Ozonation: Head Loss, Foam/Entrained Gas And Degassing Designs

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation technology has evolved significantly since its first application in water treatment in the late 19th century. Initially used primarily for disinfection purposes, ozonation has expanded into various industrial and municipal applications due to its powerful oxidizing properties. The technology utilizes ozone (O₃), an unstable molecule consisting of three oxygen atoms, which readily decomposes to release nascent oxygen with exceptional oxidizing capabilities. This characteristic makes ozonation particularly effective for water and wastewater treatment, air purification, and numerous industrial processes.

The evolution of ozonation systems has been marked by continuous improvements in ozone generation methods, from early corona discharge techniques to modern advanced plasma and electrolytic systems. These advancements have significantly enhanced energy efficiency and ozone production rates, making the technology more economically viable across diverse applications. Parallel developments in materials science have addressed corrosion challenges associated with ozone's highly reactive nature, extending system lifespans and reliability.

Current technological trends in ozonation focus on optimizing hydraulic efficiency, managing gas-liquid interactions, and improving degassing designs. These aspects are critical as they directly impact system performance, energy consumption, and operational costs. Head loss considerations have become increasingly important as facilities seek to minimize pumping requirements and energy usage while maintaining effective ozone transfer rates. Similarly, foam and entrained gas management represents a significant challenge in ozonation systems, affecting both process efficiency and downstream operations.

The primary objectives of modern ozonation technology development center on addressing these hydraulic and gas management challenges. Specifically, the industry aims to develop innovative designs that minimize head loss through ozonation contactors while maintaining optimal contact time for reactions. Additionally, there is a pressing need for effective foam control strategies and entrained gas management to prevent operational issues such as pump cavitation, reduced treatment efficiency, and instrumentation interference.

Degassing design optimization represents another critical objective, focusing on efficiently removing excess ozone and other gases from treated water before distribution or subsequent treatment processes. This aspect is essential for both process efficiency and safety considerations, as residual ozone can cause materials degradation and potential health concerns if not properly managed.

The technological trajectory points toward integrated system designs that holistically address these interconnected challenges, leveraging computational fluid dynamics, advanced materials, and innovative contactor configurations to optimize hydraulic performance while effectively managing gas-liquid interactions throughout the treatment process.

The evolution of ozonation systems has been marked by continuous improvements in ozone generation methods, from early corona discharge techniques to modern advanced plasma and electrolytic systems. These advancements have significantly enhanced energy efficiency and ozone production rates, making the technology more economically viable across diverse applications. Parallel developments in materials science have addressed corrosion challenges associated with ozone's highly reactive nature, extending system lifespans and reliability.

Current technological trends in ozonation focus on optimizing hydraulic efficiency, managing gas-liquid interactions, and improving degassing designs. These aspects are critical as they directly impact system performance, energy consumption, and operational costs. Head loss considerations have become increasingly important as facilities seek to minimize pumping requirements and energy usage while maintaining effective ozone transfer rates. Similarly, foam and entrained gas management represents a significant challenge in ozonation systems, affecting both process efficiency and downstream operations.

The primary objectives of modern ozonation technology development center on addressing these hydraulic and gas management challenges. Specifically, the industry aims to develop innovative designs that minimize head loss through ozonation contactors while maintaining optimal contact time for reactions. Additionally, there is a pressing need for effective foam control strategies and entrained gas management to prevent operational issues such as pump cavitation, reduced treatment efficiency, and instrumentation interference.

Degassing design optimization represents another critical objective, focusing on efficiently removing excess ozone and other gases from treated water before distribution or subsequent treatment processes. This aspect is essential for both process efficiency and safety considerations, as residual ozone can cause materials degradation and potential health concerns if not properly managed.

The technological trajectory points toward integrated system designs that holistically address these interconnected challenges, leveraging computational fluid dynamics, advanced materials, and innovative contactor configurations to optimize hydraulic performance while effectively managing gas-liquid interactions throughout the treatment process.

Market Demand Analysis for Advanced Ozonation Systems

The global market for advanced ozonation systems is experiencing significant growth, driven by increasing concerns about water quality and stringent environmental regulations. The water treatment sector represents the largest market segment, with municipal water treatment facilities investing heavily in ozonation technology to address emerging contaminants and disinfection byproduct regulations. Current market estimates value the global ozonation equipment market at approximately $1.5 billion, with projected annual growth rates of 6-8% through 2028.

