Ozonation: Catalytic Ozonation, Activated Carbon Synergy And Micropollutant Removal

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology has evolved significantly since its initial application in water treatment during the late 19th century. Originally utilized primarily for disinfection purposes, ozonation has progressively expanded into a versatile advanced oxidation process (AOP) capable of addressing a wide spectrum of water contaminants. The technology leverages ozone's powerful oxidizing properties (E° = 2.07 V) to break down complex organic compounds and inactivate pathogens through direct and indirect oxidation mechanisms.

The evolution of ozonation technology has been marked by several key developments. In the 1970s and 1980s, researchers began exploring ozone's potential beyond simple disinfection, investigating its efficacy against emerging contaminants. The 1990s witnessed significant advancements in ozone generation efficiency and process optimization, making the technology more economically viable for widespread implementation.

Recent decades have seen a paradigm shift toward enhanced ozonation processes, particularly catalytic ozonation and combined systems utilizing activated carbon. These innovations address traditional ozonation limitations, including selective reactivity, formation of potentially harmful by-products, and incomplete mineralization of certain contaminants.

The growing concern over micropollutants in water systems has become a primary driver for ozonation technology advancement. Pharmaceuticals, personal care products, endocrine disruptors, and industrial chemicals present at trace concentrations (ng/L to μg/L) pose significant environmental and public health challenges due to their persistence and bioactive properties, even at extremely low concentrations.

The primary objectives of current ozonation technology research and development focus on several critical areas. First, enhancing the efficiency and selectivity of ozone-based treatment processes to target recalcitrant micropollutants while minimizing energy consumption. Second, developing novel catalytic systems that can accelerate ozone decomposition into highly reactive hydroxyl radicals, thereby improving oxidation efficiency and expanding the range of treatable contaminants.

Additionally, research aims to optimize the synergistic effects between ozonation and activated carbon, leveraging both adsorption and advanced oxidation mechanisms. This includes investigating the role of activated carbon as both an adsorbent and catalyst in the ozonation process, potentially offering more cost-effective and environmentally sustainable treatment solutions.

The ultimate goal is to establish ozonation-based technologies as a cornerstone of advanced water treatment systems capable of addressing current and emerging water quality challenges, particularly the removal of persistent micropollutants that conventional treatment processes fail to eliminate effectively.

The evolution of ozonation technology has been marked by several key developments. In the 1970s and 1980s, researchers began exploring ozone's potential beyond simple disinfection, investigating its efficacy against emerging contaminants. The 1990s witnessed significant advancements in ozone generation efficiency and process optimization, making the technology more economically viable for widespread implementation.

Recent decades have seen a paradigm shift toward enhanced ozonation processes, particularly catalytic ozonation and combined systems utilizing activated carbon. These innovations address traditional ozonation limitations, including selective reactivity, formation of potentially harmful by-products, and incomplete mineralization of certain contaminants.

The growing concern over micropollutants in water systems has become a primary driver for ozonation technology advancement. Pharmaceuticals, personal care products, endocrine disruptors, and industrial chemicals present at trace concentrations (ng/L to μg/L) pose significant environmental and public health challenges due to their persistence and bioactive properties, even at extremely low concentrations.

The primary objectives of current ozonation technology research and development focus on several critical areas. First, enhancing the efficiency and selectivity of ozone-based treatment processes to target recalcitrant micropollutants while minimizing energy consumption. Second, developing novel catalytic systems that can accelerate ozone decomposition into highly reactive hydroxyl radicals, thereby improving oxidation efficiency and expanding the range of treatable contaminants.

Additionally, research aims to optimize the synergistic effects between ozonation and activated carbon, leveraging both adsorption and advanced oxidation mechanisms. This includes investigating the role of activated carbon as both an adsorbent and catalyst in the ozonation process, potentially offering more cost-effective and environmentally sustainable treatment solutions.

The ultimate goal is to establish ozonation-based technologies as a cornerstone of advanced water treatment systems capable of addressing current and emerging water quality challenges, particularly the removal of persistent micropollutants that conventional treatment processes fail to eliminate effectively.

