Propyne's Function in Light-Emitting Polymer Synthesis

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne in LEP Synthesis: Background and Objectives

Light-emitting polymers (LEPs) have emerged as a revolutionary technology in the field of organic electronics, offering promising applications in displays, lighting, and flexible devices. The synthesis of these polymers has been a subject of intense research over the past few decades, with propyne playing a crucial role in their development.

Propyne, also known as methylacetylene, is a simple alkyne compound that has proven to be an invaluable building block in the synthesis of LEPs. Its unique structure and reactivity have enabled researchers to create polymers with tailored optical and electronic properties, essential for high-performance light-emitting devices.

The journey of propyne in LEP synthesis began in the early 1990s when scientists discovered that acetylene-based polymers could exhibit electroluminescence. This breakthrough led to the exploration of various acetylenic compounds, including propyne, as potential precursors for LEPs. The incorporation of propyne into polymer structures allowed for greater control over the conjugation length and energy levels of the resulting materials.

As research progressed, propyne's versatility in LEP synthesis became increasingly apparent. Its ability to undergo various polymerization reactions, such as Sonogashira coupling and metathesis, opened up new avenues for creating diverse polymer architectures. These reactions enabled the synthesis of both linear and branched polymers with precisely controlled molecular weights and polydispersities.

The technological evolution of propyne-based LEP synthesis has been marked by several key milestones. Early efforts focused on homopolymers and simple copolymers, while later developments led to the creation of more complex systems, including block copolymers and dendrimers. These advancements have significantly improved the efficiency, color purity, and stability of LEP-based devices.

One of the primary objectives in propyne-based LEP research has been to enhance the quantum efficiency of the resulting polymers. By fine-tuning the chemical structure and incorporating various functional groups, researchers have aimed to optimize the photophysical properties of LEPs. This has led to the development of materials with improved charge transport characteristics and reduced non-radiative decay pathways.

Another critical goal has been to expand the color range of LEPs. Propyne's reactivity has allowed for the introduction of different chromophores and electron-donating or electron-withdrawing groups, enabling the synthesis of polymers that emit across the entire visible spectrum. This versatility has been crucial in the development of full-color displays and white-light-emitting devices.

As we look to the future, the role of propyne in LEP synthesis continues to evolve. Current research aims to address challenges such as long-term stability, processability, and scalability of LEP production. The integration of propyne-based LEPs with other emerging technologies, such as quantum dots and perovskites, presents exciting opportunities for next-generation optoelectronic devices.

Propyne, also known as methylacetylene, is a simple alkyne compound that has proven to be an invaluable building block in the synthesis of LEPs. Its unique structure and reactivity have enabled researchers to create polymers with tailored optical and electronic properties, essential for high-performance light-emitting devices.

The journey of propyne in LEP synthesis began in the early 1990s when scientists discovered that acetylene-based polymers could exhibit electroluminescence. This breakthrough led to the exploration of various acetylenic compounds, including propyne, as potential precursors for LEPs. The incorporation of propyne into polymer structures allowed for greater control over the conjugation length and energy levels of the resulting materials.

As research progressed, propyne's versatility in LEP synthesis became increasingly apparent. Its ability to undergo various polymerization reactions, such as Sonogashira coupling and metathesis, opened up new avenues for creating diverse polymer architectures. These reactions enabled the synthesis of both linear and branched polymers with precisely controlled molecular weights and polydispersities.

The technological evolution of propyne-based LEP synthesis has been marked by several key milestones. Early efforts focused on homopolymers and simple copolymers, while later developments led to the creation of more complex systems, including block copolymers and dendrimers. These advancements have significantly improved the efficiency, color purity, and stability of LEP-based devices.

One of the primary objectives in propyne-based LEP research has been to enhance the quantum efficiency of the resulting polymers. By fine-tuning the chemical structure and incorporating various functional groups, researchers have aimed to optimize the photophysical properties of LEPs. This has led to the development of materials with improved charge transport characteristics and reduced non-radiative decay pathways.

