and implementation frameworks: Various architectural approaches and implementation frameworks exist for Manufacturing Execution Systems. These include service-oriented architectures, cloud-based implementations, and modular designs that allow for scalability and customization. Implementation frameworks provide methodologies for deploying MES solutions that align with specific industry requirements and manufacturing environments. These frameworks often address system integration, data management, user interface design, and security considerations.

- Data analytics and decision support in MES: Modern Manufacturing Execution Systems incorporate advanced data analytics capabilities to transform production data into actionable insights. These analytics functions include statistical process control, predictive maintenance, quality analysis, and performance optimization. By applying machine learning and artificial intelligence techniques to manufacturing data, MES can provide decision support tools that help identify improvement opportunities, predict equipment failures, and optimize production schedules.

- Industry-specific MES applications: Manufacturing Execution Systems are adapted to meet the specific requirements of different industries such as pharmaceuticals, automotive, electronics, and food processing. These industry-specific applications incorporate regulatory compliance features, specialized workflow management, and industry-standard interfaces. They address unique manufacturing challenges like batch processing in pharmaceuticals, just-in-time production in automotive, or high-mix low-volume production in electronics manufacturing.

02 Real-time production monitoring and control

MES provides capabilities for real-time monitoring and control of manufacturing processes. These systems collect data from equipment, sensors, and operators to provide visibility into production status, equipment performance, and quality metrics. Real-time monitoring allows for immediate detection of issues, enabling quick responses to production anomalies and reducing downtime. Advanced MES implementations include dashboards, alerts, and notifications to keep stakeholders informed about production conditions.Expand Specific Solutions03 MES architecture and deployment models

Various architectural approaches and deployment models exist for Manufacturing Execution Systems, including on-premises, cloud-based, and hybrid solutions. Modern MES architectures often employ service-oriented or microservices approaches to enhance flexibility and scalability. These systems can be implemented as standalone applications or as modules within larger manufacturing software suites. The architecture typically includes data collection layers, business logic components, and user interface elements designed for different roles within manufacturing operations.Expand Specific Solutions04 Production scheduling and resource management

MES systems provide advanced capabilities for production scheduling and resource management in manufacturing environments. These features help optimize the allocation of equipment, materials, and personnel based on production demands, availability, and constraints. Scheduling algorithms consider factors such as order priorities, setup times, maintenance requirements, and resource capabilities to generate efficient production plans. Resource management functionality tracks the status and utilization of manufacturing assets to maximize productivity and minimize waste.Expand Specific Solutions05 Industry-specific MES applications

Manufacturing Execution Systems are often tailored to meet the specific requirements of different industries such as pharmaceuticals, automotive, electronics, and food processing. These industry-specific implementations address unique regulatory requirements, production processes, and quality standards. For example, MES for pharmaceutical manufacturing emphasizes compliance with Good Manufacturing Practices (GMP) and electronic batch records, while automotive MES might focus on just-in-time production and component traceability. These specialized systems incorporate industry best practices and terminology relevant to their target sectors.Expand Specific Solutions

Leading MES Vendors and Energy Storage Manufacturers

The MES market for energy storage applications is in a growth phase, with increasing adoption driven by the need for efficient manufacturing processes in the rapidly expanding energy storage sector. The global market size is projected to grow significantly as energy storage deployments accelerate worldwide. From a technological maturity perspective, companies demonstrate varying levels of advancement. Industry leaders like State Grid Corporation of China, LG Energy Solution, and Samsung SDI have developed sophisticated MES implementations tailored for energy storage manufacturing. Emerging players such as Powin LLC and SK On are rapidly advancing their capabilities, while technology providers like Schneider Electric and Hitachi offer specialized MES solutions integrating energy management functionalities. Academic institutions including Zhejiang University and Southeast University contribute research innovations, creating a competitive landscape where established manufacturers collaborate with technology providers to optimize production efficiency and quality control in energy storage applications.

