Ozonation: Cold Water Performance, Temperature Effects And Dose Compensation

SEP 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology has evolved significantly since its first application in water treatment in the late 19th century. Initially used primarily for disinfection purposes, ozone treatment has expanded to address multiple water quality challenges including taste and odor control, color removal, micropollutant oxidation, and biofilm prevention. The fundamental principle involves generating ozone (O₃) through electrical discharge in oxygen-containing gas and introducing it into water systems where it acts as a powerful oxidant.

Recent technological advancements have focused on optimizing ozone generation efficiency, improving dissolution methods, and developing sophisticated monitoring and control systems. However, a persistent challenge in ozonation technology involves understanding and compensating for temperature effects, particularly in cold water applications. Research indicates that ozone solubility increases at lower temperatures while reaction kinetics simultaneously slow down, creating a complex relationship between treatment efficacy and water temperature.

The primary objective of this technical research is to comprehensively investigate cold water ozonation performance across various temperature ranges (1-25°C) and establish quantifiable relationships between temperature fluctuations and required ozone dosages. This investigation aims to develop predictive models and compensation strategies that can maintain consistent treatment efficacy despite temperature variations in real-world applications.

Current industry practices often rely on empirical adjustments or significant overdosing to account for temperature effects, leading to operational inefficiencies and increased costs. By establishing precise dose-temperature relationships, treatment facilities could potentially optimize chemical usage, reduce energy consumption, and improve process stability. This research also seeks to identify critical temperature thresholds where significant changes in dosing strategies may be required.

Additionally, this investigation aims to evaluate how temperature affects different ozonation applications (disinfection versus oxidation of specific contaminants) and whether compensation strategies should be tailored to specific treatment objectives. The research will incorporate both laboratory-scale experiments and operational data from full-scale facilities to ensure practical applicability of findings.

The ultimate goal is to develop an integrated temperature compensation framework that can be implemented in automated control systems, allowing for real-time adjustments to ozone dosing based on influent water temperature. This would represent a significant advancement in ozonation technology, particularly for facilities dealing with seasonal or daily temperature fluctuations in their water sources.

Recent technological advancements have focused on optimizing ozone generation efficiency, improving dissolution methods, and developing sophisticated monitoring and control systems. However, a persistent challenge in ozonation technology involves understanding and compensating for temperature effects, particularly in cold water applications. Research indicates that ozone solubility increases at lower temperatures while reaction kinetics simultaneously slow down, creating a complex relationship between treatment efficacy and water temperature.

The primary objective of this technical research is to comprehensively investigate cold water ozonation performance across various temperature ranges (1-25°C) and establish quantifiable relationships between temperature fluctuations and required ozone dosages. This investigation aims to develop predictive models and compensation strategies that can maintain consistent treatment efficacy despite temperature variations in real-world applications.

Current industry practices often rely on empirical adjustments or significant overdosing to account for temperature effects, leading to operational inefficiencies and increased costs. By establishing precise dose-temperature relationships, treatment facilities could potentially optimize chemical usage, reduce energy consumption, and improve process stability. This research also seeks to identify critical temperature thresholds where significant changes in dosing strategies may be required.

Additionally, this investigation aims to evaluate how temperature affects different ozonation applications (disinfection versus oxidation of specific contaminants) and whether compensation strategies should be tailored to specific treatment objectives. The research will incorporate both laboratory-scale experiments and operational data from full-scale facilities to ensure practical applicability of findings.

The ultimate goal is to develop an integrated temperature compensation framework that can be implemented in automated control systems, allowing for real-time adjustments to ozone dosing based on influent water temperature. This would represent a significant advancement in ozonation technology, particularly for facilities dealing with seasonal or daily temperature fluctuations in their water sources.

Market Demand Analysis for Cold Water Ozonation

The global market for cold water ozonation technology is experiencing significant growth driven by increasing concerns about water quality and the need for effective disinfection methods across various industries. Current market analysis indicates that the water treatment sector represents the largest application segment, with municipal water treatment facilities increasingly adopting ozonation systems specifically designed for cold water conditions.

