How Ozonation Couples With Biological Polishing For Micropollutant Removal?

SEP 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation-Biological Polishing Background and Objectives

The integration of ozonation with biological polishing represents a significant advancement in water treatment technologies, particularly for the removal of micropollutants. This combined approach has evolved over several decades, beginning with the recognition of ozone's powerful oxidation capabilities in the early 20th century. By the 1970s, ozonation had become established in European water treatment facilities, primarily for disinfection purposes. However, it was not until the 1990s that researchers began to systematically investigate the potential of coupling ozonation with biological processes for enhanced micropollutant removal.

The evolution of this technology has been driven by increasing concerns about the presence of persistent organic pollutants in water systems, including pharmaceuticals, personal care products, pesticides, and industrial chemicals. These compounds, often present at trace concentrations (ng/L to μg/L), can resist conventional treatment methods and pose potential risks to aquatic ecosystems and human health even at low levels.

Ozonation serves as a powerful initial treatment step, breaking down complex organic molecules into simpler, more biodegradable compounds through oxidation reactions. This process transforms recalcitrant micropollutants into intermediates that are more amenable to biological degradation. The subsequent biological polishing step, typically employing biofilters or activated sludge processes, then removes these transformation products and reduces overall organic content.

The technological trajectory has seen significant advancements in ozone generation efficiency, contact systems design, and the development of specialized biological treatment configurations optimized for post-ozonation conditions. Recent innovations include the integration of advanced monitoring systems that allow real-time adjustment of ozone dosages based on water quality parameters and the development of tailored microbial communities for specific contaminant profiles.

The primary objective of this coupled technology is to achieve comprehensive removal of a broad spectrum of micropollutants while minimizing energy consumption, reducing the formation of potentially harmful by-products, and maintaining cost-effectiveness. Secondary objectives include reducing the ecological footprint of water treatment processes and developing flexible systems capable of addressing emerging contaminants of concern.

Current research aims to optimize the synergistic relationship between ozonation and biological processes, focusing on parameters such as ozone dose, contact time, biofilter media selection, and operational conditions that maximize treatment efficiency while minimizing costs. Additionally, there is growing interest in understanding the microbial ecology of biological polishing systems and how it can be engineered to enhance degradation capabilities for specific contaminant classes.

The evolution of this technology has been driven by increasing concerns about the presence of persistent organic pollutants in water systems, including pharmaceuticals, personal care products, pesticides, and industrial chemicals. These compounds, often present at trace concentrations (ng/L to μg/L), can resist conventional treatment methods and pose potential risks to aquatic ecosystems and human health even at low levels.

Ozonation serves as a powerful initial treatment step, breaking down complex organic molecules into simpler, more biodegradable compounds through oxidation reactions. This process transforms recalcitrant micropollutants into intermediates that are more amenable to biological degradation. The subsequent biological polishing step, typically employing biofilters or activated sludge processes, then removes these transformation products and reduces overall organic content.

The technological trajectory has seen significant advancements in ozone generation efficiency, contact systems design, and the development of specialized biological treatment configurations optimized for post-ozonation conditions. Recent innovations include the integration of advanced monitoring systems that allow real-time adjustment of ozone dosages based on water quality parameters and the development of tailored microbial communities for specific contaminant profiles.

The primary objective of this coupled technology is to achieve comprehensive removal of a broad spectrum of micropollutants while minimizing energy consumption, reducing the formation of potentially harmful by-products, and maintaining cost-effectiveness. Secondary objectives include reducing the ecological footprint of water treatment processes and developing flexible systems capable of addressing emerging contaminants of concern.

Current research aims to optimize the synergistic relationship between ozonation and biological processes, focusing on parameters such as ozone dose, contact time, biofilter media selection, and operational conditions that maximize treatment efficiency while minimizing costs. Additionally, there is growing interest in understanding the microbial ecology of biological polishing systems and how it can be engineered to enhance degradation capabilities for specific contaminant classes.

Market Demand for Advanced Micropollutant Removal Technologies

The global market for advanced micropollutant removal technologies has experienced significant growth in recent years, driven primarily by increasing awareness of the harmful effects of micropollutants on aquatic ecosystems and human health. Regulatory frameworks worldwide have become increasingly stringent, particularly in Europe where the Water Framework Directive has established priority substance lists and environmental quality standards for surface waters.

