Ozonation: Off-Gas Catalytic/Thermal Destructors, NOx Management And Compliance

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology has evolved significantly over the past several decades as a critical water and wastewater treatment process. Initially developed in the late 19th century for drinking water disinfection, ozonation has expanded into numerous industrial applications due to its powerful oxidizing properties. The technology utilizes ozone (O₃), an unstable molecule composed of three oxygen atoms, which readily decomposes to release a free oxygen atom that acts as a potent oxidant capable of destroying a wide range of contaminants.

The evolution of ozonation systems has been marked by continuous improvements in generation efficiency, contact systems, and off-gas management. Early systems focused primarily on disinfection capabilities, while modern applications have broadened to include micropollutant removal, color reduction, odor control, and advanced oxidation processes when combined with other treatments such as hydrogen peroxide or UV radiation.

A significant challenge in ozonation technology has been the management of off-gases and associated byproducts. Ozone that doesn't dissolve or react in the treatment process becomes part of the off-gas stream, requiring proper handling to prevent environmental and health hazards. This has led to the development of off-gas destruction systems, including catalytic and thermal destructors, which have become integral components of modern ozonation installations.

The emergence of stricter air quality regulations, particularly regarding nitrogen oxides (NOx) emissions, has created new challenges for ozonation technology. Thermal destruction of ozone can generate NOx as a byproduct, especially at higher temperatures, necessitating additional control measures to ensure regulatory compliance. This regulatory landscape has driven innovation in low-NOx destruction technologies and alternative approaches to off-gas management.

The primary objectives of current ozonation technology development focus on several key areas: improving energy efficiency of ozone generation; enhancing mass transfer efficiency to reduce off-gas volumes; developing more effective and environmentally friendly off-gas destruction methods; minimizing NOx formation during thermal destruction processes; and creating integrated control systems that optimize overall process performance while ensuring compliance with increasingly stringent regulations.

Additionally, there is growing interest in developing cost-effective solutions for smaller-scale applications, as ozonation has traditionally been more economically viable for larger treatment facilities. This democratization of ozonation technology aims to make its benefits accessible across a broader range of applications and facility sizes, from municipal water treatment to specialized industrial processes.

The evolution of ozonation systems has been marked by continuous improvements in generation efficiency, contact systems, and off-gas management. Early systems focused primarily on disinfection capabilities, while modern applications have broadened to include micropollutant removal, color reduction, odor control, and advanced oxidation processes when combined with other treatments such as hydrogen peroxide or UV radiation.

A significant challenge in ozonation technology has been the management of off-gases and associated byproducts. Ozone that doesn't dissolve or react in the treatment process becomes part of the off-gas stream, requiring proper handling to prevent environmental and health hazards. This has led to the development of off-gas destruction systems, including catalytic and thermal destructors, which have become integral components of modern ozonation installations.

The emergence of stricter air quality regulations, particularly regarding nitrogen oxides (NOx) emissions, has created new challenges for ozonation technology. Thermal destruction of ozone can generate NOx as a byproduct, especially at higher temperatures, necessitating additional control measures to ensure regulatory compliance. This regulatory landscape has driven innovation in low-NOx destruction technologies and alternative approaches to off-gas management.

The primary objectives of current ozonation technology development focus on several key areas: improving energy efficiency of ozone generation; enhancing mass transfer efficiency to reduce off-gas volumes; developing more effective and environmentally friendly off-gas destruction methods; minimizing NOx formation during thermal destruction processes; and creating integrated control systems that optimize overall process performance while ensuring compliance with increasingly stringent regulations.

Additionally, there is growing interest in developing cost-effective solutions for smaller-scale applications, as ozonation has traditionally been more economically viable for larger treatment facilities. This democratization of ozonation technology aims to make its benefits accessible across a broader range of applications and facility sizes, from municipal water treatment to specialized industrial processes.

Market Analysis for Off-Gas Treatment Solutions

The global market for off-gas treatment solutions has experienced significant growth in recent years, driven by increasingly stringent environmental regulations and growing awareness of air quality impacts. The ozonation segment, particularly focusing on catalytic and thermal destructors for off-gas treatment, represents a critical component of this market with distinctive characteristics and growth patterns.

Current market valuations indicate that the global off-gas treatment market exceeds $5 billion, with ozonation technologies accounting for approximately 18% of this share. The compound annual growth rate for ozonation-based solutions is outpacing the broader market, demonstrating 7.2% growth compared to the industry average of 5.8%.

Regional analysis reveals that North America and Europe currently dominate the market for advanced off-gas treatment solutions, collectively representing over 60% of global installations. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate as these countries implement more rigorous environmental standards while expanding their industrial base.

The NOx management segment within off-gas treatment solutions has emerged as a particularly lucrative market sector, driven by tightening regulations on nitrogen oxide emissions across multiple industries. This segment is projected to grow at 8.5% annually through 2028, outperforming most other air pollution control technologies.

Industry-specific demand patterns show that chemical processing, semiconductor manufacturing, and municipal water treatment facilities represent the largest end-users of ozonation and catalytic destruction technologies. The pharmaceutical sector is emerging as a rapidly growing customer base, with increasing requirements for eliminating volatile organic compounds from production processes.