Industrial applications constitute the fastest-growing segment, particularly in pharmaceuticals, food and beverage processing, and semiconductor manufacturing. These industries require ultra-pure water and are increasingly adopting ozonation as a chemical-free treatment alternative. The Asia-Pacific region, especially China and India, demonstrates the highest growth potential due to rapid industrialization and increasing water quality concerns.

Market research indicates specific demand drivers for advanced ozonation systems that address head loss reduction, foam management, and efficient degassing designs. Facilities operating at higher capacities face significant operational challenges with traditional ozonation systems, creating market opportunities for optimized designs. Surveys of water treatment plant operators reveal that 72% consider head loss a critical factor in equipment selection, while 65% report foam and entrained gas management as significant operational challenges.

Energy efficiency has emerged as a primary market demand factor, with utilities seeking solutions that minimize pumping costs associated with head loss. Systems that can reduce head loss by 20-30% compared to conventional designs command premium pricing in the market. Similarly, facilities processing waters with high organic content require effective foam management capabilities to maintain operational efficiency.

The municipal sector demonstrates particular sensitivity to lifecycle costs rather than initial capital expenditure, creating market opportunities for advanced systems with demonstrable operational savings. Conversely, industrial users prioritize performance consistency and minimal downtime, willing to invest in premium solutions that offer superior degassing efficiency and foam control.

Market analysis reveals a significant gap between current technology offerings and end-user requirements, particularly in integrated systems that simultaneously address head loss, foam management, and degassing. This represents a substantial market opportunity for manufacturers who can develop comprehensive solutions that optimize all three parameters while maintaining treatment efficacy.

Industrial applications constitute the fastest-growing segment, particularly in pharmaceuticals, food and beverage processing, and semiconductor manufacturing. These industries require ultra-pure water and are increasingly adopting ozonation as a chemical-free treatment alternative. The Asia-Pacific region, especially China and India, demonstrates the highest growth potential due to rapid industrialization and increasing water quality concerns.

Market research indicates specific demand drivers for advanced ozonation systems that address head loss reduction, foam management, and efficient degassing designs. Facilities operating at higher capacities face significant operational challenges with traditional ozonation systems, creating market opportunities for optimized designs. Surveys of water treatment plant operators reveal that 72% consider head loss a critical factor in equipment selection, while 65% report foam and entrained gas management as significant operational challenges.

Energy efficiency has emerged as a primary market demand factor, with utilities seeking solutions that minimize pumping costs associated with head loss. Systems that can reduce head loss by 20-30% compared to conventional designs command premium pricing in the market. Similarly, facilities processing waters with high organic content require effective foam management capabilities to maintain operational efficiency.

The municipal sector demonstrates particular sensitivity to lifecycle costs rather than initial capital expenditure, creating market opportunities for advanced systems with demonstrable operational savings. Conversely, industrial users prioritize performance consistency and minimal downtime, willing to invest in premium solutions that offer superior degassing efficiency and foam control.

Market analysis reveals a significant gap between current technology offerings and end-user requirements, particularly in integrated systems that simultaneously address head loss, foam management, and degassing. This represents a substantial market opportunity for manufacturers who can develop comprehensive solutions that optimize all three parameters while maintaining treatment efficacy.

Current Challenges in Ozonation: Head Loss and Gas Entrainment

Ozonation systems face significant operational challenges related to head loss and gas entrainment that impact both efficiency and effectiveness. Head loss in ozonation systems occurs primarily at injection points, contact chambers, and degassing units, creating pressure drops that necessitate additional energy input. This phenomenon is particularly problematic in systems with high flow rates or complex piping configurations, where friction losses compound throughout the treatment train.

The relationship between gas-to-liquid ratio and head loss presents a critical design consideration. As ozone dosage increases, the volume of gas introduced into the system rises proportionally, exacerbating head loss issues. Engineers must carefully balance treatment efficacy against hydraulic efficiency, often requiring sophisticated computational fluid dynamics modeling to optimize system design.

Gas entrainment represents another significant challenge in ozonation processes. When ozone gas is introduced into water, not all gas dissolves immediately, resulting in entrained gas bubbles that can cause several operational problems. These include reduced contact efficiency between ozone and target contaminants, increased turbulence affecting hydraulic performance, and potential damage to downstream equipment such as pumps and valves due to cavitation.

