How Ozonation Minimizes AOC Formation To Reduce Downstream Biofouling?

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation Technology Background and Objectives

Ozonation has emerged as a critical water treatment technology since its first large-scale application in Nice, France in 1906. The evolution of this technology has been marked by significant advancements in understanding its chemical mechanisms and optimizing its application parameters. Initially utilized primarily for disinfection purposes, ozonation has expanded its role to address a variety of water quality challenges, including the management of assimilable organic carbon (AOC) formation and subsequent biofouling issues in water distribution systems.

The fundamental principle of ozonation involves the generation of ozone (O₃) through electrical discharge in oxygen-containing gas, followed by its dissolution into water where it acts as a powerful oxidant. This process has demonstrated remarkable efficacy in breaking down complex organic compounds into simpler, more biodegradable forms. However, this very transformation presents a paradox in water treatment: while ozonation effectively eliminates pathogens and reduces certain contaminants, it can simultaneously increase AOC levels, potentially exacerbating downstream biofouling challenges.

Recent technological developments have focused on optimizing ozonation parameters to minimize this counterproductive AOC formation while maintaining disinfection efficacy. Advanced ozone generation systems now achieve higher concentration outputs with lower energy consumption, while improved dissolution methods ensure more efficient transfer of ozone into water matrices. Concurrent developments in real-time monitoring technologies have enabled more precise control of ozone dosing based on water quality parameters, moving the industry toward a more responsive and efficient application paradigm.

The primary objective of contemporary ozonation research centers on establishing the optimal balance between effective oxidation of contaminants and minimization of AOC formation. This involves investigating the complex relationship between ozone dose, contact time, water quality characteristics, and the resulting AOC profiles. Additional research aims to develop integrated treatment approaches that couple ozonation with complementary technologies such as biological filtration, advanced oxidation processes, or membrane filtration to mitigate the biofouling potential of ozonated water.

The technological trajectory points toward more sophisticated, automated ozonation systems capable of adapting to fluctuating water quality conditions in real-time. These systems aim to maintain the beneficial aspects of ozonation while simultaneously addressing the challenges associated with AOC formation. The ultimate goal is to develop a comprehensive understanding of the mechanisms by which ozonation influences AOC levels and to leverage this knowledge to design treatment strategies that effectively control biofouling throughout water distribution networks.

The fundamental principle of ozonation involves the generation of ozone (O₃) through electrical discharge in oxygen-containing gas, followed by its dissolution into water where it acts as a powerful oxidant. This process has demonstrated remarkable efficacy in breaking down complex organic compounds into simpler, more biodegradable forms. However, this very transformation presents a paradox in water treatment: while ozonation effectively eliminates pathogens and reduces certain contaminants, it can simultaneously increase AOC levels, potentially exacerbating downstream biofouling challenges.

Recent technological developments have focused on optimizing ozonation parameters to minimize this counterproductive AOC formation while maintaining disinfection efficacy. Advanced ozone generation systems now achieve higher concentration outputs with lower energy consumption, while improved dissolution methods ensure more efficient transfer of ozone into water matrices. Concurrent developments in real-time monitoring technologies have enabled more precise control of ozone dosing based on water quality parameters, moving the industry toward a more responsive and efficient application paradigm.

The primary objective of contemporary ozonation research centers on establishing the optimal balance between effective oxidation of contaminants and minimization of AOC formation. This involves investigating the complex relationship between ozone dose, contact time, water quality characteristics, and the resulting AOC profiles. Additional research aims to develop integrated treatment approaches that couple ozonation with complementary technologies such as biological filtration, advanced oxidation processes, or membrane filtration to mitigate the biofouling potential of ozonated water.

The technological trajectory points toward more sophisticated, automated ozonation systems capable of adapting to fluctuating water quality conditions in real-time. These systems aim to maintain the beneficial aspects of ozonation while simultaneously addressing the challenges associated with AOC formation. The ultimate goal is to develop a comprehensive understanding of the mechanisms by which ozonation influences AOC levels and to leverage this knowledge to design treatment strategies that effectively control biofouling throughout water distribution networks.