Market Demand for Advanced Water Treatment Solutions

The global water treatment market is experiencing unprecedented growth, driven by increasing water scarcity, stricter environmental regulations, and growing awareness of micropollutants in water systems. The market for advanced oxidation processes, particularly ozonation technologies, is projected to grow at a compound annual growth rate of 7.2% through 2028, reaching a market value of $24.3 billion.

Industrial sectors, particularly pharmaceuticals, chemicals, and textiles, are facing mounting pressure to treat wastewater containing persistent organic pollutants before discharge. These industries collectively represent over 40% of the demand for advanced oxidation technologies like catalytic ozonation. The pharmaceutical industry alone has increased its investment in advanced water treatment solutions by 35% over the past five years to address concerns about pharmaceutical residues in water bodies.

Municipal water treatment facilities worldwide are upgrading their infrastructure to address emerging contaminants. In Europe, the implementation of the Water Framework Directive has accelerated the adoption of advanced treatment technologies, with over 300 municipal plants incorporating ozonation systems since 2018. Similarly, in North America, regulatory changes have prompted a 28% increase in ozonation system installations for drinking water treatment.

The synergistic combination of activated carbon with ozonation processes has gained significant market traction due to its enhanced efficiency in removing micropollutants. This integrated approach has seen a 45% increase in adoption rates compared to standalone ozonation systems, particularly in regions with high water stress and stringent quality requirements.

Consumer awareness regarding water quality has dramatically shifted market dynamics. A recent global survey indicated that 76% of consumers express concern about micropollutants in drinking water, including pharmaceuticals, personal care products, and industrial chemicals. This awareness has translated into increased willingness to pay premium prices for effectively treated water, creating a robust consumer market segment.

Developing economies represent the fastest-growing market for advanced water treatment technologies. Countries like China, India, and Brazil are investing heavily in water infrastructure, with combined annual expenditures exceeding $50 billion. The demand for technologies that can effectively remove micropollutants while maintaining cost efficiency is particularly strong in these regions.

The market for specialized catalysts used in catalytic ozonation processes has emerged as a high-value segment, with specialized materials commanding premium prices due to their enhanced performance in micropollutant removal. This specialized market segment has grown by 32% annually since 2020, reflecting the increasing technical sophistication of water treatment solutions.

Industrial sectors, particularly pharmaceuticals, chemicals, and textiles, are facing mounting pressure to treat wastewater containing persistent organic pollutants before discharge. These industries collectively represent over 40% of the demand for advanced oxidation technologies like catalytic ozonation. The pharmaceutical industry alone has increased its investment in advanced water treatment solutions by 35% over the past five years to address concerns about pharmaceutical residues in water bodies.

Municipal water treatment facilities worldwide are upgrading their infrastructure to address emerging contaminants. In Europe, the implementation of the Water Framework Directive has accelerated the adoption of advanced treatment technologies, with over 300 municipal plants incorporating ozonation systems since 2018. Similarly, in North America, regulatory changes have prompted a 28% increase in ozonation system installations for drinking water treatment.

The synergistic combination of activated carbon with ozonation processes has gained significant market traction due to its enhanced efficiency in removing micropollutants. This integrated approach has seen a 45% increase in adoption rates compared to standalone ozonation systems, particularly in regions with high water stress and stringent quality requirements.

Consumer awareness regarding water quality has dramatically shifted market dynamics. A recent global survey indicated that 76% of consumers express concern about micropollutants in drinking water, including pharmaceuticals, personal care products, and industrial chemicals. This awareness has translated into increased willingness to pay premium prices for effectively treated water, creating a robust consumer market segment.

Developing economies represent the fastest-growing market for advanced water treatment technologies. Countries like China, India, and Brazil are investing heavily in water infrastructure, with combined annual expenditures exceeding $50 billion. The demand for technologies that can effectively remove micropollutants while maintaining cost efficiency is particularly strong in these regions.

The market for specialized catalysts used in catalytic ozonation processes has emerged as a high-value segment, with specialized materials commanding premium prices due to their enhanced performance in micropollutant removal. This specialized market segment has grown by 32% annually since 2020, reflecting the increasing technical sophistication of water treatment solutions.