Customer purchasing behavior indicates a shift toward integrated solutions that address multiple pollutants simultaneously rather than standalone technologies. This trend favors suppliers offering comprehensive off-gas treatment systems that can handle ozone destruction while simultaneously managing NOx emissions.

Price sensitivity analysis reveals that while initial capital expenditure remains a significant consideration, total cost of ownership calculations increasingly drive purchasing decisions. Energy efficiency improvements in newer catalytic systems have reduced operational costs by approximately 30% compared to older thermal destruction technologies, creating a compelling value proposition despite higher upfront investments.

Market forecasts suggest that regulatory developments, particularly those targeting previously unregulated emission sources, will continue to expand the addressable market. The industrial sector's growing focus on sustainability metrics and environmental social governance (ESG) reporting is creating additional market pull beyond mere compliance requirements.

Current market valuations indicate that the global off-gas treatment market exceeds $5 billion, with ozonation technologies accounting for approximately 18% of this share. The compound annual growth rate for ozonation-based solutions is outpacing the broader market, demonstrating 7.2% growth compared to the industry average of 5.8%.

Regional analysis reveals that North America and Europe currently dominate the market for advanced off-gas treatment solutions, collectively representing over 60% of global installations. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate as these countries implement more rigorous environmental standards while expanding their industrial base.

The NOx management segment within off-gas treatment solutions has emerged as a particularly lucrative market sector, driven by tightening regulations on nitrogen oxide emissions across multiple industries. This segment is projected to grow at 8.5% annually through 2028, outperforming most other air pollution control technologies.

Industry-specific demand patterns show that chemical processing, semiconductor manufacturing, and municipal water treatment facilities represent the largest end-users of ozonation and catalytic destruction technologies. The pharmaceutical sector is emerging as a rapidly growing customer base, with increasing requirements for eliminating volatile organic compounds from production processes.

Customer purchasing behavior indicates a shift toward integrated solutions that address multiple pollutants simultaneously rather than standalone technologies. This trend favors suppliers offering comprehensive off-gas treatment systems that can handle ozone destruction while simultaneously managing NOx emissions.

Price sensitivity analysis reveals that while initial capital expenditure remains a significant consideration, total cost of ownership calculations increasingly drive purchasing decisions. Energy efficiency improvements in newer catalytic systems have reduced operational costs by approximately 30% compared to older thermal destruction technologies, creating a compelling value proposition despite higher upfront investments.

Market forecasts suggest that regulatory developments, particularly those targeting previously unregulated emission sources, will continue to expand the addressable market. The industrial sector's growing focus on sustainability metrics and environmental social governance (ESG) reporting is creating additional market pull beyond mere compliance requirements.

Current Challenges in Ozone Destruction Technologies

Despite significant advancements in ozone destruction technologies, several critical challenges persist in current systems that limit their efficiency, cost-effectiveness, and environmental compliance. The catalytic destruction of ozone off-gas faces catalyst deactivation issues, particularly in humid environments where water vapor competes with ozone for active sites. This competition significantly reduces catalyst lifespan and increases operational costs through frequent replacement cycles.

Thermal destruction systems, while effective at high temperatures, struggle with energy efficiency concerns. These systems typically require temperatures exceeding 350°C to achieve complete ozone decomposition, resulting in substantial energy consumption and associated operational expenses. The energy intensity of these processes contradicts sustainability goals and creates economic barriers for widespread implementation.

NOx formation presents another significant challenge, especially in thermal destruction units. At elevated temperatures, nitrogen and oxygen in the air can react to form nitrogen oxides, creating a secondary pollution problem while solving the primary ozone issue. This paradoxical outcome complicates regulatory compliance and necessitates additional treatment systems.

Material durability issues plague both catalytic and thermal systems. Ozone's highly oxidative nature accelerates material degradation in system components, particularly in high-concentration applications. This degradation leads to increased maintenance requirements and potential system failures that compromise operational reliability.

Monitoring and control systems face technical limitations in real-time performance assessment. Current sensor technologies often lack the precision and durability needed for continuous monitoring in harsh oxidative environments, creating blind spots in operational oversight and compliance verification.

Scale-up challenges impede industrial implementation, as laboratory-proven technologies frequently encounter unforeseen complications when deployed at commercial scales. These complications include uneven flow distribution, heat transfer inefficiencies, and catalyst utilization problems that weren't apparent in smaller-scale testing.

Cost barriers remain significant across all ozone destruction technologies. High-performance catalysts often contain precious metals like platinum or palladium, making initial capital investments substantial. Combined with energy costs for thermal systems and frequent maintenance requirements, the total cost of ownership presents a major obstacle to widespread adoption.

Regulatory compliance frameworks continue to evolve, creating a moving target for technology developers. Increasingly stringent emissions standards for both ozone and NOx require more sophisticated destruction systems, while the lack of harmonized international standards complicates global technology deployment strategies.