The combined ozonation and biological polishing approach addresses a critical market need for cost-effective, efficient, and environmentally friendly water treatment solutions. Municipal wastewater treatment plants represent the largest market segment, with an estimated annual growth rate of 7-8% through 2030, as facilities upgrade to meet new micropollutant removal requirements.

Industrial sectors including pharmaceuticals, chemicals, and textiles constitute another substantial market segment. These industries face mounting pressure from regulators and consumers to reduce micropollutant discharge in their effluents. The pharmaceutical industry alone is projected to invest significantly in advanced treatment technologies over the next decade to address active pharmaceutical ingredients in wastewater.

Healthcare facilities represent an emerging market with specialized needs for removing pharmaceutical residues and disinfection byproducts. Hospitals and medical centers increasingly recognize the importance of treating their wastewater before discharge to municipal systems.

Geographically, Europe leads the market adoption of advanced micropollutant removal technologies, with Switzerland and Germany at the forefront. Switzerland has already mandated ozonation or activated carbon treatment at selected wastewater treatment plants. North America follows closely, while the Asia-Pacific region shows the highest growth potential, particularly in China and India where water pollution concerns are escalating alongside industrial expansion.

Consumer awareness and demand for cleaner water resources have created market pull factors complementing regulatory push. Public perception increasingly recognizes micropollutants as "invisible pollutants" that conventional treatment cannot adequately address.

The economic value proposition of coupled ozonation-biological systems is compelling when compared to alternatives like reverse osmosis or advanced oxidation alone. Market analysis indicates that facilities can achieve up to 30% operational cost savings through the synergistic effects of combining these processes rather than implementing standalone advanced treatments.

Market research indicates growing interest in modular and scalable solutions that can be retrofitted to existing infrastructure, presenting opportunities for technology providers offering flexible implementation options for the ozonation-biological polishing approach.

The combined ozonation and biological polishing approach addresses a critical market need for cost-effective, efficient, and environmentally friendly water treatment solutions. Municipal wastewater treatment plants represent the largest market segment, with an estimated annual growth rate of 7-8% through 2030, as facilities upgrade to meet new micropollutant removal requirements.

Industrial sectors including pharmaceuticals, chemicals, and textiles constitute another substantial market segment. These industries face mounting pressure from regulators and consumers to reduce micropollutant discharge in their effluents. The pharmaceutical industry alone is projected to invest significantly in advanced treatment technologies over the next decade to address active pharmaceutical ingredients in wastewater.

Healthcare facilities represent an emerging market with specialized needs for removing pharmaceutical residues and disinfection byproducts. Hospitals and medical centers increasingly recognize the importance of treating their wastewater before discharge to municipal systems.

Geographically, Europe leads the market adoption of advanced micropollutant removal technologies, with Switzerland and Germany at the forefront. Switzerland has already mandated ozonation or activated carbon treatment at selected wastewater treatment plants. North America follows closely, while the Asia-Pacific region shows the highest growth potential, particularly in China and India where water pollution concerns are escalating alongside industrial expansion.

Consumer awareness and demand for cleaner water resources have created market pull factors complementing regulatory push. Public perception increasingly recognizes micropollutants as "invisible pollutants" that conventional treatment cannot adequately address.

The economic value proposition of coupled ozonation-biological systems is compelling when compared to alternatives like reverse osmosis or advanced oxidation alone. Market analysis indicates that facilities can achieve up to 30% operational cost savings through the synergistic effects of combining these processes rather than implementing standalone advanced treatments.

Market research indicates growing interest in modular and scalable solutions that can be retrofitted to existing infrastructure, presenting opportunities for technology providers offering flexible implementation options for the ozonation-biological polishing approach.

Current Status and Challenges in Ozonation-Biological Coupling

The integration of ozonation with biological treatment represents a significant advancement in micropollutant removal technologies. Currently, this coupling approach is implemented in various configurations across wastewater treatment facilities worldwide, with Switzerland leading adoption following their 2016 legislation mandating micropollutant removal. Several full-scale installations exist in Europe, while North America and Asia are gradually implementing pilot projects.

The primary technical configuration involves positioning ozonation before biological treatment (pre-ozonation) or after secondary treatment but before a dedicated biological polishing step (post-ozonation). Research indicates that post-ozonation followed by biological filtration achieves removal efficiencies of 80-95% for many pharmaceuticals, personal care products, and industrial chemicals that conventional treatments cannot adequately address.

