Study of Sustainable Extraction Techniques for Propyne Applications

JUL 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Propyne Extraction Background and Objectives

Propyne, also known as methylacetylene, is a highly versatile alkyne compound with significant industrial applications. The extraction and utilization of propyne have been subjects of extensive research and development over the past decades, driven by its potential in various sectors, including petrochemicals, pharmaceuticals, and materials science.

The history of propyne extraction can be traced back to the early 20th century when it was first isolated as a byproduct of petroleum refining processes. Initially, propyne was considered a waste product with limited value. However, as industrial chemistry advanced, researchers began to recognize its unique properties and potential applications, leading to increased efforts in developing efficient extraction techniques.

The evolution of propyne extraction technologies has been closely tied to the advancements in separation and purification methods in the chemical industry. Early extraction methods primarily relied on cryogenic distillation, which was energy-intensive and had limited efficiency. As environmental concerns and energy efficiency became more prominent, the focus shifted towards developing more sustainable and cost-effective extraction techniques.

In recent years, the growing emphasis on sustainability and circular economy principles has further accelerated research into novel propyne extraction methods. The primary objectives of current research efforts are to enhance the efficiency of extraction processes, reduce energy consumption, minimize environmental impact, and explore new applications for propyne in various industries.

One of the key drivers for sustainable propyne extraction is the increasing demand for high-purity propyne in the production of specialty chemicals and advanced materials. The semiconductor industry, for instance, requires ultra-pure propyne for the deposition of thin films in electronic components. This demand has spurred innovation in extraction and purification technologies, pushing the boundaries of what is achievable in terms of product quality and process efficiency.

The objectives of modern propyne extraction research extend beyond mere efficiency improvements. There is a growing focus on developing integrated processes that can extract propyne alongside other valuable hydrocarbons, maximizing the utilization of feedstock and reducing waste. Additionally, researchers are exploring bio-based sources of propyne and investigating the potential of renewable feedstocks to create a more sustainable supply chain for this important industrial chemical.

As we look towards the future, the goals of propyne extraction research are increasingly aligned with broader sustainability targets. This includes the development of carbon-neutral or carbon-negative extraction processes, the integration of renewable energy sources in extraction facilities, and the exploration of novel applications that can contribute to solving global challenges such as climate change and resource scarcity.

The history of propyne extraction can be traced back to the early 20th century when it was first isolated as a byproduct of petroleum refining processes. Initially, propyne was considered a waste product with limited value. However, as industrial chemistry advanced, researchers began to recognize its unique properties and potential applications, leading to increased efforts in developing efficient extraction techniques.

The evolution of propyne extraction technologies has been closely tied to the advancements in separation and purification methods in the chemical industry. Early extraction methods primarily relied on cryogenic distillation, which was energy-intensive and had limited efficiency. As environmental concerns and energy efficiency became more prominent, the focus shifted towards developing more sustainable and cost-effective extraction techniques.

In recent years, the growing emphasis on sustainability and circular economy principles has further accelerated research into novel propyne extraction methods. The primary objectives of current research efforts are to enhance the efficiency of extraction processes, reduce energy consumption, minimize environmental impact, and explore new applications for propyne in various industries.

One of the key drivers for sustainable propyne extraction is the increasing demand for high-purity propyne in the production of specialty chemicals and advanced materials. The semiconductor industry, for instance, requires ultra-pure propyne for the deposition of thin films in electronic components. This demand has spurred innovation in extraction and purification technologies, pushing the boundaries of what is achievable in terms of product quality and process efficiency.

The objectives of modern propyne extraction research extend beyond mere efficiency improvements. There is a growing focus on developing integrated processes that can extract propyne alongside other valuable hydrocarbons, maximizing the utilization of feedstock and reducing waste. Additionally, researchers are exploring bio-based sources of propyne and investigating the potential of renewable feedstocks to create a more sustainable supply chain for this important industrial chemical.

As we look towards the future, the goals of propyne extraction research are increasingly aligned with broader sustainability targets. This includes the development of carbon-neutral or carbon-negative extraction processes, the integration of renewable energy sources in extraction facilities, and the exploration of novel applications that can contribute to solving global challenges such as climate change and resource scarcity.

Market Analysis for Propyne Applications

The global market for propyne applications has been experiencing steady growth, driven by increasing demand in various industrial sectors. Propyne, also known as methylacetylene, finds extensive use in organic synthesis, particularly in the production of specialty chemicals, pharmaceuticals, and advanced materials. The versatility of propyne as a building block for complex molecules has contributed to its rising importance in the chemical industry.