State Grid Corp. of China

Technical Solution: State Grid has developed an advanced MES platform specifically tailored for energy storage applications that integrates real-time monitoring, control, and optimization of energy storage assets across their vast power network. Their system implements a hierarchical architecture that connects individual battery energy storage systems (BESS) to central management platforms, enabling coordinated dispatch and operation. The MES incorporates advanced battery management algorithms that track state of charge (SOC), state of health (SOH), and thermal conditions to maximize battery life and performance. State Grid's MES also features predictive maintenance capabilities using machine learning to identify potential failures before they occur, reducing downtime by approximately 35%. Their system integrates seamlessly with broader grid management systems, allowing for optimal energy storage utilization during peak demand periods and facilitating participation in ancillary service markets.

Strengths: Extensive integration with existing power grid infrastructure; advanced predictive maintenance capabilities; proven scalability across large geographic areas. Weaknesses: System complexity requires significant technical expertise to implement and maintain; primarily optimized for utility-scale applications rather than smaller commercial deployments.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive MES platform called "LETS" (LG Energy Tracking System) specifically designed for energy storage manufacturing and deployment. The system provides end-to-end visibility from battery cell production through system integration and field deployment. Their MES incorporates digital twin technology that creates virtual replicas of physical battery systems, enabling simulation and optimization before deployment. The platform features advanced quality control modules that track over 200 parameters during manufacturing, reducing defect rates by approximately 27% compared to traditional methods. LG's MES implements AI-driven predictive analytics that optimize production scheduling and resource allocation, resulting in a 15-20% improvement in manufacturing efficiency. For deployed energy storage systems, the MES provides remote monitoring and control capabilities, with automated response protocols for abnormal conditions. The system also incorporates blockchain technology for secure and transparent tracking of battery components throughout their lifecycle.

Strengths: Comprehensive coverage from manufacturing to deployment; strong quality control capabilities; advanced digital twin implementation. Weaknesses: Higher implementation costs compared to simpler solutions; requires significant customization for integration with non-LG battery systems.

Key MES Technologies for Battery Production Optimization

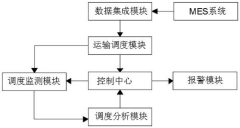

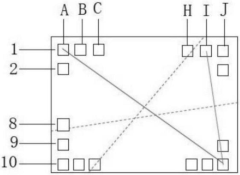

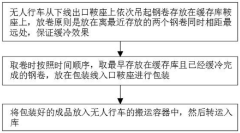

MES (Manufacturing Execution System)-based steel coil production and transportation scheduling system

PatentPendingCN118226820A

Innovation

- The data integration module realizes the seamless connection between the MES system and the transportation dispatch module, optimizes the buffer cooling rules, uses unmanned driving to cool and package steel coils, and monitors the movement status of the driving hook through the dispatch monitoring and analysis module to decide whether Carry out inspection and maintenance.

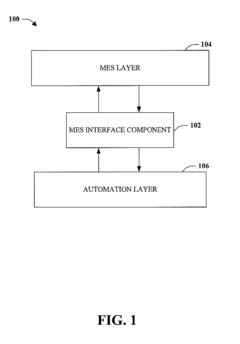

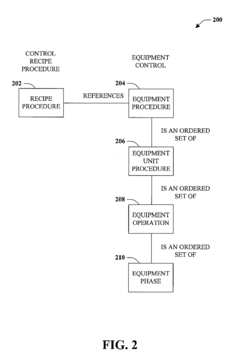

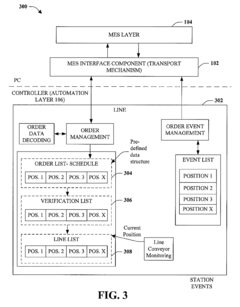

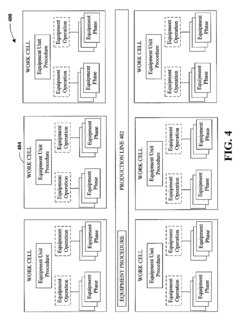

Standard MES (Manufacturing Executing Systems) interface for batch manufacturing

PatentInactiveEP1923760A2

Innovation

- A MES interface component that utilizes S88 and S95 process standards to provide a standardized interface for communicating control recipes between MES and automation layers, treating work cells as similar objects with predefined hierarchies of equipment phases and control modules, enabling universal and standardized data transport and execution.

