Ozonation: Industrial Wastewater—Recalcitrant Organics, Toxicity Reduction And Safety

SEP 18, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology emerged in the early 20th century as a water treatment method, initially focused on drinking water disinfection. The application of ozone for industrial wastewater treatment gained significant attention in the 1970s when environmental regulations became more stringent worldwide. Over the past five decades, ozonation has evolved from a simple oxidation process to a sophisticated treatment technology capable of addressing complex industrial effluents containing recalcitrant organic compounds.

The evolution of ozonation technology has been marked by significant improvements in ozone generation efficiency, from the early corona discharge methods to modern advanced plasma and electrolytic techniques. These advancements have reduced energy consumption by approximately 30-40% while increasing ozone production capacity, making the technology more economically viable for industrial applications.

Industrial wastewater presents unique challenges due to its complex composition, high concentration of persistent organic pollutants, and potential toxicity. Conventional biological treatment methods often fail to adequately address these issues, creating a technological gap that ozonation aims to fill. Particularly in industries such as pharmaceuticals, textiles, petrochemicals, and pulp and paper, the presence of recalcitrant organics necessitates advanced oxidation processes like ozonation.

The primary technical objectives of modern ozonation systems in industrial wastewater treatment include the degradation of non-biodegradable organic compounds, reduction of effluent toxicity, color removal, and improvement of biodegradability for subsequent biological treatment. Additionally, there is growing interest in developing safer ozonation processes that minimize the formation of potentially harmful by-products and reduce operational risks associated with ozone handling.

Recent research trends focus on enhancing ozonation efficiency through catalytic ozonation, combining ozone with other advanced oxidation processes (AOPs), and developing innovative reactor designs for improved mass transfer. The integration of ozonation into comprehensive treatment trains that include biological processes represents a promising direction for maximizing treatment efficacy while minimizing costs.

The global push toward sustainable industrial practices and circular economy principles has further elevated the importance of advanced wastewater treatment technologies like ozonation. The technology aims not only to meet increasingly stringent discharge regulations but also to enable water reuse opportunities, thereby reducing industrial freshwater consumption and environmental impact.

As we look toward future developments, the technical goals include reducing energy requirements, improving ozone utilization efficiency, developing more selective oxidation processes, and enhancing the safety aspects of ozonation systems through advanced monitoring and control technologies.

The evolution of ozonation technology has been marked by significant improvements in ozone generation efficiency, from the early corona discharge methods to modern advanced plasma and electrolytic techniques. These advancements have reduced energy consumption by approximately 30-40% while increasing ozone production capacity, making the technology more economically viable for industrial applications.

Industrial wastewater presents unique challenges due to its complex composition, high concentration of persistent organic pollutants, and potential toxicity. Conventional biological treatment methods often fail to adequately address these issues, creating a technological gap that ozonation aims to fill. Particularly in industries such as pharmaceuticals, textiles, petrochemicals, and pulp and paper, the presence of recalcitrant organics necessitates advanced oxidation processes like ozonation.

The primary technical objectives of modern ozonation systems in industrial wastewater treatment include the degradation of non-biodegradable organic compounds, reduction of effluent toxicity, color removal, and improvement of biodegradability for subsequent biological treatment. Additionally, there is growing interest in developing safer ozonation processes that minimize the formation of potentially harmful by-products and reduce operational risks associated with ozone handling.

Recent research trends focus on enhancing ozonation efficiency through catalytic ozonation, combining ozone with other advanced oxidation processes (AOPs), and developing innovative reactor designs for improved mass transfer. The integration of ozonation into comprehensive treatment trains that include biological processes represents a promising direction for maximizing treatment efficacy while minimizing costs.

The global push toward sustainable industrial practices and circular economy principles has further elevated the importance of advanced wastewater treatment technologies like ozonation. The technology aims not only to meet increasingly stringent discharge regulations but also to enable water reuse opportunities, thereby reducing industrial freshwater consumption and environmental impact.

As we look toward future developments, the technical goals include reducing energy requirements, improving ozone utilization efficiency, developing more selective oxidation processes, and enhancing the safety aspects of ozonation systems through advanced monitoring and control technologies.

Industrial Wastewater Treatment Market Analysis

The global industrial wastewater treatment market is experiencing robust growth, valued at approximately $38 billion in 2022 with projections to reach $64 billion by 2030, representing a compound annual growth rate (CAGR) of 6.8%. This growth is primarily driven by increasingly stringent environmental regulations worldwide, particularly in developed economies where zero liquid discharge (ZLD) policies are becoming more prevalent.