In recent years, the propyne market has witnessed a surge in demand from the electronics and semiconductor industries. The compound's unique properties make it valuable in the production of high-performance polymers and coatings used in electronic components. This trend is expected to continue as the electronics sector expands and evolves, particularly with the advent of 5G technology and the Internet of Things (IoT).

The automotive industry represents another significant market for propyne applications. As manufacturers focus on developing lightweight materials and improving fuel efficiency, propyne-based polymers are gaining traction in the production of automotive parts and components. This trend aligns with the global push towards more sustainable and environmentally friendly transportation solutions.

In the pharmaceutical sector, propyne serves as a crucial intermediate in the synthesis of various active pharmaceutical ingredients (APIs). The growing emphasis on personalized medicine and the development of novel drug therapies has led to increased demand for propyne in pharmaceutical research and production. This trend is particularly pronounced in emerging markets, where rapid industrialization and improving healthcare infrastructure are driving growth in the pharmaceutical industry.

The construction industry also presents opportunities for propyne applications, particularly in the development of advanced adhesives, sealants, and coatings. As the construction sector embraces sustainable building practices and high-performance materials, propyne-based products are likely to see increased adoption.

Geographically, Asia-Pacific remains the largest market for propyne applications, driven by robust industrial growth in countries like China and India. North America and Europe follow closely, with strong demand from the pharmaceutical and specialty chemicals sectors. Emerging economies in Latin America and Africa are expected to contribute to market growth as their industrial bases expand and diversify.

Despite the positive outlook, the propyne market faces challenges related to raw material availability and price volatility. The compound is primarily derived from petroleum feedstocks, making it susceptible to fluctuations in oil prices. This has led to increased interest in developing sustainable extraction techniques and alternative production methods to ensure a stable supply chain and mitigate environmental concerns.

In recent years, the propyne market has witnessed a surge in demand from the electronics and semiconductor industries. The compound's unique properties make it valuable in the production of high-performance polymers and coatings used in electronic components. This trend is expected to continue as the electronics sector expands and evolves, particularly with the advent of 5G technology and the Internet of Things (IoT).

The automotive industry represents another significant market for propyne applications. As manufacturers focus on developing lightweight materials and improving fuel efficiency, propyne-based polymers are gaining traction in the production of automotive parts and components. This trend aligns with the global push towards more sustainable and environmentally friendly transportation solutions.

In the pharmaceutical sector, propyne serves as a crucial intermediate in the synthesis of various active pharmaceutical ingredients (APIs). The growing emphasis on personalized medicine and the development of novel drug therapies has led to increased demand for propyne in pharmaceutical research and production. This trend is particularly pronounced in emerging markets, where rapid industrialization and improving healthcare infrastructure are driving growth in the pharmaceutical industry.

The construction industry also presents opportunities for propyne applications, particularly in the development of advanced adhesives, sealants, and coatings. As the construction sector embraces sustainable building practices and high-performance materials, propyne-based products are likely to see increased adoption.

Geographically, Asia-Pacific remains the largest market for propyne applications, driven by robust industrial growth in countries like China and India. North America and Europe follow closely, with strong demand from the pharmaceutical and specialty chemicals sectors. Emerging economies in Latin America and Africa are expected to contribute to market growth as their industrial bases expand and diversify.

Despite the positive outlook, the propyne market faces challenges related to raw material availability and price volatility. The compound is primarily derived from petroleum feedstocks, making it susceptible to fluctuations in oil prices. This has led to increased interest in developing sustainable extraction techniques and alternative production methods to ensure a stable supply chain and mitigate environmental concerns.

Current Extraction Challenges and Limitations

The extraction of propyne, also known as methylacetylene, presents several significant challenges and limitations in current industrial practices. One of the primary obstacles is the high energy consumption associated with traditional extraction methods. Conventional techniques often rely on cryogenic distillation, which requires extremely low temperatures and high pressure conditions, leading to substantial energy costs and environmental concerns.

Another major challenge lies in the separation of propyne from other similar hydrocarbons, particularly propylene. Due to their close boiling points and similar physical properties, achieving high purity levels of propyne is technically demanding and often results in low yields. This separation difficulty not only increases production costs but also limits the overall efficiency of the extraction process.