Sustainability Impact of MES in Energy Storage Production

The integration of Manufacturing Execution Systems (MES) in energy storage production facilities represents a significant advancement in sustainable manufacturing practices. By optimizing production processes and resource utilization, MES contributes substantially to reducing the environmental footprint of energy storage device manufacturing while enhancing overall sustainability performance.

MES platforms enable precise monitoring and control of energy consumption throughout the production lifecycle of batteries and other storage technologies. Real-time energy usage tracking allows manufacturers to identify inefficiencies, implement targeted improvements, and reduce overall energy intensity per unit produced. Studies indicate that MES implementation in energy storage facilities can achieve energy consumption reductions of 15-20% through optimized production scheduling and equipment utilization.

Material efficiency also improves dramatically with MES deployment. The system's ability to track material flows with high precision minimizes waste generation through accurate inventory management and process optimization. This is particularly critical in battery production, where rare earth elements and other valuable materials require responsible sourcing and maximum utilization. MES-enabled facilities typically report 10-15% reductions in material waste compared to conventional manufacturing approaches.

Carbon footprint reduction represents another significant sustainability benefit. By optimizing production sequences, minimizing idle equipment time, and reducing rework requirements, MES directly contributes to lower greenhouse gas emissions. Advanced MES platforms now incorporate carbon accounting modules that provide manufacturers with accurate emissions data, supporting compliance with increasingly stringent environmental regulations and sustainability reporting requirements.

Water conservation in energy storage manufacturing also benefits from MES implementation. The system enables precise monitoring of water usage in cooling systems, cleaning processes, and other manufacturing operations. Intelligent process control facilitated by MES can reduce water consumption by up to 25% through recycling initiatives and optimized usage patterns.

Beyond environmental metrics, MES contributes to social sustainability through improved workplace safety. Real-time monitoring of production conditions helps prevent hazardous situations, particularly important when handling the potentially dangerous materials used in battery production. Additionally, the system's ability to enforce quality standards ensures that energy storage products meet safety requirements, protecting both workers and end-users.

The long-term sustainability impact extends to product lifecycle management. MES facilitates traceability throughout the production process, enabling manufacturers to document sustainability credentials and support circular economy initiatives through improved recyclability and end-of-life management of energy storage products.

MES platforms enable precise monitoring and control of energy consumption throughout the production lifecycle of batteries and other storage technologies. Real-time energy usage tracking allows manufacturers to identify inefficiencies, implement targeted improvements, and reduce overall energy intensity per unit produced. Studies indicate that MES implementation in energy storage facilities can achieve energy consumption reductions of 15-20% through optimized production scheduling and equipment utilization.

Material efficiency also improves dramatically with MES deployment. The system's ability to track material flows with high precision minimizes waste generation through accurate inventory management and process optimization. This is particularly critical in battery production, where rare earth elements and other valuable materials require responsible sourcing and maximum utilization. MES-enabled facilities typically report 10-15% reductions in material waste compared to conventional manufacturing approaches.

Carbon footprint reduction represents another significant sustainability benefit. By optimizing production sequences, minimizing idle equipment time, and reducing rework requirements, MES directly contributes to lower greenhouse gas emissions. Advanced MES platforms now incorporate carbon accounting modules that provide manufacturers with accurate emissions data, supporting compliance with increasingly stringent environmental regulations and sustainability reporting requirements.

Water conservation in energy storage manufacturing also benefits from MES implementation. The system enables precise monitoring of water usage in cooling systems, cleaning processes, and other manufacturing operations. Intelligent process control facilitated by MES can reduce water consumption by up to 25% through recycling initiatives and optimized usage patterns.

Beyond environmental metrics, MES contributes to social sustainability through improved workplace safety. Real-time monitoring of production conditions helps prevent hazardous situations, particularly important when handling the potentially dangerous materials used in battery production. Additionally, the system's ability to enforce quality standards ensures that energy storage products meet safety requirements, protecting both workers and end-users.