Current Status and Challenges in Catalytic Ozonation

Catalytic ozonation has emerged as a promising advanced oxidation process for water treatment, combining the oxidative power of ozone with catalysts to enhance pollutant degradation efficiency. Currently, this technology has progressed from laboratory research to pilot-scale applications in several countries, with China, the United States, and European nations leading development efforts. Research centers and water treatment facilities worldwide are actively exploring catalytic ozonation for micropollutant removal.

The technology employs various catalysts including metal oxides (MnO2, TiO2, Al2O3), supported metals (Pt, Pd, Ru on different carriers), and carbon-based materials (activated carbon, graphene, carbon nanotubes). Recent advancements have focused on developing novel composite catalysts that demonstrate superior performance through synergistic effects. Particularly noteworthy is the synergy between activated carbon and ozone, which has shown remarkable efficiency in removing recalcitrant organic compounds.

Despite promising results, catalytic ozonation faces significant technical challenges. Catalyst stability remains a primary concern, as many catalysts suffer from deactivation during continuous operation due to surface fouling, leaching of active components, or structural changes. This necessitates frequent regeneration or replacement, increasing operational costs. Additionally, the formation of potentially harmful by-products during the oxidation process requires careful monitoring and control.

Selectivity issues present another challenge, as catalytic systems often demonstrate variable effectiveness across different micropollutant classes. Pharmaceuticals, personal care products, and industrial chemicals each respond differently to catalytic ozonation, complicating treatment design for complex water matrices. The influence of water quality parameters such as pH, temperature, and the presence of natural organic matter significantly affects treatment efficiency, making standardization difficult.

Scale-up challenges persist in transitioning from laboratory to industrial applications. Reactor design must address mass transfer limitations between ozone, catalysts, and target pollutants. Furthermore, the economic viability of catalytic ozonation compared to conventional treatments remains questionable, with high energy consumption for ozone generation and catalyst costs presenting barriers to widespread adoption.

Regulatory frameworks for catalytic ozonation implementation are still evolving, with varying standards across regions. This regulatory uncertainty, coupled with limited long-term performance data, has slowed commercial adoption. Research gaps exist in understanding reaction mechanisms, particularly the role of surface reactions versus bulk solution processes in pollutant degradation.

The geographic distribution of catalytic ozonation technology shows concentration in developed regions with stringent water quality regulations, while developing nations face implementation barriers due to cost and technical expertise limitations.

The technology employs various catalysts including metal oxides (MnO2, TiO2, Al2O3), supported metals (Pt, Pd, Ru on different carriers), and carbon-based materials (activated carbon, graphene, carbon nanotubes). Recent advancements have focused on developing novel composite catalysts that demonstrate superior performance through synergistic effects. Particularly noteworthy is the synergy between activated carbon and ozone, which has shown remarkable efficiency in removing recalcitrant organic compounds.

Despite promising results, catalytic ozonation faces significant technical challenges. Catalyst stability remains a primary concern, as many catalysts suffer from deactivation during continuous operation due to surface fouling, leaching of active components, or structural changes. This necessitates frequent regeneration or replacement, increasing operational costs. Additionally, the formation of potentially harmful by-products during the oxidation process requires careful monitoring and control.

Selectivity issues present another challenge, as catalytic systems often demonstrate variable effectiveness across different micropollutant classes. Pharmaceuticals, personal care products, and industrial chemicals each respond differently to catalytic ozonation, complicating treatment design for complex water matrices. The influence of water quality parameters such as pH, temperature, and the presence of natural organic matter significantly affects treatment efficiency, making standardization difficult.

Scale-up challenges persist in transitioning from laboratory to industrial applications. Reactor design must address mass transfer limitations between ozone, catalysts, and target pollutants. Furthermore, the economic viability of catalytic ozonation compared to conventional treatments remains questionable, with high energy consumption for ozone generation and catalyst costs presenting barriers to widespread adoption.

Regulatory frameworks for catalytic ozonation implementation are still evolving, with varying standards across regions. This regulatory uncertainty, coupled with limited long-term performance data, has slowed commercial adoption. Research gaps exist in understanding reaction mechanisms, particularly the role of surface reactions versus bulk solution processes in pollutant degradation.

The geographic distribution of catalytic ozonation technology shows concentration in developed regions with stringent water quality regulations, while developing nations face implementation barriers due to cost and technical expertise limitations.