Research shows that regions with predominantly cold climates, such as Northern Europe, Canada, and parts of the United States, are showing the strongest demand growth for cold water ozonation solutions. This regional demand is primarily fueled by the technical challenges associated with maintaining effective disinfection in low-temperature environments, where conventional ozonation systems often experience reduced efficiency.

The industrial sector presents another substantial market opportunity, particularly in food and beverage processing, pharmaceutical manufacturing, and aquaculture. These industries require precise disinfection protocols regardless of water temperature conditions, creating a specialized demand for temperature-compensating ozonation systems. Market forecasts suggest that the food and beverage segment alone could represent approximately one-third of the industrial application market for advanced cold water ozonation technologies.

Environmental regulations are playing a crucial role in market expansion. Stricter discharge standards and increasing restrictions on chemical disinfectants are compelling industries to adopt more environmentally friendly alternatives like ozonation. The regulatory landscape is particularly influential in developed markets where water quality standards continue to tighten, creating a compliance-driven demand for advanced treatment technologies.

Consumer awareness regarding water quality issues is also contributing to market growth in the residential and commercial building sectors. The demand for point-of-entry ozonation systems designed to function effectively in cold water conditions is growing, particularly in regions where groundwater temperatures remain consistently low throughout the year.

The economic value proposition of temperature-compensated ozonation systems is becoming increasingly recognized. Despite higher initial investment costs compared to conventional disinfection methods, the operational efficiency gains in cold water applications are driving adoption. Market analysis indicates that facilities operating in cold climate conditions can achieve significant long-term cost savings through properly designed ozonation systems that maintain disinfection efficacy without excessive energy consumption for water heating.

Technological advancements in dose compensation mechanisms represent a key market driver, as these innovations directly address the primary challenge of cold water ozonation. Systems offering automated temperature sensing and dose adjustment capabilities are commanding premium positions in the market, reflecting the high value placed on consistent performance across varying temperature conditions.

Research shows that regions with predominantly cold climates, such as Northern Europe, Canada, and parts of the United States, are showing the strongest demand growth for cold water ozonation solutions. This regional demand is primarily fueled by the technical challenges associated with maintaining effective disinfection in low-temperature environments, where conventional ozonation systems often experience reduced efficiency.

The industrial sector presents another substantial market opportunity, particularly in food and beverage processing, pharmaceutical manufacturing, and aquaculture. These industries require precise disinfection protocols regardless of water temperature conditions, creating a specialized demand for temperature-compensating ozonation systems. Market forecasts suggest that the food and beverage segment alone could represent approximately one-third of the industrial application market for advanced cold water ozonation technologies.

Environmental regulations are playing a crucial role in market expansion. Stricter discharge standards and increasing restrictions on chemical disinfectants are compelling industries to adopt more environmentally friendly alternatives like ozonation. The regulatory landscape is particularly influential in developed markets where water quality standards continue to tighten, creating a compliance-driven demand for advanced treatment technologies.

Consumer awareness regarding water quality issues is also contributing to market growth in the residential and commercial building sectors. The demand for point-of-entry ozonation systems designed to function effectively in cold water conditions is growing, particularly in regions where groundwater temperatures remain consistently low throughout the year.

The economic value proposition of temperature-compensated ozonation systems is becoming increasingly recognized. Despite higher initial investment costs compared to conventional disinfection methods, the operational efficiency gains in cold water applications are driving adoption. Market analysis indicates that facilities operating in cold climate conditions can achieve significant long-term cost savings through properly designed ozonation systems that maintain disinfection efficacy without excessive energy consumption for water heating.

Technological advancements in dose compensation mechanisms represent a key market driver, as these innovations directly address the primary challenge of cold water ozonation. Systems offering automated temperature sensing and dose adjustment capabilities are commanding premium positions in the market, reflecting the high value placed on consistent performance across varying temperature conditions.

