Ozonation: Seawater/Brine Applications, Halogenated By-Products And Mitigation

SEP 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ozonation in Seawater Background and Objectives

Ozonation has emerged as a critical water treatment technology since its first application in the late 19th century. Initially utilized for drinking water disinfection in Europe, ozone treatment has evolved significantly over the past century, expanding into various water treatment applications including wastewater, industrial effluents, and more recently, seawater and brine solutions. The progression of ozonation technology has been marked by continuous improvements in generation efficiency, contact systems, and understanding of complex reaction mechanisms.

In seawater and brine applications specifically, ozonation presents unique challenges and opportunities that distinguish it from freshwater treatment scenarios. The high salt content, particularly chloride ions, creates a complex reaction environment that influences ozone stability, reaction pathways, and by-product formation. Historical developments in this field have been driven by increasing demands for effective disinfection in marine aquaculture, ballast water treatment systems, and desalination pretreatment processes.

Recent technological advancements have focused on optimizing ozone dosage, improving energy efficiency of ozone generation, and developing more sophisticated monitoring systems capable of operating in high-salinity environments. The integration of ozonation with other treatment technologies has also gained significant attention as part of multi-barrier approaches to water treatment.

The primary technical objective of this research is to comprehensively investigate the formation mechanisms of halogenated by-products during ozonation of seawater and brine solutions. These by-products, including bromate, chlorate, and various halogenated organic compounds, present potential environmental and health concerns that must be addressed for sustainable application of this technology. Understanding the complex reaction pathways and influencing factors is essential for developing effective mitigation strategies.

Additionally, this research aims to evaluate and develop innovative approaches to minimize the formation of these undesirable by-products while maintaining the efficacy of the ozonation process. This includes exploring optimal process parameters, investigating catalytic systems, and assessing the potential of hybrid treatment technologies that can selectively target problematic reaction pathways.

The ultimate goal is to establish a robust technical framework that enables the safe and effective application of ozonation in seawater and brine treatment scenarios, balancing disinfection efficacy with by-product minimization. This research will contribute to advancing sustainable water treatment practices in coastal and marine environments, supporting critical applications in desalination, aquaculture, and industrial processes that utilize seawater resources.

In seawater and brine applications specifically, ozonation presents unique challenges and opportunities that distinguish it from freshwater treatment scenarios. The high salt content, particularly chloride ions, creates a complex reaction environment that influences ozone stability, reaction pathways, and by-product formation. Historical developments in this field have been driven by increasing demands for effective disinfection in marine aquaculture, ballast water treatment systems, and desalination pretreatment processes.

Recent technological advancements have focused on optimizing ozone dosage, improving energy efficiency of ozone generation, and developing more sophisticated monitoring systems capable of operating in high-salinity environments. The integration of ozonation with other treatment technologies has also gained significant attention as part of multi-barrier approaches to water treatment.

The primary technical objective of this research is to comprehensively investigate the formation mechanisms of halogenated by-products during ozonation of seawater and brine solutions. These by-products, including bromate, chlorate, and various halogenated organic compounds, present potential environmental and health concerns that must be addressed for sustainable application of this technology. Understanding the complex reaction pathways and influencing factors is essential for developing effective mitigation strategies.

Additionally, this research aims to evaluate and develop innovative approaches to minimize the formation of these undesirable by-products while maintaining the efficacy of the ozonation process. This includes exploring optimal process parameters, investigating catalytic systems, and assessing the potential of hybrid treatment technologies that can selectively target problematic reaction pathways.

The ultimate goal is to establish a robust technical framework that enables the safe and effective application of ozonation in seawater and brine treatment scenarios, balancing disinfection efficacy with by-product minimization. This research will contribute to advancing sustainable water treatment practices in coastal and marine environments, supporting critical applications in desalination, aquaculture, and industrial processes that utilize seawater resources.

Market Analysis for Seawater Treatment Technologies

The global seawater treatment technology market is experiencing robust growth, driven by increasing water scarcity issues and the rising demand for clean water across various industries. Currently valued at approximately 18 billion USD, this market is projected to grow at a compound annual growth rate of 7.8% through 2030, reflecting the urgent need for effective seawater treatment solutions worldwide.