Foam formation at the water surface in contact tanks presents additional complications. Excessive foam can overflow containment structures, creating safety hazards and potential environmental concerns. The foam typically contains concentrated ozone, posing both corrosion risks to nearby equipment and health hazards to operators. Current foam control strategies include mechanical skimmers, chemical anti-foaming agents, and specialized tank designs with enhanced freeboard, though each approach introduces its own set of operational complexities.

Degassing efficiency remains a persistent challenge in ozonation systems. Inadequate removal of excess gas can lead to dissolved gas supersaturation, which may cause gas bubble formation in downstream processes. This phenomenon can interfere with filtration processes, reduce UV transmittance in disinfection systems, and create air binding in granular media filters. Modern degassing designs must balance effective gas removal against space constraints and energy consumption.

The interplay between these challenges is particularly evident in advanced oxidation processes where higher ozone doses are required. Engineers must consider the cumulative effects of head loss across treatment trains while simultaneously addressing gas entrainment issues. Recent research indicates that up to 30% of operational inefficiencies in ozonation systems can be attributed to suboptimal management of these hydraulic and gas-related challenges.

The relationship between gas-to-liquid ratio and head loss presents a critical design consideration. As ozone dosage increases, the volume of gas introduced into the system rises proportionally, exacerbating head loss issues. Engineers must carefully balance treatment efficacy against hydraulic efficiency, often requiring sophisticated computational fluid dynamics modeling to optimize system design.

Gas entrainment represents another significant challenge in ozonation processes. When ozone gas is introduced into water, not all gas dissolves immediately, resulting in entrained gas bubbles that can cause several operational problems. These include reduced contact efficiency between ozone and target contaminants, increased turbulence affecting hydraulic performance, and potential damage to downstream equipment such as pumps and valves due to cavitation.

Foam formation at the water surface in contact tanks presents additional complications. Excessive foam can overflow containment structures, creating safety hazards and potential environmental concerns. The foam typically contains concentrated ozone, posing both corrosion risks to nearby equipment and health hazards to operators. Current foam control strategies include mechanical skimmers, chemical anti-foaming agents, and specialized tank designs with enhanced freeboard, though each approach introduces its own set of operational complexities.

Degassing efficiency remains a persistent challenge in ozonation systems. Inadequate removal of excess gas can lead to dissolved gas supersaturation, which may cause gas bubble formation in downstream processes. This phenomenon can interfere with filtration processes, reduce UV transmittance in disinfection systems, and create air binding in granular media filters. Modern degassing designs must balance effective gas removal against space constraints and energy consumption.

The interplay between these challenges is particularly evident in advanced oxidation processes where higher ozone doses are required. Engineers must consider the cumulative effects of head loss across treatment trains while simultaneously addressing gas entrainment issues. Recent research indicates that up to 30% of operational inefficiencies in ozonation systems can be attributed to suboptimal management of these hydraulic and gas-related challenges.

Current Engineering Solutions for Ozonation Head Loss Reduction

01 Ozonation systems with foam/gas management

Ozonation systems incorporate specialized components to manage foam and entrained gas issues that can affect treatment efficiency. These systems include foam separators, gas venting mechanisms, and bubble control devices that help maintain optimal ozone contact with water while preventing foam accumulation. The designs focus on reducing turbulence and providing controlled pathways for gas release, which minimizes head loss while ensuring effective ozone treatment.- Ozonation systems with foam/gas management: Ozonation systems often face challenges with foam and entrained gas that can affect system efficiency. These systems incorporate specialized components to manage foam formation and control entrained gas during the ozonation process. The designs include foam separators, gas venting mechanisms, and circulation pathways that minimize foam-related issues while maintaining effective ozone treatment of liquids.

- Head loss measurement and monitoring in fluid systems: Measuring and monitoring head loss is critical in ozonation systems to ensure optimal performance. Various technologies have been developed to accurately measure pressure differentials and flow characteristics in systems where gas entrainment occurs. These measurement systems help operators maintain proper system function by detecting changes in head loss that might indicate foam formation, gas entrainment issues, or other operational problems.

