How Propyne Contributes to Atomic Layer Deposition Techniques

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in ALD: Background and Objectives

Atomic Layer Deposition (ALD) has emerged as a critical technique in the semiconductor industry, enabling the precise deposition of thin films at the atomic scale. Propyne, a simple alkyne molecule, has recently gained attention for its potential to enhance ALD processes. This report aims to explore the background of propyne's role in ALD and set objectives for further investigation.

The development of ALD can be traced back to the 1970s, with significant advancements occurring in the 1990s and 2000s. As device miniaturization continues to push the limits of traditional deposition methods, ALD has become increasingly important due to its ability to create uniform, conformal coatings with precise thickness control. The introduction of propyne as a precursor in ALD represents a new frontier in this field, potentially offering improved film properties and process efficiency.

Propyne, also known as methylacetylene, is a three-carbon alkyne with the chemical formula C3H4. Its unique structure and reactivity make it an interesting candidate for ALD applications. The triple bond in propyne can participate in various surface reactions, potentially leading to more efficient deposition processes and improved film characteristics. Understanding the fundamental chemistry of propyne in the context of ALD is crucial for harnessing its full potential.

The primary objective of this investigation is to elucidate the specific contributions of propyne to ALD techniques. This includes examining how propyne interacts with substrate surfaces, its role in precursor chemistry, and its impact on film growth mechanisms. Additionally, we aim to assess the potential advantages of propyne-based ALD processes compared to conventional precursors, such as improved growth rates, lower deposition temperatures, or enhanced film properties.

Another key goal is to explore the range of materials that can be deposited using propyne-assisted ALD. This may include metal oxides, nitrides, and other compound semiconductors. Understanding the versatility of propyne in ALD could open new avenues for material synthesis and device fabrication.

Furthermore, this study will investigate the technical challenges associated with integrating propyne into existing ALD processes. This includes addressing any safety concerns related to the use of propyne, optimizing process parameters, and developing suitable equipment and handling protocols. By identifying and addressing these challenges, we can pave the way for the practical implementation of propyne-based ALD in industrial settings.

Lastly, we aim to situate propyne-assisted ALD within the broader context of emerging deposition technologies. This involves comparing its potential benefits and limitations to other innovative ALD precursors and techniques, such as plasma-enhanced ALD or area-selective ALD. By doing so, we can better understand the unique value proposition of propyne in advancing the field of atomic layer deposition.

The development of ALD can be traced back to the 1970s, with significant advancements occurring in the 1990s and 2000s. As device miniaturization continues to push the limits of traditional deposition methods, ALD has become increasingly important due to its ability to create uniform, conformal coatings with precise thickness control. The introduction of propyne as a precursor in ALD represents a new frontier in this field, potentially offering improved film properties and process efficiency.

Propyne, also known as methylacetylene, is a three-carbon alkyne with the chemical formula C3H4. Its unique structure and reactivity make it an interesting candidate for ALD applications. The triple bond in propyne can participate in various surface reactions, potentially leading to more efficient deposition processes and improved film characteristics. Understanding the fundamental chemistry of propyne in the context of ALD is crucial for harnessing its full potential.

The primary objective of this investigation is to elucidate the specific contributions of propyne to ALD techniques. This includes examining how propyne interacts with substrate surfaces, its role in precursor chemistry, and its impact on film growth mechanisms. Additionally, we aim to assess the potential advantages of propyne-based ALD processes compared to conventional precursors, such as improved growth rates, lower deposition temperatures, or enhanced film properties.

Another key goal is to explore the range of materials that can be deposited using propyne-assisted ALD. This may include metal oxides, nitrides, and other compound semiconductors. Understanding the versatility of propyne in ALD could open new avenues for material synthesis and device fabrication.

Furthermore, this study will investigate the technical challenges associated with integrating propyne into existing ALD processes. This includes addressing any safety concerns related to the use of propyne, optimizing process parameters, and developing suitable equipment and handling protocols. By identifying and addressing these challenges, we can pave the way for the practical implementation of propyne-based ALD in industrial settings.