Market Demand for Biofouling Control Solutions

The global market for biofouling control solutions has experienced significant growth in recent years, driven primarily by increasing water scarcity concerns and stricter regulations on water quality. The demand for effective biofouling control technologies, particularly those involving ozonation processes, has seen a compound annual growth rate of approximately 6.8% between 2018 and 2023, with projections indicating continued expansion through 2030.

Water treatment facilities represent the largest market segment, accounting for roughly 42% of the total demand for biofouling control solutions. These facilities face persistent challenges with membrane fouling and system efficiency degradation, creating substantial operational costs estimated at $4.5 billion annually worldwide. The implementation of advanced ozonation techniques has demonstrated potential to reduce these maintenance costs by 15-30%, presenting a compelling value proposition for facility operators.

Industrial applications constitute the second-largest market segment, particularly in sectors such as power generation, food and beverage processing, and pharmaceutical manufacturing. These industries require high-purity water and face significant economic impacts from biofouling-related downtime. Market research indicates that companies in these sectors are increasingly willing to invest in preventative technologies rather than reactive maintenance, with average budget allocations for water treatment technologies increasing by 12% over the past three years.

The healthcare sector represents an emerging market with rapidly growing demand, particularly in hospital water systems where biofilm formation can harbor dangerous pathogens. This segment has shown the highest growth rate at 9.3% annually, driven by heightened awareness of healthcare-associated infections and their relationship to water system contamination.

Geographically, North America and Europe currently dominate the market for advanced biofouling control solutions, collectively representing approximately 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily driven by rapid industrialization, increasing water stress, and substantial investments in water infrastructure modernization in countries like China, India, and Singapore.

Consumer awareness regarding water quality has also contributed to market expansion, with surveys indicating that 67% of consumers in developed markets express concerns about water contaminants. This awareness has created downstream pressure on utilities and manufacturers to adopt more effective water treatment technologies, including advanced oxidation processes like ozonation.

The market landscape is further shaped by increasing regulatory pressure, with environmental protection agencies worldwide implementing stricter guidelines for water discharge quality and disinfection byproduct formation. These regulatory frameworks have accelerated the adoption of technologies that can effectively control biofouling while minimizing harmful byproducts.

Water treatment facilities represent the largest market segment, accounting for roughly 42% of the total demand for biofouling control solutions. These facilities face persistent challenges with membrane fouling and system efficiency degradation, creating substantial operational costs estimated at $4.5 billion annually worldwide. The implementation of advanced ozonation techniques has demonstrated potential to reduce these maintenance costs by 15-30%, presenting a compelling value proposition for facility operators.

Industrial applications constitute the second-largest market segment, particularly in sectors such as power generation, food and beverage processing, and pharmaceutical manufacturing. These industries require high-purity water and face significant economic impacts from biofouling-related downtime. Market research indicates that companies in these sectors are increasingly willing to invest in preventative technologies rather than reactive maintenance, with average budget allocations for water treatment technologies increasing by 12% over the past three years.

The healthcare sector represents an emerging market with rapidly growing demand, particularly in hospital water systems where biofilm formation can harbor dangerous pathogens. This segment has shown the highest growth rate at 9.3% annually, driven by heightened awareness of healthcare-associated infections and their relationship to water system contamination.

Geographically, North America and Europe currently dominate the market for advanced biofouling control solutions, collectively representing approximately 58% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily driven by rapid industrialization, increasing water stress, and substantial investments in water infrastructure modernization in countries like China, India, and Singapore.

Consumer awareness regarding water quality has also contributed to market expansion, with surveys indicating that 67% of consumers in developed markets express concerns about water contaminants. This awareness has created downstream pressure on utilities and manufacturers to adopt more effective water treatment technologies, including advanced oxidation processes like ozonation.

The market landscape is further shaped by increasing regulatory pressure, with environmental protection agencies worldwide implementing stricter guidelines for water discharge quality and disinfection byproduct formation. These regulatory frameworks have accelerated the adoption of technologies that can effectively control biofouling while minimizing harmful byproducts.