- Gas-liquid separation techniques for ozonation processes: Effective separation of gas from liquid phases is essential in ozonation systems to prevent head loss and system inefficiencies. Technologies include specialized separation chambers, degassing devices, and vortex separators that remove entrained gas bubbles from the liquid stream. These separation techniques help maintain consistent flow rates, reduce pressure fluctuations, and ensure proper contact between ozone and the target substances.

- Flow control systems to minimize foam and entrained gas effects: Advanced flow control systems have been developed to address the challenges of foam and entrained gas in ozonation processes. These systems incorporate specialized valves, flow regulators, and monitoring equipment that adjust operational parameters based on detected foam or gas levels. By maintaining optimal flow conditions, these systems minimize head loss while ensuring effective ozone treatment and reducing energy consumption.

- Ozone contacting vessel design for reduced head loss: The design of ozone contacting vessels significantly impacts head loss and gas entrainment issues. Innovative vessel configurations incorporate features such as baffles, specialized diffusers, and optimized geometry to enhance ozone transfer efficiency while minimizing foam formation and head loss. These designs consider fluid dynamics principles to create ideal mixing conditions while preventing excessive turbulence that could lead to problematic foam or gas entrainment.

02 Head loss measurement and monitoring in ozone treatment systems

Specialized instrumentation and methods are employed to measure and monitor head loss in ozonation processes. These include differential pressure sensors, flow meters, and automated monitoring systems that can detect changes in pressure gradients caused by entrained gas or foam formation. Continuous monitoring allows for real-time adjustments to system parameters, helping to maintain optimal flow conditions and prevent excessive head loss that could reduce treatment efficiency.Expand Specific Solutions03 Degassing techniques for ozonation processes

Various degassing techniques are implemented in ozonation systems to remove excess gas and reduce head loss. These include vacuum degassing chambers, mechanical degassing devices, and specialized column designs that facilitate the separation of entrained gas from liquid. By effectively removing gas bubbles from the treatment stream, these techniques help maintain consistent flow patterns and reduce the pressure drops associated with two-phase flow conditions.Expand Specific Solutions04 Fluid flow control in ozone contacting systems

Advanced fluid flow control mechanisms are designed to optimize ozone distribution while minimizing head loss and foam formation. These include specialized diffusers, flow distributors, and hydraulic control systems that create ideal mixing conditions while preventing excessive turbulence. The controlled introduction of ozone gas into water streams helps maintain uniform distribution while reducing the formation of foam and minimizing pressure losses throughout the treatment system.Expand Specific Solutions05 Foam suppression and anti-foaming strategies in ozonation

Various foam suppression techniques are employed in ozonation systems to prevent foam accumulation and associated head loss. These include mechanical foam breakers, chemical anti-foaming agents, and specialized tank designs that provide sufficient freeboard for foam management. Some systems incorporate automated foam detection and suppression mechanisms that activate when foam levels exceed predetermined thresholds, ensuring continuous operation without excessive pressure drops or reduced treatment efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ozonation

The ozonation technology market is currently in a growth phase, characterized by increasing adoption across water treatment, industrial processes, and environmental applications. The global market size is estimated to be expanding at a CAGR of 6-8%, driven by stringent water quality regulations and growing environmental concerns. Technologically, solutions addressing head loss, foam management, and degassing designs are advancing toward maturity, with companies like Adaptive Ozone Solutions and DuPont de Nemours leading innovation in specialized applications. Research institutions including Centre National de la Recherche Scientifique and Harbin Institute of Technology are contributing significant advancements in fundamental research. Industrial players such as Hitachi, Toshiba, and Mitsubishi Electric are integrating ozonation technologies into comprehensive water treatment systems, while specialized firms like IHI Logistics & Machinery and Ebara Corporation focus on equipment optimization for reduced energy consumption and improved efficiency.

Adaptive Ozone Solutions

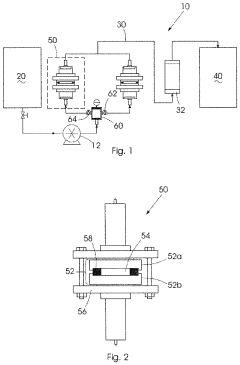

Technical Solution: Adaptive Ozone Solutions has developed advanced ozonation systems specifically addressing head loss and degassing challenges in water treatment applications. Their proprietary Venturi injection technology creates micro-bubbles that maximize ozone transfer efficiency while minimizing head loss in the treatment process. The company's systems incorporate specialized degassing chambers with optimized hydraulic designs that effectively remove entrained gases post-ozonation, preventing downstream operational issues. Their foam management technology utilizes automated sensing and control systems that detect foam formation and adjust ozone dosing and water flow parameters in real-time to mitigate excessive foaming. Additionally, they've engineered modular ozonation units with integrated degassing components that reduce system footprint while maintaining treatment efficacy across varying flow rates and contaminant loads.