Lastly, we aim to situate propyne-assisted ALD within the broader context of emerging deposition technologies. This involves comparing its potential benefits and limitations to other innovative ALD precursors and techniques, such as plasma-enhanced ALD or area-selective ALD. By doing so, we can better understand the unique value proposition of propyne in advancing the field of atomic layer deposition.

Market Analysis for Propyne-based ALD

The market for propyne-based Atomic Layer Deposition (ALD) techniques is experiencing significant growth, driven by the increasing demand for high-performance electronic devices and advanced semiconductor manufacturing processes. As the semiconductor industry continues to push the boundaries of miniaturization and performance, ALD has emerged as a critical technology for depositing ultra-thin films with precise control over thickness and composition.

Propyne, also known as methylacetylene, has gained attention as a promising precursor for ALD processes due to its unique chemical properties and reactivity. The global market for ALD equipment and materials is projected to grow steadily over the next few years, with propyne-based ALD techniques expected to capture a significant share of this expanding market.

The electronics industry, particularly the semiconductor sector, represents the largest market segment for propyne-based ALD. The technology is crucial for manufacturing advanced logic and memory chips, where the ability to deposit uniform and conformal thin films is essential for improving device performance and reliability. Additionally, propyne-based ALD techniques are finding applications in other sectors, including solar cells, optical coatings, and energy storage devices.

The adoption of propyne-based ALD is driven by several factors, including the need for higher aspect ratio structures in semiconductor devices, improved film quality, and reduced processing temperatures. These advantages make propyne-based ALD particularly attractive for next-generation semiconductor manufacturing processes, such as 3D NAND flash memory and advanced logic nodes.

Geographically, Asia-Pacific dominates the market for propyne-based ALD, with major semiconductor manufacturing hubs in countries like South Korea, Taiwan, and China driving demand. North America and Europe also represent significant markets, particularly for research and development activities and specialized applications in the aerospace and defense sectors.

Key players in the propyne-based ALD market include major semiconductor equipment manufacturers, chemical suppliers, and research institutions. These organizations are actively investing in research and development to improve the efficiency and capabilities of propyne-based ALD processes, as well as to explore new applications and markets for the technology.

Despite the promising outlook, the market for propyne-based ALD faces some challenges. These include the high cost of equipment and materials, the need for specialized expertise to optimize processes, and competition from alternative deposition techniques. However, ongoing research and development efforts are expected to address these challenges and further expand the market potential of propyne-based ALD techniques in the coming years.

Propyne, also known as methylacetylene, has gained attention as a promising precursor for ALD processes due to its unique chemical properties and reactivity. The global market for ALD equipment and materials is projected to grow steadily over the next few years, with propyne-based ALD techniques expected to capture a significant share of this expanding market.

The electronics industry, particularly the semiconductor sector, represents the largest market segment for propyne-based ALD. The technology is crucial for manufacturing advanced logic and memory chips, where the ability to deposit uniform and conformal thin films is essential for improving device performance and reliability. Additionally, propyne-based ALD techniques are finding applications in other sectors, including solar cells, optical coatings, and energy storage devices.

The adoption of propyne-based ALD is driven by several factors, including the need for higher aspect ratio structures in semiconductor devices, improved film quality, and reduced processing temperatures. These advantages make propyne-based ALD particularly attractive for next-generation semiconductor manufacturing processes, such as 3D NAND flash memory and advanced logic nodes.

Geographically, Asia-Pacific dominates the market for propyne-based ALD, with major semiconductor manufacturing hubs in countries like South Korea, Taiwan, and China driving demand. North America and Europe also represent significant markets, particularly for research and development activities and specialized applications in the aerospace and defense sectors.