Thermal destruction systems, while effective at high temperatures, struggle with energy efficiency concerns. These systems typically require temperatures exceeding 350°C to achieve complete ozone decomposition, resulting in substantial energy consumption and associated operational expenses. The energy intensity of these processes contradicts sustainability goals and creates economic barriers for widespread implementation.

NOx formation presents another significant challenge, especially in thermal destruction units. At elevated temperatures, nitrogen and oxygen in the air can react to form nitrogen oxides, creating a secondary pollution problem while solving the primary ozone issue. This paradoxical outcome complicates regulatory compliance and necessitates additional treatment systems.

Material durability issues plague both catalytic and thermal systems. Ozone's highly oxidative nature accelerates material degradation in system components, particularly in high-concentration applications. This degradation leads to increased maintenance requirements and potential system failures that compromise operational reliability.

Monitoring and control systems face technical limitations in real-time performance assessment. Current sensor technologies often lack the precision and durability needed for continuous monitoring in harsh oxidative environments, creating blind spots in operational oversight and compliance verification.

Scale-up challenges impede industrial implementation, as laboratory-proven technologies frequently encounter unforeseen complications when deployed at commercial scales. These complications include uneven flow distribution, heat transfer inefficiencies, and catalyst utilization problems that weren't apparent in smaller-scale testing.

Cost barriers remain significant across all ozone destruction technologies. High-performance catalysts often contain precious metals like platinum or palladium, making initial capital investments substantial. Combined with energy costs for thermal systems and frequent maintenance requirements, the total cost of ownership presents a major obstacle to widespread adoption.

Regulatory compliance frameworks continue to evolve, creating a moving target for technology developers. Increasingly stringent emissions standards for both ozone and NOx require more sophisticated destruction systems, while the lack of harmonized international standards complicates global technology deployment strategies.

