Ozonation: Reactor Hydraulics, Short-Circuiting And Residence-Time Distribution

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology has evolved significantly since its initial application in water treatment during the late 19th century. Originally discovered by Martinus van Marum in 1785, ozone was first utilized for drinking water disinfection in Nice, France in 1906. The technology has since progressed from simple bubble diffusion systems to sophisticated reactor designs incorporating advanced hydraulic principles and monitoring capabilities.

The evolution of ozonation technology has been driven by increasing demands for water quality, stricter regulatory requirements, and the need for more efficient treatment processes. Early applications focused primarily on disinfection, while modern systems address multiple treatment objectives including oxidation of micropollutants, taste and odor control, and enhancement of biological filtration processes.

Current technological trends in ozonation are moving toward optimized reactor designs that maximize mass transfer efficiency while minimizing energy consumption. This includes the development of advanced contacting systems, improved gas-liquid mixing technologies, and sophisticated computational fluid dynamics (CFD) modeling to predict and enhance reactor performance.

The hydraulic characteristics of ozone reactors represent a critical aspect of system design and operation. Reactor hydraulics directly influence treatment efficiency by determining the contact time between ozone and target contaminants. Ideal plug flow conditions are typically desired but rarely achieved in practical applications due to various hydraulic phenomena including short-circuiting, dead zones, and non-uniform flow distribution.

Short-circuiting, where portions of the water pass through the reactor more quickly than the theoretical hydraulic retention time would suggest, poses a significant challenge to treatment efficacy. This phenomenon can result in inadequate exposure of certain water fractions to ozone, potentially compromising disinfection or oxidation objectives.

Residence-time distribution (RTD) analysis has emerged as a fundamental tool for characterizing reactor hydraulics and quantifying deviations from ideal flow patterns. By analyzing the distribution of time that different water elements spend within the reactor, engineers can identify hydraulic inefficiencies and implement design modifications to improve performance.

The primary objectives of current research and development in ozonation technology include: optimizing reactor hydraulics to approach ideal plug flow conditions; minimizing short-circuiting through innovative baffle configurations and inlet/outlet designs; developing reliable methods for real-time monitoring of residence time distribution; and creating predictive models that accurately simulate complex hydraulic behaviors under varying operational conditions.

The evolution of ozonation technology has been driven by increasing demands for water quality, stricter regulatory requirements, and the need for more efficient treatment processes. Early applications focused primarily on disinfection, while modern systems address multiple treatment objectives including oxidation of micropollutants, taste and odor control, and enhancement of biological filtration processes.

Current technological trends in ozonation are moving toward optimized reactor designs that maximize mass transfer efficiency while minimizing energy consumption. This includes the development of advanced contacting systems, improved gas-liquid mixing technologies, and sophisticated computational fluid dynamics (CFD) modeling to predict and enhance reactor performance.

The hydraulic characteristics of ozone reactors represent a critical aspect of system design and operation. Reactor hydraulics directly influence treatment efficiency by determining the contact time between ozone and target contaminants. Ideal plug flow conditions are typically desired but rarely achieved in practical applications due to various hydraulic phenomena including short-circuiting, dead zones, and non-uniform flow distribution.

Short-circuiting, where portions of the water pass through the reactor more quickly than the theoretical hydraulic retention time would suggest, poses a significant challenge to treatment efficacy. This phenomenon can result in inadequate exposure of certain water fractions to ozone, potentially compromising disinfection or oxidation objectives.

Residence-time distribution (RTD) analysis has emerged as a fundamental tool for characterizing reactor hydraulics and quantifying deviations from ideal flow patterns. By analyzing the distribution of time that different water elements spend within the reactor, engineers can identify hydraulic inefficiencies and implement design modifications to improve performance.

The primary objectives of current research and development in ozonation technology include: optimizing reactor hydraulics to approach ideal plug flow conditions; minimizing short-circuiting through innovative baffle configurations and inlet/outlet designs; developing reliable methods for real-time monitoring of residence time distribution; and creating predictive models that accurately simulate complex hydraulic behaviors under varying operational conditions.

Market Demand Analysis for Advanced Ozonation Systems

The global market for advanced ozonation systems is experiencing robust growth, driven primarily by increasing concerns over water quality and stringent environmental regulations. Current market analysis indicates that the water treatment sector represents the largest application segment, with municipal water treatment facilities accounting for approximately 45% of the total market demand. Industrial applications, particularly in pharmaceuticals, food processing, and electronics manufacturing, constitute another significant market segment showing accelerated growth rates.