The market for advanced oxidation processes (AOPs), including ozonation technologies, is expanding at an accelerated rate of 7.5% annually, outpacing conventional treatment methods. This trend reflects the growing industrial need for solutions capable of addressing recalcitrant organic compounds that resist traditional biological treatment approaches.

Sector-specific analysis reveals that chemical manufacturing, pharmaceutical production, and textile industries collectively account for over 45% of the demand for advanced wastewater treatment technologies like ozonation. These industries generate effluents containing complex organic pollutants that conventional treatments struggle to degrade effectively.

Geographically, North America and Europe currently dominate the industrial wastewater treatment market, holding approximately 60% of the global market share. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by rapid industrialization in China and India coupled with strengthening environmental regulations in these countries.

The ozonation segment specifically is gaining significant traction due to its effectiveness in treating pharmaceutical residues, endocrine-disrupting compounds, and other micropollutants. Market data indicates that ozonation systems for industrial applications have seen a 12% increase in installations over the past three years, with particular concentration in pharmaceutical and chemical manufacturing facilities.

Customer demand patterns show increasing preference for integrated treatment solutions that combine ozonation with other technologies such as biological treatment or membrane filtration. This trend toward hybrid systems is expected to reshape the competitive landscape, favoring technology providers capable of offering comprehensive treatment trains rather than standalone solutions.

Cost analysis reveals that while initial capital expenditure for ozonation systems remains 30-40% higher than conventional treatment technologies, the total cost of ownership gap is narrowing due to improved energy efficiency and reduced chemical consumption in newer ozonation systems. Additionally, regulatory compliance benefits and potential for water reuse are increasingly factored into return-on-investment calculations by industrial end-users.

The market for advanced oxidation processes (AOPs), including ozonation technologies, is expanding at an accelerated rate of 7.5% annually, outpacing conventional treatment methods. This trend reflects the growing industrial need for solutions capable of addressing recalcitrant organic compounds that resist traditional biological treatment approaches.

Sector-specific analysis reveals that chemical manufacturing, pharmaceutical production, and textile industries collectively account for over 45% of the demand for advanced wastewater treatment technologies like ozonation. These industries generate effluents containing complex organic pollutants that conventional treatments struggle to degrade effectively.

Geographically, North America and Europe currently dominate the industrial wastewater treatment market, holding approximately 60% of the global market share. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.2% annually, driven by rapid industrialization in China and India coupled with strengthening environmental regulations in these countries.

The ozonation segment specifically is gaining significant traction due to its effectiveness in treating pharmaceutical residues, endocrine-disrupting compounds, and other micropollutants. Market data indicates that ozonation systems for industrial applications have seen a 12% increase in installations over the past three years, with particular concentration in pharmaceutical and chemical manufacturing facilities.

Customer demand patterns show increasing preference for integrated treatment solutions that combine ozonation with other technologies such as biological treatment or membrane filtration. This trend toward hybrid systems is expected to reshape the competitive landscape, favoring technology providers capable of offering comprehensive treatment trains rather than standalone solutions.

Cost analysis reveals that while initial capital expenditure for ozonation systems remains 30-40% higher than conventional treatment technologies, the total cost of ownership gap is narrowing due to improved energy efficiency and reduced chemical consumption in newer ozonation systems. Additionally, regulatory compliance benefits and potential for water reuse are increasingly factored into return-on-investment calculations by industrial end-users.

Current Ozonation Challenges in Recalcitrant Organics Removal

Despite significant advancements in ozonation technology for industrial wastewater treatment, several critical challenges persist in effectively removing recalcitrant organic compounds. These compounds, characterized by their resistance to conventional biological treatment methods, include pharmaceuticals, pesticides, industrial chemicals, and various persistent organic pollutants (POPs).

One of the primary challenges is the selective oxidation capability of ozone. While ozone effectively targets certain functional groups like unsaturated bonds, aromatic rings, and amino groups, it demonstrates limited reactivity with saturated compounds, carboxylic acids, and certain halogenated organics. This selectivity results in incomplete mineralization of complex organic mixtures typically found in industrial effluents.