Current Challenges in AOC Formation Management

Despite significant advancements in water treatment technologies, managing Assimilable Organic Carbon (AOC) formation remains a persistent challenge in water treatment systems. AOC, consisting of low molecular weight organic compounds readily utilized by microorganisms, serves as a primary nutrient source for biofilm development, leading to biofouling issues throughout distribution networks and membrane systems.

The primary challenge in AOC management lies in the paradoxical relationship between oxidation treatments and AOC formation. While ozonation effectively eliminates pathogens and breaks down complex organic compounds, it simultaneously converts recalcitrant natural organic matter (NOM) into more biodegradable forms, potentially increasing AOC concentrations by 30-300% depending on source water characteristics and treatment conditions.

Water treatment facilities face significant difficulties in real-time monitoring of AOC levels. Current analytical methods require specialized laboratory equipment, trained personnel, and extended incubation periods (3-14 days), making immediate operational adjustments nearly impossible. This monitoring gap creates uncertainty in treatment efficacy and complicates optimization efforts for downstream biofouling control.

The variability in source water quality presents another substantial challenge. Seasonal fluctuations, weather events, and anthropogenic activities significantly alter NOM composition and concentration, requiring continuous adjustment of ozonation parameters. Treatment facilities often lack predictive models to anticipate these changes, resulting in either insufficient treatment or excessive AOC formation.

Balancing disinfection requirements with AOC minimization creates operational dilemmas. Regulatory compliance mandates specific disinfection targets, often necessitating oxidant doses that inevitably increase AOC production. This regulatory-operational conflict forces utilities to choose between meeting disinfection requirements and managing downstream biofouling risks.

The integration of ozonation with biological filtration systems presents technical challenges in process optimization. Achieving the ideal balance between ozone dose, contact time, and biological treatment capacity requires sophisticated control systems and operational expertise often unavailable in smaller utilities. Suboptimal integration results in incomplete AOC removal and persistent biofouling issues.

Economic constraints further complicate AOC management strategies. Implementing comprehensive solutions involving advanced oxidation processes, enhanced biological filtration, and membrane technologies requires substantial capital investment and increased operational costs. Many utilities, particularly in developing regions, lack the financial resources to implement these multi-barrier approaches, resulting in continued biofouling challenges despite ozonation implementation.

The primary challenge in AOC management lies in the paradoxical relationship between oxidation treatments and AOC formation. While ozonation effectively eliminates pathogens and breaks down complex organic compounds, it simultaneously converts recalcitrant natural organic matter (NOM) into more biodegradable forms, potentially increasing AOC concentrations by 30-300% depending on source water characteristics and treatment conditions.

Water treatment facilities face significant difficulties in real-time monitoring of AOC levels. Current analytical methods require specialized laboratory equipment, trained personnel, and extended incubation periods (3-14 days), making immediate operational adjustments nearly impossible. This monitoring gap creates uncertainty in treatment efficacy and complicates optimization efforts for downstream biofouling control.

The variability in source water quality presents another substantial challenge. Seasonal fluctuations, weather events, and anthropogenic activities significantly alter NOM composition and concentration, requiring continuous adjustment of ozonation parameters. Treatment facilities often lack predictive models to anticipate these changes, resulting in either insufficient treatment or excessive AOC formation.

Balancing disinfection requirements with AOC minimization creates operational dilemmas. Regulatory compliance mandates specific disinfection targets, often necessitating oxidant doses that inevitably increase AOC production. This regulatory-operational conflict forces utilities to choose between meeting disinfection requirements and managing downstream biofouling risks.

The integration of ozonation with biological filtration systems presents technical challenges in process optimization. Achieving the ideal balance between ozone dose, contact time, and biological treatment capacity requires sophisticated control systems and operational expertise often unavailable in smaller utilities. Suboptimal integration results in incomplete AOC removal and persistent biofouling issues.