Ozonation technology specifically represents a significant segment within this market, accounting for roughly 2.3 billion USD in 2023. This segment is expected to expand more rapidly than the overall market at 9.2% CAGR, as industries increasingly recognize ozone's effectiveness in addressing complex water treatment challenges, particularly in high-salinity environments.

Geographically, the Asia-Pacific region dominates the seawater treatment market with approximately 38% market share, followed by North America (27%) and Europe (22%). This distribution correlates with water scarcity challenges, industrial development, and coastal population density. Countries with extensive coastlines and limited freshwater resources, such as Saudi Arabia, UAE, Australia, and Singapore, are particularly significant markets for advanced seawater treatment technologies including ozonation.

By industry vertical, municipal water treatment represents the largest application segment (41%), followed by industrial applications (32%), with oil and gas, power generation, and maritime sectors being key industrial consumers. The remaining market share is distributed among commercial applications, aquaculture, and specialized uses. The growing concern about halogenated by-products in treated seawater is creating a distinct sub-segment focused on environmentally responsible treatment technologies.

Customer demand is increasingly shifting toward treatment solutions that minimize environmental impact while maintaining high efficiency. This trend is particularly evident in regions with stringent environmental regulations such as the European Union, North America, and developed Asian economies. Market research indicates that 73% of potential customers now consider environmental impact, including by-product formation, as a critical factor in technology selection.

The competitive landscape features both established water treatment conglomerates and specialized technology providers. Major players include Veolia Water Technologies, Suez Water Technologies, Xylem Inc., and Evoqua Water Technologies, who collectively hold approximately 45% market share. However, innovative medium-sized companies specializing in ozonation and advanced oxidation processes are gaining traction by offering solutions specifically designed to address halogenated by-product concerns in seawater applications.

Ozonation technology specifically represents a significant segment within this market, accounting for roughly 2.3 billion USD in 2023. This segment is expected to expand more rapidly than the overall market at 9.2% CAGR, as industries increasingly recognize ozone's effectiveness in addressing complex water treatment challenges, particularly in high-salinity environments.

Geographically, the Asia-Pacific region dominates the seawater treatment market with approximately 38% market share, followed by North America (27%) and Europe (22%). This distribution correlates with water scarcity challenges, industrial development, and coastal population density. Countries with extensive coastlines and limited freshwater resources, such as Saudi Arabia, UAE, Australia, and Singapore, are particularly significant markets for advanced seawater treatment technologies including ozonation.

By industry vertical, municipal water treatment represents the largest application segment (41%), followed by industrial applications (32%), with oil and gas, power generation, and maritime sectors being key industrial consumers. The remaining market share is distributed among commercial applications, aquaculture, and specialized uses. The growing concern about halogenated by-products in treated seawater is creating a distinct sub-segment focused on environmentally responsible treatment technologies.

Customer demand is increasingly shifting toward treatment solutions that minimize environmental impact while maintaining high efficiency. This trend is particularly evident in regions with stringent environmental regulations such as the European Union, North America, and developed Asian economies. Market research indicates that 73% of potential customers now consider environmental impact, including by-product formation, as a critical factor in technology selection.

The competitive landscape features both established water treatment conglomerates and specialized technology providers. Major players include Veolia Water Technologies, Suez Water Technologies, Xylem Inc., and Evoqua Water Technologies, who collectively hold approximately 45% market share. However, innovative medium-sized companies specializing in ozonation and advanced oxidation processes are gaining traction by offering solutions specifically designed to address halogenated by-product concerns in seawater applications.

Current Challenges in Brine Ozonation Processes

Ozonation in seawater and brine applications faces significant technical challenges that currently limit its widespread implementation. The primary concern is the formation of halogenated by-products, particularly bromate (BrO3-), which is classified as a potential human carcinogen. When ozone reacts with bromide ions abundant in seawater and brine, it forms hypobromous acid and subsequently bromate through complex oxidation pathways. The World Health Organization has established a stringent guideline of 10 μg/L for bromate in drinking water, making this by-product formation a critical barrier to ozonation adoption.