The demand for advanced ozonation systems with optimized reactor hydraulics and residence-time distribution has seen a compound annual growth rate of 7.8% over the past five years. This growth trajectory is expected to continue as industries and municipalities face mounting pressure to remove emerging contaminants, including pharmaceutical residues, personal care products, and industrial chemicals that conventional treatment methods cannot effectively eliminate.

Regionally, North America and Europe currently dominate the market due to their established regulatory frameworks and aging water infrastructure requiring upgrades. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid industrialization, urbanization, and increasing government investments in water treatment infrastructure.

Market research indicates that end-users are increasingly prioritizing systems that can demonstrate optimal hydraulic efficiency and minimized short-circuiting. This shift is driven by the need to reduce operational costs while maximizing treatment effectiveness. Systems that can provide real-time monitoring and control of residence-time distribution are commanding premium prices, with customers willing to pay 15-20% more for technologies that offer verifiable performance improvements.

The COVID-19 pandemic has further accelerated market demand, as heightened awareness of sanitation and disinfection has prompted many facilities to reevaluate and upgrade their treatment systems. Additionally, the growing focus on micropollutants and antibiotic-resistant bacteria in water supplies has created new market opportunities for advanced ozonation technologies that can address these emerging concerns.

Industry surveys reveal that customers are increasingly seeking integrated solutions that combine ozonation with complementary technologies such as advanced oxidation processes, UV treatment, or biological filtration. This trend toward comprehensive treatment trains is reshaping the competitive landscape, favoring providers who can offer holistic water quality management rather than standalone ozonation equipment.

The market for specialized ozonation systems designed for specific applications, such as ballast water treatment in shipping or aquaculture water management, represents niche segments with above-average growth potential and less price sensitivity compared to conventional applications.

The demand for advanced ozonation systems with optimized reactor hydraulics and residence-time distribution has seen a compound annual growth rate of 7.8% over the past five years. This growth trajectory is expected to continue as industries and municipalities face mounting pressure to remove emerging contaminants, including pharmaceutical residues, personal care products, and industrial chemicals that conventional treatment methods cannot effectively eliminate.

Regionally, North America and Europe currently dominate the market due to their established regulatory frameworks and aging water infrastructure requiring upgrades. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid industrialization, urbanization, and increasing government investments in water treatment infrastructure.

Market research indicates that end-users are increasingly prioritizing systems that can demonstrate optimal hydraulic efficiency and minimized short-circuiting. This shift is driven by the need to reduce operational costs while maximizing treatment effectiveness. Systems that can provide real-time monitoring and control of residence-time distribution are commanding premium prices, with customers willing to pay 15-20% more for technologies that offer verifiable performance improvements.

The COVID-19 pandemic has further accelerated market demand, as heightened awareness of sanitation and disinfection has prompted many facilities to reevaluate and upgrade their treatment systems. Additionally, the growing focus on micropollutants and antibiotic-resistant bacteria in water supplies has created new market opportunities for advanced ozonation technologies that can address these emerging concerns.

Industry surveys reveal that customers are increasingly seeking integrated solutions that combine ozonation with complementary technologies such as advanced oxidation processes, UV treatment, or biological filtration. This trend toward comprehensive treatment trains is reshaping the competitive landscape, favoring providers who can offer holistic water quality management rather than standalone ozonation equipment.

The market for specialized ozonation systems designed for specific applications, such as ballast water treatment in shipping or aquaculture water management, represents niche segments with above-average growth potential and less price sensitivity compared to conventional applications.

Current Challenges in Ozonation Reactor Hydraulics

Despite significant advancements in ozonation technology, reactor hydraulics remains a critical challenge area that limits overall treatment efficiency. The fundamental issue stems from non-ideal flow patterns within ozonation reactors, which deviate substantially from the perfect plug flow or completely mixed flow models used in theoretical designs. These hydraulic inefficiencies manifest primarily as short-circuiting, where portions of influent water exit the reactor before adequate contact time with ozone occurs, resulting in under-treated water and compromised disinfection efficacy.

Dead zones represent another significant hydraulic challenge, where water becomes trapped in recirculation regions with minimal exchange with the main flow. These stagnant areas not only reduce the effective reactor volume but also create conditions where ozone demand can be exhausted locally, leading to treatment heterogeneity across the reactor profile. The combined effect of short-circuiting and dead zones significantly reduces the effective contact time between ozone and contaminants.