Key players in the propyne-based ALD market include major semiconductor equipment manufacturers, chemical suppliers, and research institutions. These organizations are actively investing in research and development to improve the efficiency and capabilities of propyne-based ALD processes, as well as to explore new applications and markets for the technology.

Despite the promising outlook, the market for propyne-based ALD faces some challenges. These include the high cost of equipment and materials, the need for specialized expertise to optimize processes, and competition from alternative deposition techniques. However, ongoing research and development efforts are expected to address these challenges and further expand the market potential of propyne-based ALD techniques in the coming years.

Current Challenges in Propyne ALD

Despite the promising potential of propyne in Atomic Layer Deposition (ALD) techniques, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the reactivity control of propyne during the ALD process. Propyne's high reactivity can lead to undesired side reactions, potentially compromising the quality and uniformity of the deposited films. This issue is particularly pronounced when dealing with complex substrate geometries or when attempting to achieve precise thickness control at the atomic scale.

Another challenge lies in the thermal stability of propyne under ALD conditions. The relatively low decomposition temperature of propyne can limit the processing window, making it difficult to achieve the desired film properties without inducing thermal degradation of the precursor. This thermal instability can result in carbon incorporation into the deposited films, affecting their electrical and mechanical properties.

The volatility and delivery of propyne precursors also present significant hurdles. Ensuring consistent and controlled delivery of propyne vapor to the reaction chamber is crucial for achieving uniform film deposition. However, the low boiling point of propyne and its tendency to condense can lead to fluctuations in precursor supply, affecting the reproducibility and scalability of the ALD process.

Furthermore, the integration of propyne-based ALD processes into existing manufacturing workflows poses challenges. Compatibility issues with other materials and processes in the fabrication line, as well as potential safety concerns due to propyne's flammability, need to be carefully addressed. This integration challenge is particularly relevant in the semiconductor industry, where stringent process control and contamination prevention are paramount.

The development of suitable co-reactants that can effectively pair with propyne in ALD cycles is another area of ongoing research. Finding the right balance between reactivity and selectivity of these co-reactants is crucial for expanding the range of materials that can be deposited using propyne-based ALD.

Lastly, the environmental impact and safety considerations of propyne usage in industrial-scale ALD processes require careful evaluation. Developing efficient recycling or abatement systems for unused propyne and its byproducts is essential for minimizing environmental footprint and ensuring workplace safety in large-scale manufacturing environments.

Another challenge lies in the thermal stability of propyne under ALD conditions. The relatively low decomposition temperature of propyne can limit the processing window, making it difficult to achieve the desired film properties without inducing thermal degradation of the precursor. This thermal instability can result in carbon incorporation into the deposited films, affecting their electrical and mechanical properties.

The volatility and delivery of propyne precursors also present significant hurdles. Ensuring consistent and controlled delivery of propyne vapor to the reaction chamber is crucial for achieving uniform film deposition. However, the low boiling point of propyne and its tendency to condense can lead to fluctuations in precursor supply, affecting the reproducibility and scalability of the ALD process.

Furthermore, the integration of propyne-based ALD processes into existing manufacturing workflows poses challenges. Compatibility issues with other materials and processes in the fabrication line, as well as potential safety concerns due to propyne's flammability, need to be carefully addressed. This integration challenge is particularly relevant in the semiconductor industry, where stringent process control and contamination prevention are paramount.

The development of suitable co-reactants that can effectively pair with propyne in ALD cycles is another area of ongoing research. Finding the right balance between reactivity and selectivity of these co-reactants is crucial for expanding the range of materials that can be deposited using propyne-based ALD.

Lastly, the environmental impact and safety considerations of propyne usage in industrial-scale ALD processes require careful evaluation. Developing efficient recycling or abatement systems for unused propyne and its byproducts is essential for minimizing environmental footprint and ensuring workplace safety in large-scale manufacturing environments.