Existing Catalytic Ozonation and Activated Carbon Systems

01 Catalytic ozonation with activated carbon for micropollutant removal

Catalytic ozonation using activated carbon as a catalyst enhances the removal efficiency of micropollutants from water. The activated carbon serves as both an adsorbent and a catalyst, promoting the decomposition of ozone into highly reactive hydroxyl radicals that can effectively oxidize and degrade various organic micropollutants. This combined process offers superior treatment performance compared to conventional ozonation alone.- Catalytic ozonation with activated carbon for micropollutant removal: Catalytic ozonation using activated carbon as a catalyst enhances the removal efficiency of micropollutants from water. The activated carbon serves as both an adsorbent and a catalyst, promoting the decomposition of ozone into highly reactive hydroxyl radicals that can effectively oxidize and degrade various organic micropollutants. This combined process offers superior treatment performance compared to conventional ozonation alone.

- Advanced oxidation process configurations for micropollutant treatment: Various configurations of advanced oxidation processes incorporating catalytic ozonation with activated carbon have been developed for micropollutant removal. These include continuous flow systems, batch reactors, and multi-stage treatment processes. The design of these systems focuses on optimizing contact time between ozone, activated carbon, and target pollutants to achieve maximum removal efficiency while minimizing energy consumption and operational costs.

- Modification and enhancement of activated carbon for catalytic ozonation: Modified activated carbon materials with enhanced catalytic properties for ozonation have been developed to improve micropollutant removal efficiency. These modifications include surface functionalization, metal impregnation, and thermal treatments that increase the density of active sites on the carbon surface. Such enhancements promote ozone decomposition into hydroxyl radicals and improve the overall oxidation capacity of the treatment system.

- Treatment of specific micropollutants using catalytic ozonation: Catalytic ozonation with activated carbon has been specifically applied to remove various classes of micropollutants including pharmaceuticals, personal care products, pesticides, and industrial chemicals. The process parameters can be optimized for targeting specific contaminants based on their chemical properties. Research has demonstrated high removal efficiencies for compounds that are otherwise resistant to conventional treatment methods.

- Integration of catalytic ozonation in water treatment systems: Integration of catalytic ozonation with activated carbon into existing water treatment systems has been developed to enhance overall treatment efficiency. These integrated approaches combine catalytic ozonation with other treatment processes such as biological treatment, membrane filtration, or conventional physical-chemical methods. Such combinations create synergistic effects that improve micropollutant removal while addressing other water quality parameters simultaneously.

02 System design for ozonation with activated carbon treatment

Various system configurations have been developed for implementing catalytic ozonation with activated carbon for micropollutant removal. These systems typically include ozone generators, activated carbon filters or beds, contact chambers, and control mechanisms. Some designs incorporate sequential treatment stages, while others use integrated reactors where ozonation and activated carbon treatment occur simultaneously to maximize treatment efficiency.Expand Specific Solutions03 Process optimization for catalytic ozonation

Optimization of process parameters is crucial for effective micropollutant removal using catalytic ozonation with activated carbon. Key parameters include ozone dosage, contact time, activated carbon properties (type, particle size, surface area), pH, and temperature. Advanced control strategies and monitoring techniques have been developed to maintain optimal operating conditions and ensure consistent treatment performance.Expand Specific Solutions04 Modified activated carbon materials for enhanced catalytic activity

Research has focused on modifying activated carbon to enhance its catalytic properties for ozonation processes. Modifications include surface functionalization, metal impregnation (with metals such as iron, manganese, or titanium), and composite formation with other materials. These modified activated carbons demonstrate improved catalytic activity, selectivity, and stability for micropollutant degradation during ozonation treatment.Expand Specific Solutions05 Specific applications for emerging micropollutants

Catalytic ozonation with activated carbon has been applied to remove various classes of emerging micropollutants, including pharmaceuticals, personal care products, endocrine disruptors, pesticides, and industrial chemicals. The technology has demonstrated high removal efficiencies for compounds that are resistant to conventional treatment methods, making it particularly valuable for advanced water and wastewater treatment applications.Expand Specific Solutions