Economic constraints further complicate AOC management strategies. Implementing comprehensive solutions involving advanced oxidation processes, enhanced biological filtration, and membrane technologies requires substantial capital investment and increased operational costs. Many utilities, particularly in developing regions, lack the financial resources to implement these multi-barrier approaches, resulting in continued biofouling challenges despite ozonation implementation.

Current Ozonation Methods for AOC Control

01 Ozonation processes for water treatment

Ozonation is used as an advanced oxidation process for water treatment to remove contaminants and improve water quality. The process involves introducing ozone into water systems to oxidize organic compounds, pathogens, and other pollutants. This treatment method can lead to the formation of assimilable organic carbon (AOC), which is a byproduct of the oxidation of larger organic molecules into smaller, more biodegradable compounds.- Ozonation processes for water treatment and AOC formation control: Ozonation is widely used in water treatment processes to oxidize organic compounds. However, this oxidation can lead to the formation of assimilable organic carbon (AOC), which can promote bacterial regrowth in distribution systems. Various technologies have been developed to optimize ozonation processes to minimize AOC formation while maintaining effective disinfection and oxidation capabilities. These processes often involve controlling ozone dosage, contact time, and combining ozonation with other treatment methods.

- Combined ozonation and biological filtration systems: Combining ozonation with biological filtration represents an effective approach to manage AOC formation. In these systems, ozone oxidizes organic matter, potentially increasing AOC levels, but the subsequent biological filtration step removes the formed AOC through microbial consumption. This combination optimizes water quality by leveraging the disinfection benefits of ozone while mitigating the potential negative effects of increased AOC through biological treatment processes.

- Advanced oxidation processes with ozone for AOC management: Advanced oxidation processes (AOPs) that combine ozone with other oxidants or catalysts can enhance the degradation of organic compounds while potentially reducing AOC formation. These processes include ozone combined with hydrogen peroxide, UV radiation, or catalysts. By achieving more complete mineralization of organic matter, these combined processes can reduce the formation of biodegradable byproducts that contribute to AOC, improving biological stability in treated water.

- Monitoring and control systems for ozonation and AOC formation: Sophisticated monitoring and control systems have been developed to optimize ozonation processes and minimize AOC formation. These systems include real-time sensors for measuring ozone concentration, organic carbon levels, and other water quality parameters. By continuously monitoring these parameters and adjusting treatment conditions accordingly, these systems can maintain effective disinfection while minimizing the formation of biodegradable byproducts that contribute to AOC.

- Innovative reactor designs for optimized ozonation: Novel reactor designs have been developed to enhance the efficiency of ozonation processes and control AOC formation. These designs focus on improving ozone mass transfer, optimizing contact time, and ensuring uniform distribution of ozone throughout the water being treated. By improving the efficiency of ozone utilization, these reactor designs can achieve effective oxidation and disinfection while potentially reducing the formation of biodegradable byproducts that contribute to AOC.

02 AOC formation monitoring and control systems

Systems and methods for monitoring and controlling AOC formation during ozonation processes are essential for maintaining water quality. These systems typically include sensors, analyzers, and control mechanisms that can detect AOC levels and adjust ozonation parameters accordingly. By monitoring AOC formation, operators can optimize ozone dosage and contact time to minimize the production of undesirable byproducts while maximizing treatment efficiency.Expand Specific Solutions03 Reduction of AOC formation in drinking water systems

Techniques for reducing AOC formation during ozonation of drinking water include combining ozonation with biological filtration, adjusting pH levels, and implementing multi-stage treatment processes. These approaches aim to minimize the concentration of biodegradable organic compounds that can lead to bacterial regrowth in distribution systems. By controlling AOC formation, these methods help maintain the microbiological stability of treated water and reduce the need for additional disinfection.Expand Specific Solutions04 AOC formation in wastewater treatment applications