Existing Propyne ALD Solutions

01 Synthesis and production of propyne

Various methods and processes for synthesizing and producing propyne are described. These include catalytic processes, thermal decomposition, and other chemical reactions to obtain propyne efficiently and with high purity.- Synthesis and production of propyne: Various methods and processes for synthesizing and producing propyne, including catalytic reactions, thermal decomposition, and chemical transformations. These techniques aim to improve yield, efficiency, and purity of propyne production for industrial applications.

- Propyne as a raw material in chemical processes: Utilization of propyne as a key intermediate or starting material in the synthesis of various organic compounds, polymers, and specialty chemicals. This includes its role in the production of pharmaceuticals, agrochemicals, and advanced materials.

- Purification and separation of propyne: Techniques and methods for purifying and separating propyne from mixtures or by-products. This includes distillation, adsorption, membrane separation, and other innovative approaches to obtain high-purity propyne for specific applications.

- Propyne in fuel and energy applications: Exploration of propyne's potential as a fuel additive or energy source. This includes research on its combustion properties, energy density, and possible use in specialized engines or power generation systems.

- Safety and handling of propyne: Development of safety protocols, storage methods, and handling procedures for propyne due to its flammable and potentially explosive nature. This includes the design of specialized equipment, containment systems, and risk mitigation strategies for industrial use.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials, showcasing its versatility in industrial applications.Expand Specific Solutions03 Purification and separation of propyne

Techniques for purifying and separating propyne from mixtures or by-products are discussed. These methods aim to improve the quality and purity of propyne for various applications.Expand Specific Solutions04 Propyne in fuel compositions

The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties or as an additive to improve fuel performance.Expand Specific Solutions05 Safety and handling of propyne

Safety measures and proper handling techniques for propyne are outlined. This includes storage, transportation, and usage guidelines to prevent accidents and ensure safe operations when working with this flammable gas.Expand Specific Solutions

Key Players in Propyne ALD Industry

The field of atomic layer deposition (ALD) techniques utilizing propyne is in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established semiconductor companies and specialized equipment manufacturers. Key players like Micron Technology, Applied Materials, and NAURA Microelectronics are driving innovation in this space. The technology's maturity is progressing, with companies like Picosun and Carpe Diem Tech focusing on developing advanced ALD reactors and processes. As the demand for precise thin-film deposition in semiconductor manufacturing grows, the market is expected to expand further, attracting more players and fostering technological improvements.

Picosun Oy

Technical Solution: Picosun Oy has pioneered the use of propyne in their PICOSUN® ALD systems for various applications. Their technology leverages propyne's reactivity to achieve rapid ALD cycles, significantly reducing processing time. Picosun's approach involves precise control of propyne pulse times and purge cycles, optimizing the surface reactions for each ALD layer. The company has developed specialized precursor delivery systems to handle propyne safely and efficiently, ensuring consistent vapor pressure and flow rates [4]. Picosun's ALD processes using propyne have shown particular success in depositing carbon-containing films and metal carbides with enhanced electrical and mechanical properties [5]. Their systems also incorporate in-situ monitoring tools to fine-tune the propyne-based ALD process in real-time, ensuring optimal film quality and reproducibility [6].

Strengths: Rapid ALD cycles, specialized precursor handling systems, versatility in depositing various materials including carbides. Weaknesses: May require additional safety measures due to propyne's properties, potentially higher cost compared to conventional precursors.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced Atomic Layer Deposition (ALD) techniques incorporating propyne as a precursor. Their approach utilizes propyne's unique chemical properties to enhance film deposition uniformity and conformality. The company's ALD reactors are designed to precisely control propyne flow and reaction conditions, enabling the formation of ultra-thin, high-quality films for semiconductor manufacturing. Applied Materials' process optimizes the decomposition of propyne at lower temperatures, reducing thermal budget and allowing for better integration with temperature-sensitive materials [1][3]. Their ALD technology using propyne has demonstrated improved step coverage in high-aspect-ratio structures, crucial for advanced node semiconductor devices [2].