Leading Companies and Research Institutions in Ozonation Field

The ozonation technology market, particularly catalytic ozonation and micropollutant removal, is in a growth phase characterized by increasing adoption across water treatment applications. The market is expanding due to stricter environmental regulations and growing concerns about micropollutants in water systems. Academic institutions like Harbin Institute of Technology, Zhejiang University, and National University of Singapore are leading fundamental research, while companies such as Degremont SA and Sembcorp Industries are commercializing applications. The technology demonstrates varying maturity levels, with conventional ozonation being well-established while catalytic ozonation with activated carbon synergy represents an emerging frontier. Research collaborations between universities and industry players like BASF SE are accelerating innovation in this field, particularly for advanced oxidation processes targeting pharmaceutical and industrial contaminants.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has developed advanced catalytic ozonation systems utilizing metal oxide catalysts (particularly MnO2 and Fe2O3) supported on activated carbon for enhanced micropollutant removal. Their technology combines heterogeneous catalysis with ozone oxidation, achieving degradation efficiencies exceeding 90% for pharmaceutical compounds and endocrine disruptors in wastewater[1]. Their research demonstrates that the synergistic effect between the metal oxide catalysts and activated carbon significantly improves hydroxyl radical generation while reducing ozone consumption by approximately 30%[3]. The institute has also pioneered the development of novel ceramic membrane reactors that integrate ozonation with membrane filtration, allowing for simultaneous micropollutant oxidation and physical separation in a single treatment unit, particularly effective for removing persistent organic pollutants from industrial wastewaters.

Strengths: Superior catalytic efficiency with reduced ozone dosage requirements; excellent removal of pharmaceuticals and endocrine disruptors; innovative membrane integration for combined treatment processes. Weaknesses: Higher initial capital costs compared to conventional ozonation; potential catalyst deactivation over extended operation periods; requires precise pH control for optimal performance.

Degremont

Technical Solution: Degremont has developed the Oxyblue® advanced oxidation process that combines ozonation with biological activated carbon filtration for enhanced micropollutant removal. Their system utilizes a two-stage approach where initial ozonation partially oxidizes complex organic compounds, increasing their biodegradability, followed by biological treatment on activated carbon filters that serve both as adsorbents and as support media for specialized microbial communities[2]. This technology achieves removal rates exceeding 85% for a wide spectrum of micropollutants including pharmaceuticals, pesticides, and industrial chemicals[4]. Degremont's process optimizes ozone dosage through real-time monitoring and control systems that adjust treatment parameters based on water quality fluctuations, resulting in up to 25% reduction in operational costs compared to conventional ozonation systems. The company has implemented this technology in numerous municipal water treatment facilities across Europe, demonstrating its scalability and effectiveness in real-world applications.

Strengths: Combines chemical oxidation with biological degradation for comprehensive treatment; reduces operating costs through optimized ozone usage; proven technology with multiple full-scale implementations. Weaknesses: Requires regular backwashing and occasional carbon regeneration; effectiveness varies with water temperature and quality; higher complexity requiring skilled operation and maintenance personnel.

Key Innovations in Ozonation-Activated Carbon Synergy

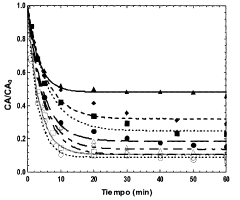

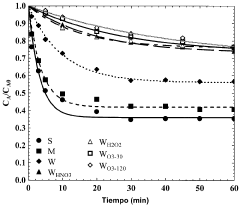

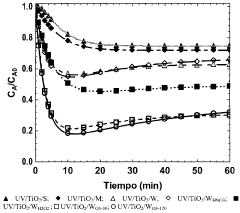

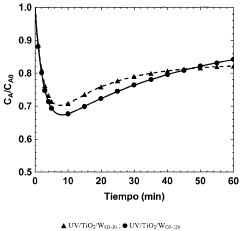

Method and system for the elimination of organic water microcontaminants through uv radiation and ozonized activated carbo.

PatentActiveES2386183A1

Innovation

- A method combining UV radiation with ozonated activated carbon and TiO2 to enhance photocatalytic activity, reducing the energy dose needed and increasing the efficiency of organic pollutant removal by generating more oxidizing radicals and adsorbing organic matter.