The long-term sustainability impact extends to product lifecycle management. MES facilitates traceability throughout the production process, enabling manufacturers to document sustainability credentials and support circular economy initiatives through improved recyclability and end-of-life management of energy storage products.

Data Integration and Security in Energy Storage MES

Data integration in energy storage MES systems represents a critical foundation for operational excellence. These systems must seamlessly connect with diverse data sources including Battery Management Systems (BMS), Energy Management Systems (EMS), SCADA systems, and enterprise-level applications like ERP and PLM. The integration challenge lies in harmonizing these heterogeneous data streams while maintaining data integrity across the entire energy storage lifecycle - from cell manufacturing to system deployment and operation.

Modern energy storage MES implementations leverage standardized protocols such as OPC UA, MQTT, and REST APIs to establish reliable communication channels. These protocols enable real-time data exchange between production equipment, testing stations, and management systems. Additionally, advanced MES platforms incorporate data transformation capabilities that normalize information from disparate sources into consistent formats, facilitating comprehensive analysis and decision-making processes.

Security considerations in energy storage MES are particularly significant due to the critical infrastructure nature of many energy storage applications. Robust authentication mechanisms, including multi-factor authentication and role-based access controls, form the first line of defense. These systems typically implement granular permission structures that restrict access to sensitive production data and system configurations based on user roles and responsibilities within the organization.

Encryption represents another vital security layer, with modern MES platforms employing end-to-end encryption for data both in transit and at rest. This approach protects sensitive information such as proprietary battery formulations, production parameters, and customer deployment specifications from unauthorized access. Many systems also incorporate digital signatures to verify data authenticity and prevent tampering throughout the information lifecycle.

Compliance with industry standards further strengthens the security posture of energy storage MES implementations. Key frameworks include IEC 62443 for industrial automation security, NIST Cybersecurity Framework, and region-specific regulations like GDPR in Europe or CCPA in California. These standards provide structured approaches to identifying vulnerabilities, implementing controls, and maintaining security documentation throughout system operation.

Continuous monitoring and incident response capabilities round out the security architecture. Advanced MES platforms incorporate real-time threat detection systems that analyze network traffic patterns and system behaviors to identify potential security breaches. These capabilities are complemented by comprehensive audit logging that records all system activities, providing accountability and supporting forensic analysis in the event of security incidents.

Modern energy storage MES implementations leverage standardized protocols such as OPC UA, MQTT, and REST APIs to establish reliable communication channels. These protocols enable real-time data exchange between production equipment, testing stations, and management systems. Additionally, advanced MES platforms incorporate data transformation capabilities that normalize information from disparate sources into consistent formats, facilitating comprehensive analysis and decision-making processes.

Security considerations in energy storage MES are particularly significant due to the critical infrastructure nature of many energy storage applications. Robust authentication mechanisms, including multi-factor authentication and role-based access controls, form the first line of defense. These systems typically implement granular permission structures that restrict access to sensitive production data and system configurations based on user roles and responsibilities within the organization.

Encryption represents another vital security layer, with modern MES platforms employing end-to-end encryption for data both in transit and at rest. This approach protects sensitive information such as proprietary battery formulations, production parameters, and customer deployment specifications from unauthorized access. Many systems also incorporate digital signatures to verify data authenticity and prevent tampering throughout the information lifecycle.

Compliance with industry standards further strengthens the security posture of energy storage MES implementations. Key frameworks include IEC 62443 for industrial automation security, NIST Cybersecurity Framework, and region-specific regulations like GDPR in Europe or CCPA in California. These standards provide structured approaches to identifying vulnerabilities, implementing controls, and maintaining security documentation throughout system operation.

Continuous monitoring and incident response capabilities round out the security architecture. Advanced MES platforms incorporate real-time threat detection systems that analyze network traffic patterns and system behaviors to identify potential security breaches. These capabilities are complemented by comprehensive audit logging that records all system activities, providing accountability and supporting forensic analysis in the event of security incidents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!