In wastewater treatment, ozonation can be used to break down complex organic compounds, but this process often results in AOC formation. The management of AOC in wastewater systems involves specialized treatment trains that may include biological treatment steps following ozonation. These processes are designed to remove the biodegradable organic carbon before the treated wastewater is discharged or reused, preventing potential environmental impacts from increased microbial activity.Expand Specific Solutions05 Innovative equipment for ozonation and AOC management

Advanced equipment designs for ozonation processes focus on improving efficiency and reducing AOC formation. These innovations include specialized ozone generators, contactors with enhanced mixing capabilities, and integrated treatment systems that combine ozonation with other processes such as UV irradiation or catalytic oxidation. By optimizing equipment design, these technologies aim to achieve better control over the oxidation process and minimize the production of biodegradable byproducts.Expand Specific Solutions

Key Industry Players in Ozonation Technology

The ozonation technology for minimizing Assimilable Organic Carbon (AOC) formation to reduce downstream biofouling is currently in a growth phase, with increasing market adoption driven by water quality regulations. The global market for advanced water treatment technologies is expanding, with significant applications in municipal and industrial sectors. Technologically, ozonation systems have reached moderate maturity, with companies like Kurita Water Industries, Air Liquide, and Veolia Water Solutions leading commercial implementations. Research institutions including Beijing University of Technology and Drexel University are advancing the fundamental understanding of ozonation mechanisms, while industrial players such as Mitsubishi Electric and Toray Industries are developing integrated treatment systems with enhanced biofouling control capabilities. The technology continues to evolve toward more energy-efficient and cost-effective solutions.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed a comprehensive ozonation technology called "Bio-Barrier Ozone System" specifically targeting AOC control to prevent biofouling. Their approach combines precise ozone generation with advanced catalytic processes that enhance hydroxyl radical formation while limiting excess ozone exposure. This system utilizes proprietary catalysts that promote selective oxidation of organic compounds, reducing the formation of biodegradable byproducts that contribute to AOC. Kurita's technology incorporates a biological stabilization stage following ozonation, employing specialized microbial consortia that efficiently consume residual AOC before water enters downstream processes. Their integrated monitoring platform continuously measures biodegradable dissolved organic carbon (BDOC) levels as a surrogate for AOC, enabling real-time adjustment of treatment parameters. Field implementations have demonstrated up to 85% reduction in biofouling rates in industrial cooling systems and up to 40% extension of membrane cleaning intervals in water treatment facilities.

Strengths: Holistic approach combining chemical and biological treatment; proprietary catalyst technology enhances oxidation efficiency; extensive experience in industrial water treatment applications. Weaknesses: Higher complexity requiring specialized operational knowledge; catalyst materials require periodic replacement; system optimization needs site-specific customization.

Ovivo, Inc.

Technical Solution: Ovivo has engineered an innovative ozonation system specifically designed to address the AOC formation challenge in water treatment. Their technology implements a two-stage ozonation process with intermediate biological treatment to minimize AOC accumulation. The first ozonation stage applies a controlled dose to partially oxidize complex organics, followed by biofiltration to remove the resulting biodegradable compounds. A second, lower-dose ozonation stage then provides final disinfection while generating minimal additional AOC. Ovivo's system incorporates real-time UV254 absorbance monitoring to track natural organic matter (NOM) oxidation and optimize ozone dosing accordingly. Their proprietary control algorithms adjust ozone application based on water quality parameters, ensuring effective treatment while minimizing downstream biofouling potential. The company has documented 65-75% reductions in biofilm formation rates in industrial cooling systems and membrane treatment plants using this optimized approach.

Strengths: Specialized focus on minimizing biological fouling in industrial and municipal applications; advanced monitoring and control systems; proven effectiveness in reducing membrane biofouling. Weaknesses: System complexity requires sophisticated automation and control; higher operational costs compared to conventional chlorination; requires regular maintenance of biological filtration components.