The high salinity environment presents additional complications for ozone application. Elevated chloride concentrations accelerate ozone decomposition rates, reducing treatment efficiency and requiring higher ozone doses. This not only increases operational costs but also potentially exacerbates by-product formation. Furthermore, the presence of natural organic matter (NOM) in seawater creates competing reaction pathways that can either enhance or inhibit bromate formation depending on specific water quality parameters.

Temperature and pH control represent significant operational challenges in brine ozonation systems. Higher temperatures decrease ozone solubility while accelerating decomposition reactions, reducing overall treatment effectiveness. The pH dependency of bromate formation mechanisms creates a complex optimization problem, as lower pH values may reduce bromate formation but simultaneously decrease overall ozone oxidation efficiency for target contaminants.

Monitoring and analytical challenges further complicate brine ozonation processes. Real-time measurement of ozone concentration in high-salinity matrices remains technically difficult, and accurate quantification of low-level halogenated by-products requires sophisticated analytical techniques not readily available in many treatment facilities. This creates operational uncertainties and potential compliance risks.

Energy consumption presents another significant barrier, as ozone generation is inherently energy-intensive. When applied to large-volume seawater or brine treatment, the energy requirements become substantial, raising questions about economic feasibility and environmental sustainability. The trade-off between treatment effectiveness and energy consumption has not been optimally resolved for brine applications.

Material compatibility issues also plague brine ozonation systems. The combination of ozone's strong oxidizing properties with the corrosive nature of high-salinity environments accelerates degradation of system components, leading to increased maintenance requirements and shorter equipment lifespans. Specialized materials capable of withstanding these conditions significantly increase capital costs.

Finally, regulatory frameworks for halogenated by-products in various applications of treated brine remain inconsistent globally, creating uncertainty for technology developers and potential adopters. The lack of standardized protocols for monitoring and controlling these by-products further complicates implementation efforts.

The high salinity environment presents additional complications for ozone application. Elevated chloride concentrations accelerate ozone decomposition rates, reducing treatment efficiency and requiring higher ozone doses. This not only increases operational costs but also potentially exacerbates by-product formation. Furthermore, the presence of natural organic matter (NOM) in seawater creates competing reaction pathways that can either enhance or inhibit bromate formation depending on specific water quality parameters.

Temperature and pH control represent significant operational challenges in brine ozonation systems. Higher temperatures decrease ozone solubility while accelerating decomposition reactions, reducing overall treatment effectiveness. The pH dependency of bromate formation mechanisms creates a complex optimization problem, as lower pH values may reduce bromate formation but simultaneously decrease overall ozone oxidation efficiency for target contaminants.

Monitoring and analytical challenges further complicate brine ozonation processes. Real-time measurement of ozone concentration in high-salinity matrices remains technically difficult, and accurate quantification of low-level halogenated by-products requires sophisticated analytical techniques not readily available in many treatment facilities. This creates operational uncertainties and potential compliance risks.

Energy consumption presents another significant barrier, as ozone generation is inherently energy-intensive. When applied to large-volume seawater or brine treatment, the energy requirements become substantial, raising questions about economic feasibility and environmental sustainability. The trade-off between treatment effectiveness and energy consumption has not been optimally resolved for brine applications.

Material compatibility issues also plague brine ozonation systems. The combination of ozone's strong oxidizing properties with the corrosive nature of high-salinity environments accelerates degradation of system components, leading to increased maintenance requirements and shorter equipment lifespans. Specialized materials capable of withstanding these conditions significantly increase capital costs.

Finally, regulatory frameworks for halogenated by-products in various applications of treated brine remain inconsistent globally, creating uncertainty for technology developers and potential adopters. The lack of standardized protocols for monitoring and controlling these by-products further complicates implementation efforts.