Despite promising results, significant challenges persist in the widespread implementation of this coupled technology. Optimization difficulties arise from the complex interaction between ozone dosage and biological treatment parameters. The efficacy of the biological polishing step heavily depends on the transformation products generated during ozonation, which vary based on water matrix composition and operational conditions.

Energy consumption represents another substantial challenge, with ozonation typically requiring 0.1-0.2 kWh per cubic meter of treated water. This energy demand contributes significantly to operational costs and carbon footprint concerns, particularly for facilities without renewable energy sources.

Formation of potentially harmful transformation products during ozonation presents ongoing concerns. While biological polishing can remove many of these intermediates, certain recalcitrant compounds may persist. Current analytical limitations make comprehensive monitoring of all transformation products technically challenging and economically unfeasible for routine operations.

Operational stability issues emerge when dealing with fluctuating influent characteristics, particularly during storm events or industrial discharge variations. These fluctuations can compromise ozone efficiency and subsequently affect biological treatment performance, requiring sophisticated control systems that many facilities lack.

Scaling considerations present additional challenges, as laboratory and pilot-scale successes don't always translate directly to full-scale operations. Differences in hydraulic retention times, mixing conditions, and microbial community development can significantly impact treatment efficiency at larger scales.

Regulatory frameworks remain inconsistent globally, with varying standards for micropollutant removal and transformation product monitoring. This regulatory uncertainty complicates technology adoption decisions and investment planning for utilities considering implementation of coupled ozonation-biological systems.

The primary technical configuration involves positioning ozonation before biological treatment (pre-ozonation) or after secondary treatment but before a dedicated biological polishing step (post-ozonation). Research indicates that post-ozonation followed by biological filtration achieves removal efficiencies of 80-95% for many pharmaceuticals, personal care products, and industrial chemicals that conventional treatments cannot adequately address.

Despite promising results, significant challenges persist in the widespread implementation of this coupled technology. Optimization difficulties arise from the complex interaction between ozone dosage and biological treatment parameters. The efficacy of the biological polishing step heavily depends on the transformation products generated during ozonation, which vary based on water matrix composition and operational conditions.

Energy consumption represents another substantial challenge, with ozonation typically requiring 0.1-0.2 kWh per cubic meter of treated water. This energy demand contributes significantly to operational costs and carbon footprint concerns, particularly for facilities without renewable energy sources.

Formation of potentially harmful transformation products during ozonation presents ongoing concerns. While biological polishing can remove many of these intermediates, certain recalcitrant compounds may persist. Current analytical limitations make comprehensive monitoring of all transformation products technically challenging and economically unfeasible for routine operations.

Operational stability issues emerge when dealing with fluctuating influent characteristics, particularly during storm events or industrial discharge variations. These fluctuations can compromise ozone efficiency and subsequently affect biological treatment performance, requiring sophisticated control systems that many facilities lack.

Scaling considerations present additional challenges, as laboratory and pilot-scale successes don't always translate directly to full-scale operations. Differences in hydraulic retention times, mixing conditions, and microbial community development can significantly impact treatment efficiency at larger scales.

Regulatory frameworks remain inconsistent globally, with varying standards for micropollutant removal and transformation product monitoring. This regulatory uncertainty complicates technology adoption decisions and investment planning for utilities considering implementation of coupled ozonation-biological systems.

Established Ozonation-Biological Polishing Integration Methods

01 Ozonation combined with biological treatment for micropollutant removal

The combination of ozonation and biological treatment processes creates an effective system for removing micropollutants from water. Ozone oxidizes complex organic compounds into simpler, more biodegradable forms, which are then more efficiently removed by subsequent biological treatment. This coupled approach enhances the overall removal efficiency of pharmaceuticals, personal care products, and other persistent organic pollutants that conventional treatment methods struggle to eliminate.- Ozonation combined with biological treatment for micropollutant removal: The combination of ozonation and biological treatment processes creates an effective system for removing micropollutants from water. Ozone oxidizes complex organic compounds into more biodegradable forms, which are then efficiently removed by subsequent biological treatment steps. This coupled approach enhances the overall removal efficiency of pharmaceuticals, personal care products, and other persistent organic pollutants that conventional treatment methods struggle to eliminate.