Technical Solutions for Ozone Off-Gas Management

01 Catalytic destruction of NOx in ozonation off-gas

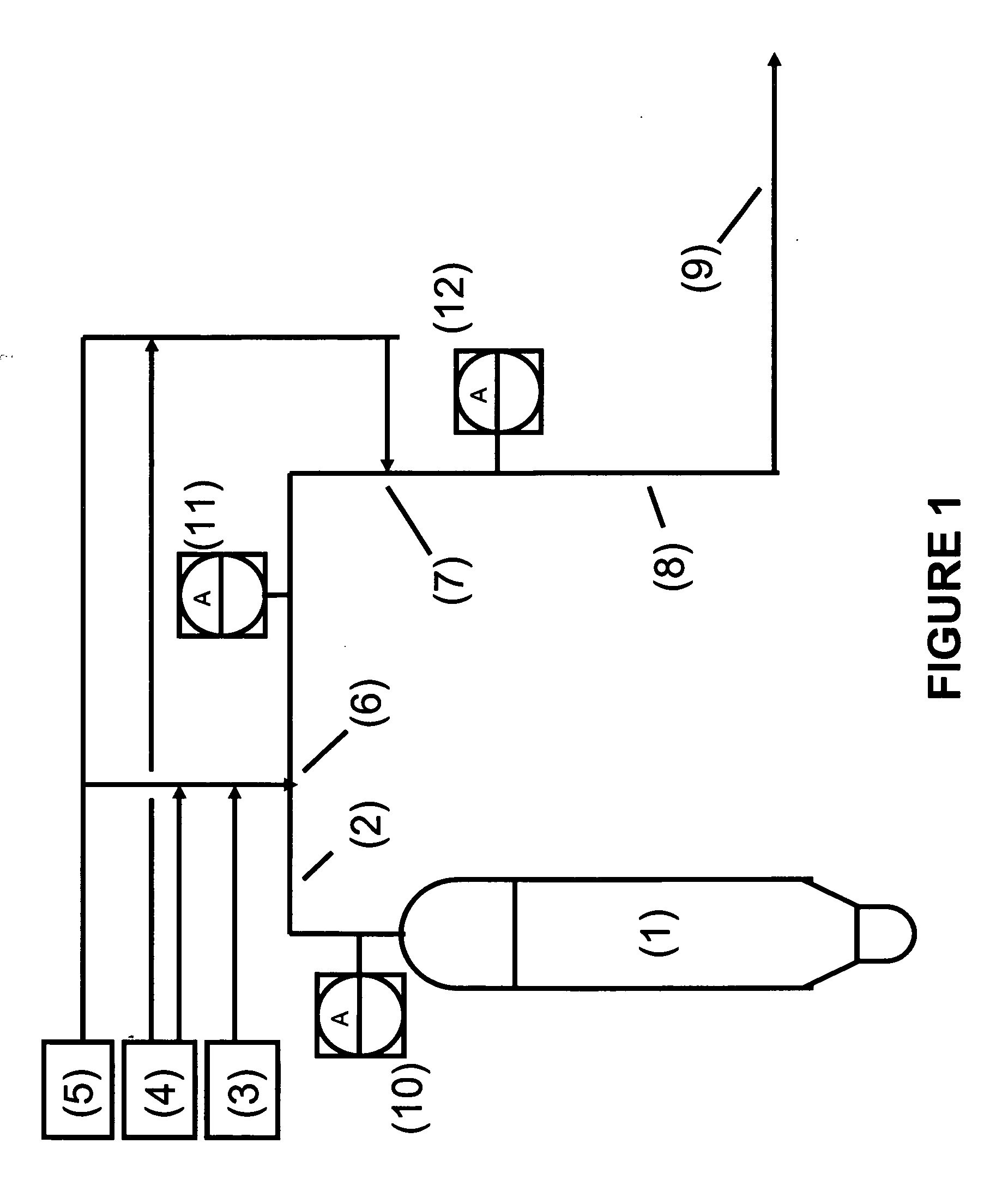

Catalytic systems are employed to destroy nitrogen oxides (NOx) in the off-gas from ozonation processes. These systems typically use selective catalytic reduction (SCR) technology with catalysts such as metal oxides or precious metals to convert NOx into harmless nitrogen and water. The catalytic destruction process operates at specific temperature ranges to optimize NOx removal efficiency while minimizing secondary pollutants.- Catalytic destruction of NOx in ozonation off-gas: Catalytic systems are employed to destroy nitrogen oxides (NOx) in the off-gas from ozonation processes. These systems typically use selective catalytic reduction (SCR) technology with various catalysts to convert NOx into harmless nitrogen and water. The catalysts enhance the reaction efficiency at lower temperatures, reducing energy consumption while effectively eliminating harmful emissions. These systems can be integrated directly into ozonation treatment plants to provide comprehensive emission control.

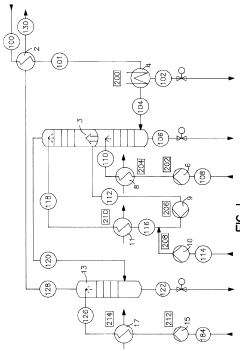

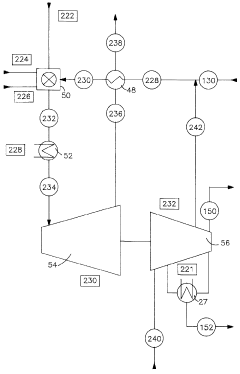

- Thermal decomposition systems for ozone and NOx removal: Thermal decomposition units are designed to eliminate both residual ozone and NOx emissions from ozonation processes. These systems operate at high temperatures to break down ozone molecules and oxidize nitrogen compounds. Some designs incorporate staged heating zones with precise temperature control to optimize the destruction efficiency while minimizing energy consumption. The thermal approach is particularly effective for handling variable gas flow rates and concentrations in industrial applications.

- Combined ozone/NOx destruction with energy recovery: Advanced off-gas treatment systems integrate NOx and ozone destruction with energy recovery mechanisms. These systems capture and utilize the heat generated during the decomposition process to improve overall energy efficiency. Heat exchangers transfer thermal energy from treated gases to incoming gas streams, reducing the external energy required for the process. Some designs incorporate regenerative thermal oxidizers that can achieve destruction efficiencies exceeding 99% while significantly reducing operational costs through energy reclamation.

- Wet scrubbing technology for NOx control in ozonation systems: Wet scrubbing systems are employed to remove NOx from ozonation off-gases through absorption into specially formulated liquid solutions. These systems typically use alkaline scrubbing liquids that react with nitrogen oxides to form stable compounds that can be safely disposed of or further processed. Multi-stage scrubbers can achieve high removal efficiencies by optimizing contact between the gas and liquid phases. Advanced designs incorporate oxidizing agents to enhance NOx solubility and reaction rates, making them particularly effective for treating concentrated emissions.

- Integrated monitoring and control systems for NOx emissions: Sophisticated monitoring and control systems are implemented to optimize the performance of NOx destruction units in ozonation processes. These systems employ continuous emission monitoring sensors that provide real-time data on NOx concentrations, allowing for automatic adjustments to destruction parameters. Advanced control algorithms balance destruction efficiency with energy consumption based on changing input conditions. Some systems incorporate predictive modeling to anticipate emission spikes and adjust operational parameters proactively, ensuring consistent compliance with environmental regulations while minimizing resource consumption.

02 Thermal decomposition systems for ozone and NOx control

Thermal decomposition units are integrated into ozonation systems to break down both residual ozone and NOx emissions. These systems operate at high temperatures, typically above 300°C, to thermally destroy ozone molecules and reduce NOx compounds. Heat exchangers are often incorporated to recover energy from the thermal destruction process, improving overall system efficiency while effectively controlling emissions.Expand Specific Solutions03 Combined ozone generation and NOx reduction systems

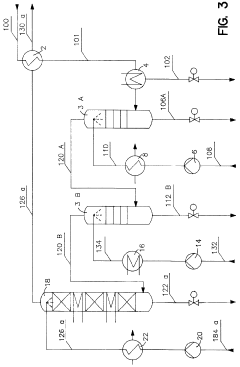

Integrated systems that combine ozone generation with NOx reduction technologies provide comprehensive emission control. These systems incorporate both ozone production units and downstream NOx treatment components such as scrubbers, catalytic converters, or thermal destructors. The integrated approach allows for optimized control of both ozone utilization and NOx emissions, with monitoring systems to ensure compliance with emission standards.Expand Specific Solutions04 Wet scrubbing technology for NOx removal in ozonation systems