The formation of potentially harmful by-products presents another significant concern. Ozonation of recalcitrant organics often leads to the generation of intermediate compounds that may, in some cases, exhibit higher toxicity than the parent compounds. These transformation products, including aldehydes, ketones, and carboxylic acids, can persist in treated water and potentially impact downstream ecosystems.

Mass transfer limitations substantially affect ozonation efficiency in industrial applications. The low solubility of ozone in water (approximately 570 mg/L at 20°C) necessitates sophisticated gas-liquid contact systems to maximize dissolution. This challenge becomes particularly pronounced when treating high-strength industrial wastewaters with elevated concentrations of recalcitrant organics and competing matrix components.

Energy consumption represents a significant economic barrier to widespread implementation. Ozone generation is inherently energy-intensive, requiring approximately 12-18 kWh per kg of ozone produced. This high energy demand translates to substantial operational costs, particularly for treating large volumes of industrial wastewater containing high concentrations of recalcitrant compounds.

The presence of scavengers in industrial wastewaters significantly reduces treatment efficiency. Compounds such as carbonates, bicarbonates, and natural organic matter compete with target pollutants for ozone and hydroxyl radicals, necessitating higher ozone doses and extended treatment times to achieve desired removal rates.

Process stability and control also present operational challenges. Fluctuations in wastewater composition, pH, temperature, and the presence of particulate matter can dramatically affect ozonation performance. These variations make it difficult to maintain consistent treatment efficiency in industrial settings where wastewater characteristics frequently change.

Safety concerns related to ozone's toxicity and reactivity require sophisticated monitoring and control systems. The OSHA permissible exposure limit for ozone is merely 0.1 ppm (8-hour TWA), necessitating robust safety protocols, gas destruction units, and continuous monitoring systems to protect operational personnel and surrounding environments.

One of the primary challenges is the selective oxidation capability of ozone. While ozone effectively targets certain functional groups like unsaturated bonds, aromatic rings, and amino groups, it demonstrates limited reactivity with saturated compounds, carboxylic acids, and certain halogenated organics. This selectivity results in incomplete mineralization of complex organic mixtures typically found in industrial effluents.

The formation of potentially harmful by-products presents another significant concern. Ozonation of recalcitrant organics often leads to the generation of intermediate compounds that may, in some cases, exhibit higher toxicity than the parent compounds. These transformation products, including aldehydes, ketones, and carboxylic acids, can persist in treated water and potentially impact downstream ecosystems.

Mass transfer limitations substantially affect ozonation efficiency in industrial applications. The low solubility of ozone in water (approximately 570 mg/L at 20°C) necessitates sophisticated gas-liquid contact systems to maximize dissolution. This challenge becomes particularly pronounced when treating high-strength industrial wastewaters with elevated concentrations of recalcitrant organics and competing matrix components.

Energy consumption represents a significant economic barrier to widespread implementation. Ozone generation is inherently energy-intensive, requiring approximately 12-18 kWh per kg of ozone produced. This high energy demand translates to substantial operational costs, particularly for treating large volumes of industrial wastewater containing high concentrations of recalcitrant compounds.

The presence of scavengers in industrial wastewaters significantly reduces treatment efficiency. Compounds such as carbonates, bicarbonates, and natural organic matter compete with target pollutants for ozone and hydroxyl radicals, necessitating higher ozone doses and extended treatment times to achieve desired removal rates.

Process stability and control also present operational challenges. Fluctuations in wastewater composition, pH, temperature, and the presence of particulate matter can dramatically affect ozonation performance. These variations make it difficult to maintain consistent treatment efficiency in industrial settings where wastewater characteristics frequently change.

Safety concerns related to ozone's toxicity and reactivity require sophisticated monitoring and control systems. The OSHA permissible exposure limit for ozone is merely 0.1 ppm (8-hour TWA), necessitating robust safety protocols, gas destruction units, and continuous monitoring systems to protect operational personnel and surrounding environments.

Existing Ozonation Solutions for Toxicity Reduction

01 Ozone-based wastewater treatment methods

Ozone treatment can be used to reduce toxicity in wastewater by oxidizing harmful compounds. These methods involve the application of ozone to break down complex organic pollutants into simpler, less toxic forms. The process can be optimized by controlling parameters such as ozone concentration, contact time, and pH to enhance the degradation of toxic substances while minimizing the formation of harmful byproducts.- Ozone treatment for wastewater detoxification: Ozone treatment processes can effectively reduce toxicity in wastewater by oxidizing harmful organic compounds and contaminants. The advanced oxidation process breaks down complex toxic molecules into simpler, less harmful substances. This approach is particularly effective for industrial effluents containing persistent organic pollutants that conventional treatment methods cannot adequately address.