Computational fluid dynamics (CFD) modeling has revealed that many existing reactor designs suffer from poor baffling configurations that fail to optimize flow distribution. Traditional tracer studies measuring residence time distribution (RTD) confirm these inefficiencies, with t10/T ratios (the ratio of time at which 10% of tracer has passed through the reactor to theoretical detention time) often falling below regulatory requirements of 0.5-0.6 for disinfection applications.

Gas-liquid mass transfer limitations further complicate hydraulic performance. The introduction of ozone gas creates complex multiphase flow patterns that can exacerbate short-circuiting. Rising gas bubbles generate localized mixing that disrupts intended flow paths, while bubble coalescence reduces mass transfer efficiency. These phenomena are particularly problematic in deep reactors where hydrostatic pressure gradients create non-uniform ozone dissolution rates.

Temperature and density stratification present additional challenges, especially in large-scale applications. Thermal gradients can create density-driven currents that bypass significant portions of the reactor volume. Similarly, concentration gradients from non-uniform ozone distribution can induce preferential flow paths that compromise treatment uniformity.

Scaling effects represent a persistent challenge when translating laboratory or pilot-scale hydraulic performance to full-scale implementations. Geometric similarities often fail to maintain dynamic similarities, resulting in unexpected hydraulic behaviors in larger reactors. The industry currently lacks standardized scaling methodologies that reliably predict full-scale hydraulic performance from smaller prototypes.

Dead zones represent another significant hydraulic challenge, where water becomes trapped in recirculation regions with minimal exchange with the main flow. These stagnant areas not only reduce the effective reactor volume but also create conditions where ozone demand can be exhausted locally, leading to treatment heterogeneity across the reactor profile. The combined effect of short-circuiting and dead zones significantly reduces the effective contact time between ozone and contaminants.

Computational fluid dynamics (CFD) modeling has revealed that many existing reactor designs suffer from poor baffling configurations that fail to optimize flow distribution. Traditional tracer studies measuring residence time distribution (RTD) confirm these inefficiencies, with t10/T ratios (the ratio of time at which 10% of tracer has passed through the reactor to theoretical detention time) often falling below regulatory requirements of 0.5-0.6 for disinfection applications.

Gas-liquid mass transfer limitations further complicate hydraulic performance. The introduction of ozone gas creates complex multiphase flow patterns that can exacerbate short-circuiting. Rising gas bubbles generate localized mixing that disrupts intended flow paths, while bubble coalescence reduces mass transfer efficiency. These phenomena are particularly problematic in deep reactors where hydrostatic pressure gradients create non-uniform ozone dissolution rates.

Temperature and density stratification present additional challenges, especially in large-scale applications. Thermal gradients can create density-driven currents that bypass significant portions of the reactor volume. Similarly, concentration gradients from non-uniform ozone distribution can induce preferential flow paths that compromise treatment uniformity.

Scaling effects represent a persistent challenge when translating laboratory or pilot-scale hydraulic performance to full-scale implementations. Geometric similarities often fail to maintain dynamic similarities, resulting in unexpected hydraulic behaviors in larger reactors. The industry currently lacks standardized scaling methodologies that reliably predict full-scale hydraulic performance from smaller prototypes.

Current Solutions for Short-Circuiting Prevention

01 Reactor design for optimal hydraulic flow

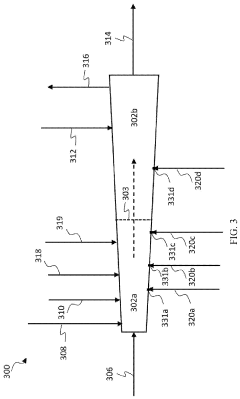

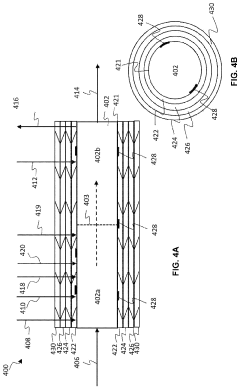

Ozonation reactor designs that optimize hydraulic flow patterns to prevent short-circuiting and ensure proper residence time distribution. These designs include specific inlet and outlet configurations, baffles, and compartmentalization to promote plug flow conditions and minimize dead zones. Proper hydraulic design ensures that all water receives adequate contact time with ozone for effective treatment.- Reactor design for optimizing residence time distribution: Specific design features in ozonation reactors can optimize residence time distribution and prevent short-circuiting. These designs include baffles, compartmentalization, and specialized flow channels that ensure proper contact time between ozone and the treated medium. Optimized hydraulic designs help eliminate dead zones and improve treatment efficiency by ensuring uniform distribution of ozone throughout the reactor volume.