Wet scrubbing systems are employed to remove NOx from ozonation off-gases through absorption into liquid solutions. These systems typically use alkaline solutions or specific chemical reagents that react with NOx compounds to form soluble nitrates or nitrites. Multi-stage scrubbers can achieve high removal efficiencies by optimizing contact between the gas and liquid phases, with the spent scrubbing solution being treated or regenerated for continuous operation.Expand Specific Solutions05 Advanced monitoring and control systems for NOx emissions

Sophisticated monitoring and control systems are implemented to continuously track and regulate NOx emissions from ozonation processes. These systems utilize sensors and analyzers to measure NOx concentrations in real-time, allowing for automatic adjustments to process parameters or destruction systems. Feedback control loops optimize the operation of catalytic or thermal destruction units based on emission levels, ensuring compliance with environmental regulations while maintaining process efficiency.Expand Specific Solutions

Key Industry Players in Off-Gas Treatment

Ozonation technology for off-gas treatment is currently in a growth phase, with increasing market demand driven by stricter environmental regulations worldwide. The market size is expanding at approximately 5-7% annually, particularly in industrial and municipal applications requiring NOx management and compliance. From a technological maturity perspective, established players like Johnson Matthey, BASF, and Haldor Topsøe lead with advanced catalytic solutions, while Toyota, Bosch, and Umicore focus on automotive applications. Academic institutions such as Zhejiang University of Technology and Southwest Jiaotong University are contributing to innovation through research partnerships with industry. The competitive landscape shows a mix of specialized environmental technology providers and diversified chemical companies developing integrated systems that combine thermal destruction with catalytic conversion for improved efficiency and compliance.

Johnson Matthey Plc

Technical Solution: Johnson Matthey has developed advanced catalytic systems specifically designed for ozone off-gas destruction and NOx management. Their technology utilizes precious metal catalysts (primarily platinum and palladium) supported on ceramic substrates that effectively convert ozone back to oxygen at relatively low temperatures (80-120°C). For NOx control, they've pioneered Selective Catalytic Reduction (SCR) systems that achieve over 95% NOx removal efficiency using metal-exchanged zeolite catalysts. Their integrated systems combine ozone destruction with NOx management in a single unit, reducing equipment footprint and operational complexity. Johnson Matthey's catalysts are engineered to maintain performance even in the presence of moisture and contaminants, with documented catalyst lifespans exceeding 40,000 operating hours in industrial applications.

Strengths: Industry-leading catalyst formulations with high conversion efficiency and long operational life; comprehensive technical support and customization capabilities. Weaknesses: Higher initial capital costs compared to non-catalytic alternatives; requires periodic catalyst replacement/regeneration; performance can be affected by certain process contaminants.

BASF SE

Technical Solution: BASF has developed a comprehensive ozonation off-gas treatment portfolio centered around their CatOxide™ technology. This system employs proprietary metal oxide catalysts that operate at temperatures between 100-200°C to decompose ozone with efficiency exceeding 99%. For NOx management, BASF offers their DeNOx catalytic systems utilizing vanadium-based formulations on titanium dioxide supports, achieving NOx reduction rates of 80-95% across wide temperature windows (300-450°C). Their dual-function catalysts can simultaneously address ozone destruction and NOx reduction, optimizing process efficiency. BASF's systems incorporate advanced catalyst coating technologies that maximize active surface area while minimizing pressure drop, crucial for high-throughput industrial applications. Their modular design approach allows for scalable implementation across various facility sizes.

Strengths: Extensive catalyst portfolio allowing application-specific optimization; robust performance in challenging industrial environments; global manufacturing and support infrastructure. Weaknesses: Systems typically require precise temperature control for optimal performance; higher complexity in system integration; potential for catalyst poisoning in certain industrial environments.

Critical Patents in Catalytic/Thermal Destruction Systems

Process for the purification of an oxidation off gas

PatentInactiveUS5891410A

Innovation

- The off-gas is purified through a process involving absorption under pressure using an ester-based absorbent, followed by partial condensation and multiple absorption stages with specific solvents, allowing for the recovery of useful products and the utilization of residual energy through combustion in an expansion turbine.