Current Challenges in Low-Temperature Ozonation

Ozonation processes face significant challenges when operating in low-temperature environments, which substantially impact treatment efficiency and operational costs. The primary challenge stems from the fundamental thermodynamic principle that reaction rates decrease as temperature drops. In cold water conditions (typically below 15°C), ozone reaction kinetics slow considerably, reducing the oxidation efficiency against target contaminants. This temperature dependency creates a non-linear relationship between ozone dosage and treatment effectiveness that water treatment facilities must constantly manage.

The solubility paradox presents another complex challenge. While ozone solubility increases in colder water—theoretically allowing for higher dissolved ozone concentrations—the reduced reaction rates often negate this potential advantage. Treatment facilities must therefore balance higher achievable concentrations against slower reaction kinetics, requiring sophisticated process control systems that many existing facilities lack.

Mass transfer limitations become more pronounced at lower temperatures, as the diffusion coefficient of ozone decreases, reducing the transfer efficiency from gas to liquid phase. This necessitates higher energy inputs for ozone generation and dissolution, directly impacting operational costs. Studies indicate that ozone transfer efficiency can decrease by 1.5-3% for each degree Celsius drop in water temperature, creating significant economic implications for facilities in colder regions or during winter operations.

Microbial inactivation efficacy also diminishes in cold water conditions. Research has demonstrated that achieving equivalent log reductions of pathogens like Cryptosporidium and Giardia may require 20-40% higher CT (concentration × time) values at 5°C compared to 20°C. This creates compliance challenges for utilities operating under strict disinfection regulations while facing seasonal temperature fluctuations.

The formation of disinfection by-products (DBPs) exhibits complex temperature-dependent behavior. While some ozonation by-products form more slowly in cold water, others—particularly bromate in bromide-containing waters—may still form at concerning levels due to extended ozone persistence. This creates a regulatory compliance challenge that requires continuous monitoring and process adjustment.

Current dose compensation strategies often rely on simplistic temperature correction factors that fail to account for water-specific matrix effects and contaminant profiles. The lack of standardized, adaptive dosing models that incorporate real-time temperature fluctuations represents a significant gap in operational practice. Most existing models were developed under laboratory conditions that poorly represent the complex, variable conditions of full-scale treatment plants.

Instrumentation and monitoring systems face additional challenges in cold water environments, including sensor drift, reduced response times, and calibration difficulties. These technical limitations hinder the implementation of advanced process control strategies that could otherwise optimize ozone utilization across temperature ranges.

The solubility paradox presents another complex challenge. While ozone solubility increases in colder water—theoretically allowing for higher dissolved ozone concentrations—the reduced reaction rates often negate this potential advantage. Treatment facilities must therefore balance higher achievable concentrations against slower reaction kinetics, requiring sophisticated process control systems that many existing facilities lack.

Mass transfer limitations become more pronounced at lower temperatures, as the diffusion coefficient of ozone decreases, reducing the transfer efficiency from gas to liquid phase. This necessitates higher energy inputs for ozone generation and dissolution, directly impacting operational costs. Studies indicate that ozone transfer efficiency can decrease by 1.5-3% for each degree Celsius drop in water temperature, creating significant economic implications for facilities in colder regions or during winter operations.

Microbial inactivation efficacy also diminishes in cold water conditions. Research has demonstrated that achieving equivalent log reductions of pathogens like Cryptosporidium and Giardia may require 20-40% higher CT (concentration × time) values at 5°C compared to 20°C. This creates compliance challenges for utilities operating under strict disinfection regulations while facing seasonal temperature fluctuations.

The formation of disinfection by-products (DBPs) exhibits complex temperature-dependent behavior. While some ozonation by-products form more slowly in cold water, others—particularly bromate in bromide-containing waters—may still form at concerning levels due to extended ozone persistence. This creates a regulatory compliance challenge that requires continuous monitoring and process adjustment.