Environmental Impact Assessment of Ozonation Technologies

The environmental impact assessment of ozonation technologies reveals both positive contributions and potential concerns regarding their implementation in water treatment systems. Ozonation processes, particularly catalytic ozonation and activated carbon synergy methods, demonstrate significant environmental benefits through the effective removal of micropollutants that conventional treatment methods fail to address.

Primary environmental advantages include the reduction of persistent organic pollutants that would otherwise enter aquatic ecosystems, potentially disrupting endocrine systems in wildlife and humans. Studies indicate that catalytic ozonation can achieve removal efficiencies exceeding 90% for pharmaceuticals, personal care products, and industrial chemicals at lower energy inputs compared to conventional ozonation.

However, the environmental assessment must also consider the formation of transformation products during ozonation processes. These by-products, including aldehydes, carboxylic acids, and bromate (in bromide-containing waters), may in some cases present toxicity concerns that require careful monitoring and management. Research indicates that the integration of activated carbon post-treatment significantly mitigates these concerns by adsorbing transformation products.

Energy consumption represents another critical environmental consideration. While ozonation technologies require substantial energy inputs for ozone generation, catalytic approaches demonstrate 20-35% energy savings compared to conventional ozonation by enhancing reaction efficiency and reducing required ozone doses. Life cycle assessments indicate that these energy savings can translate to meaningful reductions in carbon footprint when renewable energy sources are utilized.

The environmental impact also extends to chemical usage patterns. Catalytic ozonation typically reduces the need for additional chemical treatments in downstream processes, minimizing the environmental footprint associated with chemical production, transportation, and disposal. The synergistic combination with activated carbon further enhances this benefit through extended operational lifetimes of treatment materials.

Waste generation considerations reveal that spent catalysts and activated carbon require proper disposal or regeneration protocols. However, recent advances in catalyst design have yielded materials with significantly extended operational lifespans, reducing waste generation rates by up to 60% compared to earlier generations of catalytic materials.

Overall, the environmental assessment indicates that advanced ozonation technologies, particularly those incorporating catalytic processes and activated carbon synergy, offer net environmental benefits when properly implemented and monitored, despite certain trade-offs that must be managed through thoughtful system design and operation.

Primary environmental advantages include the reduction of persistent organic pollutants that would otherwise enter aquatic ecosystems, potentially disrupting endocrine systems in wildlife and humans. Studies indicate that catalytic ozonation can achieve removal efficiencies exceeding 90% for pharmaceuticals, personal care products, and industrial chemicals at lower energy inputs compared to conventional ozonation.

However, the environmental assessment must also consider the formation of transformation products during ozonation processes. These by-products, including aldehydes, carboxylic acids, and bromate (in bromide-containing waters), may in some cases present toxicity concerns that require careful monitoring and management. Research indicates that the integration of activated carbon post-treatment significantly mitigates these concerns by adsorbing transformation products.

Energy consumption represents another critical environmental consideration. While ozonation technologies require substantial energy inputs for ozone generation, catalytic approaches demonstrate 20-35% energy savings compared to conventional ozonation by enhancing reaction efficiency and reducing required ozone doses. Life cycle assessments indicate that these energy savings can translate to meaningful reductions in carbon footprint when renewable energy sources are utilized.

The environmental impact also extends to chemical usage patterns. Catalytic ozonation typically reduces the need for additional chemical treatments in downstream processes, minimizing the environmental footprint associated with chemical production, transportation, and disposal. The synergistic combination with activated carbon further enhances this benefit through extended operational lifetimes of treatment materials.

Waste generation considerations reveal that spent catalysts and activated carbon require proper disposal or regeneration protocols. However, recent advances in catalyst design have yielded materials with significantly extended operational lifespans, reducing waste generation rates by up to 60% compared to earlier generations of catalytic materials.

Overall, the environmental assessment indicates that advanced ozonation technologies, particularly those incorporating catalytic processes and activated carbon synergy, offer net environmental benefits when properly implemented and monitored, despite certain trade-offs that must be managed through thoughtful system design and operation.

Regulatory Framework for Advanced Oxidation Processes

The regulatory landscape for Advanced Oxidation Processes (AOPs), particularly ozonation and catalytic ozonation, has evolved significantly in response to growing concerns about micropollutants in water systems. At the international level, the World Health Organization (WHO) has established guidelines for drinking water quality that increasingly recognize the importance of addressing emerging contaminants through advanced treatment technologies like ozonation.