The use of harmful solvents in some extraction methods poses environmental and safety risks. Many current techniques employ organic solvents that are potentially toxic and environmentally hazardous. This not only raises concerns about worker safety but also necessitates complex waste management procedures, adding to the overall operational complexity and cost.

Scalability remains a significant limitation for many existing propyne extraction techniques. While some methods may work effectively at laboratory scales, translating these processes to industrial-scale production often proves challenging. Issues such as equipment design, process control, and maintaining consistent quality across large volumes of production continue to hinder widespread implementation.

The economic viability of propyne extraction is another critical limitation. The high costs associated with specialized equipment, energy-intensive processes, and purification steps often make propyne production economically unfeasible for many potential applications. This economic barrier has restricted the broader use of propyne in various industries, despite its potential benefits.

Sustainability concerns also pose significant challenges to current extraction methods. Many existing techniques have substantial carbon footprints, contributing to greenhouse gas emissions and environmental degradation. The lack of environmentally friendly alternatives has become a pressing issue, especially in light of growing global emphasis on sustainable industrial practices.

Lastly, the variability in feedstock composition presents ongoing challenges for propyne extraction. Different sources of raw materials can lead to inconsistencies in the extraction process, requiring constant adjustments and potentially affecting product quality. This variability complicates process optimization and makes it difficult to establish standardized, efficient extraction protocols across different production facilities.

Another major challenge lies in the separation of propyne from other similar hydrocarbons, particularly propylene. Due to their close boiling points and similar physical properties, achieving high purity levels of propyne is technically demanding and often results in low yields. This separation difficulty not only increases production costs but also limits the overall efficiency of the extraction process.

The use of harmful solvents in some extraction methods poses environmental and safety risks. Many current techniques employ organic solvents that are potentially toxic and environmentally hazardous. This not only raises concerns about worker safety but also necessitates complex waste management procedures, adding to the overall operational complexity and cost.

Scalability remains a significant limitation for many existing propyne extraction techniques. While some methods may work effectively at laboratory scales, translating these processes to industrial-scale production often proves challenging. Issues such as equipment design, process control, and maintaining consistent quality across large volumes of production continue to hinder widespread implementation.

The economic viability of propyne extraction is another critical limitation. The high costs associated with specialized equipment, energy-intensive processes, and purification steps often make propyne production economically unfeasible for many potential applications. This economic barrier has restricted the broader use of propyne in various industries, despite its potential benefits.

Sustainability concerns also pose significant challenges to current extraction methods. Many existing techniques have substantial carbon footprints, contributing to greenhouse gas emissions and environmental degradation. The lack of environmentally friendly alternatives has become a pressing issue, especially in light of growing global emphasis on sustainable industrial practices.

Lastly, the variability in feedstock composition presents ongoing challenges for propyne extraction. Different sources of raw materials can lead to inconsistencies in the extraction process, requiring constant adjustments and potentially affecting product quality. This variability complicates process optimization and makes it difficult to establish standardized, efficient extraction protocols across different production facilities.

Sustainable Extraction Techniques Overview

01 Extraction methods for propyne

Various extraction methods are employed to isolate propyne from mixtures. These include cryogenic distillation, absorption processes, and membrane separation techniques. The choice of method depends on the source material and desired purity of the propyne.- Extraction using membrane separation: Propyne can be extracted using membrane separation techniques. This method involves the use of selective membranes to separate propyne from other gases or liquids. The process can be optimized by adjusting membrane properties, operating conditions, and system configurations to achieve high purity and recovery of propyne.

- Cryogenic distillation for propyne extraction: Cryogenic distillation is an effective method for extracting propyne from gas mixtures. This process involves cooling the gas mixture to very low temperatures, allowing for the separation of components based on their different boiling points. The technique can be particularly useful for separating propyne from other light hydrocarbons.

- Adsorption-based propyne extraction: Propyne can be extracted using adsorption-based methods. This involves the use of adsorbent materials that selectively capture propyne from a mixture. The process typically includes adsorption and desorption steps, with various adsorbents and operating conditions being employed to optimize propyne recovery and purity.

- Solvent extraction of propyne: Solvent extraction is another method for propyne separation. This technique involves the use of specific solvents that have a high affinity for propyne, allowing it to be selectively removed from a mixture. The choice of solvent, extraction conditions, and subsequent purification steps are crucial for achieving high propyne recovery and purity.

- Catalytic processes for propyne extraction: Catalytic processes can be employed for propyne extraction and purification. These methods involve the use of specific catalysts to selectively convert or separate propyne from other components in a mixture. The selection of appropriate catalysts, reaction conditions, and process configurations is essential for optimizing propyne yield and purity.