Another critical goal has been to expand the color range of LEPs. Propyne's reactivity has allowed for the introduction of different chromophores and electron-donating or electron-withdrawing groups, enabling the synthesis of polymers that emit across the entire visible spectrum. This versatility has been crucial in the development of full-color displays and white-light-emitting devices.

As we look to the future, the role of propyne in LEP synthesis continues to evolve. Current research aims to address challenges such as long-term stability, processability, and scalability of LEP production. The integration of propyne-based LEPs with other emerging technologies, such as quantum dots and perovskites, presents exciting opportunities for next-generation optoelectronic devices.

Market Analysis for Propyne-based LEPs

The market for propyne-based light-emitting polymers (LEPs) is experiencing significant growth, driven by the increasing demand for advanced display technologies and energy-efficient lighting solutions. The global organic light-emitting diode (OLED) market, which includes propyne-based LEPs, is projected to reach substantial market value in the coming years, with a compound annual growth rate (CAGR) outpacing many other segments in the electronics industry.

The automotive sector represents a key market for propyne-based LEPs, as manufacturers increasingly adopt OLED technology for interior and exterior lighting applications. The enhanced flexibility and design possibilities offered by these materials allow for innovative lighting solutions that can improve both aesthetics and functionality in vehicles. Additionally, the aerospace industry is showing growing interest in propyne-based LEPs for cabin lighting and display systems, valuing their lightweight properties and energy efficiency.

Consumer electronics continue to be a major driver for propyne-based LEP market growth. Smartphones, tablets, and wearable devices are incorporating OLED displays at an accelerating rate, with propyne-based materials playing a crucial role in enhancing display performance and energy efficiency. The trend towards foldable and flexible displays further amplifies the demand for these advanced polymer materials.

In the lighting industry, propyne-based LEPs are gaining traction as alternatives to traditional lighting technologies. The ability to create large-area, uniform light sources with these materials is particularly attractive for architectural and decorative lighting applications. The push for energy-efficient lighting solutions in both residential and commercial sectors aligns well with the properties of propyne-based LEPs.

Geographically, Asia-Pacific dominates the market for propyne-based LEPs, with South Korea, Japan, and China leading in both production and consumption. These countries host major manufacturers of OLED displays and lighting products, driving significant demand for propyne-based materials. North America and Europe follow, with growing adoption in high-end consumer electronics and automotive applications.

The market landscape is characterized by intense competition and rapid technological advancements. Key players in the propyne-based LEP market are investing heavily in research and development to improve material properties, enhance manufacturing processes, and reduce production costs. Collaborations between material suppliers, device manufacturers, and end-users are becoming increasingly common, fostering innovation and market expansion.

Despite the positive outlook, challenges remain in the widespread adoption of propyne-based LEPs. Cost considerations, particularly for large-scale applications, continue to be a limiting factor. However, ongoing research and economies of scale are expected to gradually address this issue, potentially opening up new market opportunities in the future.

The automotive sector represents a key market for propyne-based LEPs, as manufacturers increasingly adopt OLED technology for interior and exterior lighting applications. The enhanced flexibility and design possibilities offered by these materials allow for innovative lighting solutions that can improve both aesthetics and functionality in vehicles. Additionally, the aerospace industry is showing growing interest in propyne-based LEPs for cabin lighting and display systems, valuing their lightweight properties and energy efficiency.

Consumer electronics continue to be a major driver for propyne-based LEP market growth. Smartphones, tablets, and wearable devices are incorporating OLED displays at an accelerating rate, with propyne-based materials playing a crucial role in enhancing display performance and energy efficiency. The trend towards foldable and flexible displays further amplifies the demand for these advanced polymer materials.