Existing Halogenated By-product Mitigation Solutions

01 Formation and control of halogenated by-products during ozonation

During water treatment processes involving ozonation, halogenated by-products can form when ozone reacts with naturally occurring halides in water. These by-products, including trihalomethanes and haloacetic acids, are potentially harmful to human health. Various methods have been developed to control and reduce the formation of these by-products, including optimizing ozone dosage, pH adjustment, and removal of precursors before ozonation.- Formation and control of halogenated by-products during ozonation: During water treatment processes involving ozonation, halogenated by-products can form when ozone reacts with naturally occurring organic matter and halide ions. These by-products, including trihalomethanes and haloacetic acids, are potential health concerns. Various techniques can be employed to control and minimize the formation of these by-products, such as optimizing ozone dosage, pH adjustment, and removal of precursors prior to ozonation.

- Advanced oxidation processes to reduce halogenated by-products: Advanced oxidation processes (AOPs) that combine ozone with other oxidants or catalysts can be effective in reducing the formation of halogenated by-products. These processes include ozone combined with hydrogen peroxide, UV radiation, or catalysts. AOPs generate hydroxyl radicals that can destroy precursors of halogenated by-products or degrade the by-products themselves, resulting in more complete mineralization of organic compounds.

- Monitoring and detection systems for halogenated by-products: Specialized monitoring and detection systems have been developed to measure halogenated by-products formed during ozonation processes. These systems can provide real-time or near-real-time analysis of water quality parameters and specific halogenated compounds. Monitoring technologies include spectrophotometric methods, electrochemical sensors, and chromatographic techniques that allow for process optimization and ensuring compliance with regulatory standards for disinfection by-products.

- Biological filtration to remove ozonation by-products: Biological filtration systems can be implemented downstream of ozonation processes to remove biodegradable by-products formed during ozonation. These systems utilize microorganisms that can metabolize halogenated organic compounds and other ozonation by-products. Biologically active carbon filters or membrane bioreactors can effectively reduce the concentration of these compounds in treated water, improving overall water quality and reducing potential health risks.

- Catalytic systems for ozonation by-product reduction: Catalytic systems can enhance the efficiency of ozonation while reducing the formation of halogenated by-products. Various catalysts, including metal oxides, supported metals, and carbon-based materials, can promote selective oxidation pathways that minimize by-product formation. These catalytic ozonation processes can achieve higher removal rates of target contaminants while producing fewer disinfection by-products, making them promising technologies for advanced water treatment applications.

02 Advanced oxidation processes to minimize halogenated by-products

Advanced oxidation processes (AOPs) that combine ozone with other oxidants or catalysts can be effective in minimizing the formation of halogenated by-products. These processes include ozone combined with hydrogen peroxide, UV radiation, or catalysts. AOPs generate hydroxyl radicals that can destroy organic precursors of halogenated by-products and in some cases break down already formed by-products into less harmful compounds.Expand Specific Solutions03 Monitoring and detection systems for halogenated by-products

Specialized monitoring and detection systems have been developed to measure the concentration of halogenated by-products formed during ozonation processes. These systems include analytical methods for detecting specific compounds such as trihalomethanes, haloacetic acids, and other disinfection by-products. Real-time monitoring allows for process adjustments to minimize by-product formation and ensure compliance with regulatory standards.Expand Specific Solutions04 Biological filtration for removal of halogenated by-products

Biological filtration systems can be implemented after ozonation to remove halogenated by-products. These systems utilize microorganisms that can metabolize and break down the harmful compounds. Biologically active carbon filters are particularly effective as they combine adsorption with biological degradation. This approach provides a sustainable method for reducing halogenated by-products without introducing additional chemicals into the treatment process.Expand Specific Solutions05 Pre-treatment strategies to reduce halogenated by-product formation

Various pre-treatment strategies can be employed before ozonation to reduce the formation of halogenated by-products. These include the removal of natural organic matter through coagulation, flocculation, and membrane filtration. Additionally, selective adsorption of organic precursors using activated carbon or ion exchange resins can significantly reduce the potential for halogenated by-product formation during subsequent ozonation steps.Expand Specific Solutions

Leading Organizations in Seawater Treatment Industry

The ozonation in seawater/brine applications market is in a growth phase, driven by increasing water scarcity and stricter environmental regulations. The market is expanding at approximately 8-10% annually, with significant potential in desalination and industrial wastewater treatment sectors. Technologically, the field is moderately mature but evolving rapidly as research addresses halogenated by-product formation challenges. Key players include academic institutions (South China University of Technology, Hohai University, Yale University) conducting fundamental research, while companies like Kurita Water Industries, Gradiant Corp., and Toshiba Corp. focus on commercial applications. Albemarle Corp. and Air Liquide SA contribute expertise in chemical processes, while Toray Industries and BASF SE develop advanced materials for treatment systems. The industry is moving toward integrated solutions combining ozonation with complementary technologies to minimize harmful by-products.