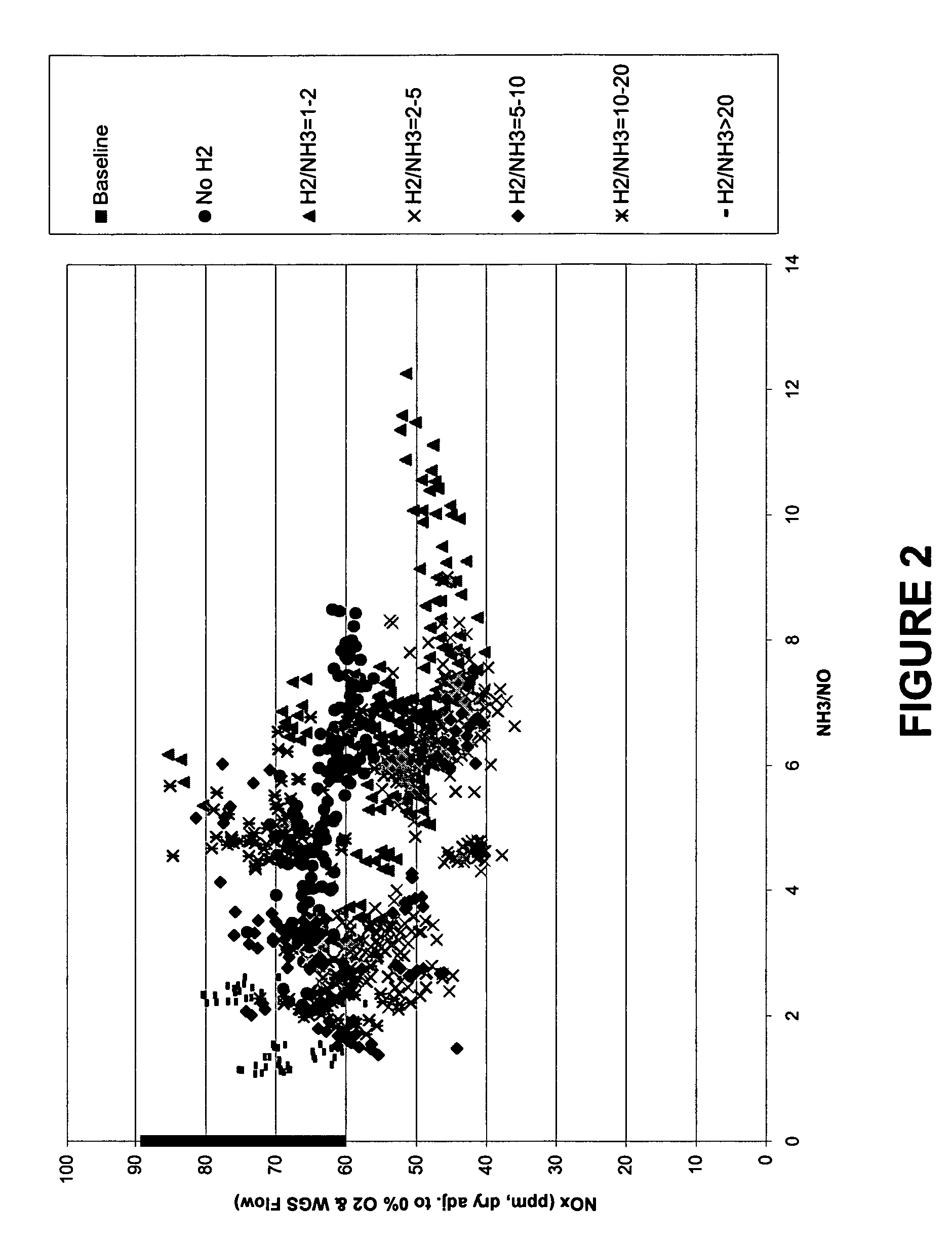

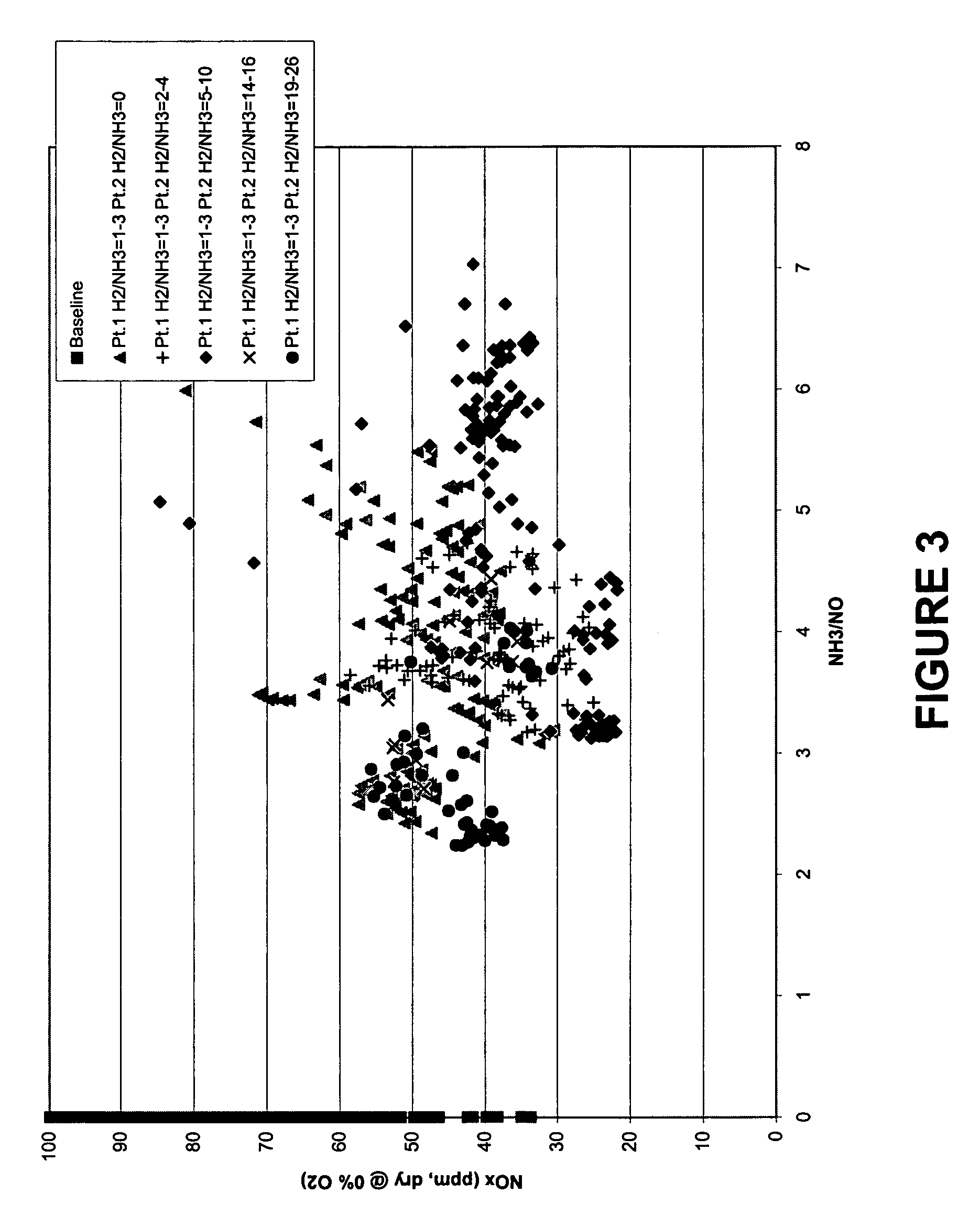

Non-catalytic reduction and oxidation process for the removal of NOx

PatentInactiveUS20060233688A1

Innovation

- A process involving the injection of a reducing agent, such as ammonia or urea, combined with a readily-oxidizable gas, followed by a second injection of another oxidizable gas, to reduce NOx concentrations, and then using sodium hypochlorite and chlorine dioxide to oxidize NOx species to higher, more soluble oxides, which are removed using a treated caustic solution from a wet gas scrubber.

Regulatory Compliance Framework for NOx Emissions

The regulatory landscape for NOx emissions has evolved significantly over the past decades, becoming increasingly stringent as understanding of environmental and health impacts has grown. In the United States, the Clean Air Act and its amendments establish the primary framework for NOx regulation, with the National Ambient Air Quality Standards (NAAQS) setting concentration limits for nitrogen dioxide (NO2) in ambient air.

The Environmental Protection Agency (EPA) implements these standards through various programs, including New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP), which specifically target ozonation processes and their associated off-gas treatment systems. Additionally, the NOx Budget Trading Program and Cross-State Air Pollution Rule (CSAPR) create market-based mechanisms for reducing emissions across state boundaries.

At the state level, regulatory frameworks vary considerably, with California's Air Resources Board (CARB) typically implementing the most stringent requirements. Many states have adopted State Implementation Plans (SIPs) that outline specific strategies for meeting federal standards, often including requirements for Best Available Control Technology (BACT) for new installations.