- Catalytic ozonation systems: Catalytic ozonation enhances toxicity reduction by combining ozone with catalysts such as metal oxides or activated carbon. These catalysts improve the efficiency of the oxidation process, allowing for more complete degradation of toxic compounds at lower ozone doses. The catalytic approach reduces treatment time and energy consumption while achieving higher detoxification rates compared to conventional ozonation.

- Combined ozone and biological treatment: Integrating ozonation with biological treatment processes creates a synergistic effect for toxicity reduction. Ozone pre-treatment breaks down complex toxic compounds into biodegradable intermediates that can be further processed by microorganisms. This combined approach is particularly effective for treating pharmaceutical waste, pesticides, and other biorecalcitrant compounds that resist conventional biological treatment alone.

- Ozone-based advanced oxidation processes: Advanced oxidation processes combining ozone with hydrogen peroxide, UV radiation, or ultrasound significantly enhance toxicity reduction capabilities. These combinations generate highly reactive hydroxyl radicals that can degrade even the most persistent toxic compounds. The versatility of these advanced processes allows for customization based on specific contaminant profiles and treatment requirements.

- Controlled ozonation parameters for toxicity minimization: Precise control of ozonation parameters such as dosage, contact time, pH, and temperature is crucial for effective toxicity reduction while preventing formation of harmful byproducts. Optimized ozonation conditions ensure maximum degradation of target contaminants while minimizing the formation of potentially toxic intermediates. Monitoring and adjustment systems help maintain ideal treatment conditions throughout the process.

02 Catalytic ozonation for enhanced toxicity reduction

Catalytic ozonation combines ozone with catalysts to improve the efficiency of toxicity reduction. This approach enhances the formation of hydroxyl radicals, which have stronger oxidation potential than ozone alone. Various catalysts, including metal oxides and supported metals, can be used to accelerate the decomposition of ozone and increase the degradation rate of toxic compounds, resulting in more effective detoxification with lower ozone dosages.Expand Specific Solutions03 Combined ozonation and biological treatment systems

Integrating ozonation with biological treatment processes creates synergistic effects for toxicity reduction. Ozonation can be applied as a pre-treatment to break down recalcitrant compounds into biodegradable forms, or as a post-treatment to remove residual toxicity. This combination enhances overall treatment efficiency by utilizing ozone to target specific toxic compounds while allowing biological processes to handle the biodegradable fraction, resulting in more complete detoxification.Expand Specific Solutions04 Advanced oxidation processes incorporating ozone

Advanced oxidation processes (AOPs) that incorporate ozone with other oxidants or energy sources can significantly reduce toxicity in contaminated water. These processes include combinations of ozone with hydrogen peroxide, UV radiation, or ultrasound to generate highly reactive hydroxyl radicals. The synergistic effects of these combinations enhance the degradation of persistent toxic compounds that are resistant to conventional treatment methods, providing more complete mineralization and detoxification.Expand Specific Solutions05 Monitoring and control systems for ozonation toxicity reduction

Sophisticated monitoring and control systems can optimize ozonation processes for toxicity reduction. These systems employ sensors and analyzers to measure key parameters such as dissolved ozone concentration, oxidation-reduction potential, and toxicity indicators in real-time. Automated control algorithms adjust ozone dosage and other operational parameters based on these measurements, ensuring effective toxicity reduction while minimizing energy consumption and preventing the formation of harmful byproducts.Expand Specific Solutions

Leading Companies in Industrial Wastewater Ozonation

The ozonation technology for industrial wastewater treatment, particularly for recalcitrant organics and toxicity reduction, is in a growth phase with increasing market adoption. The global market is expanding rapidly due to stricter environmental regulations and growing industrial wastewater volumes, estimated to reach $5-7 billion by 2025. Technologically, the field shows varying maturity levels, with companies like Axine Water Technologies pioneering electrolytic oxidation solutions, while established players such as Evoqua Water Technologies, Siemens AG, and Ecolab offer more conventional ozonation systems. Research institutions including South China University of Technology, CNRS, and National University of Singapore are advancing the technology through innovations in catalytic ozonation and hybrid processes, while industrial giants like China Petroleum & Chemical Corp and Mitsubishi Gas Chemical are implementing large-scale applications.