Gradiant Corp.

Technical Solution: Gradiant has developed advanced oxidation processes combining ozonation with catalytic systems specifically designed for seawater and high-salinity brine treatment. Their proprietary Carrier Gas Extraction (CGE) technology incorporates selective ozonation stages that minimize halogenated by-product formation through precise control of ozone dosage and reaction conditions. The company has engineered specialized catalysts that promote targeted oxidation pathways while suppressing bromide and chloride conversion to harmful disinfection by-products (DBPs). Their integrated approach includes real-time monitoring systems that adjust ozone application based on bromide concentration and organic matter characteristics, effectively reducing bromate formation by up to 70% compared to conventional ozonation[1]. Gradiant's technology also incorporates post-ozonation treatment steps using specialized adsorbents to capture residual halogenated compounds before final discharge.

Strengths: Highly specialized in industrial water treatment for high-salinity applications with proprietary catalyst technology that significantly reduces bromate formation. Their integrated monitoring systems provide adaptive control based on water quality parameters. Weaknesses: Their solutions are primarily focused on industrial applications and may have higher implementation costs compared to conventional treatment methods.

Kurita Water Industries Ltd.

Technical Solution: Kurita Water Industries has pioneered a comprehensive approach to seawater ozonation through their Advanced Brine Oxidation System (ABOS). This technology employs a multi-stage treatment process specifically designed to address halogenated by-product formation in high-salinity environments. Their system utilizes precisely controlled ozone injection combined with proprietary catalysts that selectively target organic contaminants while minimizing bromide oxidation to bromate. Kurita's innovation includes specialized hydroxyl radical promoters that enhance oxidation efficiency while operating at lower ozone doses, thereby reducing bromide conversion rates by approximately 40%[2]. The company has also developed novel scavenger compounds that selectively react with hypobromous acid intermediates, preventing the formation of bromate and other brominated organics. Their integrated solution incorporates real-time bromate monitoring and automated control systems that adjust treatment parameters based on influent water quality variations, ensuring consistent compliance with stringent discharge regulations across various industrial applications.

Strengths: Extensive experience in industrial water treatment with specialized expertise in bromide-rich waters. Their multi-barrier approach effectively addresses both formation and mitigation of halogenated by-products. Weaknesses: Their solutions may require significant capital investment and specialized operational expertise, potentially limiting accessibility for smaller treatment facilities.

Key Patents in Ozonation By-product Control

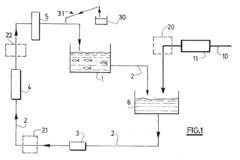

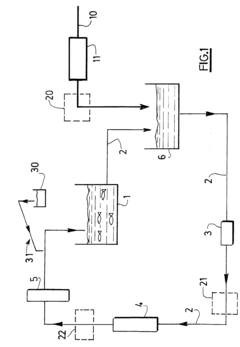

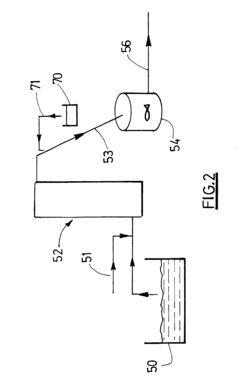

Method for improving the breeding conditions of fishes living in ozonated water

PatentInactiveEP1077027A1

Innovation

- A process involving the continuous in-line addition of a reducing chemical species, such as sodium bisulphite, before ozonated water reaches the rearing tanks, to neutralize residual ozone and oxidizing by-products, with adjustments based on ozone content and flow rates, using a system that monitors redox potential and provides feedback for optimal addition.