Current dose compensation strategies often rely on simplistic temperature correction factors that fail to account for water-specific matrix effects and contaminant profiles. The lack of standardized, adaptive dosing models that incorporate real-time temperature fluctuations represents a significant gap in operational practice. Most existing models were developed under laboratory conditions that poorly represent the complex, variable conditions of full-scale treatment plants.

Instrumentation and monitoring systems face additional challenges in cold water environments, including sensor drift, reduced response times, and calibration difficulties. These technical limitations hinder the implementation of advanced process control strategies that could otherwise optimize ozone utilization across temperature ranges.

Current Temperature Compensation Solutions

01 Temperature effects on ozone solubility and stability in water

Temperature significantly affects ozone solubility and stability in water, with lower temperatures generally increasing ozone solubility and extending its half-life. Cold water can retain dissolved ozone for longer periods, enhancing treatment efficiency. The relationship between temperature and ozone performance follows Henry's Law, where decreasing water temperature increases gas solubility. This principle is crucial for optimizing ozonation systems in various water treatment applications.- Temperature effects on ozone solubility and reactivity in water: Temperature significantly affects ozone solubility and reactivity in water. At lower temperatures, ozone has higher solubility in water, which can enhance treatment efficiency. Cold water ozonation typically achieves better disinfection results as ozone remains stable for longer periods, allowing extended contact time with contaminants. The decreased decomposition rate of ozone in cold water improves overall treatment effectiveness for various applications including drinking water purification and wastewater treatment.

- Cold water ozonation system design considerations: Designing ozonation systems for cold water applications requires specific considerations. These systems often incorporate specialized gas injection methods, optimized contact chambers, and temperature control mechanisms to maintain treatment efficiency. Cold water ozonation systems may feature enhanced mixing technologies, pressurized dissolution chambers, and materials resistant to low-temperature operation. Proper system design ensures effective ozone distribution and utilization despite the challenges posed by low water temperatures.

- Monitoring and control systems for temperature-dependent ozonation: Advanced monitoring and control systems are essential for managing temperature-dependent ozonation processes. These systems typically include temperature sensors, ozone concentration monitors, and automated dosing controls that adjust ozone generation based on water temperature fluctuations. Real-time monitoring allows for dynamic adjustment of ozone dosage to maintain consistent treatment effectiveness across varying temperature conditions, optimizing both energy consumption and treatment outcomes.

- Energy efficiency in cold water ozonation processes: Cold water ozonation offers energy efficiency advantages compared to warm water applications. The higher ozone solubility in cold water reduces the energy required for ozone generation and dissolution. Systems designed specifically for cold water operation can incorporate energy recovery mechanisms and optimized gas-to-liquid transfer technologies. These energy-saving features make cold water ozonation particularly attractive for large-scale water treatment facilities and industrial applications where operational costs are significant considerations.

- Applications and performance metrics for cold water ozonation: Cold water ozonation finds applications across various industries with specific performance metrics. These applications include drinking water disinfection, aquaculture, food processing, and industrial wastewater treatment. Performance metrics for cold water ozonation typically focus on pathogen reduction efficiency, chemical oxidation rates, by-product formation, and system stability under temperature fluctuations. Research indicates that properly designed cold water ozonation systems can achieve superior disinfection results with reduced formation of harmful by-products compared to other treatment methods.

02 Cold water ozonation system design considerations

Designing ozonation systems for cold water applications requires specific considerations to maximize performance. These include appropriate contact chamber designs, optimized gas-to-liquid ratios, and specialized diffusion methods that account for increased ozone solubility at lower temperatures. Systems may incorporate temperature control mechanisms, specialized mixing technologies, and materials resistant to ozone's oxidative properties under cold conditions to ensure efficient treatment while preventing system degradation.Expand Specific Solutions03 Enhanced disinfection efficiency in cold water ozonation