- Advanced oxidation processes with biological polishing: Advanced oxidation processes (AOPs) involving ozone combined with other oxidants or catalysts generate highly reactive hydroxyl radicals that break down recalcitrant micropollutants. When followed by biological polishing steps, these systems achieve higher removal rates of transformation products. The biological stage metabolizes partially oxidized compounds, reducing overall toxicity and preventing the formation of harmful byproducts in the treated water.

- Membrane bioreactor systems with ozonation for micropollutant elimination: Membrane bioreactor (MBR) technology integrated with ozonation processes provides a comprehensive solution for micropollutant removal. The membrane component ensures physical separation of particulates while the biological component degrades biodegradable compounds. Ozonation either before or after the MBR process targets specific micropollutants that are resistant to biological treatment alone, creating a multi-barrier approach that significantly improves water quality.

- Optimization of ozone dosage and contact time with biological treatment: The effectiveness of combined ozonation and biological treatment systems depends on optimizing operational parameters such as ozone dosage, contact time, and biological retention time. Controlled ozonation prevents excessive oxidation that could inhibit biological activity while ensuring sufficient transformation of target compounds. Proper sequencing and timing between oxidation and biological processes maximize micropollutant removal efficiency while minimizing energy consumption and operational costs.

- Biofilm-based systems for enhanced micropollutant degradation after ozonation: Biofilm-based biological polishing systems offer advantages for post-ozonation treatment of micropollutants. Fixed-film reactors, moving bed biofilm reactors, and biological activated carbon filters provide high surface area for specialized microbial communities that can degrade transformation products from ozonation. These biofilm systems maintain diverse microbial populations capable of metabolizing a wide range of partially oxidized compounds, leading to more complete removal of micropollutants and their metabolites.

02 Advanced oxidation processes with biological polishing

Advanced oxidation processes (AOPs) that incorporate ozone with other oxidants such as hydrogen peroxide or UV radiation, followed by biological treatment, provide enhanced micropollutant degradation. These combined processes generate highly reactive hydroxyl radicals that break down recalcitrant compounds into biodegradable intermediates. The biological polishing stage then removes these intermediates and reduces overall toxicity, resulting in more complete contaminant removal than either process alone could achieve.Expand Specific Solutions03 Biofiltration systems following ozonation for water treatment

Specialized biofiltration systems designed to follow ozonation treatment utilize microbial communities that are particularly effective at degrading ozonation byproducts. These systems often employ biofilms on various media such as activated carbon, sand, or engineered carriers that provide habitat for diverse microbial populations. The biological activity in these filters not only removes biodegradable organic matter produced during ozonation but also contributes to the elimination of remaining micropollutants and reduction of potential harmful ozonation byproducts.Expand Specific Solutions04 Membrane bioreactor systems with integrated ozonation

Membrane bioreactor (MBR) systems integrated with ozonation processes offer a compact and efficient solution for micropollutant removal. In these systems, ozone can be applied either before the biological treatment to enhance biodegradability, or after to polish the effluent. The membrane component provides physical separation of biomass and treated water, allowing for higher microbial concentrations and more complete biological degradation. This configuration is particularly effective for treating wastewaters containing complex mixtures of micropollutants.Expand Specific Solutions05 Process optimization and control strategies for ozonation-biological treatment

Effective control strategies and process optimization techniques are essential for maximizing micropollutant removal in combined ozonation and biological treatment systems. These include real-time monitoring of ozone dosage, adjustment based on water quality parameters, optimization of hydraulic retention times, and management of microbial communities in the biological stage. Advanced control systems can dynamically adjust treatment parameters to maintain optimal performance while minimizing energy consumption and operational costs, ensuring consistent micropollutant removal across varying influent conditions.Expand Specific Solutions

Leading Organizations in Water Treatment Technology Development

The micropollutant removal market through ozonation coupled with biological polishing is in a growth phase, with increasing regulatory pressure driving adoption. The market is expanding as water quality standards become more stringent globally, though implementation costs remain a barrier. Technologically, academic institutions like Tsinghua University, Nanjing University, and Zhejiang University are advancing fundamental research, while companies demonstrate varying maturity levels. Industrial players such as Linde GmbH and IHI Corp. offer commercial-scale solutions, with engineering firms like HaskoningDHV Nederland BV providing implementation expertise. Research collaborations between universities and companies like Wacker Chemie AG are accelerating innovation in hybrid treatment systems that optimize both oxidation efficiency and biological degradation pathways.