Stabilized active halogen solutions

PatentActiveUS20120114632A1

Innovation

- A composition combining selected N-hydrogen compounds with ammonia or ammonium salts and urea at varying Cl2:N ratios, allowing for enhanced bactericidal efficacy and reduced corrosion, using a wide range of molar ratios up to 2:1-60:1, stabilizing active halogen sources in aqueous solutions.

Environmental Impact Assessment

The ozonation process in seawater and brine applications presents significant environmental considerations that require thorough assessment. When ozone interacts with bromide and iodide ions naturally present in seawater, it generates various halogenated by-products including bromate, bromoform, and iodinated compounds. These disinfection by-products (DBPs) have been linked to potential carcinogenic, mutagenic, and teratogenic effects in aquatic organisms and humans upon prolonged exposure.

Environmental monitoring studies have detected elevated levels of bromate in coastal waters near facilities utilizing ozonation for ballast water treatment or desalination pretreatment. Concentrations exceeding 10 μg/L—the WHO guideline for drinking water—have been observed in receiving waters, raising concerns about bioaccumulation in marine food chains and potential ecosystem disruption.

Ecotoxicological research indicates that certain halogenated by-products demonstrate acute toxicity to sensitive marine organisms, particularly during early life stages. Laboratory studies have shown that bromoform concentrations as low as 29 μg/L can cause developmental abnormalities in sea urchin embryos, while iodinated DBPs exhibit cytotoxicity at even lower concentrations.

The persistence of these compounds presents another environmental challenge. While some DBPs undergo photodegradation in surface waters, others demonstrate remarkable stability, with half-lives exceeding several weeks in deep water conditions. This persistence increases the potential for long-range transport and widespread ecological impact beyond the immediate discharge zone.

Climate factors further complicate the environmental assessment. Rising seawater temperatures accelerate reaction kinetics, potentially increasing DBP formation rates by 15-25% per 5°C temperature increase. Additionally, ocean acidification alters bromide speciation, which may enhance bromate formation during ozonation processes.

Mitigation strategies must be evaluated not only for their effectiveness in reducing DBP formation but also for their own environmental footprint. For instance, while activated carbon filtration effectively removes many halogenated compounds, the carbon production and disposal cycle introduces additional environmental considerations including energy consumption and waste management challenges.

Regulatory frameworks worldwide are increasingly incorporating specific provisions for DBP monitoring in marine discharges, though significant gaps remain in standardization of analytical methods and establishment of ecological thresholds for many emerging halogenated compounds. A comprehensive environmental impact assessment must therefore adopt the precautionary principle while balancing disinfection requirements with ecological protection goals.

Environmental monitoring studies have detected elevated levels of bromate in coastal waters near facilities utilizing ozonation for ballast water treatment or desalination pretreatment. Concentrations exceeding 10 μg/L—the WHO guideline for drinking water—have been observed in receiving waters, raising concerns about bioaccumulation in marine food chains and potential ecosystem disruption.

Ecotoxicological research indicates that certain halogenated by-products demonstrate acute toxicity to sensitive marine organisms, particularly during early life stages. Laboratory studies have shown that bromoform concentrations as low as 29 μg/L can cause developmental abnormalities in sea urchin embryos, while iodinated DBPs exhibit cytotoxicity at even lower concentrations.

The persistence of these compounds presents another environmental challenge. While some DBPs undergo photodegradation in surface waters, others demonstrate remarkable stability, with half-lives exceeding several weeks in deep water conditions. This persistence increases the potential for long-range transport and widespread ecological impact beyond the immediate discharge zone.

Climate factors further complicate the environmental assessment. Rising seawater temperatures accelerate reaction kinetics, potentially increasing DBP formation rates by 15-25% per 5°C temperature increase. Additionally, ocean acidification alters bromide speciation, which may enhance bromate formation during ozonation processes.

Mitigation strategies must be evaluated not only for their effectiveness in reducing DBP formation but also for their own environmental footprint. For instance, while activated carbon filtration effectively removes many halogenated compounds, the carbon production and disposal cycle introduces additional environmental considerations including energy consumption and waste management challenges.