Critical Patents in Ozonation-Based Biofouling Prevention

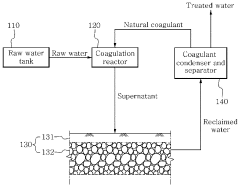

Aquifer storage and recovery system using natural coagulant

PatentActiveUS11142472B2

Innovation

- An aquifer storage and recovery system utilizing a natural coagulant, where metal ions like iron, aluminum, copper, and cobalt are dissolved and used to form a coagulant that effectively removes AOC by inducing floc formation and precipitation in a coagulation reactor, with a coagulant condenser and separator further refining the treated water.

Environmental Impact Assessment

Ozonation as a water treatment process demonstrates significant environmental implications that must be carefully assessed when considering its implementation for biofouling control. The environmental footprint of ozonation systems primarily stems from energy consumption required for ozone generation, which varies between 10-20 kWh per kg of ozone produced. This energy demand contributes to indirect carbon emissions when non-renewable energy sources are utilized, though this impact can be mitigated through integration with renewable energy systems.

The decomposition of ozone in water produces hydroxyl radicals that effectively oxidize organic compounds without introducing persistent chemical residues, unlike alternative biocides such as chlorine which can form harmful disinfection by-products (DBPs). Studies indicate that ozonation typically reduces the formation of regulated DBPs by 30-50% compared to chlorination processes, significantly lowering potential ecological toxicity in receiving water bodies.

Ozone's rapid decomposition to oxygen represents a key environmental advantage, as it leaves no harmful residuals in treated effluent. The half-life of ozone in water ranges from seconds to minutes depending on water quality parameters, ensuring minimal long-term environmental persistence. This characteristic makes ozonation particularly suitable for environmentally sensitive applications where discharge regulations are stringent.

When properly optimized to minimize AOC formation, ozonation can reduce downstream chemical cleaning requirements by up to 60%, decreasing the volume of cleaning chemicals released into the environment. This reduction in cleaning frequency also translates to extended membrane life in filtration systems, reducing waste generation associated with membrane replacement and disposal.

Risk assessment studies have identified potential concerns regarding bromate formation when ozonating bromide-containing waters, as bromate is classified as a potential carcinogen. However, advanced process control strategies can maintain bromate levels below regulatory thresholds of 10 μg/L while still achieving effective biofouling control through AOC minimization.

Life cycle assessment (LCA) comparisons between ozonation and conventional biofouling control methods demonstrate that despite higher initial energy inputs, ozonation's reduced chemical usage and extended equipment lifespan often result in a 15-25% lower overall environmental impact when evaluated across a 10-year operational period. These benefits become more pronounced in water-stressed regions where sustainable water management practices are critical.

The implementation of ozonation systems with AOC minimization strategies also supports circular economy principles by reducing waste streams associated with conventional chemical treatments and extending the service life of downstream infrastructure, contributing to more sustainable water management practices across industrial and municipal applications.

The decomposition of ozone in water produces hydroxyl radicals that effectively oxidize organic compounds without introducing persistent chemical residues, unlike alternative biocides such as chlorine which can form harmful disinfection by-products (DBPs). Studies indicate that ozonation typically reduces the formation of regulated DBPs by 30-50% compared to chlorination processes, significantly lowering potential ecological toxicity in receiving water bodies.

Ozone's rapid decomposition to oxygen represents a key environmental advantage, as it leaves no harmful residuals in treated effluent. The half-life of ozone in water ranges from seconds to minutes depending on water quality parameters, ensuring minimal long-term environmental persistence. This characteristic makes ozonation particularly suitable for environmentally sensitive applications where discharge regulations are stringent.

When properly optimized to minimize AOC formation, ozonation can reduce downstream chemical cleaning requirements by up to 60%, decreasing the volume of cleaning chemicals released into the environment. This reduction in cleaning frequency also translates to extended membrane life in filtration systems, reducing waste generation associated with membrane replacement and disposal.

Risk assessment studies have identified potential concerns regarding bromate formation when ozonating bromide-containing waters, as bromate is classified as a potential carcinogen. However, advanced process control strategies can maintain bromate levels below regulatory thresholds of 10 μg/L while still achieving effective biofouling control through AOC minimization.