Axine Water Technologies, Inc.

Technical Solution: Axine has developed an innovative electrochemical oxidation technology specifically designed for treating industrial wastewater containing recalcitrant organics. Their solution employs advanced electrode materials that generate hydroxyl radicals and other powerful oxidants directly in the wastewater stream without requiring chemical additives. The system utilizes specialized catalytic electrodes that enhance oxidation efficiency while operating at ambient temperature and pressure. Axine's modular treatment units can be scaled to accommodate various flow rates and contaminant concentrations, making them adaptable to different industrial settings. The technology has demonstrated particular effectiveness in treating pharmaceutical compounds, PFAS, and other persistent organic pollutants that traditional biological treatments cannot address[1][3]. Their systems incorporate real-time monitoring and control features that optimize energy consumption based on wastewater characteristics and treatment objectives.

Strengths: Eliminates hazardous chemical handling associated with traditional ozonation; achieves high removal rates for pharmaceuticals and other recalcitrant compounds; modular design allows for flexible implementation. Weaknesses: Higher energy consumption compared to some conventional treatments; electrode materials may require periodic replacement; effectiveness can be reduced in wastewaters with high suspended solids content.

Oxytec LLC

Technical Solution: Oxytec has developed a specialized ozonation technology platform specifically targeting recalcitrant organics in industrial wastewater. Their system employs a proprietary "Controlled Radical Oxidation" approach that optimizes the formation and utilization of hydroxyl radicals during the treatment process. The technology incorporates advanced gas-liquid contacting systems that achieve exceptionally high mass transfer efficiency, ensuring maximum utilization of generated ozone. Oxytec's solution features innovative reactor designs that create optimal hydraulic conditions for contaminant oxidation while minimizing energy requirements[7]. Their systems include specialized catalysts that enhance the decomposition of ozone into hydroxyl radicals, particularly effective against pharmaceutical compounds, pesticides, and industrial chemicals resistant to conventional treatment. The technology incorporates a comprehensive safety framework with continuous ozone monitoring, leak detection systems, and emergency response protocols to address the hazards associated with ozone handling. Oxytec's platform includes an intelligent control system that continuously adjusts treatment parameters based on influent characteristics and treatment objectives, optimizing both treatment effectiveness and operational costs[8].

Strengths: Achieves high removal rates for difficult-to-treat compounds like PFAS and pharmaceutical residues; energy-efficient design reduces operational costs; advanced monitoring provides detailed performance analytics. Weaknesses: May require pre-treatment for wastewaters with high suspended solids; system complexity necessitates specialized operator training; potential for bromate formation in waters containing bromide.

Key Patents in Recalcitrant Organics Degradation

Electrochemical cell for wastewater treatment with increased removal rates of pollutants

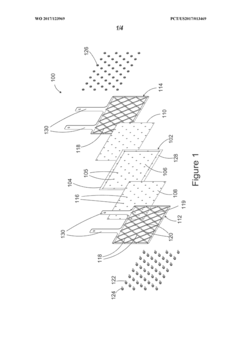

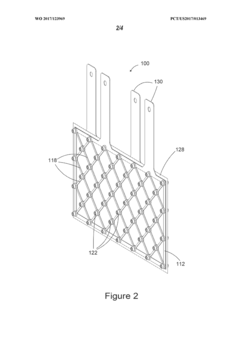

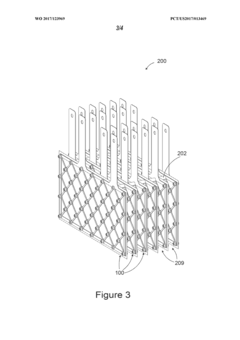

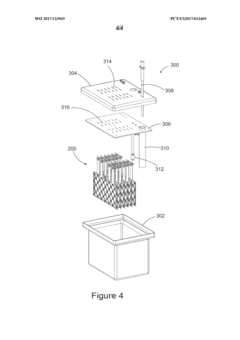

PatentWO2017123969A1

Innovation

- An electrochemical cell design featuring a solid polymer electrolyte membrane with anode and cathode catalyst layers, open pore meshes, and compression frames that distribute force uniformly across the active area, eliminating the need for supporting electrolytes and reducing electrode gaps, allowing for higher pollutant removal rates and efficient operation.