Tsinghua University

Technical Solution: Tsinghua University has developed an innovative coupled ozonation-biological treatment system specifically targeting pharmaceutical and personal care product (PPCP) micropollutants in municipal wastewater. Their approach utilizes a sequential ozonation-membrane bioreactor (O₃-MBR) process with optimized ozone dosing strategies. Research has demonstrated removal efficiencies exceeding 95% for antibiotics and endocrine disrupting compounds when applying moderate ozone doses (0.5-0.8 mg O₃/mg DOC) followed by biological treatment in an MBR system. Their technology incorporates catalytic ozonation using metal oxides to enhance hydroxyl radical formation, improving oxidation efficiency while reducing energy consumption by approximately 30% compared to conventional ozonation. The university has also pioneered the development of bioaugmented systems where specific bacterial strains capable of degrading ozonation by-products are introduced to the biological treatment stage, further enhancing overall treatment performance and reducing potential ecotoxicity[5][6].

Strengths: High removal efficiency for a wide range of micropollutants; energy-efficient catalytic processes; innovative bioaugmentation approaches for enhanced biological polishing. Weaknesses: Complex system requiring sophisticated control; potential membrane fouling issues in the MBR component; higher implementation costs compared to conventional treatments.

Zhejiang University

Technical Solution: Zhejiang University has developed an advanced integrated ozonation-biological treatment system for micropollutant removal from various water matrices. Their technology employs a three-stage process: pre-ozonation for initial transformation of recalcitrant compounds, biological treatment with specialized microbial communities, and post-ozonation polishing. Research has shown that their sequential batch reactor (SBR) system with intermittent ozonation achieves removal rates exceeding 90% for pharmaceuticals, pesticides, and industrial chemicals. A key innovation is their development of ozone-resistant biofilms cultivated under gradual ozone exposure, which can effectively degrade ozonation by-products including aldehydes, carboxylic acids, and assimilable organic carbon. Their process optimization includes real-time monitoring of effluent organic matter characteristics using fluorescence excitation-emission matrices (EEM) coupled with parallel factor analysis (PARAFAC) to dynamically adjust ozone dosage, reducing operational costs by up to 25% while maintaining treatment efficacy[7][8].

Strengths: Highly adaptable system suitable for various water qualities; specialized microbial communities for enhanced biodegradation; advanced monitoring and control systems. Weaknesses: Requires sophisticated analytical techniques for process monitoring; higher energy consumption compared to conventional biological treatment alone; potential for incomplete mineralization of certain persistent compounds.

Critical Technologies in Micropollutant Transformation Pathways

Ozone-based advanced oxidation method

PatentPendingIN202421008156A

Innovation

- The development of a prediction model using Response Surface Methodology (RSM) and Artificial Neural Network (ANN) techniques to optimize the decolorization efficiency of acid black azo dye through three ozone-based advanced oxidation processes: O3, O3/UV, and O3/Fe (II), which attack the conjugated double bonds in dye molecules.

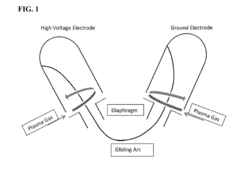

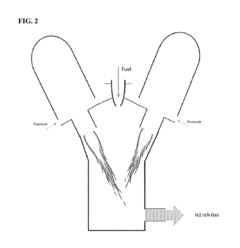

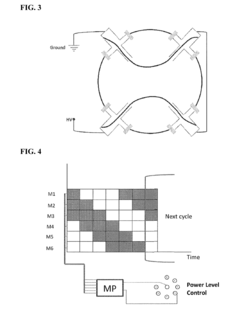

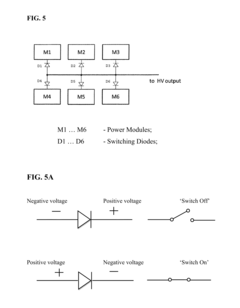

Fluid treatment using plasma technology

PatentActiveUS20150274554A1

Innovation

- A plasma-based water treatment system that uses a pulsed plasma discharge generated by a suitable electrode configuration to inactivate microorganisms in water, producing UV radiation, active chemical species, and shock waves, which are effective in deactivating microorganisms without the drawbacks of traditional methods.