In the lighting industry, propyne-based LEPs are gaining traction as alternatives to traditional lighting technologies. The ability to create large-area, uniform light sources with these materials is particularly attractive for architectural and decorative lighting applications. The push for energy-efficient lighting solutions in both residential and commercial sectors aligns well with the properties of propyne-based LEPs.

Geographically, Asia-Pacific dominates the market for propyne-based LEPs, with South Korea, Japan, and China leading in both production and consumption. These countries host major manufacturers of OLED displays and lighting products, driving significant demand for propyne-based materials. North America and Europe follow, with growing adoption in high-end consumer electronics and automotive applications.

The market landscape is characterized by intense competition and rapid technological advancements. Key players in the propyne-based LEP market are investing heavily in research and development to improve material properties, enhance manufacturing processes, and reduce production costs. Collaborations between material suppliers, device manufacturers, and end-users are becoming increasingly common, fostering innovation and market expansion.

Despite the positive outlook, challenges remain in the widespread adoption of propyne-based LEPs. Cost considerations, particularly for large-scale applications, continue to be a limiting factor. However, ongoing research and economies of scale are expected to gradually address this issue, potentially opening up new market opportunities in the future.

Current Challenges in Propyne Utilization

Despite the promising potential of propyne in light-emitting polymer synthesis, several significant challenges currently hinder its widespread utilization. One of the primary obstacles is the high reactivity of propyne, which makes it difficult to handle and store safely. This reactivity often leads to undesired side reactions during polymer synthesis, resulting in reduced yield and purity of the final product.

Another major challenge is the limited availability and high cost of high-purity propyne. The production of propyne typically involves energy-intensive processes, contributing to its elevated price point. This economic barrier restricts its application in large-scale industrial production of light-emitting polymers, particularly when competing with more readily available and cost-effective alternatives.

The controlled incorporation of propyne into polymer structures presents another significant hurdle. Achieving precise control over the degree of propyne incorporation and its distribution within the polymer chain is crucial for optimizing the light-emitting properties of the resulting materials. However, current synthetic methodologies often struggle to provide this level of control, leading to inconsistent product quality and performance.

Furthermore, the stability of propyne-containing polymers remains a concern. The triple bond in propyne can be susceptible to degradation under certain conditions, potentially compromising the long-term performance and reliability of light-emitting devices based on these materials. This instability issue necessitates the development of more robust synthetic strategies and protective measures to enhance the durability of propyne-based light-emitting polymers.

The scalability of propyne-based synthesis processes also presents challenges. While laboratory-scale experiments have demonstrated promising results, translating these processes to industrial-scale production introduces complexities in maintaining reaction conditions, ensuring consistent product quality, and managing safety concerns associated with large quantities of reactive propyne.

Additionally, the environmental impact of propyne production and utilization in polymer synthesis is an emerging concern. The carbon footprint associated with propyne synthesis, coupled with potential emissions during polymer production, calls for the development of more sustainable and eco-friendly approaches to harness the benefits of propyne in light-emitting polymer applications.

Lastly, the regulatory landscape surrounding the use of propyne in consumer products, particularly in light-emitting devices, presents another challenge. Ensuring compliance with safety standards and environmental regulations while leveraging the unique properties of propyne-based polymers requires careful navigation of the regulatory framework and potentially extensive testing and certification processes.

Another major challenge is the limited availability and high cost of high-purity propyne. The production of propyne typically involves energy-intensive processes, contributing to its elevated price point. This economic barrier restricts its application in large-scale industrial production of light-emitting polymers, particularly when competing with more readily available and cost-effective alternatives.

The controlled incorporation of propyne into polymer structures presents another significant hurdle. Achieving precise control over the degree of propyne incorporation and its distribution within the polymer chain is crucial for optimizing the light-emitting properties of the resulting materials. However, current synthetic methodologies often struggle to provide this level of control, leading to inconsistent product quality and performance.