Safety Protocols and Risk Management in Ozonation

Ozonation processes in industrial wastewater treatment present significant safety challenges that require comprehensive protocols and risk management strategies. The primary hazards associated with ozonation include the high toxicity of ozone gas, which can cause severe respiratory issues at concentrations as low as 0.1 ppm and potentially fatal effects at 50 ppm. Additionally, ozone's strong oxidizing properties create risks of equipment corrosion and potential material degradation in treatment systems.

Effective safety protocols begin with proper system design incorporating fail-safe mechanisms. These include automatic shutdown systems that activate when ozone leaks are detected, pressure relief valves to prevent system overpressurization, and redundant control systems to maintain operational stability. Modern ozonation facilities increasingly implement real-time monitoring systems with sensors strategically positioned throughout treatment areas to provide continuous measurement of ambient ozone levels.

Personal protective equipment requirements for operators include respiratory protection with appropriate filters, chemical-resistant clothing, and eye protection when working near ozone generation or application points. Standard operating procedures must clearly define emergency response protocols for ozone leaks, including evacuation procedures, ventilation activation, and notification chains.

Risk management in ozonation facilities necessitates regular preventive maintenance schedules for all system components, particularly ozone destructors, which convert residual ozone back to oxygen before release. Comprehensive staff training programs must cover normal operations, emergency procedures, and the chemical properties of ozone. These programs should be refreshed annually and updated whenever system modifications occur.

Environmental safety considerations extend beyond the facility boundaries, requiring monitoring of ozone off-gassing from treated water and potential impacts on surrounding ecosystems. Advanced facilities implement automated control systems that adjust ozone dosage based on real-time water quality parameters, minimizing excess ozone production and associated risks.

International standards and regulations governing ozonation safety vary by region but generally include OSHA standards in the United States (limiting workplace exposure to 0.1 ppm over an 8-hour period), EU directives on chemical handling, and ISO standards for equipment safety. Compliance with these regulations requires documented risk assessments, regular safety audits, and continuous improvement of safety protocols.

Recent technological advances have enhanced safety through the development of ozone-resistant materials, improved destruction catalysts, and more energy-efficient generation methods that reduce operational risks. These innovations, combined with rigorous safety protocols, have significantly improved the risk profile of industrial ozonation systems while maintaining their effectiveness in treating recalcitrant organic compounds.

Effective safety protocols begin with proper system design incorporating fail-safe mechanisms. These include automatic shutdown systems that activate when ozone leaks are detected, pressure relief valves to prevent system overpressurization, and redundant control systems to maintain operational stability. Modern ozonation facilities increasingly implement real-time monitoring systems with sensors strategically positioned throughout treatment areas to provide continuous measurement of ambient ozone levels.

Personal protective equipment requirements for operators include respiratory protection with appropriate filters, chemical-resistant clothing, and eye protection when working near ozone generation or application points. Standard operating procedures must clearly define emergency response protocols for ozone leaks, including evacuation procedures, ventilation activation, and notification chains.

Risk management in ozonation facilities necessitates regular preventive maintenance schedules for all system components, particularly ozone destructors, which convert residual ozone back to oxygen before release. Comprehensive staff training programs must cover normal operations, emergency procedures, and the chemical properties of ozone. These programs should be refreshed annually and updated whenever system modifications occur.

Environmental safety considerations extend beyond the facility boundaries, requiring monitoring of ozone off-gassing from treated water and potential impacts on surrounding ecosystems. Advanced facilities implement automated control systems that adjust ozone dosage based on real-time water quality parameters, minimizing excess ozone production and associated risks.

International standards and regulations governing ozonation safety vary by region but generally include OSHA standards in the United States (limiting workplace exposure to 0.1 ppm over an 8-hour period), EU directives on chemical handling, and ISO standards for equipment safety. Compliance with these regulations requires documented risk assessments, regular safety audits, and continuous improvement of safety protocols.

Recent technological advances have enhanced safety through the development of ozone-resistant materials, improved destruction catalysts, and more energy-efficient generation methods that reduce operational risks. These innovations, combined with rigorous safety protocols, have significantly improved the risk profile of industrial ozonation systems while maintaining their effectiveness in treating recalcitrant organic compounds.

Environmental Compliance and Regulatory Framework

The regulatory landscape governing ozonation technologies for industrial wastewater treatment has become increasingly stringent worldwide, reflecting growing environmental concerns and public health priorities. In the United States, the Clean Water Act (CWA) establishes the primary framework for regulating discharges of pollutants into water bodies, with the National Pollutant Discharge Elimination System (NPDES) permit program imposing specific limitations on industrial effluents. Ozonation processes must demonstrate compliance with these discharge standards, particularly regarding persistent organic pollutants and toxicity levels.