Environmental Impact Assessment of Treatment Byproducts

The ozonation process coupled with biological polishing for micropollutant removal, while effective, generates various treatment byproducts that require thorough environmental impact assessment. Ozonation transforms parent compounds into oxidation byproducts through complex reaction pathways, potentially creating substances with unknown toxicological profiles. These transformation products may exhibit different environmental behaviors compared to their parent compounds, including altered persistence, mobility, and bioaccumulation potential.

Primary concerns include the formation of bromate, a regulated carcinogen, when ozonating bromide-containing waters. Studies have documented bromate formation at concentrations exceeding regulatory thresholds in certain water matrices, necessitating careful process optimization. Additionally, ozonation of waters containing natural organic matter produces assimilable organic carbon (AOC), which can promote microbial regrowth in distribution systems if not adequately addressed by subsequent biological treatment.

Ecotoxicological assessments reveal that while ozonation typically reduces the overall toxicity of micropollutant-laden waters, certain transformation products may exhibit increased toxicity compared to parent compounds. Bioassays targeting specific toxicological endpoints have demonstrated that ozonation can sometimes increase estrogenic activity, genotoxicity, or reactive toxicity in treated waters before biological polishing. The biological polishing step generally mitigates these concerns by biodegrading many of these reactive intermediates.

Lifecycle assessment studies comparing ozonation-biofiltration with alternative advanced treatment technologies indicate moderate environmental footprints. The primary environmental burdens stem from energy consumption for ozone generation and the production of oxygen required for the process. However, when considering the entire treatment train, the environmental benefits of micropollutant removal often outweigh these impacts, particularly in sensitive receiving environments.

Monitoring strategies for treatment byproducts remain challenging due to analytical limitations in identifying unknown transformation products. Non-target screening approaches using high-resolution mass spectrometry have revealed hundreds of transformation products in ozonated waters, many with uncharacterized environmental fates. Regulatory frameworks are evolving to address these knowledge gaps, with some jurisdictions implementing effect-based monitoring approaches that evaluate overall biological effects rather than focusing solely on individual compound concentrations.

Risk management strategies include process optimization to minimize byproduct formation, such as adjusting ozone dosage, enhancing the biological polishing step, and implementing pre-treatment to remove precursors. The environmental risk-benefit analysis generally supports the implementation of ozonation-biofiltration systems when properly designed and operated, particularly when considering the reduced ecological impacts from micropollutant removal in receiving waters.

Primary concerns include the formation of bromate, a regulated carcinogen, when ozonating bromide-containing waters. Studies have documented bromate formation at concentrations exceeding regulatory thresholds in certain water matrices, necessitating careful process optimization. Additionally, ozonation of waters containing natural organic matter produces assimilable organic carbon (AOC), which can promote microbial regrowth in distribution systems if not adequately addressed by subsequent biological treatment.

Ecotoxicological assessments reveal that while ozonation typically reduces the overall toxicity of micropollutant-laden waters, certain transformation products may exhibit increased toxicity compared to parent compounds. Bioassays targeting specific toxicological endpoints have demonstrated that ozonation can sometimes increase estrogenic activity, genotoxicity, or reactive toxicity in treated waters before biological polishing. The biological polishing step generally mitigates these concerns by biodegrading many of these reactive intermediates.

Lifecycle assessment studies comparing ozonation-biofiltration with alternative advanced treatment technologies indicate moderate environmental footprints. The primary environmental burdens stem from energy consumption for ozone generation and the production of oxygen required for the process. However, when considering the entire treatment train, the environmental benefits of micropollutant removal often outweigh these impacts, particularly in sensitive receiving environments.

Monitoring strategies for treatment byproducts remain challenging due to analytical limitations in identifying unknown transformation products. Non-target screening approaches using high-resolution mass spectrometry have revealed hundreds of transformation products in ozonated waters, many with uncharacterized environmental fates. Regulatory frameworks are evolving to address these knowledge gaps, with some jurisdictions implementing effect-based monitoring approaches that evaluate overall biological effects rather than focusing solely on individual compound concentrations.

Risk management strategies include process optimization to minimize byproduct formation, such as adjusting ozone dosage, enhancing the biological polishing step, and implementing pre-treatment to remove precursors. The environmental risk-benefit analysis generally supports the implementation of ozonation-biofiltration systems when properly designed and operated, particularly when considering the reduced ecological impacts from micropollutant removal in receiving waters.