Strengths: Highly specialized in ozone applications with purpose-built solutions for gas management challenges; systems offer excellent automation and control features for foam prevention. Weaknesses: Potentially higher initial capital costs compared to conventional systems; may require more specialized maintenance expertise than simpler treatment technologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has engineered comprehensive ozonation solutions addressing the critical challenges of head loss, foam management, and degassing in water treatment applications. Their systems feature advanced contactor designs that optimize hydraulic conditions to minimize pressure drops while maximizing ozone transfer efficiency. DuPont's proprietary bubble diffusion technology creates uniform micro-bubbles (typically 0.5-2mm diameter) that enhance mass transfer while reducing the formation of problematic foam. For degassing, they've developed multi-stage separation systems incorporating both mechanical and membrane-based technologies that effectively remove entrained gases to prevent downstream equipment damage and process disruptions. Their foam management approach combines preventative design elements with reactive control measures, including specialized surfactants that modify bubble surface tension properties and automated foam detection systems that trigger corrective actions when excessive foam formation occurs. DuPont's integrated control systems continuously monitor key parameters including dissolved ozone concentration, pressure differentials, and gas flow rates to maintain optimal performance across varying operational conditions.

Strengths: Extensive materials science expertise applied to component design and selection; comprehensive approach addressing multiple aspects of ozonation challenges simultaneously. Weaknesses: Solutions may be chemically complex, potentially introducing additional operational considerations; systems typically designed for larger industrial applications rather than small-scale implementations.

Key Technical Innovations in Foam Control and Degassing Design

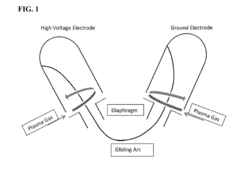

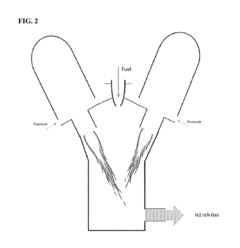

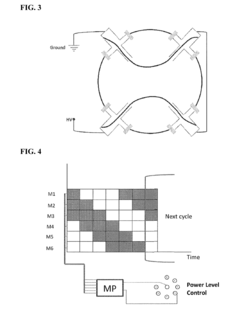

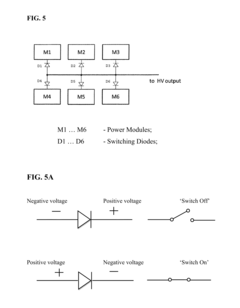

Fluid treatment using plasma technology

PatentActiveUS20150274554A1

Innovation

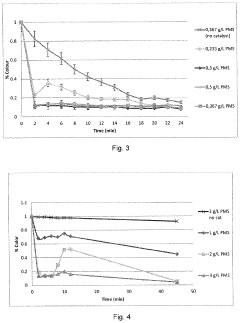

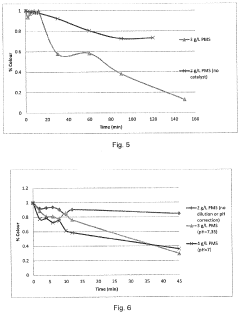

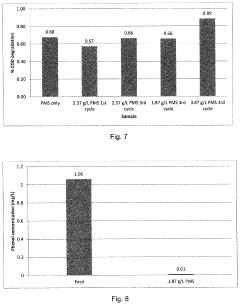

- A plasma-based water treatment system that uses a pulsed plasma discharge generated by a suitable electrode configuration to inactivate microorganisms in water, producing UV radiation, active chemical species, and shock waves, which are effective in deactivating microorganisms without the drawbacks of traditional methods.