- Monitoring and control systems for residence time: Advanced monitoring and control systems can be implemented to measure and adjust residence time distribution in ozonation reactors. These systems use sensors and analytical techniques to detect flow patterns, short-circuiting, and mixing efficiency in real-time. By continuously monitoring hydraulic parameters, operators can make adjustments to optimize treatment performance and ensure consistent ozone exposure throughout the reactor.

- Multi-stage ozonation configurations: Multi-stage ozonation reactor configurations can improve hydraulic efficiency and residence time distribution. By dividing the treatment process into sequential stages with controlled flow patterns between them, these designs minimize short-circuiting and ensure more uniform ozone exposure. Each stage can be optimized for specific treatment objectives while maintaining overall hydraulic efficiency throughout the system.

- Mixing technologies to prevent short-circuiting: Various mixing technologies can be incorporated into ozonation reactors to prevent short-circuiting and improve residence time distribution. These include static mixers, diffusers, turbulence generators, and mechanical agitation systems that promote thorough mixing of ozone with the treated medium. Effective mixing ensures that all portions of the fluid receive adequate exposure to ozone, eliminating preferential flow paths that could lead to untreated or under-treated zones.

- Computational modeling for hydraulic optimization: Computational fluid dynamics (CFD) and other modeling techniques can be used to predict and optimize hydraulic behavior in ozonation reactors. These models simulate flow patterns, residence time distribution, and mixing characteristics under various operating conditions. By identifying potential short-circuiting issues before construction or during troubleshooting, engineers can implement design modifications that improve hydraulic efficiency and treatment performance.

02 Residence time distribution monitoring and control

Methods and systems for monitoring and controlling residence time distribution in ozonation reactors. These include tracer studies, sensors, and automated control systems that measure flow patterns and adjust operational parameters to maintain optimal residence time. Real-time monitoring helps identify short-circuiting issues and ensures consistent treatment efficiency across varying flow conditions.Expand Specific Solutions03 Multi-chamber reactor configurations

Multi-chamber or multi-stage ozonation reactor designs that improve residence time distribution by creating sequential treatment zones. These configurations use multiple interconnected chambers with controlled flow paths to prevent short-circuiting and ensure adequate contact time. The staged approach allows for optimized ozone dosing and mixing in each zone while maintaining overall hydraulic efficiency.Expand Specific Solutions04 Mixing enhancement technologies

Technologies that enhance mixing within ozonation reactors to improve residence time distribution and prevent short-circuiting. These include static mixers, diffuser designs, mechanical agitators, and injection systems that create turbulence and promote uniform ozone distribution. Enhanced mixing ensures that ozone contacts all water particles evenly, eliminating preferential flow paths and dead zones.Expand Specific Solutions05 Computational modeling for hydraulic optimization

Computational fluid dynamics (CFD) and other modeling approaches used to analyze and optimize hydraulic conditions in ozonation reactors. These methods simulate flow patterns, residence time distributions, and mixing characteristics to identify potential short-circuiting issues before construction. Modeling helps engineers design more efficient reactors and troubleshoot existing systems to improve treatment performance.Expand Specific Solutions

Leading Companies and Research Institutions in Ozonation Technology

Ozonation technology for water treatment is currently in a growth phase, with the market expanding due to increasing water quality regulations and environmental concerns. The global ozonation market is estimated to be worth several billion dollars, with steady annual growth projected. Technologically, the field is maturing with significant advancements in reactor hydraulics and residence-time distribution optimization. Leading players include established water treatment specialists like Degremont SA, Kurita Water Industries, and Nijhuis Water Technology, alongside chemical giants such as Air Liquide SA and SABIC. Chinese companies like Zhejiang Zhongkairuipu are rapidly gaining market share by combining innovative approaches with cost advantages. Research institutions including ITRI and Korea Research Institute of Chemical Technology are driving fundamental improvements in ozonation efficiency and effectiveness.