Furthermore, the stability of propyne-containing polymers remains a concern. The triple bond in propyne can be susceptible to degradation under certain conditions, potentially compromising the long-term performance and reliability of light-emitting devices based on these materials. This instability issue necessitates the development of more robust synthetic strategies and protective measures to enhance the durability of propyne-based light-emitting polymers.

The scalability of propyne-based synthesis processes also presents challenges. While laboratory-scale experiments have demonstrated promising results, translating these processes to industrial-scale production introduces complexities in maintaining reaction conditions, ensuring consistent product quality, and managing safety concerns associated with large quantities of reactive propyne.

Additionally, the environmental impact of propyne production and utilization in polymer synthesis is an emerging concern. The carbon footprint associated with propyne synthesis, coupled with potential emissions during polymer production, calls for the development of more sustainable and eco-friendly approaches to harness the benefits of propyne in light-emitting polymer applications.

Lastly, the regulatory landscape surrounding the use of propyne in consumer products, particularly in light-emitting devices, presents another challenge. Ensuring compliance with safety standards and environmental regulations while leveraging the unique properties of propyne-based polymers requires careful navigation of the regulatory framework and potentially extensive testing and certification processes.

Existing Propyne-LEP Synthesis Methods

01 Synthesis and production of propyne

Various methods and processes for synthesizing and producing propyne are described. These include catalytic reactions, thermal decomposition, and other chemical processes to obtain propyne efficiently and with high purity.- Synthesis and production of propyne: Various methods and processes for synthesizing and producing propyne are described. These include catalytic processes, thermal cracking, and other chemical reactions to obtain propyne from different precursors. The techniques aim to improve yield, efficiency, and purity of the propyne product.

- Propyne as a raw material in chemical processes: Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials. The applications include its use in organic synthesis, as a precursor for specialty chemicals, and in the manufacturing of industrial products.

- Purification and separation of propyne: Methods and systems for purifying and separating propyne from mixtures are presented. These include distillation techniques, membrane separation, adsorption processes, and other purification methods to obtain high-purity propyne. The focus is on improving the efficiency and effectiveness of separation processes.

- Propyne in fuel compositions: The use of propyne in fuel compositions is explored. This includes its potential as an additive or component in various fuel formulations to enhance combustion properties, improve engine performance, or reduce emissions. Research focuses on optimizing propyne-containing fuel blends for different applications.

- Safety and handling of propyne: Safety measures and handling procedures for propyne are discussed. This includes storage methods, transportation guidelines, risk assessment, and safety protocols for working with propyne in industrial and laboratory settings. The focus is on preventing accidents and ensuring safe usage of this flammable gas.

02 Propyne as a raw material in chemical processes

Propyne serves as an important raw material in various chemical processes. It is used in the production of other chemicals, polymers, and materials, showcasing its versatility in industrial applications.Expand Specific Solutions03 Purification and separation of propyne

Techniques for purifying and separating propyne from mixtures or by-products are discussed. These methods aim to improve the quality and purity of propyne for subsequent use in industrial processes.Expand Specific Solutions04 Propyne in fuel compositions

The use of propyne in fuel compositions is explored. It can be incorporated into various fuel blends to enhance combustion properties or as an additive to improve fuel performance in engines.Expand Specific Solutions05 Safety and handling of propyne

Safety measures and proper handling techniques for propyne are outlined. This includes storage, transportation, and usage guidelines to prevent accidents and ensure safe industrial practices when working with this flammable gas.Expand Specific Solutions

Key Players in Propyne-LEP Research

The competitive landscape for propyne's function in light-emitting polymer synthesis is in an early development stage, with a growing market potential as demand for advanced display technologies increases. The technology is still evolving, with research institutions and major electronics companies leading innovation. Key players like Samsung Display, Sharp, and BASF are investing in R&D to improve polymer light-emitting diode (PLED) efficiency and performance. Universities such as Chongqing University and Fudan University are contributing to fundamental research. While the market size is expanding, commercialization challenges remain, indicating a nascent but promising field with opportunities for technological breakthroughs and industrial applications.