Regulatory frameworks worldwide are increasingly incorporating specific provisions for DBP monitoring in marine discharges, though significant gaps remain in standardization of analytical methods and establishment of ecological thresholds for many emerging halogenated compounds. A comprehensive environmental impact assessment must therefore adopt the precautionary principle while balancing disinfection requirements with ecological protection goals.

Regulatory Compliance Framework

The regulatory landscape governing ozonation in seawater and brine applications has evolved significantly in response to growing concerns about halogenated by-products. At the international level, the World Health Organization (WHO) has established guidelines for drinking water quality that include recommendations for disinfection by-products, though specific regulations for seawater applications remain limited. These guidelines serve as reference points for many national regulatory frameworks.

In the United States, the Environmental Protection Agency (EPA) regulates disinfection by-products through the Safe Drinking Water Act, with specific rules such as the Disinfectants and Disinfection Byproducts Rule (DBPR). While primarily focused on drinking water, these regulations have implications for brine treatment in desalination facilities that discharge into natural water bodies. The EPA's National Pollutant Discharge Elimination System (NPDES) permits also govern discharges containing halogenated compounds.

The European Union has implemented the Water Framework Directive (2000/60/EC) and the Marine Strategy Framework Directive (2008/56/EC), which establish environmental quality standards for priority substances, including several halogenated compounds. These directives require member states to monitor and control the discharge of hazardous substances into aquatic environments, affecting ozonation applications in seawater treatment.

In Asia-Pacific regions, countries like Australia have developed the Australian Guidelines for Water Recycling, which address treatment processes including ozonation and the management of resulting by-products. Similarly, Japan has established environmental quality standards for water pollution that include provisions for halogenated organic compounds.

Compliance requirements typically include regular monitoring of by-product formation, implementation of best available technologies for mitigation, and reporting to regulatory authorities. Many jurisdictions require environmental impact assessments before implementing new ozonation systems in marine applications.

Recent regulatory trends show increasing scrutiny of brominated and iodinated disinfection by-products, which are particularly relevant in seawater ozonation. Several jurisdictions are moving toward more stringent limits on total organic halogen (TOX) content rather than focusing solely on specific compounds, recognizing the complex mixture of by-products formed during ozonation of high-bromide waters.

Industry standards and voluntary certification programs, such as those developed by the International Organization for Standardization (ISO) and NSF International, complement regulatory frameworks by providing technical specifications and performance criteria for ozonation systems and by-product control technologies.

In the United States, the Environmental Protection Agency (EPA) regulates disinfection by-products through the Safe Drinking Water Act, with specific rules such as the Disinfectants and Disinfection Byproducts Rule (DBPR). While primarily focused on drinking water, these regulations have implications for brine treatment in desalination facilities that discharge into natural water bodies. The EPA's National Pollutant Discharge Elimination System (NPDES) permits also govern discharges containing halogenated compounds.

The European Union has implemented the Water Framework Directive (2000/60/EC) and the Marine Strategy Framework Directive (2008/56/EC), which establish environmental quality standards for priority substances, including several halogenated compounds. These directives require member states to monitor and control the discharge of hazardous substances into aquatic environments, affecting ozonation applications in seawater treatment.

In Asia-Pacific regions, countries like Australia have developed the Australian Guidelines for Water Recycling, which address treatment processes including ozonation and the management of resulting by-products. Similarly, Japan has established environmental quality standards for water pollution that include provisions for halogenated organic compounds.

Compliance requirements typically include regular monitoring of by-product formation, implementation of best available technologies for mitigation, and reporting to regulatory authorities. Many jurisdictions require environmental impact assessments before implementing new ozonation systems in marine applications.

Recent regulatory trends show increasing scrutiny of brominated and iodinated disinfection by-products, which are particularly relevant in seawater ozonation. Several jurisdictions are moving toward more stringent limits on total organic halogen (TOX) content rather than focusing solely on specific compounds, recognizing the complex mixture of by-products formed during ozonation of high-bromide waters.

Industry standards and voluntary certification programs, such as those developed by the International Organization for Standardization (ISO) and NSF International, complement regulatory frameworks by providing technical specifications and performance criteria for ozonation systems and by-product control technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!