Strengths: Excellent film uniformity and conformality, lower thermal budget, improved step coverage in complex structures. Weaknesses: Potential safety concerns due to propyne's flammability, may require specialized handling and storage systems.

Core Innovations in Propyne ALD

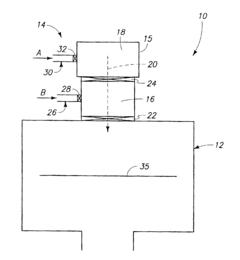

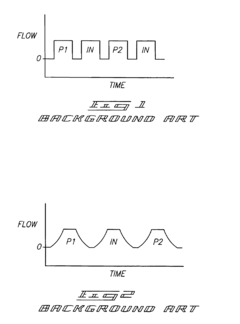

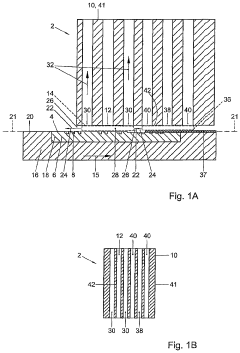

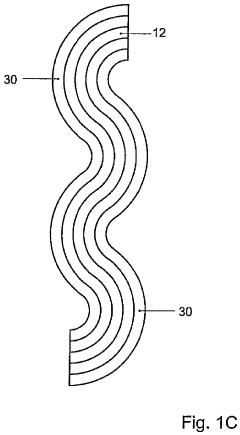

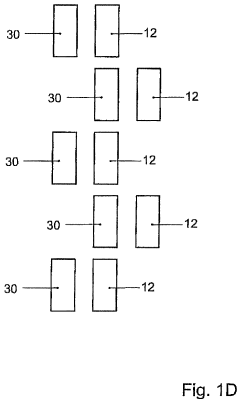

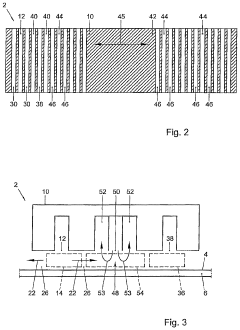

Atomic layer deposition apparatus and methods

PatentInactiveUS6896730B2

Innovation

- The implementation of a gas feed manifold assembly with serially arranged gas chambers and valves allows for precise control of fixed volume precursor and purge gas flows, ensuring sharp transitions and efficient deposition by serially flowing these gases to the substrate.

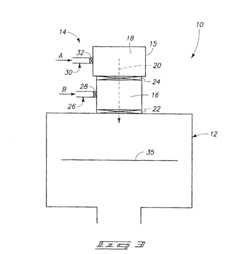

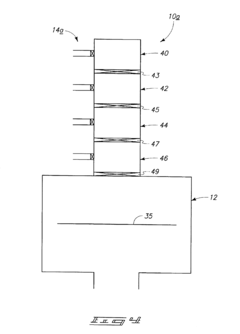

Apparatus and method for atomic layer deposition

PatentActiveUS11549180B2

Innovation

- An apparatus with a precursor injector head that confines the precursor gas to the deposition space adjacent to the substrate surface using a confining structure and relative motion, allowing for precise control of pressure and efficient gas distribution, thereby reducing waste and contamination.

Environmental Impact of Propyne ALD

The environmental impact of propyne-based Atomic Layer Deposition (ALD) techniques is a critical consideration in the semiconductor industry's pursuit of sustainable manufacturing processes. Propyne, also known as methylacetylene, has emerged as a promising precursor in ALD due to its unique chemical properties and reactivity. However, its use in industrial applications necessitates a thorough assessment of its environmental footprint.

Propyne ALD processes generally exhibit lower environmental impact compared to traditional chemical vapor deposition methods. The precise control over film thickness and composition in ALD results in more efficient material usage, reducing waste and minimizing the release of potentially harmful byproducts. Additionally, the lower deposition temperatures typically employed in propyne ALD contribute to reduced energy consumption, aligning with global efforts to decrease industrial carbon footprints.