Life cycle assessment (LCA) comparisons between ozonation and conventional biofouling control methods demonstrate that despite higher initial energy inputs, ozonation's reduced chemical usage and extended equipment lifespan often result in a 15-25% lower overall environmental impact when evaluated across a 10-year operational period. These benefits become more pronounced in water-stressed regions where sustainable water management practices are critical.

The implementation of ozonation systems with AOC minimization strategies also supports circular economy principles by reducing waste streams associated with conventional chemical treatments and extending the service life of downstream infrastructure, contributing to more sustainable water management practices across industrial and municipal applications.

Cost-Benefit Analysis of Ozonation Systems

The implementation of ozonation systems for biofouling control requires substantial initial capital investment, ranging from $500,000 to $2 million depending on treatment capacity and system complexity. This includes costs for ozone generators, contact chambers, monitoring equipment, and integration with existing water treatment infrastructure. However, these upfront expenditures must be evaluated against long-term operational benefits and cost savings.

Operational expenses for ozonation systems primarily consist of energy consumption, maintenance, and periodic replacement of components. Energy costs typically represent 40-60% of operational expenses, as ozone generation is energy-intensive. Nevertheless, modern ozone generators have achieved significant efficiency improvements, reducing energy requirements by approximately 25% compared to systems from a decade ago.

When analyzing return on investment, facilities implementing ozonation for AOC control have reported 30-45% reductions in membrane cleaning frequency and 15-25% extensions in membrane life expectancy. These benefits translate to substantial cost savings in maintenance labor, cleaning chemicals, and replacement membranes. A typical municipal water treatment plant processing 10 million gallons daily can realize annual savings of $75,000-$120,000 through reduced cleaning and extended equipment life.

Additionally, ozonation systems provide secondary benefits that enhance their economic value proposition. These include reduced chemical usage (particularly chlorine and biocides), improved finished water quality, and potential regulatory compliance advantages. Many facilities report 20-30% reductions in chemical treatment costs following ozonation implementation.

Life-cycle cost analysis indicates that most ozonation systems achieve financial break-even within 4-7 years of operation, depending on facility size and specific application parameters. Smaller systems typically have longer payback periods due to economies of scale affecting both capital and operational costs.

Risk factors affecting cost-benefit calculations include energy price volatility, regulatory changes that might mandate additional treatment processes, and potential technological advancements that could render current systems obsolete. Sensitivity analysis suggests that energy cost increases of 20% would extend payback periods by approximately 1-1.5 years, highlighting the importance of energy efficiency in system design and operation.

Operational expenses for ozonation systems primarily consist of energy consumption, maintenance, and periodic replacement of components. Energy costs typically represent 40-60% of operational expenses, as ozone generation is energy-intensive. Nevertheless, modern ozone generators have achieved significant efficiency improvements, reducing energy requirements by approximately 25% compared to systems from a decade ago.

When analyzing return on investment, facilities implementing ozonation for AOC control have reported 30-45% reductions in membrane cleaning frequency and 15-25% extensions in membrane life expectancy. These benefits translate to substantial cost savings in maintenance labor, cleaning chemicals, and replacement membranes. A typical municipal water treatment plant processing 10 million gallons daily can realize annual savings of $75,000-$120,000 through reduced cleaning and extended equipment life.

Additionally, ozonation systems provide secondary benefits that enhance their economic value proposition. These include reduced chemical usage (particularly chlorine and biocides), improved finished water quality, and potential regulatory compliance advantages. Many facilities report 20-30% reductions in chemical treatment costs following ozonation implementation.

Life-cycle cost analysis indicates that most ozonation systems achieve financial break-even within 4-7 years of operation, depending on facility size and specific application parameters. Smaller systems typically have longer payback periods due to economies of scale affecting both capital and operational costs.

Risk factors affecting cost-benefit calculations include energy price volatility, regulatory changes that might mandate additional treatment processes, and potential technological advancements that could render current systems obsolete. Sensitivity analysis suggests that energy cost increases of 20% would extend payback periods by approximately 1-1.5 years, highlighting the importance of energy efficiency in system design and operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!