Idemitsu Kosan Co., Ltd.

Technical Solution: Idemitsu Kosan has developed a proprietary synthesis method for light-emitting polymers using propyne as a key building block. Their approach involves the controlled polymerization of propyne-based monomers to create conjugated polymer structures with tunable optoelectronic properties. The company has optimized the reaction conditions to achieve high molecular weights and narrow polydispersity indices, resulting in improved film-forming properties and enhanced device performance[1]. Idemitsu's propyne-based polymers exhibit excellent color purity and efficiency in blue and green emission regions, addressing a critical challenge in OLED technology[2].

Strengths: Precise control over polymer structure and properties, high color purity in blue-green region. Weaknesses: Potential scalability issues, higher production costs compared to some alternative methods.

BASF Corp.

Technical Solution: BASF has developed a novel approach to incorporating propyne units into light-emitting polymers through a controlled copolymerization process. Their method involves the use of propyne-derived comonomers in combination with other aromatic monomers to create highly efficient and stable emissive materials. BASF's technology allows for fine-tuning of the polymer backbone composition, enabling precise control over the HOMO-LUMO energy levels and emission wavelengths[3]. The company has also implemented advanced purification techniques to remove catalyst residues and other impurities, resulting in materials with improved device lifetimes and reduced efficiency roll-off[4].

Strengths: Versatile copolymerization approach, ability to fine-tune electronic properties. Weaknesses: Complexity of synthesis process, potential batch-to-batch variations.

Innovative Propyne Functionalization Techniques

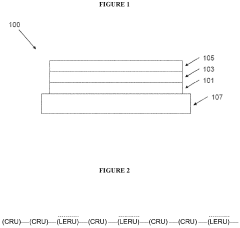

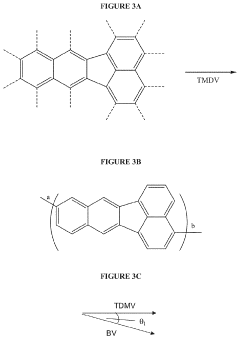

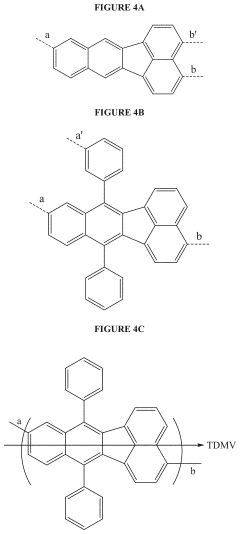

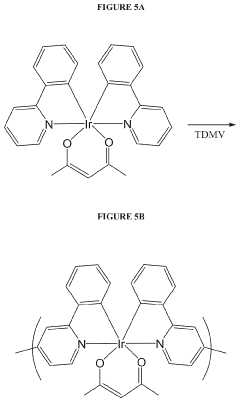

Organic light emitting polymer comprising light-emitting repeat unit in backbone of polymer and device therewith

PatentActiveUS11788001B2

Innovation

- The development of light-emitting polymers with aligned transition dipole moments relative to the polymer backbone, specifically through the alignment of light-emitting repeat units during polymerization, enhances the external quantum efficiency by minimizing the angle between bond vectors and transition dipole moments, resulting in an anisotropy factor of no more than 0.8.

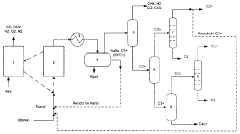

process FOR THE PRODUCTION OF PROPYLENE AND ETHYLENE FROM ETHANOL USING A ZEOLITE CATALYST

PatentPendingCO6470100A1

Innovation

- A catalyst composed of amorphous alumina or silica-alumina and ZSM-5 zeolite, doped with chromium, molybdenum, or tungsten, is used to enhance propylene production by limiting hydrogen transfer reactions and high molecular weight compound formation, favoring propylene formation through controlled oligomerization and cracking mechanisms.