Fluid treatment process

PatentInactiveUS20200331781A1

Innovation

- A continuous process utilizing a replaceable permeable reaction barrier loaded with a transition metal compound like Co3O4, which acts as an oxidizing agent activator, is introduced to treat contaminated fluids by contacting them with oxidizing agents like peroxymonosulfate, allowing for efficient degradation of organic contaminants without the need for catalyst removal or sludge production.

Environmental Impact and Sustainability of Ozonation Processes

Ozonation processes, while effective for water and wastewater treatment, present significant environmental considerations that must be addressed for sustainable implementation. The environmental footprint of ozonation systems is primarily influenced by energy consumption, which varies based on system design efficiency, particularly in head loss management and degassing operations.

Energy consumption represents the most substantial environmental impact of ozonation processes. Traditional ozonation systems require considerable electricity for ozone generation, with energy requirements typically ranging from 10-15 kWh per kg of ozone produced. Systems with poorly designed hydraulics resulting in excessive head loss can further increase pumping energy requirements by 15-30%, significantly affecting the carbon footprint of the treatment process.

Foam formation and entrained gas management also contribute to environmental considerations. Inefficient gas-liquid contact systems can result in off-gassing of unreacted ozone, which must be captured and destroyed to prevent atmospheric release. Modern degassing designs have improved capture efficiency to over 95%, substantially reducing potential atmospheric ozone emissions compared to earlier systems that achieved only 70-80% capture rates.

The sustainability profile of ozonation has improved significantly through technological advancements. Integration of renewable energy sources for ozone generation can reduce greenhouse gas emissions by up to 60% compared to conventional grid-powered systems. Additionally, energy recovery systems that capture pressure energy from degassing chambers can improve overall energy efficiency by 5-10% in large-scale installations.

Life cycle assessments of modern ozonation systems with optimized head loss management and efficient degassing designs demonstrate favorable environmental performance compared to alternative disinfection methods. These systems typically show 20-30% lower global warming potential than chlorination processes when considering full life cycle impacts, primarily due to the elimination of chemical transportation and storage requirements.

Water quality benefits further enhance the environmental value proposition of ozonation. By reducing disinfection byproducts by 40-70% compared to chlorination, ozonation minimizes potential ecological impacts in receiving waters. The improved biodegradability of organic compounds after ozonation also enhances downstream biological treatment efficiency, reducing overall system energy requirements by 5-15% in integrated treatment trains.

Future sustainability improvements in ozonation technology focus on developing low-pressure drop contactors, advanced foam control mechanisms, and energy-efficient degassing systems. Research indicates potential energy efficiency improvements of 15-25% through next-generation designs that optimize hydraulic profiles and gas transfer efficiency while minimizing head loss throughout the treatment process.

Energy consumption represents the most substantial environmental impact of ozonation processes. Traditional ozonation systems require considerable electricity for ozone generation, with energy requirements typically ranging from 10-15 kWh per kg of ozone produced. Systems with poorly designed hydraulics resulting in excessive head loss can further increase pumping energy requirements by 15-30%, significantly affecting the carbon footprint of the treatment process.

Foam formation and entrained gas management also contribute to environmental considerations. Inefficient gas-liquid contact systems can result in off-gassing of unreacted ozone, which must be captured and destroyed to prevent atmospheric release. Modern degassing designs have improved capture efficiency to over 95%, substantially reducing potential atmospheric ozone emissions compared to earlier systems that achieved only 70-80% capture rates.

The sustainability profile of ozonation has improved significantly through technological advancements. Integration of renewable energy sources for ozone generation can reduce greenhouse gas emissions by up to 60% compared to conventional grid-powered systems. Additionally, energy recovery systems that capture pressure energy from degassing chambers can improve overall energy efficiency by 5-10% in large-scale installations.

Life cycle assessments of modern ozonation systems with optimized head loss management and efficient degassing designs demonstrate favorable environmental performance compared to alternative disinfection methods. These systems typically show 20-30% lower global warming potential than chlorination processes when considering full life cycle impacts, primarily due to the elimination of chemical transportation and storage requirements.

Water quality benefits further enhance the environmental value proposition of ozonation. By reducing disinfection byproducts by 40-70% compared to chlorination, ozonation minimizes potential ecological impacts in receiving waters. The improved biodegradability of organic compounds after ozonation also enhances downstream biological treatment efficiency, reducing overall system energy requirements by 5-15% in integrated treatment trains.