Nijhuis Water Technology BV

Technical Solution: Nijhuis Water Technology has developed the i-OZONE® reactor system specifically engineered to optimize hydraulic performance in ozonation processes. Their technology incorporates a modular design with sequential reaction chambers and carefully positioned flow distributors to minimize short-circuiting effects. The company's approach utilizes computational fluid dynamics to optimize baffle configurations and inlet structures, achieving t10/t0 ratios exceeding 0.7 (compared to 0.3-0.5 in conventional designs). Their system features variable-depth injection systems that automatically adjust ozone distribution based on real-time hydraulic conditions. Nijhuis has implemented pulse-response testing with fluorescent tracers to validate their hydraulic models, demonstrating residence time distributions approaching ideal plug flow behavior. Their technology incorporates specialized flow conditioners at critical transition points to prevent preferential flow paths and ensure uniform ozone exposure throughout the treatment volume. The company has documented energy savings of 15-25% through their hydraulically optimized designs compared to conventional ozonation systems with equivalent treatment objectives.

Strengths: Modular design allows customization for specific applications; validated hydraulic performance through extensive field testing; energy-efficient operation through optimized mass transfer. Weaknesses: Requires precise flow control for optimal performance; more complex installation compared to conventional systems; higher initial capital investment.

Degremont SA

Technical Solution: Degremont SA has developed advanced ozonation reactor systems with optimized hydraulic designs to minimize short-circuiting effects. Their technology incorporates computational fluid dynamics (CFD) modeling to predict flow patterns and optimize baffle configurations within ozone contact chambers. Their Ozonia® system features multi-compartment designs with strategic inlet/outlet positioning to achieve plug flow conditions, approaching an ideal residence time distribution (RTD) curve. The company has implemented tracer studies using lithium chloride to validate their hydraulic efficiency improvements, demonstrating up to 30% increase in disinfection efficiency compared to conventional designs. Their patented contactor design incorporates fine bubble diffusers with optimized placement to ensure uniform ozone distribution while maintaining hydraulic efficiency.

Strengths: Advanced CFD modeling capabilities allow precise prediction of hydraulic behavior; validated performance through extensive field testing; integrated monitoring systems for real-time hydraulic performance assessment. Weaknesses: Higher capital costs compared to conventional systems; requires specialized expertise for optimal operation; performance can be sensitive to influent water quality fluctuations.

Key Innovations in Residence-Time Distribution Optimization

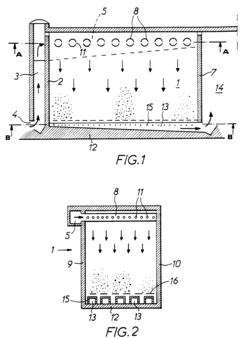

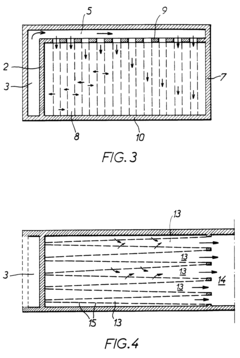

Apparatus for treating a fluid with gas such as an ozonisation of waste water

PatentInactiveEP0485270A1

Innovation

- A reactor design featuring uniformly distributed distribution chutes and return drains with calibrated orifices ensures a constant flow velocity throughout, combined with uniformly distributed gas injection to enhance ozone/water contact efficiency.

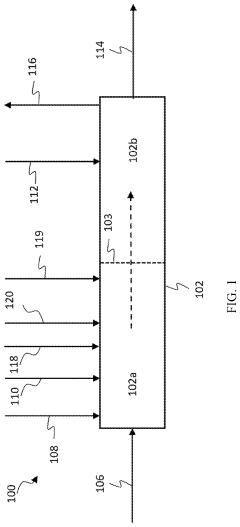

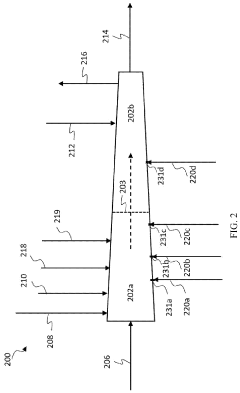

Process for producing olefins and aromatics through hydro pyrolysis and coke management

PatentPendingUS20230407190A1

Innovation

- The process involves contacting a hydrocarbon feed stream with a catalyst and hydrogen source to reduce coke formation, followed by contacting the used catalyst with a coke precursor to deposit coke, thereby maintaining catalyst activity and enhancing heat management and yield of high-value chemicals like olefins and aromatics.