Internationally, the Gothenburg Protocol under the Convention on Long-range Transboundary Air Pollution establishes emission ceilings for NOx across Europe. The European Union's Industrial Emissions Directive (IED) further requires the use of Best Available Techniques (BAT) for pollution prevention and control, with specific reference documents (BREFs) detailing requirements for ozonation processes.

Compliance monitoring requirements typically include Continuous Emission Monitoring Systems (CEMS) for larger facilities, with periodic stack testing for smaller operations. Reporting obligations vary by jurisdiction but generally include quarterly or annual submissions of emissions data to regulatory authorities.

Recent regulatory trends indicate a move toward more integrated approaches that consider multiple pollutants simultaneously and focus on total environmental impact rather than single-pollutant controls. This shift has implications for ozonation facilities, which must increasingly balance NOx control with management of other pollutants and energy efficiency considerations.

Penalties for non-compliance can be severe, including substantial fines calculated per day of violation, mandatory facility upgrades, and in extreme cases, criminal prosecution of responsible officials. Many jurisdictions also provide compliance assistance programs and technical resources to help facilities meet requirements.

The Environmental Protection Agency (EPA) implements these standards through various programs, including New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP), which specifically target ozonation processes and their associated off-gas treatment systems. Additionally, the NOx Budget Trading Program and Cross-State Air Pollution Rule (CSAPR) create market-based mechanisms for reducing emissions across state boundaries.

At the state level, regulatory frameworks vary considerably, with California's Air Resources Board (CARB) typically implementing the most stringent requirements. Many states have adopted State Implementation Plans (SIPs) that outline specific strategies for meeting federal standards, often including requirements for Best Available Control Technology (BACT) for new installations.