The European Union's Water Framework Directive (WFD) and Industrial Emissions Directive (IED) similarly mandate comprehensive approaches to water quality management, emphasizing the reduction of priority hazardous substances. These regulations increasingly recognize ozonation as a Best Available Technique (BAT) for certain industrial sectors, particularly when dealing with recalcitrant organic compounds resistant to conventional treatment methods.

Safety regulations present another critical compliance dimension for ozonation systems. Occupational Safety and Health Administration (OSHA) in the US and similar agencies worldwide have established strict exposure limits for ozone, typically around 0.1 ppm for an 8-hour time-weighted average. These standards necessitate robust monitoring systems, proper ventilation, and comprehensive safety protocols in industrial ozonation facilities.

Emerging regulatory trends indicate a shift toward more holistic environmental assessment frameworks. This includes consideration of treatment by-products formed during ozonation processes, particularly brominated disinfection by-products and transformation products of pharmaceutical compounds. The EU's REACH regulation exemplifies this approach by requiring thorough evaluation of chemical substances and their potential impacts throughout their lifecycle.

Regional variations in regulatory frameworks create significant compliance challenges for multinational industrial operations. While developed economies typically maintain comprehensive regulatory structures, emerging economies often exhibit evolving regulatory landscapes with rapidly changing compliance requirements. This necessitates adaptable ozonation system designs capable of meeting increasingly stringent standards as they develop.

Industry-specific regulations further complicate compliance considerations. Pharmaceutical, textile, and chemical manufacturing sectors face particularly stringent requirements regarding specific compounds of concern. The pharmaceutical industry, for instance, must increasingly address concerns about active pharmaceutical ingredients (APIs) in wastewater, with ozonation emerging as a preferred treatment option for these compounds.

Future regulatory developments are likely to focus on emerging contaminants of concern, including microplastics, per- and polyfluoroalkyl substances (PFAS), and endocrine-disrupting compounds. Ozonation technologies will need to demonstrate efficacy against these contaminants while maintaining compliance with increasingly comprehensive regulatory frameworks addressing both environmental and safety considerations.

The European Union's Water Framework Directive (WFD) and Industrial Emissions Directive (IED) similarly mandate comprehensive approaches to water quality management, emphasizing the reduction of priority hazardous substances. These regulations increasingly recognize ozonation as a Best Available Technique (BAT) for certain industrial sectors, particularly when dealing with recalcitrant organic compounds resistant to conventional treatment methods.

Safety regulations present another critical compliance dimension for ozonation systems. Occupational Safety and Health Administration (OSHA) in the US and similar agencies worldwide have established strict exposure limits for ozone, typically around 0.1 ppm for an 8-hour time-weighted average. These standards necessitate robust monitoring systems, proper ventilation, and comprehensive safety protocols in industrial ozonation facilities.

Emerging regulatory trends indicate a shift toward more holistic environmental assessment frameworks. This includes consideration of treatment by-products formed during ozonation processes, particularly brominated disinfection by-products and transformation products of pharmaceutical compounds. The EU's REACH regulation exemplifies this approach by requiring thorough evaluation of chemical substances and their potential impacts throughout their lifecycle.

Regional variations in regulatory frameworks create significant compliance challenges for multinational industrial operations. While developed economies typically maintain comprehensive regulatory structures, emerging economies often exhibit evolving regulatory landscapes with rapidly changing compliance requirements. This necessitates adaptable ozonation system designs capable of meeting increasingly stringent standards as they develop.

Industry-specific regulations further complicate compliance considerations. Pharmaceutical, textile, and chemical manufacturing sectors face particularly stringent requirements regarding specific compounds of concern. The pharmaceutical industry, for instance, must increasingly address concerns about active pharmaceutical ingredients (APIs) in wastewater, with ozonation emerging as a preferred treatment option for these compounds.

Future regulatory developments are likely to focus on emerging contaminants of concern, including microplastics, per- and polyfluoroalkyl substances (PFAS), and endocrine-disrupting compounds. Ozonation technologies will need to demonstrate efficacy against these contaminants while maintaining compliance with increasingly comprehensive regulatory frameworks addressing both environmental and safety considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!