Cold water ozonation demonstrates superior disinfection efficiency compared to warmer water applications. The extended half-life of ozone in cold water allows for prolonged contact time with pathogens, enhancing microbial inactivation. This improved performance is particularly valuable in applications requiring high sanitation standards, such as drinking water treatment, food processing, and medical facilities. The relationship between temperature reduction and increased disinfection effectiveness follows a predictable pattern that can be leveraged for optimized treatment protocols.Expand Specific Solutions04 Energy efficiency and operational cost considerations

Temperature management in ozonation systems presents important energy efficiency and operational cost considerations. While cold water improves ozone performance, achieving and maintaining lower temperatures may require additional energy input. Advanced systems incorporate heat exchange technologies, insulation methods, and process optimization to balance the benefits of cold water ozonation with energy consumption. Seasonal temperature variations must be accounted for in system design to maintain consistent treatment efficiency throughout the year while optimizing operational costs.Expand Specific Solutions05 Monitoring and control systems for temperature-dependent ozonation

Sophisticated monitoring and control systems are essential for managing temperature-dependent ozonation processes. These systems typically include real-time temperature sensors, dissolved ozone monitors, automated dosing controls, and feedback mechanisms that adjust ozone production based on water temperature fluctuations. Advanced control algorithms can predict and compensate for temperature effects on ozone performance, ensuring consistent treatment results despite varying conditions. Integration with SCADA systems allows for comprehensive process management and optimization of cold water ozonation applications.Expand Specific Solutions

Key Industry Players in Ozonation Systems

Ozonation technology for cold water treatment is currently in a growth phase, with increasing market adoption driven by stringent water quality regulations. The global market for ozonation systems is expanding at approximately 6-7% annually, reaching $1.5-2 billion. Technologically, cold water ozonation presents unique challenges requiring temperature compensation mechanisms. Leading players include Mitsubishi Electric Corp. and Air Liquide SA, who have developed advanced temperature-responsive dosing systems, while Nomura Micro Science and NanoSun are pioneering specialized applications for semiconductor manufacturing. Research institutions like Tsinghua University and Drexel University are advancing fundamental understanding of temperature effects on ozone solubility and reaction kinetics, collaborating with industry partners to optimize performance across varying temperature conditions.

Nomura Micro Science Co., Ltd.

Technical Solution: Nomura Micro Science has developed specialized ozonation systems for ultrapure water applications that incorporate sophisticated temperature compensation mechanisms. Their technology focuses on maintaining precise ozone concentrations in semiconductor manufacturing processes where water temperature variations can significantly impact treatment efficacy. The company's approach utilizes a combination of dissolved ozone monitoring and feedback control systems that continuously adjust ozone generation based on real-time water temperature measurements. Their proprietary "TempAdapt" algorithm incorporates both thermodynamic solubility factors and reaction kinetics parameters to calculate optimal ozone dosing across temperature ranges from 5°C to 40°C. Nomura's systems feature specialized gas-liquid contactors designed to maximize mass transfer efficiency in cold water conditions, achieving dissolution rates up to 95% even at temperatures below 10°C. The company has documented performance showing their systems can maintain consistent microbiological control and organic contaminant oxidation across this temperature range by implementing their dynamic dose compensation technology. Their latest generation systems incorporate machine learning algorithms that continuously optimize the temperature compensation parameters based on actual performance data, allowing the system to adapt to specific water quality characteristics over time.

Strengths: Exceptional precision in maintaining target dissolved ozone concentrations regardless of temperature fluctuations; specialized expertise in ultrapure water applications for semiconductor and pharmaceutical industries; advanced monitoring and control systems with self-optimization capabilities. Weaknesses: Systems primarily optimized for industrial applications rather than municipal water treatment; higher cost structure compared to conventional ozonation systems; requires more sophisticated operator training and maintenance protocols.