In the European Union, the Water Framework Directive (2000/60/EC) and the Drinking Water Directive (2020/2184) have progressively incorporated requirements for the removal of micropollutants, with specific attention to pharmaceutical residues and endocrine-disrupting compounds. Several EU member states, notably Switzerland and Germany, have implemented pioneering regulations mandating the upgrade of municipal wastewater treatment plants with advanced oxidation technologies, including ozonation systems.

The United States Environmental Protection Agency (EPA) regulates ozonation under the Safe Drinking Water Act and the Clean Water Act. The EPA's Contaminant Candidate List (CCL) and Unregulated Contaminant Monitoring Rule (UCMR) provide frameworks for identifying and monitoring emerging contaminants that may require treatment through AOPs. Additionally, the EPA has established disinfection byproduct regulations that impact ozonation implementation due to potential formation of bromate and other oxidation byproducts.

Regulatory standards specifically addressing catalytic ozonation remain limited, though this technology is gaining recognition for its enhanced efficiency in micropollutant removal. Current regulations typically focus on treatment outcomes rather than prescribing specific technologies, allowing flexibility in implementation while ensuring water quality targets are met.

Risk assessment frameworks for AOPs have been developed by various regulatory bodies, considering both treatment efficacy and potential formation of transformation products. These frameworks increasingly incorporate the concept of non-target screening to identify unknown transformation products that may result from oxidation processes.

Compliance monitoring requirements for facilities employing ozonation typically include parameters such as dissolved ozone concentration, CT values (concentration × contact time), and specific micropollutant removal efficiencies. Advanced analytical techniques, including liquid chromatography-mass spectrometry (LC-MS/MS), are increasingly required for monitoring trace contaminants and transformation products.

Future regulatory trends indicate a move toward more comprehensive approaches that consider the entire treatment train, with ozonation and activated carbon adsorption often recommended as complementary technologies. Emerging regulatory frameworks are also beginning to address the energy consumption and carbon footprint of advanced treatment technologies, promoting more sustainable implementation of ozonation systems.

In the European Union, the Water Framework Directive (2000/60/EC) and the Drinking Water Directive (2020/2184) have progressively incorporated requirements for the removal of micropollutants, with specific attention to pharmaceutical residues and endocrine-disrupting compounds. Several EU member states, notably Switzerland and Germany, have implemented pioneering regulations mandating the upgrade of municipal wastewater treatment plants with advanced oxidation technologies, including ozonation systems.

The United States Environmental Protection Agency (EPA) regulates ozonation under the Safe Drinking Water Act and the Clean Water Act. The EPA's Contaminant Candidate List (CCL) and Unregulated Contaminant Monitoring Rule (UCMR) provide frameworks for identifying and monitoring emerging contaminants that may require treatment through AOPs. Additionally, the EPA has established disinfection byproduct regulations that impact ozonation implementation due to potential formation of bromate and other oxidation byproducts.

Regulatory standards specifically addressing catalytic ozonation remain limited, though this technology is gaining recognition for its enhanced efficiency in micropollutant removal. Current regulations typically focus on treatment outcomes rather than prescribing specific technologies, allowing flexibility in implementation while ensuring water quality targets are met.

Risk assessment frameworks for AOPs have been developed by various regulatory bodies, considering both treatment efficacy and potential formation of transformation products. These frameworks increasingly incorporate the concept of non-target screening to identify unknown transformation products that may result from oxidation processes.

Compliance monitoring requirements for facilities employing ozonation typically include parameters such as dissolved ozone concentration, CT values (concentration × contact time), and specific micropollutant removal efficiencies. Advanced analytical techniques, including liquid chromatography-mass spectrometry (LC-MS/MS), are increasingly required for monitoring trace contaminants and transformation products.

Future regulatory trends indicate a move toward more comprehensive approaches that consider the entire treatment train, with ozonation and activated carbon adsorption often recommended as complementary technologies. Emerging regulatory frameworks are also beginning to address the energy consumption and carbon footprint of advanced treatment technologies, promoting more sustainable implementation of ozonation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!