Environmental Impact and Sustainability Considerations

Ozonation processes, while effective for water treatment, present significant environmental considerations that must be carefully evaluated. The environmental footprint of ozonation systems is directly influenced by reactor hydraulics, short-circuiting phenomena, and residence-time distribution patterns. When reactors operate with optimal hydraulic efficiency, they require less energy and fewer chemical inputs to achieve treatment goals, thereby reducing the overall environmental impact.

Energy consumption represents one of the most substantial environmental concerns in ozonation systems. The generation of ozone is inherently energy-intensive, typically requiring 10-20 kWh per kg of ozone produced. Poor hydraulic design leading to short-circuiting can necessitate higher ozone doses to compensate for treatment inefficiencies, resulting in increased energy demands and associated greenhouse gas emissions from power generation.

Chemical usage patterns in ozonation systems also carry environmental implications. When residence time distribution is non-uniform, operators often compensate by increasing chemical dosages, which can lead to the formation of undesirable by-products. These by-products, including bromate and aldehydes, may persist in treated effluent and potentially impact aquatic ecosystems if not properly managed.

The sustainability profile of ozonation systems can be significantly enhanced through hydraulic optimization. Research indicates that well-designed reactors with minimal short-circuiting can reduce ozone demand by 15-30%, with corresponding reductions in energy consumption and carbon footprint. Implementation of computational fluid dynamics (CFD) modeling during design phases has demonstrated potential for reducing environmental impacts while maintaining treatment efficacy.

Life cycle assessment (LCA) studies comparing optimized versus conventional ozonation systems reveal that hydraulic improvements can reduce the overall environmental impact by 20-40% across multiple impact categories, including climate change potential, acidification, and resource depletion. These benefits become particularly significant when scaled to large municipal treatment facilities serving populations of several hundred thousand.

Water conservation aspects must also be considered, as hydraulically efficient reactors minimize the need for backwashing and maintenance operations that consume additional water resources. Systems designed with proper residence-time distribution typically require 5-15% less operational water, contributing to overall water conservation efforts in regions facing scarcity challenges.

Regulatory frameworks increasingly recognize these environmental dimensions, with some jurisdictions now mandating hydraulic efficiency standards for new ozonation installations. These regulations typically specify minimum hydraulic efficiency indices and maximum allowable short-circuiting ratios to ensure environmental sustainability objectives are met alongside treatment performance goals.

Energy consumption represents one of the most substantial environmental concerns in ozonation systems. The generation of ozone is inherently energy-intensive, typically requiring 10-20 kWh per kg of ozone produced. Poor hydraulic design leading to short-circuiting can necessitate higher ozone doses to compensate for treatment inefficiencies, resulting in increased energy demands and associated greenhouse gas emissions from power generation.

Chemical usage patterns in ozonation systems also carry environmental implications. When residence time distribution is non-uniform, operators often compensate by increasing chemical dosages, which can lead to the formation of undesirable by-products. These by-products, including bromate and aldehydes, may persist in treated effluent and potentially impact aquatic ecosystems if not properly managed.

The sustainability profile of ozonation systems can be significantly enhanced through hydraulic optimization. Research indicates that well-designed reactors with minimal short-circuiting can reduce ozone demand by 15-30%, with corresponding reductions in energy consumption and carbon footprint. Implementation of computational fluid dynamics (CFD) modeling during design phases has demonstrated potential for reducing environmental impacts while maintaining treatment efficacy.

Life cycle assessment (LCA) studies comparing optimized versus conventional ozonation systems reveal that hydraulic improvements can reduce the overall environmental impact by 20-40% across multiple impact categories, including climate change potential, acidification, and resource depletion. These benefits become particularly significant when scaled to large municipal treatment facilities serving populations of several hundred thousand.

Water conservation aspects must also be considered, as hydraulically efficient reactors minimize the need for backwashing and maintenance operations that consume additional water resources. Systems designed with proper residence-time distribution typically require 5-15% less operational water, contributing to overall water conservation efforts in regions facing scarcity challenges.

Regulatory frameworks increasingly recognize these environmental dimensions, with some jurisdictions now mandating hydraulic efficiency standards for new ozonation installations. These regulations typically specify minimum hydraulic efficiency indices and maximum allowable short-circuiting ratios to ensure environmental sustainability objectives are met alongside treatment performance goals.