Tohoku University

Technical Solution: Tohoku University has conducted extensive research on ozonation performance across temperature gradients, developing a comprehensive mathematical model that accurately predicts ozone decomposition kinetics in cold water environments. Their research team has identified specific temperature coefficients for ozone reactions with various organic and inorganic compounds, enabling precise dose compensation calculations. The university's approach incorporates advanced oxidation process (AOP) enhancement techniques that combine ozone with hydrogen peroxide or UV radiation, which they've shown can partially overcome the kinetic limitations in cold water. Their laboratory has developed a novel temperature-compensated CT (concentration × time) calculation method that accounts for both the increased ozone solubility and decreased reaction rates at lower temperatures. This model has been validated through extensive pilot-scale testing across temperature ranges from 1°C to 30°C. Particularly noteworthy is their work on quantifying the relationship between temperature and disinfection efficacy against various pathogen classes, demonstrating that certain microorganisms (particularly viruses) require significantly higher CT values at lower temperatures. Their research has established that ozone dose requirements increase by approximately 25-30% for every 10°C decrease in water temperature to maintain equivalent log reduction values for most pathogens.

Strengths: Exceptionally strong theoretical foundation and mathematical modeling capabilities; comprehensive understanding of fundamental ozone reaction kinetics across temperature ranges; innovative approaches to enhancing cold water ozonation through combined processes. Weaknesses: Research-focused approach that may require additional engineering development for commercial implementation; limited focus on cost optimization for practical applications; models may require calibration for specific water quality conditions beyond those tested in laboratory settings.

Core Patents in Cold Water Ozonation Technology

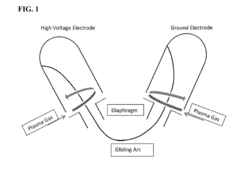

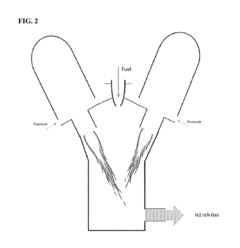

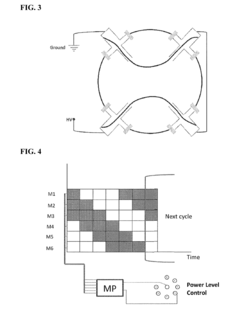

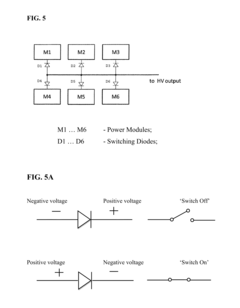

Fluid treatment using plasma technology

PatentActiveUS20150274554A1

Innovation

- A plasma-based water treatment system that uses a pulsed plasma discharge generated by a suitable electrode configuration to inactivate microorganisms in water, producing UV radiation, active chemical species, and shock waves, which are effective in deactivating microorganisms without the drawbacks of traditional methods.

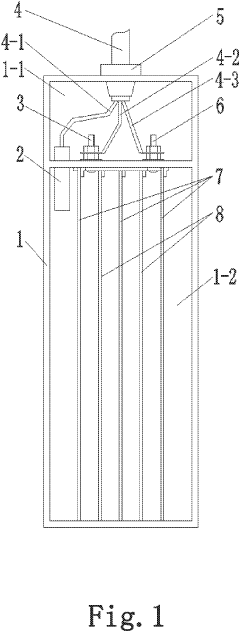

Ozone generator for ozone sanitization and disinfection of ice makers

PatentInactiveUS20230141973A1

Innovation

- A submerged ozone generator with a simplified structure using coated titanium anode and cathode plates in an electrolysis chamber, activated by a temperature sensor when the ice maker starts, producing ozone gas that dissolves into water without nitrogen oxides, ensuring sanitization and disinfection of the ice-making water tank and its components.

Regulatory Framework for Water Treatment

The regulatory landscape for water treatment using ozonation is complex and multifaceted, varying significantly across different regions and jurisdictions. In the United States, the Environmental Protection Agency (EPA) has established comprehensive guidelines under the Safe Drinking Water Act that specifically address disinfection processes including ozonation. These regulations mandate minimum disinfection requirements while limiting disinfection by-products (DBPs), with particular attention to temperature-dependent reactions that occur during ozonation.