Despite these advantages, the production and use of propyne in ALD are not without environmental concerns. The synthesis of propyne often involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. Furthermore, propyne is a flammable gas, necessitating stringent safety measures and potentially increasing the risk of accidental releases during transportation and storage.

In terms of atmospheric impact, propyne has a relatively short atmospheric lifetime and low global warming potential compared to many other industrial gases. However, its reactivity in the atmosphere can lead to the formation of secondary pollutants, including ozone and particulate matter, which may contribute to local air quality issues if not properly managed.

Water and soil contamination risks associated with propyne ALD are generally low due to the controlled nature of the deposition process. However, proper disposal of spent precursors and byproducts is essential to prevent potential environmental contamination. Industry best practices include closed-loop recycling systems and treatment of exhaust gases to minimize the release of volatile organic compounds.

The semiconductor industry's increasing adoption of propyne ALD has spurred research into green chemistry alternatives and process optimizations. Efforts are underway to develop bio-based propyne production methods, which could significantly reduce the environmental impact of precursor synthesis. Additionally, advancements in ALD reactor designs aim to improve precursor utilization efficiency and reduce emissions.

As environmental regulations become more stringent globally, the adoption of propyne ALD must be accompanied by comprehensive life cycle assessments and continuous improvement in environmental management practices. This includes optimizing process parameters to minimize precursor consumption, implementing effective abatement systems, and exploring opportunities for circular economy approaches in precursor and byproduct management.

Propyne ALD processes generally exhibit lower environmental impact compared to traditional chemical vapor deposition methods. The precise control over film thickness and composition in ALD results in more efficient material usage, reducing waste and minimizing the release of potentially harmful byproducts. Additionally, the lower deposition temperatures typically employed in propyne ALD contribute to reduced energy consumption, aligning with global efforts to decrease industrial carbon footprints.

Despite these advantages, the production and use of propyne in ALD are not without environmental concerns. The synthesis of propyne often involves petrochemical processes, which can contribute to greenhouse gas emissions and resource depletion. Furthermore, propyne is a flammable gas, necessitating stringent safety measures and potentially increasing the risk of accidental releases during transportation and storage.

In terms of atmospheric impact, propyne has a relatively short atmospheric lifetime and low global warming potential compared to many other industrial gases. However, its reactivity in the atmosphere can lead to the formation of secondary pollutants, including ozone and particulate matter, which may contribute to local air quality issues if not properly managed.

Water and soil contamination risks associated with propyne ALD are generally low due to the controlled nature of the deposition process. However, proper disposal of spent precursors and byproducts is essential to prevent potential environmental contamination. Industry best practices include closed-loop recycling systems and treatment of exhaust gases to minimize the release of volatile organic compounds.

The semiconductor industry's increasing adoption of propyne ALD has spurred research into green chemistry alternatives and process optimizations. Efforts are underway to develop bio-based propyne production methods, which could significantly reduce the environmental impact of precursor synthesis. Additionally, advancements in ALD reactor designs aim to improve precursor utilization efficiency and reduce emissions.

As environmental regulations become more stringent globally, the adoption of propyne ALD must be accompanied by comprehensive life cycle assessments and continuous improvement in environmental management practices. This includes optimizing process parameters to minimize precursor consumption, implementing effective abatement systems, and exploring opportunities for circular economy approaches in precursor and byproduct management.

Safety Protocols for Propyne ALD

Safety protocols for propyne atomic layer deposition (ALD) are critical to ensure the safe handling and use of this highly flammable gas in semiconductor manufacturing processes. The primary safety concerns associated with propyne ALD include its flammability, potential for explosion, and toxicity. To mitigate these risks, a comprehensive set of safety measures must be implemented.