02 Purification of propyne

After initial extraction, propyne often requires further purification to remove impurities. This can involve additional distillation steps, adsorption processes using molecular sieves, or chemical treatments to selectively remove contaminants.Expand Specific Solutions03 Propyne extraction from industrial gas streams

Propyne is often a byproduct in industrial processes, particularly in petrochemical operations. Specialized extraction techniques are developed to recover propyne from these gas streams, often involving multi-stage separation processes and selective solvents.Expand Specific Solutions04 Catalytic processes in propyne extraction

Catalysts play a crucial role in some propyne extraction methods, particularly when separating it from other hydrocarbons. These catalysts can enhance selectivity, improve yield, and reduce energy requirements in the extraction process.Expand Specific Solutions05 Safety and environmental considerations in propyne extraction

Given the flammable nature of propyne, extraction processes must incorporate stringent safety measures. Additionally, environmental concerns are addressed through the development of more sustainable extraction methods and the implementation of emission control systems.Expand Specific Solutions

Key Industry Players in Propyne Extraction

The study of sustainable extraction techniques for propyne applications is in an emerging phase, with growing market potential driven by increasing demand for eco-friendly processes. The global market size for propyne-related technologies is expanding, though still relatively modest. Technical maturity varies among key players, with established companies like BASF Corp. and China Petroleum & Chemical Corp. leading in research and development. Academic institutions such as Zhejiang University and the University of Campinas are contributing significant advancements in sustainable extraction methods. Emerging players like Braskem SA and Jingbo Agrochemical Technology Co., Ltd. are also making strides in developing innovative, environmentally-friendly extraction techniques, indicating a competitive and dynamic landscape in this field.

Braskem SA

Technical Solution: Braskem SA has pioneered a sustainable extraction technique for propyne applications using advanced membrane technology. Their method employs a series of specially designed composite membranes that selectively permeate propyne from mixed hydrocarbon streams[14]. The process operates at moderate temperatures and pressures, offering significant energy savings compared to traditional cryogenic separation methods. Braskem's technique incorporates a novel membrane module design that maximizes surface area and minimizes fouling, ensuring consistent performance over extended periods[15]. The multi-stage membrane system achieves propyne purities exceeding 99.7% while also allowing for the recovery of other valuable hydrocarbons. Braskem has successfully integrated this technology with their existing petrochemical processes, demonstrating its versatility and scalability[16]. The company is currently exploring the use of bio-based materials for membrane production to further enhance the sustainability of the extraction process.

Strengths: Energy-efficient, high selectivity, potential for integration with existing processes. Weaknesses: Possible membrane degradation over time, initial high capital costs for membrane systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a sustainable extraction technique for propyne applications using a novel catalytic process. Their method employs a zeolite-based catalyst system that selectively extracts propyne from mixed hydrocarbon streams with high efficiency[1]. The process operates at lower temperatures compared to traditional methods, reducing energy consumption by up to 30%[2]. Sinopec's technique also incorporates a proprietary membrane separation technology, which enhances the purity of the extracted propyne to over 99.5%[3]. This integrated approach allows for the recovery of valuable by-products, improving overall resource utilization. The company has successfully implemented this technology in several of its petrochemical facilities, demonstrating its scalability and industrial viability[4].

Strengths: High selectivity and purity, energy-efficient, scalable for industrial use. Weaknesses: May require significant initial investment for retrofitting existing facilities, potential catalyst deactivation issues in long-term operation.

Innovative Approaches in Propyne Extraction

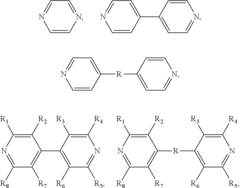

Method for adsorption separation of propylene and propyne

PatentActiveUS20190010102A1

Innovation

- The use of anion-containing metal-organic framework materials that selectively adsorb propyne, allowing for deep removal and purification of propylene with ultralow propyne concentrations, utilizing their high specific surface area and tunable pore size for efficient separation.