Environmental Impact of Propyne-LEP Production

The production of light-emitting polymers (LEPs) using propyne as a key component has significant environmental implications that warrant careful consideration. The synthesis process involves several stages, each with potential environmental impacts. Firstly, the extraction and production of propyne itself contribute to carbon emissions and energy consumption. Propyne is typically derived from petroleum refining or natural gas processing, which are energy-intensive processes with associated greenhouse gas emissions.

During the polymer synthesis, the use of propyne and other chemical precursors may result in the release of volatile organic compounds (VOCs) and other potentially harmful substances. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities if not properly managed. Additionally, the synthesis process often requires solvents and catalysts, some of which may be toxic or environmentally persistent.

The energy requirements for LEP production are substantial, particularly in maintaining precise reaction conditions and in the purification of the final product. This energy demand typically translates to increased electricity consumption, which, depending on the energy source, can lead to indirect environmental impacts through power generation.

Waste management is another critical environmental concern in propyne-LEP production. The process generates various waste streams, including unreacted materials, byproducts, and spent catalysts. Proper disposal or recycling of these wastes is essential to prevent soil and water contamination. Some of the waste materials may be hazardous, requiring specialized treatment and disposal methods.

On the positive side, LEPs produced using propyne often exhibit improved efficiency and longevity compared to traditional lighting technologies. This can lead to reduced energy consumption and waste generation over the product lifecycle, potentially offsetting some of the environmental impacts of production. Furthermore, advances in green chemistry and sustainable manufacturing practices are gradually being applied to LEP production, aiming to reduce its environmental footprint.

The end-of-life management of LEP products is an emerging environmental concern. While these polymers offer advantages in terms of energy efficiency, their disposal and recycling present challenges due to the complex nature of the materials. Improper disposal can lead to the release of potentially harmful substances into the environment.

In conclusion, while propyne-based LEP production offers promising technological advancements, it also presents significant environmental challenges. Balancing the benefits of improved lighting efficiency with the environmental impacts of production requires ongoing research and development in cleaner synthesis methods, more efficient resource use, and improved waste management strategies.

During the polymer synthesis, the use of propyne and other chemical precursors may result in the release of volatile organic compounds (VOCs) and other potentially harmful substances. These emissions can contribute to air pollution and pose health risks to workers and surrounding communities if not properly managed. Additionally, the synthesis process often requires solvents and catalysts, some of which may be toxic or environmentally persistent.

The energy requirements for LEP production are substantial, particularly in maintaining precise reaction conditions and in the purification of the final product. This energy demand typically translates to increased electricity consumption, which, depending on the energy source, can lead to indirect environmental impacts through power generation.

Waste management is another critical environmental concern in propyne-LEP production. The process generates various waste streams, including unreacted materials, byproducts, and spent catalysts. Proper disposal or recycling of these wastes is essential to prevent soil and water contamination. Some of the waste materials may be hazardous, requiring specialized treatment and disposal methods.

On the positive side, LEPs produced using propyne often exhibit improved efficiency and longevity compared to traditional lighting technologies. This can lead to reduced energy consumption and waste generation over the product lifecycle, potentially offsetting some of the environmental impacts of production. Furthermore, advances in green chemistry and sustainable manufacturing practices are gradually being applied to LEP production, aiming to reduce its environmental footprint.

The end-of-life management of LEP products is an emerging environmental concern. While these polymers offer advantages in terms of energy efficiency, their disposal and recycling present challenges due to the complex nature of the materials. Improper disposal can lead to the release of potentially harmful substances into the environment.

In conclusion, while propyne-based LEP production offers promising technological advancements, it also presents significant environmental challenges. Balancing the benefits of improved lighting efficiency with the environmental impacts of production requires ongoing research and development in cleaner synthesis methods, more efficient resource use, and improved waste management strategies.