Internationally, the Gothenburg Protocol under the Convention on Long-range Transboundary Air Pollution establishes emission ceilings for NOx across Europe. The European Union's Industrial Emissions Directive (IED) further requires the use of Best Available Techniques (BAT) for pollution prevention and control, with specific reference documents (BREFs) detailing requirements for ozonation processes.

Compliance monitoring requirements typically include Continuous Emission Monitoring Systems (CEMS) for larger facilities, with periodic stack testing for smaller operations. Reporting obligations vary by jurisdiction but generally include quarterly or annual submissions of emissions data to regulatory authorities.

Recent regulatory trends indicate a move toward more integrated approaches that consider multiple pollutants simultaneously and focus on total environmental impact rather than single-pollutant controls. This shift has implications for ozonation facilities, which must increasingly balance NOx control with management of other pollutants and energy efficiency considerations.

Penalties for non-compliance can be severe, including substantial fines calculated per day of violation, mandatory facility upgrades, and in extreme cases, criminal prosecution of responsible officials. Many jurisdictions also provide compliance assistance programs and technical resources to help facilities meet requirements.

Environmental Impact Assessment of Ozonation Systems

The environmental impact of ozonation systems extends beyond their primary water treatment function, encompassing various ecological and health considerations. Ozone treatment processes, while effective for disinfection and contaminant removal, generate off-gases containing residual ozone and potentially harmful byproducts that require careful management to minimize environmental harm.

Atmospheric emissions from ozonation systems primarily consist of unreacted ozone and nitrogen oxides (NOx) formed during the ozonation process. Without proper destruction systems, these emissions can contribute to air pollution, particularly in urban areas where they may exacerbate photochemical smog formation. The ozone released can also damage vegetation in the immediate vicinity of treatment facilities if not properly contained and neutralized.

Catalytic and thermal destructors represent the primary technologies for mitigating these environmental concerns. Thermal destruction systems operate by heating off-gases to temperatures exceeding 350°C, effectively breaking down ozone molecules. While efficient, these systems consume significant energy, resulting in indirect environmental impacts through increased carbon emissions if powered by fossil fuels.

Catalytic destruction systems offer a more energy-efficient alternative, utilizing metal oxide catalysts to decompose ozone at lower temperatures (typically 60-80°C). These systems reduce the carbon footprint associated with off-gas treatment but require periodic catalyst replacement and proper disposal of spent catalysts, which may contain heavy metals.

NOx emissions present a particular environmental challenge in ozonation systems. These compounds contribute to acid rain formation, ground-level ozone production, and respiratory health issues in exposed populations. Advanced NOx management techniques, including selective catalytic reduction (SCR) and low-NOx burners, have been developed to address these concerns, though their implementation increases system complexity and operational costs.

Water discharge considerations also factor into the environmental assessment of ozonation systems. Ozonation byproducts, including bromate and aldehydes, may form during treatment and potentially impact aquatic ecosystems if not properly monitored and controlled. Comprehensive water quality monitoring programs are essential to ensure that treated effluent meets regulatory standards and does not adversely affect receiving water bodies.

The life cycle environmental impact of ozonation systems encompasses raw material extraction, manufacturing, operation, and eventual decommissioning. Energy consumption during operation typically represents the largest environmental burden, though advances in energy recovery systems and renewable energy integration are progressively reducing this impact in modern installations.

Atmospheric emissions from ozonation systems primarily consist of unreacted ozone and nitrogen oxides (NOx) formed during the ozonation process. Without proper destruction systems, these emissions can contribute to air pollution, particularly in urban areas where they may exacerbate photochemical smog formation. The ozone released can also damage vegetation in the immediate vicinity of treatment facilities if not properly contained and neutralized.

Catalytic and thermal destructors represent the primary technologies for mitigating these environmental concerns. Thermal destruction systems operate by heating off-gases to temperatures exceeding 350°C, effectively breaking down ozone molecules. While efficient, these systems consume significant energy, resulting in indirect environmental impacts through increased carbon emissions if powered by fossil fuels.

Catalytic destruction systems offer a more energy-efficient alternative, utilizing metal oxide catalysts to decompose ozone at lower temperatures (typically 60-80°C). These systems reduce the carbon footprint associated with off-gas treatment but require periodic catalyst replacement and proper disposal of spent catalysts, which may contain heavy metals.

NOx emissions present a particular environmental challenge in ozonation systems. These compounds contribute to acid rain formation, ground-level ozone production, and respiratory health issues in exposed populations. Advanced NOx management techniques, including selective catalytic reduction (SCR) and low-NOx burners, have been developed to address these concerns, though their implementation increases system complexity and operational costs.

Water discharge considerations also factor into the environmental assessment of ozonation systems. Ozonation byproducts, including bromate and aldehydes, may form during treatment and potentially impact aquatic ecosystems if not properly monitored and controlled. Comprehensive water quality monitoring programs are essential to ensure that treated effluent meets regulatory standards and does not adversely affect receiving water bodies.

The life cycle environmental impact of ozonation systems encompasses raw material extraction, manufacturing, operation, and eventual decommissioning. Energy consumption during operation typically represents the largest environmental burden, though advances in energy recovery systems and renewable energy integration are progressively reducing this impact in modern installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!