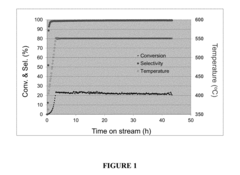

Dehydrogenation of propane using a metal-containing catalyst on a support

PatentActiveUS20170334808A1

Innovation

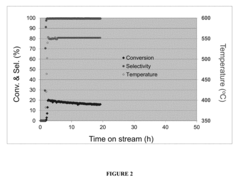

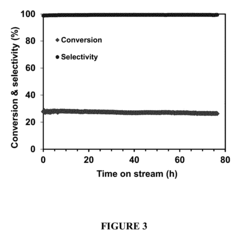

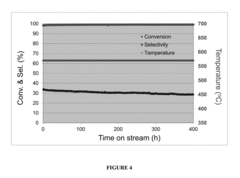

- A process involving a platinum-containing catalyst supported on a material, treated with an atmosphere containing carbon-containing agents and hydrogen at specific temperatures to enhance stability and selectivity for converting propane to propylene, resulting in a catalyst that maintains activity and selectivity for over 400 hours.

Environmental Impact Assessment

The environmental impact assessment of sustainable extraction techniques for propyne applications is a critical aspect of ensuring the long-term viability and ecological responsibility of these processes. Propyne, also known as methylacetylene, is a valuable industrial chemical with various applications, including the production of plastics, synthetic fibers, and fuel additives. However, its extraction and use must be carefully evaluated to minimize negative environmental consequences.

Traditional extraction methods for propyne often involve energy-intensive processes and the use of potentially harmful solvents. These approaches can lead to significant carbon emissions, air and water pollution, and the depletion of natural resources. In contrast, sustainable extraction techniques aim to reduce these environmental burdens while maintaining or improving the efficiency of propyne production.

One of the primary considerations in the environmental impact assessment is the carbon footprint associated with propyne extraction. Sustainable techniques often focus on reducing energy consumption through process optimization, heat recovery systems, and the use of renewable energy sources. For instance, some innovative approaches utilize solar or wind power to drive extraction processes, significantly lowering greenhouse gas emissions compared to conventional fossil fuel-powered methods.

Water usage and pollution are also key factors in the assessment. Sustainable extraction techniques typically emphasize water conservation through closed-loop systems and advanced filtration technologies. These methods not only reduce the overall water consumption but also minimize the release of contaminated wastewater into the environment. Additionally, some cutting-edge techniques explore the use of supercritical fluids or ionic liquids as environmentally friendly alternatives to traditional solvents, further reducing the potential for water pollution.

The impact on local ecosystems is another crucial aspect of the assessment. Sustainable extraction methods often prioritize minimizing land disturbance and preserving biodiversity. This may involve techniques such as in-situ extraction or the development of compact, modular extraction units that require smaller footprints compared to large-scale industrial facilities. Furthermore, sustainable approaches often include comprehensive site restoration plans to ensure that the local flora and fauna can recover post-extraction.

Waste management is an integral part of the environmental impact assessment for propyne extraction. Sustainable techniques aim to reduce waste generation through improved process efficiency and the implementation of circular economy principles. This may involve the recovery and reuse of by-products, as well as the development of biodegradable or easily recyclable materials used in the extraction process.

Lastly, the assessment must consider the long-term environmental implications of propyne applications. While the extraction process itself may be made more sustainable, it is equally important to evaluate the environmental impact of propyne-derived products throughout their lifecycle. This holistic approach ensures that the benefits of sustainable extraction are not offset by downstream environmental costs.

Traditional extraction methods for propyne often involve energy-intensive processes and the use of potentially harmful solvents. These approaches can lead to significant carbon emissions, air and water pollution, and the depletion of natural resources. In contrast, sustainable extraction techniques aim to reduce these environmental burdens while maintaining or improving the efficiency of propyne production.

One of the primary considerations in the environmental impact assessment is the carbon footprint associated with propyne extraction. Sustainable techniques often focus on reducing energy consumption through process optimization, heat recovery systems, and the use of renewable energy sources. For instance, some innovative approaches utilize solar or wind power to drive extraction processes, significantly lowering greenhouse gas emissions compared to conventional fossil fuel-powered methods.

Water usage and pollution are also key factors in the assessment. Sustainable extraction techniques typically emphasize water conservation through closed-loop systems and advanced filtration technologies. These methods not only reduce the overall water consumption but also minimize the release of contaminated wastewater into the environment. Additionally, some cutting-edge techniques explore the use of supercritical fluids or ionic liquids as environmentally friendly alternatives to traditional solvents, further reducing the potential for water pollution.