Regulatory Framework for Ozonation Applications

The regulatory landscape governing ozonation applications has evolved significantly over the past decades, reflecting growing understanding of both the benefits and potential risks associated with this water treatment technology. In the United States, the Environmental Protection Agency (EPA) established the Surface Water Treatment Rule (SWTR) in 1989, which recognized ozone as an effective disinfectant for controlling microbial contaminants. This was further refined in the Enhanced Surface Water Treatment Rule (ESWTR) and the Disinfectants/Disinfection By-products Rule (D/DBPR), which set specific compliance criteria for ozonation systems.

The European Union has implemented the Drinking Water Directive (98/83/EC, updated in 2020), which establishes quality standards for drinking water, including parameters relevant to ozonation processes. This directive specifically addresses concerns about disinfection by-products while acknowledging ozone's effectiveness against pathogens resistant to conventional chlorination, such as Cryptosporidium.

Regulatory frameworks worldwide increasingly focus on the hydraulic efficiency of ozonation reactors, recognizing that short-circuiting can significantly compromise treatment efficacy. The German standard ATV-DVWK-M 205E specifically addresses residence time distribution in ozonation systems, requiring validation through tracer studies to ensure compliance with minimum contact time (CT) values.

In wastewater treatment applications, regulations have expanded to include ozonation for micropollutant removal. Switzerland pioneered this approach with its 2016 Water Protection Act amendment, mandating ozonation in selected wastewater treatment plants to reduce micropollutant loads by 80%. This regulatory approach has influenced similar initiatives in Germany, France, and the Netherlands.

The World Health Organization's Guidelines for Drinking-water Quality provide international benchmarks for ozonation applications, emphasizing the importance of proper hydraulic design to achieve disinfection targets while minimizing by-product formation. These guidelines specifically reference the challenges of short-circuiting and recommend computational fluid dynamics (CFD) modeling during design phases.

Regulatory compliance increasingly requires demonstration of hydraulic efficiency through tracer testing and residence time distribution analysis. The USEPA Guidance Manual for Compliance with the Filtration and Disinfection Requirements specifies that the T10 value (time at which 10% of water has passed through the contactor) must be used when calculating CT values, directly addressing short-circuiting concerns in regulatory compliance calculations.

Recent regulatory trends indicate a move toward performance-based standards rather than prescriptive design requirements, allowing greater flexibility in reactor design while maintaining strict outcome-based compliance metrics focused on pathogen inactivation rates and by-product formation.

The European Union has implemented the Drinking Water Directive (98/83/EC, updated in 2020), which establishes quality standards for drinking water, including parameters relevant to ozonation processes. This directive specifically addresses concerns about disinfection by-products while acknowledging ozone's effectiveness against pathogens resistant to conventional chlorination, such as Cryptosporidium.

Regulatory frameworks worldwide increasingly focus on the hydraulic efficiency of ozonation reactors, recognizing that short-circuiting can significantly compromise treatment efficacy. The German standard ATV-DVWK-M 205E specifically addresses residence time distribution in ozonation systems, requiring validation through tracer studies to ensure compliance with minimum contact time (CT) values.

In wastewater treatment applications, regulations have expanded to include ozonation for micropollutant removal. Switzerland pioneered this approach with its 2016 Water Protection Act amendment, mandating ozonation in selected wastewater treatment plants to reduce micropollutant loads by 80%. This regulatory approach has influenced similar initiatives in Germany, France, and the Netherlands.

The World Health Organization's Guidelines for Drinking-water Quality provide international benchmarks for ozonation applications, emphasizing the importance of proper hydraulic design to achieve disinfection targets while minimizing by-product formation. These guidelines specifically reference the challenges of short-circuiting and recommend computational fluid dynamics (CFD) modeling during design phases.

Regulatory compliance increasingly requires demonstration of hydraulic efficiency through tracer testing and residence time distribution analysis. The USEPA Guidance Manual for Compliance with the Filtration and Disinfection Requirements specifies that the T10 value (time at which 10% of water has passed through the contactor) must be used when calculating CT values, directly addressing short-circuiting concerns in regulatory compliance calculations.

Recent regulatory trends indicate a move toward performance-based standards rather than prescriptive design requirements, allowing greater flexibility in reactor design while maintaining strict outcome-based compliance metrics focused on pathogen inactivation rates and by-product formation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!