Proper storage and handling of propyne cylinders are essential. Cylinders should be stored in well-ventilated areas, away from heat sources and oxidizing agents. They must be secured to prevent falling and equipped with appropriate pressure regulators and flow control devices. Regular inspections of storage areas and equipment are necessary to identify and address potential leaks or damage.

Personal protective equipment (PPE) is crucial for personnel working with propyne ALD systems. This includes flame-resistant clothing, safety goggles, and appropriate gloves. Respiratory protection may be required in certain situations, particularly when there is a risk of exposure to propyne vapors.

Adequate ventilation is paramount in propyne ALD facilities. Properly designed exhaust systems must be in place to remove any propyne vapors that may escape during the deposition process. Gas detection systems should be installed to monitor propyne levels in the work area continuously and trigger alarms if concentrations approach dangerous levels.

Emergency response procedures must be established and regularly practiced. This includes evacuation plans, fire suppression protocols, and spill containment measures. All personnel working with propyne ALD systems should receive thorough training on these procedures and the proper use of emergency equipment.

Process control measures are essential to prevent accidents during propyne ALD operations. This includes implementing fail-safe systems, such as automatic shutoffs for gas flow in case of equipment malfunction or power failure. Regular maintenance and calibration of ALD equipment are necessary to ensure proper functioning and minimize the risk of gas leaks or uncontrolled reactions.

Proper waste management is another critical aspect of propyne ALD safety. Any unreacted propyne or byproducts must be properly neutralized or disposed of according to local regulations. This may involve the use of scrubbers or other treatment systems to render the waste safe for disposal.

Collaboration with local fire departments and emergency services is advisable to ensure they are prepared to respond to potential incidents involving propyne. This includes providing them with information about the location and quantities of propyne stored on-site, as well as any specific hazards associated with its use in ALD processes.

By implementing these comprehensive safety protocols, the risks associated with propyne ALD can be effectively managed, allowing for the safe utilization of this technology in semiconductor manufacturing and other advanced materials applications.

Proper storage and handling of propyne cylinders are essential. Cylinders should be stored in well-ventilated areas, away from heat sources and oxidizing agents. They must be secured to prevent falling and equipped with appropriate pressure regulators and flow control devices. Regular inspections of storage areas and equipment are necessary to identify and address potential leaks or damage.

Personal protective equipment (PPE) is crucial for personnel working with propyne ALD systems. This includes flame-resistant clothing, safety goggles, and appropriate gloves. Respiratory protection may be required in certain situations, particularly when there is a risk of exposure to propyne vapors.

Adequate ventilation is paramount in propyne ALD facilities. Properly designed exhaust systems must be in place to remove any propyne vapors that may escape during the deposition process. Gas detection systems should be installed to monitor propyne levels in the work area continuously and trigger alarms if concentrations approach dangerous levels.

Emergency response procedures must be established and regularly practiced. This includes evacuation plans, fire suppression protocols, and spill containment measures. All personnel working with propyne ALD systems should receive thorough training on these procedures and the proper use of emergency equipment.

Process control measures are essential to prevent accidents during propyne ALD operations. This includes implementing fail-safe systems, such as automatic shutoffs for gas flow in case of equipment malfunction or power failure. Regular maintenance and calibration of ALD equipment are necessary to ensure proper functioning and minimize the risk of gas leaks or uncontrolled reactions.

Proper waste management is another critical aspect of propyne ALD safety. Any unreacted propyne or byproducts must be properly neutralized or disposed of according to local regulations. This may involve the use of scrubbers or other treatment systems to render the waste safe for disposal.

Collaboration with local fire departments and emergency services is advisable to ensure they are prepared to respond to potential incidents involving propyne. This includes providing them with information about the location and quantities of propyne stored on-site, as well as any specific hazards associated with its use in ALD processes.

By implementing these comprehensive safety protocols, the risks associated with propyne ALD can be effectively managed, allowing for the safe utilization of this technology in semiconductor manufacturing and other advanced materials applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!