Regulatory Framework for Micropollutant Removal Standards

The regulatory landscape for micropollutant removal has evolved significantly in response to growing environmental and public health concerns. The European Union has been at the forefront with the Water Framework Directive (2000/60/EC), which established a comprehensive approach to water protection and management. This directive was further strengthened by the Environmental Quality Standards Directive (2008/105/EC), which specifically addresses priority substances in water bodies and sets environmental quality standards for these contaminants.

In Switzerland, a pioneering regulatory framework was implemented in 2016, mandating the upgrade of selected wastewater treatment plants to include advanced treatment processes specifically targeting micropollutants. This legislation requires an 80% reduction in micropollutant loads from municipal wastewater, positioning Switzerland as a global leader in micropollutant regulation.

The United States Environmental Protection Agency (EPA) addresses micropollutants through the Clean Water Act and the Safe Drinking Water Act. While comprehensive federal standards specifically for micropollutants are still evolving, the EPA's Contaminant Candidate List (CCL) identifies emerging contaminants for potential regulatory action. Several states, including California and New York, have implemented their own more stringent standards for certain micropollutants.

In Asia, countries like Japan and Singapore have developed advanced regulatory frameworks. Japan's environmental quality standards for water pollution include specific limits for various micropollutants, while Singapore's NEWater program incorporates advanced treatment technologies to ensure the removal of trace contaminants from recycled water.

International organizations such as the World Health Organization (WHO) provide guidelines for drinking water quality that address various micropollutants. These guidelines serve as a reference for many countries developing their own regulatory standards.

The regulatory standards typically specify maximum allowable concentrations for specific micropollutants in different water bodies. For ozonation coupled with biological polishing systems, these standards often dictate the required removal efficiencies, which typically range from 70% to 90% for priority micropollutants.

Monitoring requirements constitute another critical aspect of the regulatory framework. Authorities increasingly mandate regular sampling and analysis using advanced analytical techniques capable of detecting micropollutants at trace concentrations (ng/L to μg/L range). The frequency of monitoring and the suite of compounds to be analyzed vary by jurisdiction but generally focus on pharmaceuticals, personal care products, pesticides, and industrial chemicals with known environmental impacts.

As scientific understanding of micropollutant impacts continues to evolve, regulatory frameworks are becoming more comprehensive, with a trend toward lower acceptable concentration limits and broader coverage of contaminant classes. This regulatory evolution directly influences the development and implementation of advanced treatment technologies like ozonation coupled with biological polishing.

In Switzerland, a pioneering regulatory framework was implemented in 2016, mandating the upgrade of selected wastewater treatment plants to include advanced treatment processes specifically targeting micropollutants. This legislation requires an 80% reduction in micropollutant loads from municipal wastewater, positioning Switzerland as a global leader in micropollutant regulation.

The United States Environmental Protection Agency (EPA) addresses micropollutants through the Clean Water Act and the Safe Drinking Water Act. While comprehensive federal standards specifically for micropollutants are still evolving, the EPA's Contaminant Candidate List (CCL) identifies emerging contaminants for potential regulatory action. Several states, including California and New York, have implemented their own more stringent standards for certain micropollutants.

In Asia, countries like Japan and Singapore have developed advanced regulatory frameworks. Japan's environmental quality standards for water pollution include specific limits for various micropollutants, while Singapore's NEWater program incorporates advanced treatment technologies to ensure the removal of trace contaminants from recycled water.

International organizations such as the World Health Organization (WHO) provide guidelines for drinking water quality that address various micropollutants. These guidelines serve as a reference for many countries developing their own regulatory standards.

The regulatory standards typically specify maximum allowable concentrations for specific micropollutants in different water bodies. For ozonation coupled with biological polishing systems, these standards often dictate the required removal efficiencies, which typically range from 70% to 90% for priority micropollutants.

Monitoring requirements constitute another critical aspect of the regulatory framework. Authorities increasingly mandate regular sampling and analysis using advanced analytical techniques capable of detecting micropollutants at trace concentrations (ng/L to μg/L range). The frequency of monitoring and the suite of compounds to be analyzed vary by jurisdiction but generally focus on pharmaceuticals, personal care products, pesticides, and industrial chemicals with known environmental impacts.

As scientific understanding of micropollutant impacts continues to evolve, regulatory frameworks are becoming more comprehensive, with a trend toward lower acceptable concentration limits and broader coverage of contaminant classes. This regulatory evolution directly influences the development and implementation of advanced treatment technologies like ozonation coupled with biological polishing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!