Intellectual Property Landscape for Propyne-LEPs

The intellectual property landscape for propyne-based light-emitting polymers (LEPs) has evolved significantly over the past two decades, reflecting the growing interest in this technology for display and lighting applications. A comprehensive analysis of patent filings reveals a steady increase in research and development activities, with a notable surge in the last five years.

Major technology companies and academic institutions have been at the forefront of propyne-LEP innovation. Key players include multinational corporations like Samsung, LG, and Philips, as well as specialized materials science companies such as Merck and Universal Display Corporation. These entities have established strong patent portfolios, covering various aspects of propyne-LEP synthesis, device fabrication, and application methods.

Patent clusters predominantly focus on several key areas within propyne-LEP technology. These include novel polymer structures incorporating propyne moieties, synthesis routes for high-purity propyne-containing monomers, and methods for controlling polymer chain length and branching. Additionally, there is significant patenting activity around the integration of propyne-LEPs into device architectures, particularly for OLED displays and solid-state lighting.

Geographically, the patent landscape shows a concentration of filings in East Asia, particularly Japan, South Korea, and China, reflecting the strong presence of display and electronics manufacturers in these regions. However, substantial patent activity is also observed in the United States and Europe, often originating from research institutions and specialty chemical companies.

Recent trends in patent filings indicate a growing interest in enhancing the efficiency and stability of propyne-LEPs. This includes patents on novel crosslinking methods to improve thermal stability, strategies for tuning the emission wavelength, and approaches to mitigate degradation mechanisms. There is also an emerging focus on environmentally friendly synthesis routes and the development of solution-processable propyne-LEPs for large-area applications.

The patent landscape also reveals potential areas for future innovation. These include the development of propyne-LEPs with improved charge transport properties, exploration of new host materials for propyne-based emitters, and the integration of propyne-LEPs with other emerging technologies such as quantum dots or perovskite materials for hybrid light-emitting devices.

Overall, the intellectual property landscape for propyne-LEPs demonstrates a mature yet still evolving field, with ample opportunities for further innovation and technological advancement. The high level of patent activity underscores the commercial potential of this technology and suggests continued investment in research and development in the coming years.

Major technology companies and academic institutions have been at the forefront of propyne-LEP innovation. Key players include multinational corporations like Samsung, LG, and Philips, as well as specialized materials science companies such as Merck and Universal Display Corporation. These entities have established strong patent portfolios, covering various aspects of propyne-LEP synthesis, device fabrication, and application methods.

Patent clusters predominantly focus on several key areas within propyne-LEP technology. These include novel polymer structures incorporating propyne moieties, synthesis routes for high-purity propyne-containing monomers, and methods for controlling polymer chain length and branching. Additionally, there is significant patenting activity around the integration of propyne-LEPs into device architectures, particularly for OLED displays and solid-state lighting.

Geographically, the patent landscape shows a concentration of filings in East Asia, particularly Japan, South Korea, and China, reflecting the strong presence of display and electronics manufacturers in these regions. However, substantial patent activity is also observed in the United States and Europe, often originating from research institutions and specialty chemical companies.

Recent trends in patent filings indicate a growing interest in enhancing the efficiency and stability of propyne-LEPs. This includes patents on novel crosslinking methods to improve thermal stability, strategies for tuning the emission wavelength, and approaches to mitigate degradation mechanisms. There is also an emerging focus on environmentally friendly synthesis routes and the development of solution-processable propyne-LEPs for large-area applications.

The patent landscape also reveals potential areas for future innovation. These include the development of propyne-LEPs with improved charge transport properties, exploration of new host materials for propyne-based emitters, and the integration of propyne-LEPs with other emerging technologies such as quantum dots or perovskite materials for hybrid light-emitting devices.

Overall, the intellectual property landscape for propyne-LEPs demonstrates a mature yet still evolving field, with ample opportunities for further innovation and technological advancement. The high level of patent activity underscores the commercial potential of this technology and suggests continued investment in research and development in the coming years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!