The European Union's Drinking Water Directive (98/83/EC) and its recent updates provide stringent frameworks for ozonation implementation, emphasizing the importance of temperature monitoring and dose adjustment in cold water conditions. The directive specifically requires water utilities to demonstrate adequate disinfection efficacy across seasonal temperature variations, acknowledging that ozone's reactivity decreases significantly in colder water temperatures.

World Health Organization (WHO) guidelines serve as international benchmarks, recommending temperature-specific dosing protocols for ozonation. These guidelines emphasize the need for increased contact time or higher ozone concentrations when treating cold water to achieve equivalent disinfection results. The WHO framework also addresses the balance between effective pathogen inactivation and minimizing harmful by-product formation across different temperature ranges.

Japan's Ministry of Health, Labour and Welfare has developed particularly advanced regulatory approaches for ozonation, incorporating temperature compensation algorithms into their treatment standards. These regulations require automated systems that adjust ozone dosage based on real-time water temperature measurements, ensuring consistent disinfection efficacy throughout seasonal changes.

Regulatory compliance monitoring for ozonation typically includes continuous temperature measurement alongside residual ozone concentration. Most frameworks mandate documentation of temperature-dose relationships and validation of disinfection efficacy across the operational temperature range experienced by the facility. This approach recognizes that CT values (concentration × time) must be adjusted to account for decreased ozone reactivity in cold water conditions.

Recent regulatory trends show increasing focus on climate change impacts, with emerging requirements for water utilities to develop temperature-specific ozonation protocols that can adapt to more extreme temperature variations. Several jurisdictions now require risk assessment plans that specifically address how ozonation systems will maintain compliance during cold water events, including automated dose compensation strategies.

Industry standards from organizations like AWWA (American Water Works Association) and IWA (International Water Association) complement regulatory frameworks by providing technical guidance on temperature-based ozone dosing models and control system specifications. These standards often become incorporated into regulatory requirements through reference or adoption by oversight agencies.

The European Union's Drinking Water Directive (98/83/EC) and its recent updates provide stringent frameworks for ozonation implementation, emphasizing the importance of temperature monitoring and dose adjustment in cold water conditions. The directive specifically requires water utilities to demonstrate adequate disinfection efficacy across seasonal temperature variations, acknowledging that ozone's reactivity decreases significantly in colder water temperatures.

World Health Organization (WHO) guidelines serve as international benchmarks, recommending temperature-specific dosing protocols for ozonation. These guidelines emphasize the need for increased contact time or higher ozone concentrations when treating cold water to achieve equivalent disinfection results. The WHO framework also addresses the balance between effective pathogen inactivation and minimizing harmful by-product formation across different temperature ranges.

Japan's Ministry of Health, Labour and Welfare has developed particularly advanced regulatory approaches for ozonation, incorporating temperature compensation algorithms into their treatment standards. These regulations require automated systems that adjust ozone dosage based on real-time water temperature measurements, ensuring consistent disinfection efficacy throughout seasonal changes.

Regulatory compliance monitoring for ozonation typically includes continuous temperature measurement alongside residual ozone concentration. Most frameworks mandate documentation of temperature-dose relationships and validation of disinfection efficacy across the operational temperature range experienced by the facility. This approach recognizes that CT values (concentration × time) must be adjusted to account for decreased ozone reactivity in cold water conditions.

Recent regulatory trends show increasing focus on climate change impacts, with emerging requirements for water utilities to develop temperature-specific ozonation protocols that can adapt to more extreme temperature variations. Several jurisdictions now require risk assessment plans that specifically address how ozonation systems will maintain compliance during cold water events, including automated dose compensation strategies.

Industry standards from organizations like AWWA (American Water Works Association) and IWA (International Water Association) complement regulatory frameworks by providing technical guidance on temperature-based ozone dosing models and control system specifications. These standards often become incorporated into regulatory requirements through reference or adoption by oversight agencies.

Energy Efficiency Considerations

Energy efficiency represents a critical dimension in the evaluation and implementation of ozonation systems, particularly when considering cold water applications and temperature variations. The energy consumption of ozonation processes is significantly influenced by water temperature, with colder water conditions typically demanding higher energy inputs to achieve equivalent disinfection efficacy.