The impact on local ecosystems is another crucial aspect of the assessment. Sustainable extraction methods often prioritize minimizing land disturbance and preserving biodiversity. This may involve techniques such as in-situ extraction or the development of compact, modular extraction units that require smaller footprints compared to large-scale industrial facilities. Furthermore, sustainable approaches often include comprehensive site restoration plans to ensure that the local flora and fauna can recover post-extraction.

Waste management is an integral part of the environmental impact assessment for propyne extraction. Sustainable techniques aim to reduce waste generation through improved process efficiency and the implementation of circular economy principles. This may involve the recovery and reuse of by-products, as well as the development of biodegradable or easily recyclable materials used in the extraction process.

Lastly, the assessment must consider the long-term environmental implications of propyne applications. While the extraction process itself may be made more sustainable, it is equally important to evaluate the environmental impact of propyne-derived products throughout their lifecycle. This holistic approach ensures that the benefits of sustainable extraction are not offset by downstream environmental costs.

Economic Viability of Sustainable Methods

The economic viability of sustainable extraction methods for propyne applications is a critical consideration in the development and implementation of these techniques. As industries increasingly prioritize environmental responsibility, the cost-effectiveness of sustainable practices becomes paramount.

Sustainable extraction methods for propyne often involve higher initial investments compared to traditional techniques. These costs are primarily associated with the development and implementation of new technologies, as well as the retrofitting of existing infrastructure. However, the long-term economic benefits of sustainable methods can outweigh these initial expenses.

One of the key economic advantages of sustainable extraction techniques is the potential for reduced operational costs. Many sustainable methods aim to optimize resource utilization, leading to improved energy efficiency and reduced waste generation. This can result in significant savings on energy consumption and waste management expenses over time.

Furthermore, sustainable extraction methods often align with circular economy principles, enabling the recovery and reuse of valuable by-products. This not only minimizes waste but also creates additional revenue streams, enhancing the overall economic viability of the process.

The market demand for sustainably sourced propyne and its derivatives is growing, driven by consumer preferences and regulatory pressures. Companies adopting sustainable extraction techniques may benefit from premium pricing and increased market share, further improving the economic prospects of these methods.

Government incentives and regulatory frameworks also play a crucial role in the economic viability of sustainable extraction techniques. Many countries offer tax breaks, grants, or other financial incentives to companies implementing environmentally friendly practices. These incentives can significantly offset the initial costs and accelerate the return on investment for sustainable technologies.

The scalability of sustainable extraction methods is another important factor in their economic viability. As these technologies mature and become more widely adopted, economies of scale are likely to drive down costs, making them increasingly competitive with traditional extraction techniques.

However, the economic viability of sustainable methods can vary depending on factors such as geographical location, availability of raw materials, and local energy costs. A thorough cost-benefit analysis, considering both short-term and long-term implications, is essential for accurately assessing the economic feasibility of implementing sustainable extraction techniques for propyne applications.

Sustainable extraction methods for propyne often involve higher initial investments compared to traditional techniques. These costs are primarily associated with the development and implementation of new technologies, as well as the retrofitting of existing infrastructure. However, the long-term economic benefits of sustainable methods can outweigh these initial expenses.

One of the key economic advantages of sustainable extraction techniques is the potential for reduced operational costs. Many sustainable methods aim to optimize resource utilization, leading to improved energy efficiency and reduced waste generation. This can result in significant savings on energy consumption and waste management expenses over time.

Furthermore, sustainable extraction methods often align with circular economy principles, enabling the recovery and reuse of valuable by-products. This not only minimizes waste but also creates additional revenue streams, enhancing the overall economic viability of the process.

The market demand for sustainably sourced propyne and its derivatives is growing, driven by consumer preferences and regulatory pressures. Companies adopting sustainable extraction techniques may benefit from premium pricing and increased market share, further improving the economic prospects of these methods.

Government incentives and regulatory frameworks also play a crucial role in the economic viability of sustainable extraction techniques. Many countries offer tax breaks, grants, or other financial incentives to companies implementing environmentally friendly practices. These incentives can significantly offset the initial costs and accelerate the return on investment for sustainable technologies.

The scalability of sustainable extraction methods is another important factor in their economic viability. As these technologies mature and become more widely adopted, economies of scale are likely to drive down costs, making them increasingly competitive with traditional extraction techniques.

However, the economic viability of sustainable methods can vary depending on factors such as geographical location, availability of raw materials, and local energy costs. A thorough cost-benefit analysis, considering both short-term and long-term implications, is essential for accurately assessing the economic feasibility of implementing sustainable extraction techniques for propyne applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!