Future sustainability improvements in ozonation technology focus on developing low-pressure drop contactors, advanced foam control mechanisms, and energy-efficient degassing systems. Research indicates potential energy efficiency improvements of 15-25% through next-generation designs that optimize hydraulic profiles and gas transfer efficiency while minimizing head loss throughout the treatment process.

Regulatory Framework and Compliance Standards for Ozonation

The regulatory landscape for ozonation technologies is complex and multifaceted, encompassing various international, national, and local standards that govern the implementation and operation of ozone treatment systems. The United States Environmental Protection Agency (EPA) has established comprehensive guidelines under the Safe Drinking Water Act, specifically addressing disinfection byproducts (DBPs) through the Stage 1 and Stage 2 Disinfectants and Disinfection Byproducts Rules. These regulations set maximum contaminant levels for bromate, a significant byproduct of ozonation, at 10 μg/L.

In the European Union, the Drinking Water Directive (98/83/EC, updated in 2020) provides the regulatory framework for ozonation processes, with specific attention to ozone dosage, contact time, and residual management. The directive emphasizes the importance of proper degassing designs to minimize dissolved ozone in treated water, setting the maximum allowable concentration at 50 μg/L.

The World Health Organization's Guidelines for Drinking-water Quality serve as an international benchmark, recommending ozonation parameters and addressing foam management concerns in treatment facilities. These guidelines emphasize the importance of proper hydraulic design to minimize head loss while ensuring adequate contact time for effective disinfection.

Industry-specific standards from organizations such as the International Ozone Association (IOA) and the American Water Works Association (AWWA) provide detailed technical specifications for ozonation equipment, including requirements for gas entrainment prevention and foam control mechanisms. AWWA Standard B304-18 specifically addresses ozone systems for water treatment, detailing requirements for system components, safety measures, and operational parameters.

Occupational safety regulations, including OSHA standards in the United States and similar frameworks internationally, govern workplace exposure limits for ozone (typically 0.1 ppm for an 8-hour time-weighted average) and mandate specific safety protocols for handling entrained gases and potential foam incidents.

Compliance monitoring requirements vary by jurisdiction but typically include continuous monitoring of ozone concentration, residual levels, and hydraulic parameters related to head loss. The NSF/ANSI 61 standard specifically addresses materials compatibility in ozonation systems, ensuring that components do not leach harmful substances into treated water.

Emerging regulations increasingly focus on energy efficiency and environmental impact, with some jurisdictions implementing carbon footprint considerations for treatment technologies. These evolving standards are driving innovation in degassing designs and foam management strategies to optimize both treatment efficacy and operational sustainability.

In the European Union, the Drinking Water Directive (98/83/EC, updated in 2020) provides the regulatory framework for ozonation processes, with specific attention to ozone dosage, contact time, and residual management. The directive emphasizes the importance of proper degassing designs to minimize dissolved ozone in treated water, setting the maximum allowable concentration at 50 μg/L.

The World Health Organization's Guidelines for Drinking-water Quality serve as an international benchmark, recommending ozonation parameters and addressing foam management concerns in treatment facilities. These guidelines emphasize the importance of proper hydraulic design to minimize head loss while ensuring adequate contact time for effective disinfection.

Industry-specific standards from organizations such as the International Ozone Association (IOA) and the American Water Works Association (AWWA) provide detailed technical specifications for ozonation equipment, including requirements for gas entrainment prevention and foam control mechanisms. AWWA Standard B304-18 specifically addresses ozone systems for water treatment, detailing requirements for system components, safety measures, and operational parameters.

Occupational safety regulations, including OSHA standards in the United States and similar frameworks internationally, govern workplace exposure limits for ozone (typically 0.1 ppm for an 8-hour time-weighted average) and mandate specific safety protocols for handling entrained gases and potential foam incidents.

Compliance monitoring requirements vary by jurisdiction but typically include continuous monitoring of ozone concentration, residual levels, and hydraulic parameters related to head loss. The NSF/ANSI 61 standard specifically addresses materials compatibility in ozonation systems, ensuring that components do not leach harmful substances into treated water.

Emerging regulations increasingly focus on energy efficiency and environmental impact, with some jurisdictions implementing carbon footprint considerations for treatment technologies. These evolving standards are driving innovation in degassing designs and foam management strategies to optimize both treatment efficacy and operational sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!