In ozonation systems, energy is primarily consumed in two key processes: ozone generation and dissolution. Ozone generators operate on the corona discharge principle, where electrical energy transforms oxygen into ozone. This conversion process exhibits temperature-dependent efficiency characteristics, with optimal performance typically occurring within specific temperature ranges. When operating in cold water environments, the energy required for ozone generation can increase by 15-25% compared to moderate temperature conditions.

The dissolution phase presents additional energy considerations. As water temperature decreases, ozone solubility increases—a phenomenon that theoretically enhances treatment efficiency. However, this advantage is often counterbalanced by reduced reaction kinetics in colder water, necessitating longer contact times or higher doses to achieve target disinfection levels. These compensatory measures frequently translate to increased energy expenditure through extended pumping operations or elevated ozone production requirements.

Modern ozonation systems incorporate various energy optimization strategies specifically designed for cold water applications. Variable frequency drives (VFDs) on ozone generators allow dynamic adjustment of energy input based on real-time water temperature and quality parameters. Advanced monitoring systems that continuously track ozone demand and residual concentrations enable precise dose control, preventing energy waste from overdosing while maintaining treatment efficacy across temperature fluctuations.

Heat recovery systems represent another significant advancement in energy efficiency for ozonation processes. These systems capture waste heat from ozone generators and cooling systems, redirecting it to pre-warm incoming water or support other facility operations. In cold climate installations, such heat recovery mechanisms have demonstrated energy savings of 10-30%, substantially improving the overall sustainability profile of ozonation treatment.

The economic implications of energy consumption in temperature-variable ozonation systems extend beyond operational costs. Capital investment decisions increasingly incorporate life-cycle energy analysis, particularly for facilities experiencing significant seasonal temperature variations. Research indicates that properly optimized systems with temperature-responsive controls can achieve payback periods of 2-4 years through energy savings alone, highlighting the importance of considering temperature effects in system design and operation.

In ozonation systems, energy is primarily consumed in two key processes: ozone generation and dissolution. Ozone generators operate on the corona discharge principle, where electrical energy transforms oxygen into ozone. This conversion process exhibits temperature-dependent efficiency characteristics, with optimal performance typically occurring within specific temperature ranges. When operating in cold water environments, the energy required for ozone generation can increase by 15-25% compared to moderate temperature conditions.

The dissolution phase presents additional energy considerations. As water temperature decreases, ozone solubility increases—a phenomenon that theoretically enhances treatment efficiency. However, this advantage is often counterbalanced by reduced reaction kinetics in colder water, necessitating longer contact times or higher doses to achieve target disinfection levels. These compensatory measures frequently translate to increased energy expenditure through extended pumping operations or elevated ozone production requirements.

Modern ozonation systems incorporate various energy optimization strategies specifically designed for cold water applications. Variable frequency drives (VFDs) on ozone generators allow dynamic adjustment of energy input based on real-time water temperature and quality parameters. Advanced monitoring systems that continuously track ozone demand and residual concentrations enable precise dose control, preventing energy waste from overdosing while maintaining treatment efficacy across temperature fluctuations.

Heat recovery systems represent another significant advancement in energy efficiency for ozonation processes. These systems capture waste heat from ozone generators and cooling systems, redirecting it to pre-warm incoming water or support other facility operations. In cold climate installations, such heat recovery mechanisms have demonstrated energy savings of 10-30%, substantially improving the overall sustainability profile of ozonation treatment.

The economic implications of energy consumption in temperature-variable ozonation systems extend beyond operational costs. Capital investment decisions increasingly incorporate life-cycle energy analysis, particularly for facilities experiencing significant seasonal temperature variations. Research indicates that properly optimized systems with temperature-responsive controls can achieve payback periods of 2-4 years through energy savings alone, highlighting the importance of considering temperature effects in system design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!